aircraft lcd displays manufacturer

... supports multiple display sizes—6×8-inch, 8×10-inch, 18×8-inch, etc.—through its flexible and common core architecture. Displays include a fully-assembled, lighted switch panel, high-resolution active ...

... 4 Primary Navigation Display upgrades your cockpit with the bright, wide-angle display technology found in the latest generation of aircraft. Boasting a high- reliability LED backlight, the SN4500’s display ...

SkyView Displays: Very bright, high-resolution screens driven by advanced graphics processors create highly visible and readable display. Even in direct sunlight!

Interface manufactures an array of custom control display units (CDUs). These products employ a full-color AMLCD along with integrated keyboard and modular electronics. The CDUs can be tailored to a customer’s unique ...

The IS&S 10” Flat Panel Display is a self-contained display unit with a built-in Symbol Generator, offering superior performance with a high resolution XGA multi-color LCD flat panel ...

... lighter, quieter, more entertaining in-flight display that incorporates features not found on displays twice as thick. Our displays not only achieve these goals, they ...

Manufacturer of custom computer peripherals including monitors, touch screens, keyboards and terminals. Military-grade, industrial-grade, commercial-grade, air traffic control, panel mount, rack mount, standalone, VESA mount, rack mount drawer, flip-up, flip-down, large format, open frame, rugged, sunlight readable, NVIS and waterproof sealed LCD monitors are offered. Additional product add-ons include power supplies, video amplifiers, cables, AC power cords, mounting arms, rack mount keyboards and desktop keyboards. Suitable for military, industrial and commercial applications. Optical bonding, display enhancements, contract manufacturing, testing, engineering, product development. All products are manufactured, serviced and supported in the USA. Software engineering, certification compliance services for safety-critical devices, avionics, medical, industrial and transportation. All software services are performed onshore in the USA.

In the commercial aircraft industry, touchscreen LCD monitors are now being used to provide the highest in performance and reliability. When it comes to aircrafts, airplanes, and airliners, using the highest standard of technology is of the utmost importance, particularly when it comes to safety.

LCD displays and monitors are commonly used in commercial aircrafts. While passengers will most readily see these monitors being used throughout the seating area (typically for entertainment purposes), they are vitally important in the cockpit of any aircraft (military, commercial, shipping) for navigational purposes.

In the past, cathode-ray tube (CTR) displays were used in aircrafts for both navigational and in-flight displays. This type of technology is now outdated and does not provide the best value, safety, reliability, or cost-effectiveness. Instead, liquid crystal displays (LCDs) offer better functionality and capability. As well, new advances to LCD technology continue to offer improvements.

Aircraft video displays are necessary for use in cockpits, where pilots use them for navigation, display panels, systems displays, and other functions. These displays provide mapping and weather information, terrain elevation, altitude, alert systems, and other necessary functions and capabilities for flight in a commercial aircraft.

Aircraft LCDs must also adhere to a number of standards and expectations for safety purposes. They need to be visible in all lighting conditions, resistant to damage, and offer accessible ease of use.

Aircraft touchscreen video displays offer a new advantage when used in commercial aircrafts, allowing for more effective control and greater ease of use. In aircrafts, where precision and following protocol are key, a touchscreen monitor for aircraft cockpits offers the greatest benefit.

These aircraft LCDs can also have other functionalities that allow for greater performance. Some of the benefits of our commercial and military LCDs are as follow:

Aircraft video displays with an open frame allow for more accessibility and integration into aircrafts. These displays can be made to fit into existing enclosures, and are able to be integrated into any type of aircraft cockpit. Chassis size can be an impediment, and many lower-end displays can be difficult or impossible to integrate into the cockpit environment without greater expense.

Commercial-grade LCDs and monitors offer full HD resolution, ensuring the best visibility and clarity for use in aircrafts. Precision and accuracy is crucial in commercial aircraft functions. When paired with sunlight-readable capability and low-light functionality, these LCD monitors can offer the most reliability and highest performance.

With a touchscreen, pilots and co-pilots have greater control and quicker access to functionalities in their aircraft. Touchscreens offer the highest standard of ease of use, ensuring intuitive control and minimizing risk of error.

Commercial or military LCDs need to be altitude resistant, able to withstand changes in altitude and air pressure without sustaining damage. Rugged LCD aircraft monitors are designed to be altitude resistant, providing extended range of use and ensuring durability and damage-resistance in the aircraft environment.

Are you looking for a commercial display? Nauticomp Inc. is an established display manufacturer with worldwide brand recognition as an innovative industry leader. We are dedicated to providing high-performance displays that are at the forefront of leading-edge display technology. Contact us at 1-705-328-2992 for Canadian service and at 1-800-267-9491 for U.S. service.

Our Display Engineers will analyze your requirements and design the best solution for your specific application. Once we design a solution, we will manufacture, do quality control and deliver a high quality display at the best value. To find out more about our Engineered Display Solutions Process, visit our Custom Displays page.

Swiss avionics manufacturer THOMMEN AIRCRAFT EQUIPMENT announced its display replacement services coming to the broader market for CRT (cathode-ray tube) and first-generation LCD display in legacy aircraft.

THOMMEN offers in-house lamination and assembly services thanks to a state-of-the-art ISO class 5 certified cleanroom with aerospace-grade standards and display manufacturing capabilities. Modern LCDs can be tailor-cut to virtually any size of displays that are used in aircraft cockpits and mission systems. THOMMEN has completed multiple similar upgrade programs replacing aging CRT displays with modern LCD units and is now ready to offer this service to the broader marketplace.

“There are a lot of good avionics systems out there that have old CRT displays on them and are becoming increasingly more costly and difficult to keep airworthy, simply because of the numerous obsolescence issues those CRT units are facing.” said Pete Ring, senior sales executive for North America, “Thommen has solutions available today to update and modernize most aging legacy CRT and older LCD displays, breathing new life into these venerable systems and airframes at a fraction of the cost of a brand-new full panel upgrade.”

In the upgrade process, analog information is converted and processed to color and composite video signals to provide accurate navigation and mission data to the flight crew in a digital format. THOMMEN’s display solutions are fully functional, fully customizable and designed to meet the harsh requirements of helicopters and fixed wing aircraft operating in all environments thanks to its environmental qualifications that meet and exceed most mission requirements. THOMMEN also offers display mounting solutions, custom bezels, and specialized finishes designed to meet any customers unique specifications.

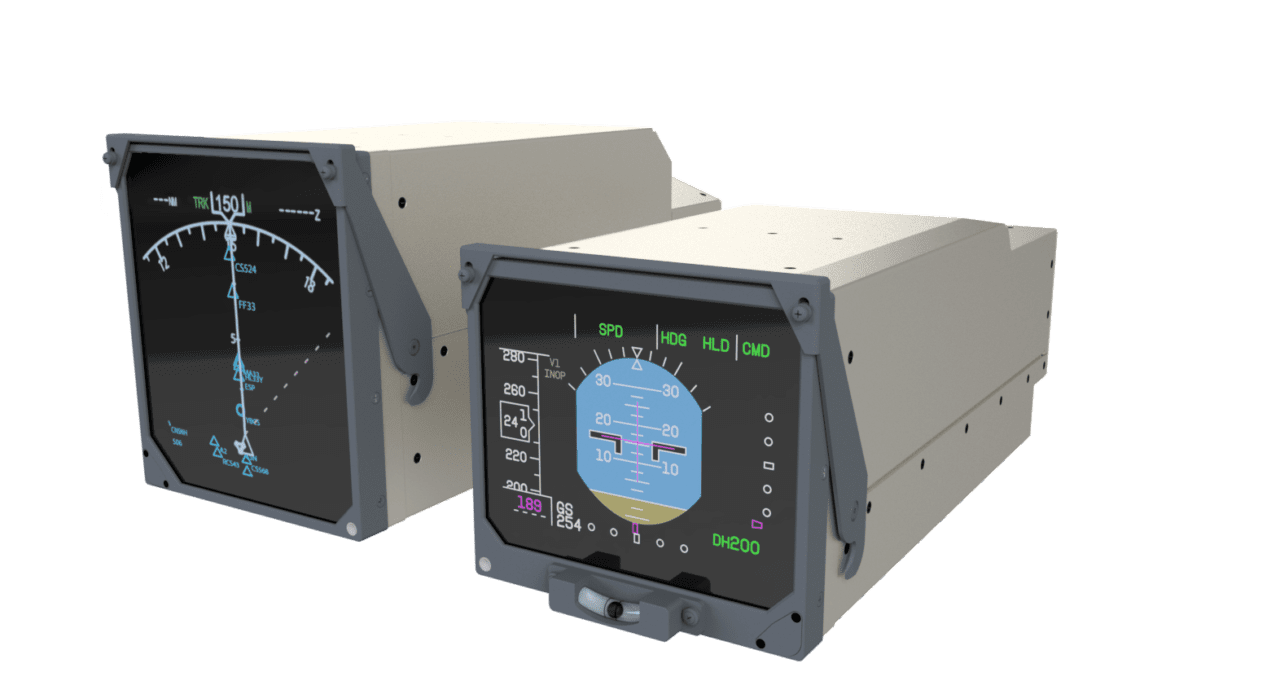

Thomas Global has developed proprietary technology which facilitates the cost effective life cycle management of avionic display technology and other vital avionics. Working together with avionics OEMs, airlines and government agencies, Thomas Global has the industry’s leading capability to engineer and manufacture new LCD assemblies to replace obsolete, unreliable or uneconomic avionic LCD assemblies. In addition, we have the capability to design and produce form-fit avionics for many other avionic components.

Our support and replacement solutions allow aircraft operators to manage obsolescence, enhance component reliability, lower costs and restore supply chain predictability. Our expertise allows us to deliver equivalent products with new materials and driver sets incorporating the latest technology, meaning operators can keep current avionics flying longer and more efficiently.

Our objective is to provide comprehensive support solutions for all avionic LCD display assemblies, backed by our trusted pedigree in the design, manufacture and support of critical avionics.

We have been developing and manufacturing liquid crystal display (LCD) panels of aircraft intended for Defense Agency of Japan. Recently, these LCD panels have been employed not only in military aircraft but also in commercial airplanes, thereby increasing demand for the LCD panels.

This time, we have developed LCD panels for commercial airplanes, based on the experience accumulated in LCD technology for the defense business. We have optimally designed the LCD panels to meet the optical characteristics and environmental conditions required in the cockpits of commercial airplanes, so that the panels have achieved good viewability performance at wide viewing angles both day and night.

For the recent cockpits of aircraft, the conventional CRT displays have been being replaced by liquid crystal display (LCD) panels. The LCD panels are superior to CRT display units with regard to space, viewability both in sunlight and at night, weight, reliability, power consumption, and others. Thus, they have been employed in the military aircraft field and are also beginning to be adopted in the commercial airplane field. In the current new passenger airplanes, LCD panels are about to become mainstream. The construction of LCD panels used for aircraft is basically the same as those for LCDs used in personal computers and others, but the LCDs for aircraft are subjected to severer environments as to temperature, barometric pressure, vibration, impact, etc. Moreover, they are also required to demonstrate display performance specific to the cockpits of aircraft. This time, we have taken measures to meet the requirements of these characteristics and have developed LCD panels suitable for commercial airplanes. This paper outlines the cockpit environments of commercial airplanes, the characteristics required of display devices, and the performance of the LCD panels.

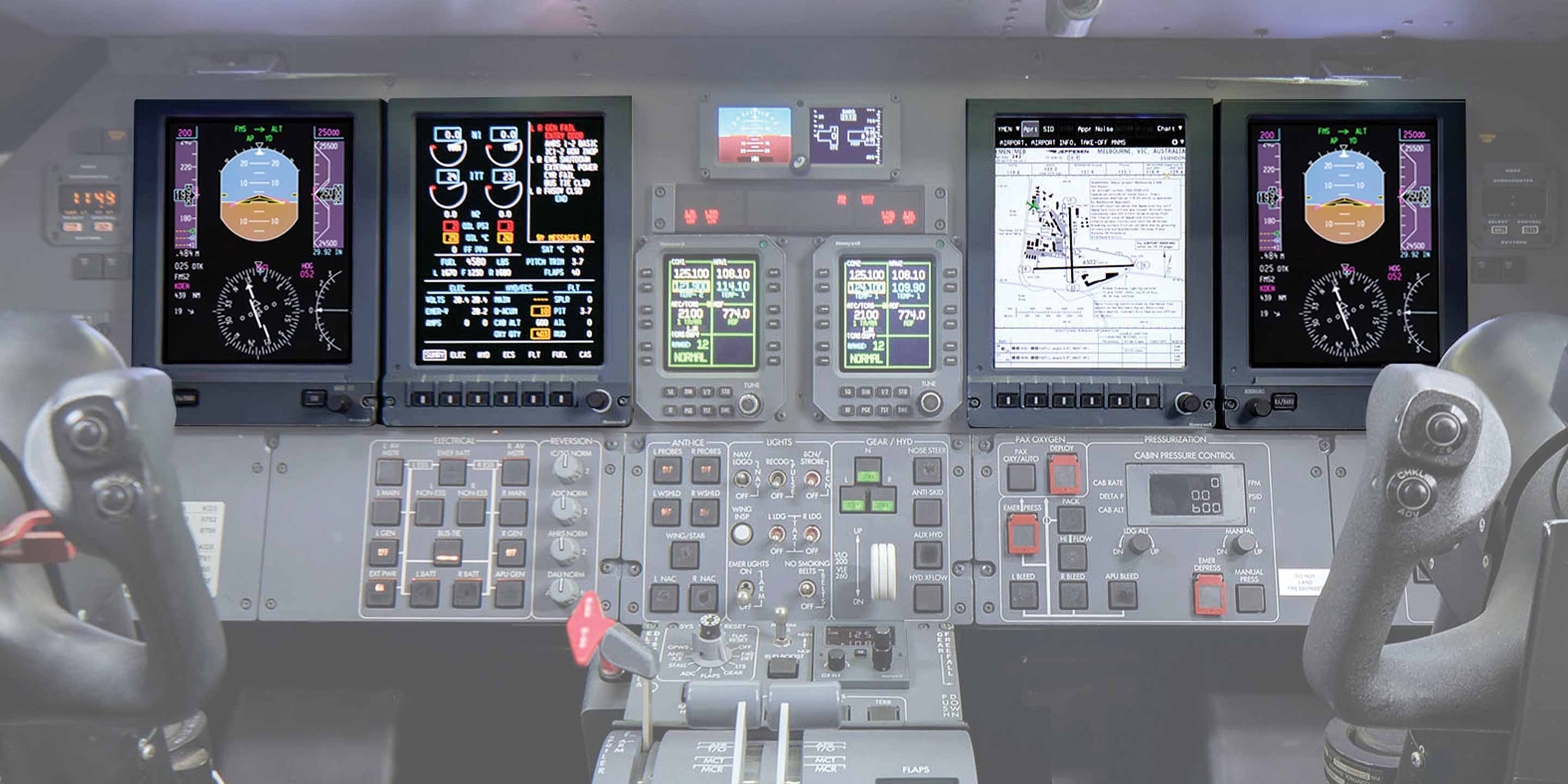

Figure 2 shows an example of the configuration of cockpit displays for commercial airplanes. Generally, the cockpit has six displays and the captain and co-pilot are seated right and left to manipulate devices and equipment. The following describes what LCD panels must take into account in order to accurately convey information to the pilots in this configuration.

The captain and co-pilot mutually check (crosscheck) information indicated on the displays as shown in Figure 3. In this case, the captain and co-pilot are required to accurately recognize indications on displays on both sides, half of which are on the opposing side of each pilot. Therefore, the displays are required to provide high contrast (brightness of the white display against the black display) at a wide viewing angle. It is especially important to reduce the brightness of the black display to achieve high contrast.

Accurate color identification and recognition are important aspects of flight information, and the displays for aircraft are required to ensure highly accurate chromaticity. Each display must consistently show the same colors in full color, especially for halftone colors. Thus, it is necessary to control variations in the chromaticity on a display basis.

Color information is also recognized as an important parameter during crosscheck. If the chromaticity of a display viewed from the front is different from that of the display on the co-pilot side when viewed by the captain, flight information can be mistakenly identified, presenting a significant problem in terms of flight safety. Thus, it is important that the chromaticity does not vary at wide viewing angles. Therefore, changes in the chromaticity have been specified in detail in the SAE Standards ARP4256, an international LCD display standard for aircraft. In general, the LCD panels for aircraft are developed in compliance with this standard.

In the cockpit, the displays are required to deliver good viewability in environments ranging from low-light conditions at night to bright conditions where sunlight streams through the windows in the daytime. At night, an LCD panel can achieve optimum brightness in relation to the surrounding environment by reducing the luminance of the backlight at the rear of the LCD panel. During the daytime, the luminance of the backlight can be raised to increase the display brightness. However, if sunlight streams directly onto the display, its viewability becomes poor due to reflections on the display surface. Therefore, it is essential to secure a display surface with a low reflection coefficient so that the displayed items can be recognized accurately.

The displays for aircraft are subjected to operation in environments more severe than those of general-purpose LCDs for office automation equipment, etc.

Because commercial airplanes are used worldwide, the required temperature range must include all temperature environments encountered, ranging widely from low to high temperatures. The cockpits are air-conditioned during flights. However, the displays for aircraft must provide accurate indications in low-temperature environments experienced if air-conditioning fails due to an accident, etc. or if start-up occurs in cold climates, or in high and low temperature environments.

In addition to the vibration and impact during landing which are encountered during the normal operations of an aircraft, the display panels are also required to withstand the stresses of conditions occurring during accidents, such as the bursting of a wheel or the breakage of engine blades. Under these circumstances, it is essential for the LCD panels of aircraft to meet the requirements of testing specified in RTCA DO160 (in Table 1).

An example of the configuration of an LCD panel module is shown in Figure 4. The LCD panel module consists of an LCD panel, the front glass, and the driving circuit, and it is illuminated by a backlight module from the back of the panel.

In order to alleviate loads on the backlight, LCD panels are required to have a high aperture ratio. For this, thin-film transistors (TFT) were employed and wiring patterns were optimally designed to reduce the electrode areas thus achieving a high aperture ratio.

The LCD panels use an optical compensation film to address the challenge of wide viewing angles. We have analyzed the characteristics of optical compensation films and also the optimum design conditions achievable by a combination of the films with the LCD panels. This allows the LCDs to achieve high contrast at the required wide viewing angle, with ± 60 degrees or more horizontal angle.

We have conducted spectral analyses on the materials that make up liquid crystal cells, including chromaticity errors in color filters, and have analyzed the effects of cell-gap variations on the chromaticity, etc. These studies have allowed us to develop LCD panels with small changes in the chromaticity at wide viewing angles.

Generally, there are few liquid crystal materials that satisfy operation requirements at both high and low temperatures. In our current development, we have adopted new liquid crystal materials to meet the requirements of the LCD panels for aircraft and have achieved a wide operating temperature range.

Unlike general LCD panels, LCD panels for cockpits have a layer of front glass on the front face of an LCD panel to protect the LCD. This prevents the LCD panels from being damaged by direct contact or from spillage of liquids such as coffee, etc. However, when the reduction of the reflection coefficient is considered, the LCD panels must be optimally designed to minimize the reflection from the front glass in addition to that of the LCD panel.

Figure 5-1 shows the factors responsible for reflection. Reflection occurs at an interface between media of different density. For LCD panels with front glass, both faces of the front glass and the surface of the polarizing plate on an LCD panel will be the major factors responsible for the reflection coefficient. We have newly developed LCD panels based on the following measures to achieve the characteristics necessary to meet the non- reflective requirements.

Generally, anti-glare (AG) and anti-reflection (AR) coatings are used as surface treatments for limiting surface reflection to a low level. AG coating is capable of minimizing specular reflection, but diffuses deflection increases, causing the entire screen to appear whitish under sunlight. This results in significantly diminished viewability. On the other hand, AR coating is a treatment that vapor-deposits a reflection- preventive thin film on the surface. For the LCD panels of aircraft, this AR coating is generally employed. Application of an AR coating to the front glass and to the polarizing plate allows a significant lower reflection coefficient to be achieved.

Apart from these measures against surface reflection, we have achieved a design that realizes a low reflection coefficient by taking the internal construction and LCD panel materials into consideration, thereby achieving good viewability even under sunlight.

To achieve high contrast, the brightness of the black display needs to be minimized. Increasing the voltage applied to an LCD panel causes the liquid crystals to cut off light, thereby limiting the brightness of the black display to a low level. Thus, we have adopted a high-voltage driver IC for driving the LCD in order to achieve high contrast. This driver IC is connected to the LCD panel using the tape automatic bonding (TAB) method.

In order for each LCD panel to display the same chromaticity in halftone display (amber, magenta, etc.), each gamma value must be the same. However, it is difficult for LCD panels to achieve the uniform gamma values due to variations in cell gaps and the ∆ n value (optical anisotropy) of liquid crystal materials. Therefore, as a means of smoothing out individual differences caused during production, we have employed a method of correcting the gamma values of individual panels using a driving circuit to solve chromaticity errors between each LCD panel.

The specifications of the currently developed LCD panels are summarized in Table 2. The pixel dimensions are 70 µm ( × RGB) × 210 µm of fine pixels to support the high grade, high precision display required of the displays for aircraft. By optimization of cell gaps and adoption of high-voltage driving, we have achieved the necessary high contrast within the required viewing angle range of commercial airplanes. As to the environment-resistance characteristics, we have conducted the noted RTCA DO160 testing with satisfactory results.

The currently developed LCD panels have display dots as small as 70 µm × 210 µm to deliver high precision. The reliability of fine pitch connections between an LCD panel and TAB also becomes important from the viewpoint of environmental- resistance performance on temperatures, vibration, etc. TAB and LCD panels are thermo-compression bonded using an anisotropic conductive film (ACF).

In the current project, we have proceeded with the development of a high-precision TAB bonder in parallel with the development of the LCD panels to achieve high precision, reliable TAB.

This paper has introduced the characteristics required of LCD panels for aircraft and outlined how to achieve these characteristics and the special requirements of the LCD panels developed for commercial airplanes. Currently, the development of new display devices to replace LCD panels is being conducted increasingly. However, the thus far achieved new devices have both merits and demerits and it is still too early to adopt them as display devices for aircraft. Therefore, we believe that LCD panels will remain in the mainstream for aircraft displays for the time being.

These currently developed LCD panels are scheduled to be used aboard the new Airbus A340-600 and others. In future, we hope to further enter the commercial aircraft market and to expand our product share therein, starting with this product.

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

OLED Displays are emissive displays and do not utilize liquid crystal. Each pixel is emissive with light. Passive OLED displays multiplex power and logic through the IC. Active OLED displays add a transistor at each pixel to supply power directly to the pixels and the IC only performs logical functions.

With more sensor data being transformed into actionable information at the edge, the military displays disseminating that information must be clear, crisp, and able to operate in a wide range of temperatures and surroundings. And because application requirements can vary greatly across platforms, displays must also be agile and flexible — what works well in a plane, may not in a vehicle.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey