pressure on lcd screen manufacturer

Pressure damage usually happens by accident when transporting or cleaning an LCD screen. To avoid this type of damage, use extreme caution whenever moving a screen. If your screen is on a laptop, always place it in its carrying case when not in use. If your LCD screen is larger, like a television, try to avoid touching the LCD surface altogether during transport.

When cleaning an LCD screen, use a combination of water and isopropyl alcohol or vinegar. Harsher chemical cleaners can damage the screen. Never apply the solution directly to the LCD monitor; instead, apply it first to a soft cotton cloth. Gently wipe the screen in one direction. If you come across a spot that is harder to clean, resist the temptation to apply pressure. Instead, continue wiping the screen in one direction -- preferably from top to bottom -- until the spot comes off.

If you store your LCD, make sure never to place anything on top of the screen. Even light objects can, over time, apply enough pressure to leave a permanent mark on your screen.

LCD -- short for liquid crystal display -- technology is used in a wide variety of electronic devices. Everything from computer screens to television sets uses this technology, which creates images by passing light through a series of liquid crystals. If you apply too much pressure to one of these sensitive screens, it may suffer permanent damage.

An LCD screen is a layer of liquid crystals sandwiched between two sheets of glass. Because of this construction, the screen -- both the glass and the crystals -- are fragile and vulnerable to damage. LCDs have a rod-like molecular structure, and possess traits similar to both liquids and crystals, hence their name. When you apply too much pressure to these crystals, whether intentionally or accidentally, you can disrupt not only the physical composition of the crystals, but also their orientation between the layers of glass. This can lead to a permanent pressure mark.

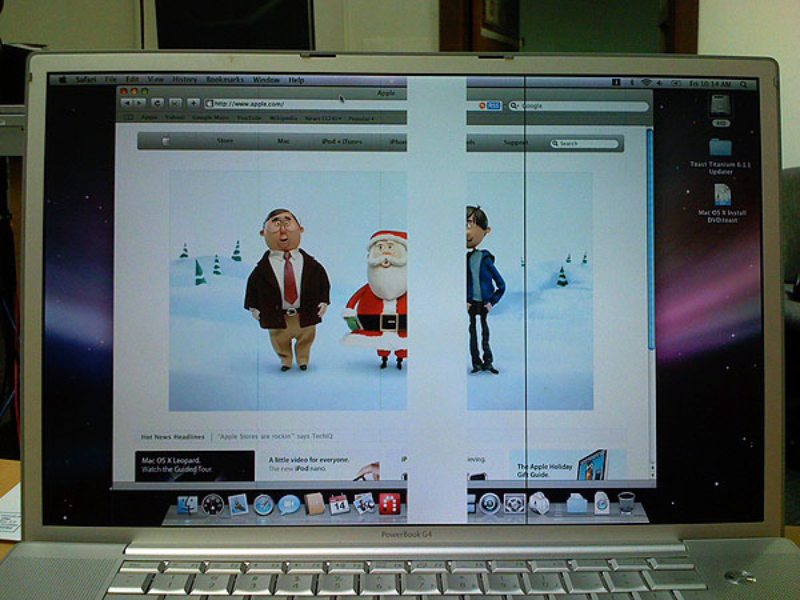

Pressure damage can take on different appearances based on the type of LCD screen on your device, as well as the amount of pressure applied. For example, an LCD screen that only produces black or white -- such as one found on a washing machine -- will show pixelated damage in only those colors; however, a full-color LCD screen on a television will show damage in all colors. Damage to these full-color screens is generally less obvious when the screen is completely black or completely white; rather, it"s most visible when there are many colors on the screen at once. Instead of a pixelated appearance, the damage may also take on the look of shadows on the screen or look like a bruise. The more pressure you apply, the more severe the damage will be.

Unfortunately, there is no way to repair pressure damage to an LCD screen. Many manufacturers -- including Toshiba -- do not include pressure damage under their product warranties, meaning if your LCD screen suffers this kind of damage, you"ll have to pay for a replacement out of your own pocket.

Pressure damage usually happens by accident when transporting or cleaning an LCD screen. To avoid this type of damage, use extreme caution whenever moving a screen. If your screen is on a laptop, always place it in its carrying case when not in use. If your LCD screen is larger, like a television, try to avoid touching the LCD surface altogether during transport.

When cleaning an LCD screen, use a combination of water and isopropyl alcohol or vinegar. Harsher chemical cleaners can damage the screen. Never apply the solution directly to the LCD monitor; instead, apply it first to a soft cotton cloth. Gently wipe the screen in one direction. If you come across a spot that is harder to clean, resist the temptation to apply pressure. Instead, continue wiping the screen in one direction -- preferably from top to bottom -- until the spot comes off.

If you store your LCD, make sure never to place anything on top of the screen. Even light objects can, over time, apply enough pressure to leave a permanent mark on your screen.

A pressure mark is a sign of physical damage to the inside of an LCD screen. It is related to, but not always synonymous with, the problem of dead or stuck pixels. Usually it is not financially viable to repair pressure marks.

Virtually all laptops have a liquid crystal display screen, mainly because the technology lends itself to light and thin screens. LCD involves shining light through a sheet of crystals which combine properties of a solid and a liquid. These crystals are red, green and blue and can be electrically controlled to be "on" (meaning they let light through) and "off" (meaning they block light.) The combination of the different colored crystals across the screen being either on or off and the backlight passing through creates the colored image on the screen.

A pressure mark is where physical pressure on the screen has led to the layer of crystal being crushed between the two layers of glass that surround it in the screen. This could cause crystals to lose either their liquid or solid properties, meaning they can no longer be manipulated by the computer to act as a filter for the back lighting. Another problem is that the crystal may be pushed out of position, for example by being twisted or rotated. These forms of damage may be visible in the screen by showing the wrong colors, or the image may be blurred or distorted, looking a little like if a drop of water fell on a painting that hadn"t yet dried.

A stuck or defective pixel is a specific problem with a laptop screen. It may be a symptom of the damage that caused a pressure mark, but may also be the result of unrelated problems such as electrical failure. A stuck pixel is one in which at least one of its three sub-pixels (which are colored red, green and blue) remains permanently on or off, meaning the pixel will often appear to be the wrong color. A dead pixel has all three sub-pixels permanently off, meaning the pixel is continually black. The fact that pixels are extremely small means that most pressure marks will involve numerous pixels being affected, whereas other causes can lead to a single pixel being dead or stuck.

To reduce the risk of pressure marks, avoid pressing or holding the screen wherever possible (unless of course it is a touchscreen, which is designed for such pressure.) Take particular care not to press down when wiping the screen. When transporting the laptop, make sure it is securely closed and that you have not left any objects such as a pen or a magazine between the keyboard and screen.

Some online resources claim the ability to fix dead or stuck pixels through techniques such as repeatedly flashing the screen dark and light. While the success of these techniques is debatable, they are not relevant to pressure damage as they are attempting to fix an electrical fault. Pressure marks are a sign of physical damage which cannot be undone without physical attention to the layer of crystals -- and even this is not a guaranteed fix. As physically dealing with the crystals involves taking apart the laptop screen -- a tricky and intricate task -- it is rarely if ever economical to fix a pressure mark compared to replacing the screen (if that is possible with a particular laptop) or replacing the entire laptop. If you do get a pressure mark on your screen, generally you will have to decide if the visual annoyance outweighs the cost of replacing the screen or laptop.

A professional writer since 1998 with a Bachelor of Arts in journalism, John Lister ran the press department for the Plain English Campaign until 2005. He then worked as a freelance writer with credits including national newspapers, magazines and online work. He specializes in technology and communications.

... within 266 pressure transmitter portfolio. This certification is a real guarantee of protection and makes of 266NSH the smartest fit in Safety-critical loops.

... differential pressure transmitter DPT 200 has been especially designed for the process industry and can be used for level measurement of closed, pressurized tanks, pump or filter controlling, etc.

The precise pressure transmitter x|act i has been especially designed for food industry, pharmacy and biotechnology and measures vacuum, gauge and absolute pressure of gases, steams and ...

Hygienic pressure transmitter, designed for food and pharmaceutical industry, is suitable for CIP/SIP cleaning and sterilization. Smart compact design, the wetted parts is made of high quality stainless ...

DMP305X-DST monosilicon pressure transmitter is typically used in process or environmental applications for continuous measurement of pressure differences in liquids, vapors and gases. ...

SMP858-NST Monosilicon pressure transmitter is a high performance pressure transmitter with international leading technology meticulously designed by LEEG instrument, ...

The Kobold differential pressure transmitter model PAD is a micro processor based high performance transmitter, that features flexible pressure calibration and output, ...

This pressure transmitter is particularly well suited for monitoring filters and pressures in HVAC (heating, ventilation and air conditioning) applications. DIP switches allow users to ...

... differential pressure transmitter is designed for pressure monitoring applications in cleanrooms, laboratories, pharmaceutical plants and operating theatres as well as for special uses ...

... differential pressure transmitters are available in a wide range of precision classes and therefore suitable for applications in the heating, air-conditioning and ventilation industries as well as sophisticated ...

HK71 In-Line Capacitance Pressure Transmitters are the industry standard for gage and absolute pressure measurement. The in-line, compact design allows the transmitter ...

... multivariable transmitter that has been optimized for the extremely accurate flow measurement of air and gas at or near atmospheric pressure (5 - 25 psia). Allowing for the measurement of up to four separate ...

Name:Differential Pressure TransmitterDescriptionThe gauge and absolute pressure transmitter model PT124B-3507 adopts modularity design, consist of pressure ...

SH pressure transmitters are developed for measuring gas and liquid pressures. They find applications in many industries like water supply & agricultural engineering, heating engineering, ...

The Model 178 Series variable capacitance pressure sensors are low range differential pressure transmitters. Each unit features a push-activated ZERO function and an associated LCD ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Summary:LCD Manufacturing is an ever-growing industrial segment with big demands on quality and quantity. Manufacturers can greatly benefit from the Ultra-Low Pressure Fuji Prescale Film as a means of Quality Assurance and increased manufacturing yield.

With the ever-increasing number of LCD devices, the market needs also increase. There are over 5 billion cell phones in use world-wide. Add to it the number of laptops, LCD TVs, Sat-Navs, smart cars etc. and it would not be an overstatement to say that there"s at least two LCD panels per each person on Earth, and it keeps on growing.

LCD manufacturers are pressed to launch new LCD panel models with higher resolution, higher contrast, lighter, tougher, touch-sensitive, multi-touch sensitive, cheaper, more reliable... the list goes on.

In order for LCD manufacturers to keep track with the growing demand for high-quality LCD panels, there is a constant pursuit of improving the manufacturing process.

One of the key LCD panel requirements is ideally flat surface so that contrast and color-consistency are as high as possible. To achieve this, manufacturers rely on precision polishing machines that use even tactile pressure and polishing solvents to achieve high-grade panel shine for each individual LCD panel.

The polishing process relies on close to perfect vertical alignment of the polishing head, stage and LCD panel itself. Small discrepancies of this alignment will result in un-even pressure distribution that can lead to surface chipping of glass shavings. When the polarizing plate is mounted to a panel with glass shavings, the quality of the LCD assembly will be compromised because of the trapped air bubbles around these glass shavings.

Even though the washing of the polished surface may help, in reality this is only treating the symptom, not the underlining cause for it. Uneven pressure distribution is what causes the glass shavings, and solving the alignment problem is best done using the Ultra-Low Pressure Fuji Prescale Film.

The Prescale film is placed between the polishing unit and the panel adsorption stage and the nominal pressure is applied. This develops the Fuji Prescale film and the read-outs can be used to directly determine the plate alignment.

The image on the left is from a defective polishing machine where the plates are not in alignment. The tactile pressure is out of balance to such extent that there is barely any pressure exerted on almost 2/3 of the tactile surface. Such misalignment will cause chipping and air bubbles will be an inevitable result.

Using the Fuji Prescale film, the LCD manufacturers can increase overal quality and yield by quickly and easily testing polishing machines for alignment. Thanks to the Fuji Prescale film"s on-the-spot readouts, technicians can run maintenance checks often and ensure a consistent manufacturing quality. This will in turn result in reliable products and optimally utilized manufacturing time.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I have a blood pressure monitor (Avita BPM645 - http://www.avita.com.tw/BPM64en.html) that has the LCD broken and doesn"t work. The problem is that I can"t find the replacement LCD, because there aren"t model or serial number on the screen that can help identifying the part

Six Core Competencies, The Industry Absolute Leader:The liquid crystal writing screen makes full use of the bistable characteristics of the liquid crystal molecules and utilizes the reflection display principle of the liquid crystal molecules. It can display a stable content without an external electric field for a long time, so the power consumption is extremely low. And it is widely used in the field of high-grade electronic paper and writing board. It has the advantages of energy saving, lightweight, flexibility, pressure sensitive, etc, can be used repeatly for over 100 thousand times.

No Dust, No Ink, Environmental-friendly: Change the traditional way of writing, needn"t a chalk or maker to write. No dust and ink pollution, good for health.

Many medical applications require sustainability and long product lifecycles. AZ Displays supports the medical application market by offering a reliable and stable product that can be supported for up to 7 years. AZ Displays also offers extensive value-add options, including optical bonding, strengthened cover glass, gaskets and sealants (to consider IP ratings and fluid ingress), silk printing, discrete touch buttons, and more. For more information on our standard product and value add services, please visit our website at www.AZDISPLAYS.com or contact the author below.

YS-100A intelligent digital pressure gauge adopts full electronic structure and imported 16-bit microcontroller, with super anti-interference ability and extremely fast sampling speed.

Our company supplies different kinds of products. High quality and favorable price. We"re pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

FAQ:1.The Quality Of Our ProductsOurPressure gaugeare all100% inspected, and with standard production process.2.PriceWe can provide our high quality products with reasonable price.3.OEM servicesIn the past years, we have many OEM orders from very famous company all over the world.4.DeliveryWe can provides intime delivery. Some stocked models can be instant delivered.5.ServiceWe provide best after-sale service all the time, for our goal is a long trade cooperation term.6.ReputationOur factory have 28 years experiences.We have already gaining the best reputation and response from the customers from all over the world.We may accept consumers order with special requirement for instrument and meter!

Hongqi Instrument, established in 1993, is one of the leading manufacturers and suppliers of 100mm lcd screen intelligent digital pressure gauge in China. Providing you with low price and good service, we welcome you to wholesale the famous brands" gauge made in China at cheap price from our factory.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey