pressure on lcd screen made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Are you looking for how to get rid of those irritating spots on your phone screen? This article shows you everything you need to know on how to fix pressure spots on LCD screens and how to prevent them in the future.

One of the deadliest and most frustrating issues you could have with your mobile phone is screen damages. And for pressure spots on LCD screens, it"s somewhat annoying than breaking the whole screen itself, as it requires going for replacement in most cases.

As its name implies, pressure spots on phone screens can render the display useless (or irritating, based on how you see it) by creating spots of different shapes and styles on the screen. These spots show continually, and most times, permanently on the display and can obstruct your viewing or cause other problems such as dead pixels, flickering, or blurriness.

When you apply too much pressure on your phone’s display – whether accidentally, intentionally, or carelessly, it damaged the LCD components, hence creating different spots on the display.

Pressure spots on LCD screens can come in different forms and shapes depending on the density of pressure applied. Sometimes, the spots can be whitish, deep black, or come in various colors depending on what’s currently showing on the screen.

Unfortunately, learning how to fix pressure spots on LCD screens isn"t the same as learning how to fix simple hardware and software issues. Simply put, there is no way to repair a phone screen that was damaged by pressure.

Attempting to get rid of pressure spots on LCD screens can cause more harm than good. Hence, you had better find a professional phone repairer to help you with screen replacement.

Meanwhile, some users reported that the pressure spots on their phone screen got healed after a few years. But do you want to keep seeing the same issue on your screen for years? So, a screen replacement is the only way out.

Fortunately, if you use a TECNO, Infinix, or itel smartphone, Carlcare Service is the best bet for you when it comes to replacing your damaged screen and fixing other issues on the device. We"re the official after-sales service provider to render professional repair and customer services for these brands.

And if you’ve bought our extra Screen Protection Plan for your TECNO, Infinix, or itel device earlier, you might be able to replace your screen for free, or better still, get huge discounts on-screen replacement at Carlcare.

Also, if you notice pressure spots on your Syinix TV, the best thing to do is bring it down to our service centre for proper screen replacement with genuine stock parts.

Paying for screen replacement from your own pocket (especially when you don’t have any form of screen insurance or protection plan), can be a pain in the ass. However, there’s probably nothing you could have done better than learning how to protect your phone screen from pressure spots in the future.

Pressure spots on LCD screens (or any screen in general) occur accidentally or carelessly. The only way to avoid such damage in the future is to handle your phone carefully. Try as much to shun applying much pressure on the screen while playing games and performing other tasks.

When inserting your phone into your pocket, purse or bag, ensure there"s enough space to accommodate it. Also, ensure there are no other objects inside the pocket, purse, or bag.

Equally important, if you"re wearing a dress with tight pockets, we recommend you keep your phone somewhere else rather than forcing it inside the pocket, as it may be pressurized when you move your body.

Overall, the only way to prevent your phone screen from getting pressure spots in the feature is to handle it carefully whenever and wherever possible. If you ever come across the need to drop your phone somewhere, ensure you don’t place anything on it.

Taking these few things into consideration would help you protect your phone screen from pressure spots in the future, rather than looking for how to fix pressure spots on LCD screen when it happens.

Now, if you’ve accidentally applied much pressure on your phone’s screen and some spots are showing on it when you turn it on, the best thing you can do is to visit the official service provider for your device for a screen replacement. Trying to shift the spots away or performing some DIY tricks may cause more harm than good.

By continuing to use AliExpress you accept our use of cookies (view more on our Privacy Policy). You can adjust your Cookie Preferences at the bottom of this page.

YS-100A intelligent digital pressure gauge adopts full electronic structure and imported 16-bit microcontroller, with super anti-interference ability and extremely fast sampling speed.

Our company supplies different kinds of products. High quality and favorable price. We"re pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

FAQ:1.The Quality Of Our ProductsOurPressure gaugeare all100% inspected, and with standard production process.2.PriceWe can provide our high quality products with reasonable price.3.OEM servicesIn the past years, we have many OEM orders from very famous company all over the world.4.DeliveryWe can provides intime delivery. Some stocked models can be instant delivered.5.ServiceWe provide best after-sale service all the time, for our goal is a long trade cooperation term.6.ReputationOur factory have 28 years experiences.We have already gaining the best reputation and response from the customers from all over the world.We may accept consumers order with special requirement for instrument and meter!

Hongqi Instrument, established in 1993, is one of the leading manufacturers and suppliers of 100mm lcd screen intelligent digital pressure gauge in China. Providing you with low price and good service, we welcome you to wholesale the famous brands" gauge made in China at cheap price from our factory.

(Yicai Global) June 13 -- BOE Technology Group, TCL China Star Optoelectronics Technology and other big Chinese liquid crystal display manufacturers are reducing output starting from this month to try and stop a freefall in prices caused by a global glut.

Panel makers are cutting production by 16 percent on average from this month, Rong Chaoping, senior researcher at market research firm AVC Revo, told Yicai Global. Television panel makers are expected to ship 3.6 million less panels than last month.

Panel makers will reduce capacity by between 15 and 20 percent this month, said Wu Rongbing, chief analyst at Chinese semiconductor intelligence service Omdia.

TCL China Star intends to continue with its production cuts until September, while Beijing-based BOE and HKC Optoelectronics Technology have not yet decided how long they will reduce output, Rong said. None of the three companies responded when contacted by Yicai Global.

LCD TV display shipments from China’s five largest panel manufacturers accounted for 68.5 percent of the global market in April, a new high, and they were expected to exceed 70 percent this year, according to Omdia.

But there is much less demand for notebook computers, monitors and TVs now that fewer people are working from home as the Covid-19 pandemic wanes and amid pressure from global inflation. This is driving prices down, said Li Yaqin, general manager of market research firm Sigmaintell.

The global panel industry is expected to slash production by about 20 percent this year, according to Beijing-based Sigmaintell. It is the first time since 2013 that the worldwide sector has implemented such a large-scale and wide-ranging cut in manufacturing. But it should help to slow the fall in prices, Li said.

The price of small and medium-sized TV displays has more than halved since the highest point last year, and that of large-sized screens have fallen by more than 40 percent, according to AVC Revo.

“Panel makers are facing rising liquidity pressure and bigger losses as prices are now below cost price, so the display industry is likely to undergo another big reshuffle,” Rong said.

Excess supply will ease in the third quarter once output is cut, and prices will start to pick up and then flatten out, Li said. Demand for consumer electronic products is shrinking by far more than expected so it is too early to tell whether prices will rebound in the second half, she added.

Panel prices are likely to stop dropping this month or next as output falls, Wu said. Whether prices will start to pick up soon depends on when demand improves.

BEIJING (Reuters) - A joint venture between Hon Hai Precision Industry Co, known as Foxconn, and Sharp Corpplans to build a 61 billion yuan ($8.8 billion) factory in China to produce liquid-crystal displays (LCDs).

Sakai Display Products Corp’s plant will be a so-called Gen-10.5 facility specializing in large-screen LCDs and will be operational by 2019, the company said at a signing event with local officials in Guangzhou on Friday. It said the plant will have capacity equating to 92 billion yuan a year.

Global LCD output was hit this year by the closure of a Samsungfactory that accounted for 3 percent of the market, as well as factory stoppages in Taiwan after an earthquake in March.

China’s largest LCD panel maker, BOE Technology Group, began construction on its own Gen-10.5 plant in Hefei in December last year, with production scheduled to begin in 2018.

In May Shenzhen China Optoelectronics Technology Co, asubsidiary of TCL Corp, announced that it would begin construction on a 50 billion yuan LCD plant in Shenzhen.

Sakai Display Products Corp’s plans for the Guangzhou plant come as Hon Hai seeks to turn the joint venture into a subsidiary, investing a total of 15.1 billion yuan in the company.

The venture will also sell 436,000 shares for 17.1 billion yuan to an investment co-owned by Hon Hai Chairman Terry Gou, giving Hon Hai a 53 percent interest in the business and lowering Sharp’s stake from to 26 percent from 40 percent.

This is in response to your correspondence, dated June 11, 2020, on behalf of your client, Wacom Technology Corporation, (“WTC”). In your letter, you have requested a ruling pursuant to 19 C.F.R. Part 177 regarding the country of origin of the Wacom Cintiq Pro 16 drawing tablet.

The merchandise under consideration is identified as the Wacom Cintiq 16 with Pro Pen 2 (Cintiq 16). The Cintiq 16 is a device known as a drawing tablet, and it is described as a multifunctional device that has a liquid crystal display (LCD) with a touch screen that operates in conjunction with automatic data processing (ADP) machines. Therefore, the Cintiq 16 does not operate as a stand-alone unit. The user of the Cintiq 16 can make professional drawings and images, such as animations and industrial designs, and is able to draw directly onto the LCD screen by using a specialized stylus, a pen-like drawing apparatus stylus. The Cintiq 16 only functions as a drawing tablet and does not perform any other operations. The product is comprised of an LCD display module, front and back cover assemblies, and various printed circuit board assemblies (PCBAs). When it is sold to the consumer, the Cintiq16 is retail packaged with a power adapter, specialized cables, and the stylus pen.

The Cintiq 16 contains technology that allows the tablet to capture each pen stroke pressure, and permits the tablet to tilt digitally to replicate the use of a pencil, paintbrush, etc. The stylus pen imported with the Cintiq 16 interacts with the tablet’s pressure-sensitive features to let the user determine how thick or thin a line should be by instantly capturing handwritten notations. The tablet wirelessly interacts with the stylus pen by plotting its location in microseconds as it makes the user’s edits onto the screen.

Once the Cintiq 16 is connected, the display image from the ADP machine’s monitor is duplicated on the Cintiq 16 LCD. Thus, the LCD screen on the Cintiq 16 tablet functions as a secondary display while users create and/or edit content via the touch surface. Likewise, users have the capability to interact with their project and can visualize the results via an ADP machine’s display output.

To perform its functions, the Cintiq 16 uses four PCBAs which are the electro-magnetic resonance (EMR) board, the keypad board, the scaler board, and the sensor control board (SCB). In New York Ruling Letter (NY) N308714, dated January 23, 2020, we considered the country of origin of a previous version of the Cintiq 16 that was produced with a different production process. The manufacturing process for making the new Cintiq16, SKU DTK-1660/KO-AB and KO-AC has now been changed. In NY N308714, three of the four PCBA boards contained in the device, the EMR board, the keypad board, and the scaler board were made in China, and only the SCB PCBA was manufactured in Taiwan. Now, WTC will populate two additional PCBA’s, the scaler board and the keypad board with components using Surface Mount Technology (“SMT”) in Taiwan instead of China. This means that under the new proposed production scenario, the keypad board, scaler board, and SCB will be produced in Taiwan instead of China.

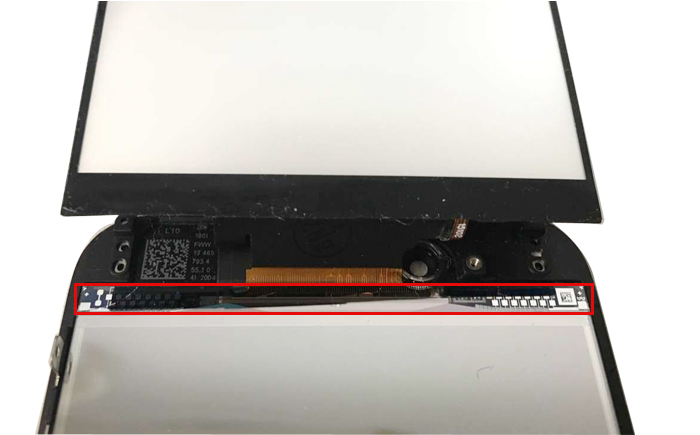

The first two stages of production of the Cintiq 16 involves manufacturing two subassemblies in China, which are identified as the back-cover module and the front-cover module. The back cover module contains air vents inside the plastic cover, a pen tag and two small rubber anti-rolling strips on the external body of the plastic cover. The assembly of the front-cover module consists of (1) placing glass on the plastic cover; (2) attaching the LCD panel behind the cover; (3) attaching the EMR board behind the LCD panel; and (4) placing the open cells and the backlight behind the cover.

The Chinese-origin back-cover and front-cover modules will then be shipped to Taiwan together with the stylus pen, pen holder, AC adaptor, and a power cable. In addition, the following three bare Printed Circuit Boards (“PCBs”) (bare SCB PCB, bare scaler board PCB, and bare keypad board PCB) will be shipped to Taiwan for further manufacturing into the finished PCBAs through SMT. In Taiwan, the SMT processes will be used to populate each of the bare PCB’s boards with the various electronic components so that they will become fully built PCBAs. Upon completion of the SMT processes, Japanese-origin WTC tablet firmware will be installed on the SCB and Taiwanese-origin scaler board firmware will be installed on the scaler board.

The scaler board is attached to the front-cover module. The SCB is attached to the LCD panel in the front-cover module so that it can sense and capture each pen stroke’s pressure on the bare EMR board. Without the SCB underlying it, it is claimed that the EMR board will not function as a sensor. The keypad board is also assembled to the front-cover module, and it is interconnected to the scaler board with cables to allow the transmission of signals and to function as a complete unit. The back-cover module is then combined with the front-cover module with screws.

Counsel contends that the EMR board is a simple PCB board with tiny magnetic sensor coils, and it has no electronic components on it. It is attached behind the LCD screen to allow the sensor coils to magnetically capture each pen stroke. Counsel also claims that the SCB monitors the movement of the sensor coils attached on the EMR board, and that it recognizes each pen stroke, the pen’s location, pressure, and speed, and that it transmits these interpreted, digitized input signals to the output unit, i.e., the scaler board.

In addition, counsel states that the role of the scaler board is as an output unit that generates images on the LCD screen. The scaler board has the highest number of components among the four different PCBAs. While the scaler board is responsible for producing the images on the LCD screen, as an alternative the consumer/artist can still use the Cintiq 16 tablet without the LCD screen, since the user can always view drawings produced on a connected external monitor.

The fourth and final PCBA in the Cintiq 16 is the keypad board (called the “power switch”). It is responsible for directing power currents in the Cintiq 16 tablet. It functions basically as an on and off switch.

The United States Trade Representative (“USTR”) has determined that an additional ad valorem duty will be imposed on certain Chinese imports pursuant to USTR’s authority under Section 301(b) of the Trade Act of 1974 (“Section 301 measures”). See Section XXII, Chapter 99, Subchapter III, U.S. Note 20(r), HTSUS. The Section 301 measures apply to products of China enumerated in Section XXII, Chapter 99, Subchapter III, U.S. Note 20(s)(i), HTSUS.

When determining the country of origin for purposes of applying trade remedies under Section 301, the substantial transformation analysis is applicable. The test for determining whether a substantial transformation will occur is whether an article emerges from a process with a new name, character, or use, different from that possessed by the article prior to processing. See Texas Instruments, Inc. v. United States, 681 F.2d 778 (CCPA 1982). In deciding whether the combining of parts or materials constitutes a substantial transformation, the determinative issue is the extent of operations performed and whether the parts lose their identity and become an integral part of the new article. See Belcrest Linens v. United States, 6 CIT 204, 573 F. Supp. 1149 (1983), aff’d, 741 F.2d 1368 (Fed. Cir. 1984). Assembly operations that are minimal or simple, as opposed to complex or meaningful, will generally not result in a substantial transformation. Factors which may be relevant in this evaluation may include the nature of the operation (including the number of components assembled), the number of different operations involved, and whether a significant period of time, skill, detail, and quality control are necessary for the assembly operation. See C.S.D. 80-111, C.S.D. 85-25, C.S.D. 89-110, C.S.D. 89-118, C.S.D. 90-51, and C.S.D. 90-97.

Additionally, factors such as the resources expended on product design and development, the extent and nature of post-assembly inspection and testing procedures, and worker skill required during the actual manufacturing process will be considered when determining whether a substantial transformation has occurred. No one factor is determinative

Counsel points out that there are four major components that make up the Cintiq 16 tablet. They are the SCB, scaler board, keypad board, and front-cover module. Consistent with CBP’s previous decisions on PCBAs, populating PCBs with various microelectronic components by using SMT constitutes a substantial transformation of the blank PCB boards and individual microelectronic components contained on the boards. See C.S.D 19 Cust. Bull. 844 (1985). Therefore, we find that the country of origin of the three individual PCBAs that are populated with components in Taiwan using SMT, (the SCB, the Scaler Board, and the Keypad Board) is Taiwan. However, in determining the country of origin of the finished Cintiq 16, we must analyze whether these Taiwanese origin PCBAs and the other manufacturing operations performed in Taiwan determine its country of origin when combined with the Chinese-origin components.

NY N308714 explained that the finished Cintiq 16 consisted of several discrete subassemblies that were previously manufactured in China. Furthermore, it was pointed out that each of the Chinese subassemblies was dedicated for use in the Cintiq 16, such that they had no other purpose other than as components of the subject input/output device. The ruling further noted that the assembly operations performed in Taiwan, which consisted of attaching, fastening, and taping and/or gluing, were not very complex. The Cintiq 16 was produced by joining these subassemblies together to form a touch screen input/output device, but the Chinese subassemblies did not undergo a physical change in Taiwan by the assembly operations performed in that country. Therefore, it was determined in NY N308714 that the assembly process performed in Taiwan did not result in a substantial transformation of the Chinese origin components and subassemblies. The components themselves were not transformed in Taiwan into a new and different article of commerce with a name, character, and use distinct from

the articles which were exported from China. Consequently, NY N308714 held that the Wacom Cintiq 16 with Pro Pen 2, PN DTK1660, was a product of China for origin and marking purposes.

As has already been noted, since the issuance of NY N308714, WTC has changed the way the Cintiq 16 will be manufactured by having two additional PCBA’s, the scaler board and the keypad board, populated with electronic components using SMT in Taiwan, instead of China. This means that under this new proposed production process, three out of the four PCBAs contained in the Cintiq 16, the keypad board, scaler board, and SCB, are now produced in Taiwan instead of China.

Counsel contends that the Taiwanese-made PCBAs impart the essence to the Cintiq 16 drawing tablet and that three of the four PCBAs used in the Cintiq 16 will now be made in Taiwan. Counsel emphasizes the importance of the SCB PCBA because it is the component in the drawing tablet that provides the specialized pressure sensitive technology used in the drawing process and what separates the Cintiq 16 drawing tablets from similar devices like other tablets which also permit basic drawing onto an LCD screen with a stylus, such as an “Apple iPad” or a “Microsoft Surface.” It is this technology why consumers would choose to buy the Cintiq 16 drawing tablet. In addition, counsel points out that the Taiwanese-made PCBAs are more sophisticated than the Chinese-made subassemblies and parts, such as the EMR board, and they contain far more individual components. Counsel maintains that the accessories, such as the stylus pen, the power adapter, and specialized cables that are sold together with the Cintiq 16 tablet should not be given a lot of weight in determining the country of origin of the finished product.

In cases concerning the country of origin of origin of a device containing multiple PCBAs, CBP has examined the function of the PCBAs contained in the device to determine the origin of the device. For instance, in NY N308544, dated January 15, 2020, CBP considered the country of origin of a satellite television receiver and an entertainment system which consisted of two primary PCBAs from Taiwan and two auxiliary PCBAs from China (among others). The final assembly was performed in China. CBP determined that the country of origin of the receiver was Taiwan because (1) the two primary PCBAs from Taiwan imparted the essence of the finished product; and (2) the assembly process performed in China did not substantially transform these primary PCBAs.

Accordingly, in analyzing what is the country of origin of the Cintiq 16, we consider the various functions of the components of the Cintiq 16 to see if they determine the essence of the finished product. We recognize that the Cintiq 16 is a combined input/output device that has two distinct functions. The first function is that of an input device by manipulating images that are drawn using a specialized uniquely suited stylus ono the LCD screen. The second function of the Cintiq 16 is to perform as an output device by showing the images drawn on the LCD screen of the Cintiq 16 and, at the same time, onto a monitor of a linked ADP machine, such as a computer if that computer has a monitor connected to it. However, it is noted that if an attached desktop PC does not have a monitor and the Cintiq 16 is plugged into the desktop, the LCD of the Cintiq 16 will function as the primary monitor with a touch surface. Consequently, an attached monitor from the ADP machine is not required for the Cintiq 16 to function as a drawing tablet.

It is also noted that for the drawing tablet to create an image, an electromagnetic signal between the stylus and the PCBAs located in the drawing tablet must be generated. The magnetic field emanating from the stylus pen is recognized by sensor boards (EMR Board and the SCB PCBA). The electromagnetic resonance technology allows for the stylus pen"s location, pressure, and speed to be tracked and registered. The Chinese origin stylus pen generates a data signal which is detected by the tablet. When a user draws a line using the stylus, the coil circuit transfers the signals to the main circuit inside the stylus. By using electromagnetic signals, the tablet can sense the position of the stylus. The tablet generates an electromagnetic signal, which is received by a circuit in the stylus. The stylus works as an antenna that receives the signal and generates another electromagnetic field that "talks" back to the tablet. The SCB board receives a signal from the stylus and, through its pressure sensitive technology, contributes to making the image drawn on the Cintiq 16. The SCB monitors the movement of the sensor coils attached on the EMR board, and recognizes each pen stroke, the pen’s location, pressure, and speed, and transmits these interpreted, digitized input signals to the output unit, i.e., the scaler board. Without the SCB underlying it, it is claimed that the EMR board does not function as a sensor. In other words, it is the interaction between the Chinese origin stylus and the Chinese origin EMR board with the Taiwanese origin SCB board that allows the Cintiq 16 to generate a visible image.

The fact that the image shown on the LCD screen is duplicated on a monitor and on a connected ADP machine does not negate the fact that the Cintiq tablet 16 also functions as an output device by displaying an image on its LCD screen. With respect to which components of the Cintiq 16 impart its output function, we note that the Chinese-made LCD panel subassembly displays the image of what is being drawn as well as duplicating the primary display. However, the Taiwanese-made scaler board also greatly contributes to allowing an image to be displayed. Thus, again, it is the combination of Taiwanese and Chinese components in the Cintiq 16, that allows the Cintiq 16 to function as an output device that can display images.

Counsel contends that the greater number of components on the three Taiwanese PCBA boards indicates that they are more complex, and that they are the most important of the PCBAs contained in the Cintiq 16. We do not necessarily agree that the sheer number of electronic individual components contained on the PCBA boards means that these PCBA boards play a more vital role in the function of the device, which is to generate and display images and designs. Rather, we believe that the role of the components and the subassemblies must be considered and how they function in the finished device to determine if there are dominant components which

impart the essence of the device. In this instance, it is the interplay between the stylus, EMR SCB, scaler boards, and LCD that allow the Cintiq 16 to generate the images and to display those images onto a screen.

Counsel also points out that the Cintiq 16 is equipped with a pressure-sensitive mechanism that lets an artist put a certain amount of nuance into the computer-aided drawings. With this capability, a user of the Cintiq 16 can mimic traditional artistic techniques, such as airbrushing. When it senses the pressure that a user applies to the stylus, the Cintiq 16 can make better images that are more precise as well as more creative or artistic. It is our understanding that the Taiwanese origin SCB PCBA, with the accompanying software, is the component of the Cintiq 16 that is chiefly responsible for this pressure-sensitive mechanism. Still, the SCB and the accompanying software are not the only items in the Cintiq 16 that are responsible for the creation of the images. Rather, while the pressure-sensitive technology helps to make the images or designs generated on the Cintiq 16 to be more creative, artistic, and precise, we nonetheless do not believe that the pressure sensitive technology of the Cintiq 16 drawing tablet should be the sole basis of determining its country of origin because this specialized technology merely represents only an enhancement of the tablet’s basic functionality.

In this case, as noted, both the Chinese and Taiwanese components of the Cintiq 16 tablet play a vital role in the functions that allow the user to create images that can be electronically displayed on a screen. Accordingly, since we cannot ascertain dominant components, including the PCBAs, which are more important in providing the essence to the finished Cintiq 16 drawing tablet, we look to the nature of the processing operations to see where the most significant work involved in making the Cintiq 16 is being performed.

In HQ H015324, CBP was asked to determine the country of origin of stereoscopic displays assembled in the U.S. from non-U.S. parts. The displays consisted of two LCD monitors from China or Taiwan, mounted in a custom-made stand with a special beamsplitter mirror mounted at a bisecting angle between the two monitors. A graphics card in the computer separately transmitted right eye and left eye video. The importer would send one of the monitors to a third-party in the U.S. for an optical transformation process, after which the displays would be assembled, aligned, and tested. CBP found that the processing and assembly operations in the U.S. resulted in a substantial transformation of the imported LCD monitors and the beamsplitter mirror. We found that the polarization process performed in the U.S. changed the essential character of the LCD and imparted the stereoscopic functionality to the entire system. In addition, the assembly, testing and alignment of the display required a significant amount of time and precision by skilled technicians. In other words, it was the extensive processing performed in Taiwan that determined the country of origin of the stereoscopic displays.

In this case, under the new proposed production scenario, we find that the most significant work in manufacturing of the Cintiq 16 is now being performed in Taiwan. This processing work now includes the production of the three PCBA boards, the SCB PCBA, the scaler board, and the keypad board, with the addition of the Taiwanese firmware. We note that building the three PCBA boards is technically intricate and a complex operation. It involves using SMT to populate a myriad of electronic components, including the attachment of the active and passive elements as well as other components onto a bare printed circuit board by soldering, gluing and other means. In addition to the intricate work of populating the components onto the blank PCB boards, they will be programmed with specially written firmware and software, which lets the Cintiq 16 tablet perform its function as a drawing tablet. Consequently, in this new production scenario, the production operations performed in the Taiwan are more extensive and complex than the work that was being performed in Taiwan in NY N308714. In addition to producing the three PCBAs in Taiwan, other processing operations will also be performed in Taiwan to manufacture the Cintiq 16m, including installing the PCBAs into the housing, connecting cables, installing firmware, and final assembly of all the various components to produce the finished tablets. We note that the total processing operation that will be performed in Taiwan to make the Cintiq 16 requires a significant amount of time and skill to complete.

Based on the information provided in this case, we find that the proposed processing and assembly operations performed in Taiwan will result in a substantial transformation of the Chinese components of the Cintiq 16, which are shipped to Taiwan. Therefore, under the new production scenario that Counsel has set forth in his most submission, we find that the country of origin of the Cintiq 16 drawing tablet is Taiwan. As a product of Taiwan, in accordance 19 U.S.C. 1304, the Cintiq 16 drawing tablet must be marked to indicate that its country of origin is Taiwan. In addition, because the Cintiq 16 drawing tablet is a product of Taiwan and not China, it will not be subject to Section 301 duties.

The country of origin of the Cintiq 16 drawing tablets is Taiwan, and in accordance with the requirements of 19 U.S.C. 1304, it must be marked to indicate that its country of origin is Taiwan. As the merchandise is not a product of China, for the purposes of the application of subheading 9903.88.03, HTSUS, Section 301 measures do not apply.

A copy of this ruling letter should be attached to the entry documents filed at the time the goods are entered. If the documents have been filed without a copy of this ruling, it should be brought to the attention of the CBP officer handling the transaction. Sincerely,

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Approximately 90 percent of all LCD modules are manufactured in mainland China. The remaining 10 percent are manufactured primarily between Japan and Taiwan, and some in Korea. China’s clear stronghold in manufacturing, coupled with its large volume of imports to the U.S., mean these tariffs will definitely impact the industry.

The US government said the tariffs where created in response to China’s Unfair Trade Practices. Specifically, the Section 301 investigation by the USTR revealed:

China uses joint venture requirements, foreign investment restrictions, and administrative review and licensing processes to require or pressure technology transfer from U.S. companies.

China directs and unfairly facilitates the systematic investment in, and acquisition of, U.S. companies and assets to generate large-scale technology transfer.

China conducts and supports cyber intrusions into U.S. commercial computer networks to gain unauthorized access to commercially valuable business information.

Unfortunately, while the USTR works to rectify inequities in these unfair practices, many American manufacturers will have to pay higher prices for their components. That works its way up the supply chain and can ultimately lead to higher prices for American consumers.

The USITC (Office of Tariff Affairs and Trade Agreements) is responsible for publishing the Harmonized Tariff Schedule of the United States Annotated (HTSA). The HTSA provides the applicable tariff rates and statistical categories for all merchandise imported into the United States; it is based on the international Harmonized System, the global system of nomenclature that is used to describe most world trade in goods. Although the USITC publishes and maintains the HTSA in its various forms, Customs and Border Protection is the only agency that can provide legally binding advice or rulings on classification of imports.

Many people are asking about using alternate HTC codes with lower burden implications. Unfortunately, these codes are abundant and complicated. There should be exactly one code that properly categorizes your product.

When a display is designed and built for a single application, it may be more appropriate to use a harmonized tariff code for the end-product instead of the display component. An LCD in a cellphone is a good example of this.

A popular way to do this is to reevaluate your current HTC codes and make sure they’re correct. This can be done with in-house council or the use of a consultant specializing in this area of the government. Ultimately, however, you need get a ruling from the government to be certain you are using the correct code.

Some companies are searching for key suppliers outside of the China region and working towards qualifications of those factories. Others are exploring having key components of the purchased assembly outsourced outside of China so it still satisfies the correct definition of Country of Origin. Again, violating these definitions can lead to costly fines and penalties.

lcd screen pressure sensitive provide the touch interface in smartphones, which are vital for them to function. Alibaba.com stocks a stunning range of high-tech lcd screen pressure sensitive with vibrant color depictions. Truly crystal-clear displays of lcd screen pressure sensitive are available covering various brands and models such as the Samsung Galaxy Edge 2, OnePlus 7T, Samsung Galaxy C5, and many more.

lcd screen pressure sensitive are the most commonly used displays, as they produce great image quality while consuming low power. Rather than emitting light directly, they use back lights or reflectors to produce images, which allows for easy readability even under direct sunlight. lcd screen pressure sensitive are energy-efficient, and are comparatively safer to dispose of, than CRTs. lcd screen pressure sensitive are much more efficient when it comes to usage in battery-powered electronic equipment, due to their minimal power consumption.

Some other advantages of lcd screen pressure sensitive over the CRT counterparts are - sharper images, little to no heat emission, unaffected by magnetic fields, narrow frame borders, and extreme compactness, which make them very thin and light. Some types of lcd screen pressure sensitive are transmissive, reflective, and transflective displays. Transmissive displays provide better image quality in the presence of low or medium-light, while reflective displays work best in the presence of bright light. The third type of lcd screen pressure sensitive, transflective, combine the best features of both the other types and provide a well-balanced display.

Whether as an individual purchaser, supplier or wholesaler, browse for an extensive spectrum of lcd screen pressure sensitive at Alibaba.com if you don"t want to stretch a dollar yet find the best fit.

After getting the newly released iPhone SE, we did a thorough study in which parts that the iPhone 5S and iPhone SE share in common (Check for more detailed information with iPhone SE Full Tear down Comparison with iPhone 5S by ETrade Supply). Not surprisingly, many replacements parts of iPhone SE are compatible with iPhone 5S, their internal structure are almost the same. What excited us most is that they can totally share the same LCD screen and digitizer assembly, which with no doubts will reduce the inventory and supply chain integration pressures of repair shops. However, with the original LCD screen is getting more and more difficult to be obtained, most repair shops are using more replacements parts produced by third party manufacturer in China.

In order to figure out whether the iPhone 5S LCD screens produced by the third party manufacturer are compatible with iPhone SE or not, we did the following experiment in iPhone SE:

What beyond our imagination is that all of the China made LCDs can act well whether on display or touch function in iPhone 5S, however, when being used in iPhone SE, there are serious problems like shaking screen, black screen, Vertical lines on display (which just like you didn"t connect the LCD screen connectors well).

First thing we need to know is the sources and production process of the China made LCDs. The TM/LT/JDF/In-cell LCDs assemblies in the market are not completely produced by the manufacturers themselves, they just provide the cut LCD screens, the rest processes are finished by the other third party manufacturers which also provide assemble the glass lens, digitizer frame, the LCD back plate shield and the LCD drive IC and other related small parts. It is not only the LCD itself which influences the display function, the compatibility between LCD drive IC and the motherboard is also another important involving factor. In order to save costs, pursue higher profits, these third party manufacturers are using OEM-compliant LCD drive IC, which just debugged with the compatibility of 5S"s motherboard, not with SE"s.

Most China made LCDs are using the OEM-Compliant LCD driving IC at present. When replacing iPhone SE LCD screen with it, there is a big chance to encounter the phenomenon of shaking screen, black screen and vertical lines on display.

1.Original and brand new LCD screen would be your best choice when replacing iPhone SE LCD screen, if not, the assembled original screen and original-refurbished screen are second choices.

Every aspect of your day involves interacting with an LCD Display Touch Screen. They are used in numerous places, including mobile phones, automated teller machines, kiosks, ticket vending machines, and factories. LCD display touch screens have dominated the market for years, and their dominance shows no signs of abating any time soon. Mechanical engineers are always working to enhance their hardware and software algorithms to render traditional input devices like keyboards and mice unnecessary.

An LCD display touch screen"s adaptability means it may be used in almost any setting, including those that are noisy, chaotic, or even dirty because of the high volume of traffic expected. This has numerous positive implications for many different types of businesses.

Because of their intended use in commercial and industrial settings, these displays are equipped with safeguards to prevent damage over time. Touchscreens used in commercial and industrial settings are made to last for years, even when subjected to extreme temperatures, humidity, and pressure. LCD touch screen displays can be configured to the precise characteristics required by a wide variety of applications, making them ideal for supermarkets, restaurants, stores, warehouses, distribution centers, hospitals, and even military and maritime activities.

LCD display touch screen ultra-compact and lightweight design. The liquid crystal display takes up only a third as much room as the bulkier CRT display, uses less power, and stays cool under pressure. When compared to cathode ray tube (CRT) displays, this device has a significantly lower power usage. The liquid crystal display generates zero thermal energy and emits zero harmful radiation, making it a safe and healthy choice. The display is gentle on the eyes. The lack of flickering on an LCD panel means less strain on the eyes and a more comfortable viewing experience than with CRT technology.

Therefore, it is crucial that these multipurpose systems can continue functioning normally and at peak efficiency even in the harshest environmental conditions, with as little system failure and hardware damage as possible. They might be responsible for saving someone"s life.

One of your least tech-savvy employees should be able to set up these devices with ease. You can save yourself a ton of time and money by not having to hire a computer professional to set up your portable industrial computer monitor because it is very similar to setting up a personal or office computer.

A-TOPS Electronics Co., Ltd., founded in 1998, is an industry leader in LCD display R&D and production. We have a distinct competitive advantage when it comes to producing individualized and specially designed products for our clients in addition to the more commonplace industrial displays.

When it comes to meeting the unique requirements of our customers, A-TOPS is always looking for new methods to improve and broaden our product offerings. We contribute to the value plus quality and service that our customers need to flourish in today"s competitive market by offering expert solutions at a fair price and prompt, helpful customer service.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey