revolution of the tft lcd technology factory

The introduction of flat panel displays that are fabricated with thin-film-transistor liquid-crystal displays (TFT LCDs) has changed human"s lifestyle very significantly. Traditionally, the revolution of the TFT LCD technology has been presented by the timeline of product introduction. Namely, it first started with audio/video (AV) and notebook applications in the early 1990s, and then began to replace cathode-ray tubes (CRTs) for monitor and TV applications. Certainly, TFT LCDs will continue to expand in all areas of our daily life in the future. Here a new concept of the revolution of the TFT LCD technology is presented for the major TFT LCD makers. In this new concept, there are four waves of technology revolution with the following themes, respectively: 1) product introduction; 2) performance enrichment; 3) power and material utilization; and 4) functions for human interface. The role of the LCD-TV in the revolution is also discussed.

TFT Liquid crystal display products are diversified, convenient and versatile, simple to keep up, upgrade, update, long service life, and have many alternative characteristics.

The display range covers the appliance range of all displays from one to forty inches and, therefore, the giant projection plane could be a large display terminal.

Display quality from the most straightforward monochrome character graphics to high resolution, high colour fidelity, high brightness, high contrast, the high response speed of various specifications of the video display models.

In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of paperless offices and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be generally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can be used as a mobile terminal display or desktop terminal display and can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and sound characteristics of large-scale industrial production. TFT LCD industry technology is mature, with a more than 90% mass production rate.

It is an ideal combination of large-scale semiconductor integrated circuit technology and light source technology and has good potential for more development.

From the beginning of flat glass plates, its display effect is flat right angles, letting a person have a refreshing feeling. LCDs are simple to achieve high resolution on small screens.

The introduction of flat panel displays that are fabricated with thin-film-transistor liquid-crystal displays (TFT LCDs) has changed human"s lifestyle very significantly. Traditionally, the revolution of the TFT LCD technology has been presented by the timeline of product introduction. Namely, it first started with audio/video (AV) and notebook applications in the early 1990s, and then began to replace cathode-ray tubes (CRTs) for monitor and TV applications. Certainly, TFT LCDs will continue…Expand

With its excellent performance, mass production, a high degree of automation, low cost of raw materials, and broad development space,TFT-LCDwill rapidly become the mainstream product in the new century and a bright spot in the global economic growth in the 21st century.

And TN technology is different,TFTdisplay using "back-penetrating" irradiation - imaginary light source path is not like TN liquid crystal as from top to bottom, but from the bottom up. This approach is to set up a special light tube in the back of the liquid crystal, the light source when irradiated through the lower polarizer upward transmission. As the electrodes of the upper and lower sandwich layer are changed to FET electrodes and common electrodes when the FET electrode is turned on, the performance of the liquid crystal molecules will also change, which can be shaded and transmitted to achieve the purpose of display, and the response time is greatly improved to about 80ms. Because it has a higher contrast ratio and richer colors than TN-LCD, the screen update frequency is also faster, so TFT is commonly known as "true color".

Compared to DSTN, TFT LCD"s main feature is to configure a semiconductor switching device for each pixel. Since each pixel can be directly controlled through the dot pulse. Thus, each node is relatively independent and can be continuously controlled. This design method not only improves the response speed of the display but also can accurately control the display grayscale, which is theTFTcolor is more realistic than the DSTN reasons.

With the maturity of TFT technology in the early nineties, color LCD flat panel display rapid development, less than 10 years, TFT LCD rapidly grew into the mainstream display, which has the advantages of it is inseparable. The main features are.

(1) use characteristics: low-voltage applications, low driving voltage, solidified use of safety and reliability; flat, and thin, saving a lot of raw materials, and use of space. Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT LCD even only about one percent of the CRT, saving a lot of energy. TFT LCD products and specifications, size series, variety, easy and flexible use, maintenance, update, easy to upgrade, long service life, and many other features. The display range covers all display applications from 1" to 40" as well as large projection surfaces, making it a full-size display terminal. The display quality ranges from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, and high responsiveness of video displays of all sizes and models. Display methods include direct view, projection, see-through, and reflective.

(2) Good environmental characteristics: no radiation, no flicker, no harm to the user"s health. In particular, TFT LCD electronic books and magazines will bring mankind into the paperless office, paperless printing era, leading to human learning, dissemination and record planted civilization way of revolution.

(3) wide range of applications, from -20 ℃ to +50 ℃ of the temperature range can be used normally, through the temperature hardening process of TFT LCD low temperature operating temperature can reach minus 80 ℃. Can be used as a mobile terminal display, desktop terminal display, and can be used for large-screen projection TV, which is an excellent performance of the full-size video display terminal.

(4) manufacturing technology, a high degree of automation, large-scale industrial production characteristics of good. TFT LCD industry, mature technology, large-scale production of the yield rate of more than 90%.

(5) TFT LCD easy integration and upgrading, is a perfect combination of large-scale semiconductor integrated circuit technology and light source technology, continue to develop great potential. At present there are amorphous, polycrystalline, and monocrystalline silicon TFT LCD, the future will have other materials of TFT, both glass substrate and a plastic substrate.

TFT (Thin Film Transistor) LCD thin film field effect transistor (LCD) is a kind of active matrix liquid crystal display (AM-LCD). The liquid crystal display panel, especially TFT-LCD, is currently the only and display more than CRT fully catch up with the comprehensive performance of brightness, contrast, power, life, size and weight, its excellent performance, large-scale production of good properties, high degree of automation, raw materials, low cost, broad space for development, will become the mainstream the product of the new century, is one of the highlights of the twenty-first Century global economic growth.

TFT shows the use of "back through" - the way the imaginary light source is not like the TN LCD from top to bottom, but from the bottom up. This approach is set up in the back of the liquid crystal special light pipe, light source when exposed to the light through the polarizer. The electrode under dissection into the FET electrode and the common electrode, the FET electrode is conducted, the performance of the liquid crystal molecules will change, can be light and shading to achieve the purpose of the show, the response time greatly increased to about 80ms. Because of its higher than TN-LCD contrast and more colorful, faster screen refresh rate, the TFT called "true color".

Compared with DSTN, the main feature of TFT-LCD is to configure a semiconductor switch device for each pixel. Since each pixel can be directly controlled by the point pulse. Thus each node is relatively independent and can be controlled continuously. This design method not only improves the response speed of the display, but also can accurately control the display of gray level, which is the reason why the TFT color is more realistic than DSTN.

With the maturity of TFT technology in the early 90s, the development of color LCD flat panel display, less than 10 years, the rapid growth of TFT-LCD into the mainstream display, which has its advantages are inseparable. Main features are:

The application of low voltage, low driving voltage, solid use safety and reliability is improved; flat, and thin, save a lot of raw materials and the use of space; low power consumption, the power consumption is about CRT display 1/10, left and right one percent reflective TFT-LCD even only CRT, save a lot of energy and TFT-LCD products; specification, size series, variety, flexible and easy to use, maintenance, update, easy to upgrade, long service life and many other features. Display range from 1 inches to 40 inches display all application range and large projection plane is full size display terminal; display quality from the most simple monochromatic character graphics to high resolution, high color fidelity, high brightness, high contrast, high response speed of the video display of various specifications; display has a direct type of projection type, perspective, also reflection type.

No radiation, no flicker, no harm to the health of users. In particular, the appearance of TFT-LCD electronic books and periodicals, will bring human beings into paperless office, paperless printing era, lead to human learning, dissemination and record of civilization revolution.

It can be used normally in the temperature range from -20 DEG C to +50 DEG C, and the working temperature of TFT-LCD can be reduced to 80 degrees below zero. The utility model not only can be used as a mobile terminal display, but also can be used as a large screen projection tv.

Large scale industrial production characteristics. TFT-LCD industry mature technology, large-scale production of finished product rate of 90% or more.

It is the perfect combination of large scale semiconductor integrated circuit technology and light source technology. At present, there are amorphous, polycrystalline and monocrystalline silicon TFT-LCD, there will be other materials in the future TFT, both the glass substrate and plastic substrate.

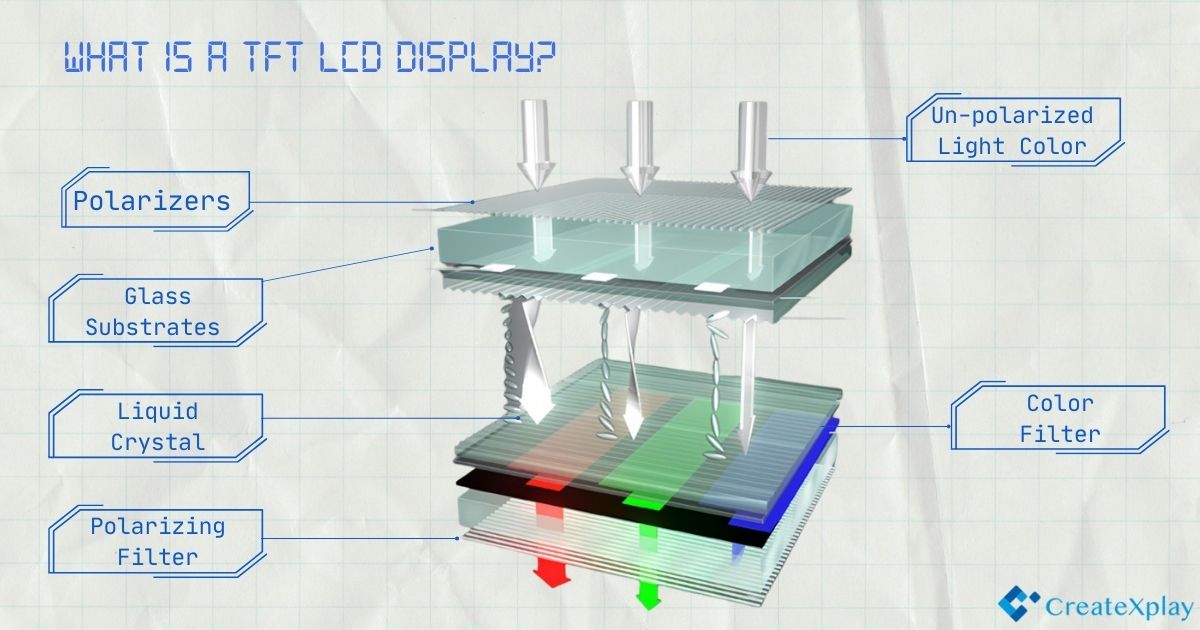

Simply put, TFT-LCD panels can be regarded as two pieces of glass substrate sandwiched between a liquid crystal layer, the upper glass substrate with color filter (Color Filter), while the lower glass is inlaid in the upper transistor. When the current changes in the electric field generated by the transistor, liquid crystal molecules resulting deflection of light in order to change the bias polarity, then use Polaroid decision pixels (Pixel) and dark states. In addition, because the upper glass and color filter lamination form each pixel (Pixel) each containing three red blue green color, which emit red blue and green colors constitutes the image pixel on the screen panel.

Array preceding process and semiconductor manufacturing process is similar, but the difference is that the thin film transistors fabricated on glass, instead of silicon wafer.

The middle section of the Cell, is the previous paragraph Array glass as substrate, and the color filter glass substrate, and between two glass substrate into the liquid crystal (LC).

After the module assembly process is the process after the glass Cell and others such as backlight, circuit, frame and other components assembly production.

Liquid crystal display structure as a sandwich, the liquid crystal sandwiched between two glass substrates, the two glass substrate is TFT Array glass and color filter. TFT Array glass above a myriad of pixels (pixel) arranged, the color filter is the source of the color screen, the LCD will be sandwiched between the TFT and Array color filter. When the voltage applied to TFT (transistor), liquid crystal steering, then the light passes through the liquid crystal panel to produce a pixel, and the light source module is responsible for providing the backlight. At this time, the color filter of each pixel given a specific color. With a different color for each pixel of the image of the front panel is.

The TFT-LCD must be manufactured in a clean, clean room with more than 300 processes. Clean room cleanliness, the highest level up to "10", that is, in the clean room environment, each cubic foot only 10 dust.

The TFT-LCD plant has evolved from the past 1 generations to the present generation of the 7.5 generation. The difference between the generations is the size of the glass substrate. The larger the glass substrate, the larger the size of the panel can be cut. For example, a 7.5 generation glass substrate size up to 195 cm X 225 cm, the size of more than one double bed to increase, it can be cut into eight pieces of 42 inch panel, or 6 pieces of 46 inch panel.

The manufacturing process of TFT-LCD can be divided into three stages: pre Array, middle Cell, and post module assembly. The Array process is similar to the semiconductor process, but the difference is that the thin film transistors on glass, rather than on silicon wafers.

The middle section of the Cell, is the previous paragraph TFT Array glass as the substrate, and the color filter glass substrate, and the two pieces of glass substrate between the liquid crystal on the substrate, and then cut into a large glass panel.

After the module assembling process, is the Cell veneer with glass after cutting, and other components such as circuit board, backlight, frame and other components of the assembly production.

TFT LCD display is characterized by good brightness, high contrast, strong sense of layering, and bright colors, but it also has the disadvantages ofrelatively highpowerconsumptionand high cost. TFT LCD technology has accelerated the development ofmobile phone color screens. Many of the new-generation color screen mobile phones support 65536-color displays, and some even support 160,000-color displays. At this time, the advantages of TFT high contrast and rich colors are very important.

TFT technology was developed in the 1990s. It adopts new materials and new processes for large-scale semiconductor full integrated circuit manufacturing technology. It is aliquidcrystal(LC), inorganic and organic thin film electroluminescence (EL and OEL) flat panel display. basis. TFTs are formed on glass or plastic substrates and other non-single wafers (of course, they can also be on wafers) by sputtering and chemical deposition processes to form various films necessary for manufacturing circuits, and large-scale semiconductor integrated circuits (LSIC) are produced by processing the films . The use of non-single-crystal substrates can greatly reduce costs, which is the extension of traditional large-scale integrated circuits to large areas, multi-functions, and low costs.Manufacturing TFTs thatcontrolthe switching performance of pixels (LC or OLED) on large-area glass or plastic substrates is more difficult than manufacturing large-scale ICs on silicon wafers. The requirements for the production environment (purification degree is 100), the requirements for the purity of raw materials (the purity of electronic special gas is 99.999985%), the requirements for production equipment and production technology exceed the large-scale integration of semiconductors, and are the top of modern large-scale production technology. Its main features are:

(1) Large area: The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into operation in the early 1990s. By the first half of 2000, the area ofthe glass substrate had been expanded to 680mm×880mm), and 950mm×1200mm The glass substrate will also be put into operation. In principle, there is no area limit.

(2) High integration: The resolution of the 1.3-inch TFT chip used for liquid crystal projection is XGA containing millions of pixels. The 16.1-inch TFT array amorphous silicon with a resolution of SXGA (1280×1024) has a film thickness of only 50 nm, and TABONGLASS and SYSTEMONGLASS technologies. The IC integration, the requirements for equipment and supply technology, and the technical difficulty are more than traditional LSI.

(3) Powerful function: TFT was thefirst matrix addressingcircuitto improve the light valve characteristics of liquid crystal. For high-resolution displays, through the voltage adjustment in the range of 0-6V (its typical value is 0.2 to 4V), the precise control of the object element is realized, thereby making it possible for the LCD to achieve high-quality high-resolution display. TFT-LCD is the first flat panel display in human history that exceeds CRT in display quality. And people began to integrate the driver IC on the glass substrate, the function of the entire TFT will be more powerful, which is unmatched bytraditional large-scalesemiconductorintegrated circuits.

(4) Low cost: Glass substrates and plastic substrates have fundamentally solved the cost problem of large-scale semiconductor integrated circuits, and opened up a broad application space for the application of large-scale semiconductor integrated circuits.

(5)Flexibleprocess: In addition to sputtering, CVD (Chemical Vapor Deposition), MCVD (Molecular Chemical Vapor Deposition) and other traditional processes for film formation, laser annealing technology has also begun to be applied. It can produce both amorphous and polycrystalline films. A single crystal film can be manufactured. Not only can silicon films be made, but other II-VI and III-V semiconductor thin films can also be made.

(6) Wide application fields, LCD flat panel displays based on TFT technology are the pillar industries of the information society, and the technology can also be applied to the rapidly growing thin film transistor organic electroluminescence (TFT-OLED) flat panel displays. Growing up.

With the maturity of TFT technology in the early 1990s, color liquid crystal flat panel displays have developed rapidly. In less than 10 years, TFT-LCD has rapidly grown into a mainstream display, which is inseparable from its advantages. The main features are:

(1) Good use characteristics: low-voltage application, low driving voltage, solidified use safety and reliability improvement; flat, light and thin, saving a lot of raw materials and use space; low power consumption, its power consumption is about CRT display One tenth, reflective TFT-LCD is only about 1% of CRT, which saves a lot of energy; TFT-LCD products also have specifications, sizes, series, variety, convenient and flexible use, maintenance, update , Easy upgrade, long service life and many other features. The display range covers the application range of all displays ranging from 1 inch to 40 inches and the large plane of projection. It is afull-size displayterminal; the display quality ranges from the simplest monochrome character graphics to high resolution, high color fidelity, High-brightness, high-contrast and high-response video monitors of various specifications and models; display methods include direct-view type, projection type, perspective type, and reflective type.

(2) Good environmental protection characteristics: no radiation, no flicker, no damage to the user"s health. In particular, the emergence of TFT-LCD electronic books and periodicals will bring human beings into the era of paperless office and paperlessprinting, triggering a revolution in the way humans learn, spread, and document civilization.

(3) Wide application range, can be used normally within the temperature range from -20℃to +50℃, and the low-temperature working temperature of the TFT-LCD after temperature strengthening treatment can reach minus 80℃. It can be used as a mobile terminal display, desktop terminal display, and can also be used as a large-screen projection TV. It is a full-size video display terminal with excellent performance.

(4) The degree of automation of manufacturing technology is high, and the characteristics of large-scale industrial production are good. The technology of the TFT-LCD industry is mature, and the yield rate of large-scale production reaches more than 90%.

(5) TFT-LCD is easy to integrate and update, it is the perfect combination of large-scale semiconductor integrated circuit technology andlightsource technology, and there is great potential for continued development. There are currently amorphous, polycrystalline, and monocrystalline silicon TFT-LCDs, and in the future there will be TFTs of other materials, both glass substrates and plastic substrates.

If you ended up on this page doing normal allowed operations, please contact our support at support@mdpi.com. Please include what you were doing when this page came up and the Ray ID & Your IP found at the

Recently, there is a lot of buzz about whether Apple will choose Mini-LEDover OLED, for the next round of iPads, MacBooks and other products. Regardless of the fascination analyzing current product releases, or one specific consumer-product company, the more significant movement over the last 5~10 years, has been the steep upwards ramp in Micro-LED Startups, IP, investments and acquisitions by: Apple, Facebook, and Google. And from the chip makers themselves such as Intel, Global-Foundries, in Startups such as Luxview, InfiniLED, Plessey, Aledia, Compound Photonics and more.

For an industry that is literally in the business of visualization, the display industry often seems rather opaque, mysterious, and even geo-politically contentious (refer: Foxconn"s LCD Fab in Wisconsin). These articles will cover aspects not well-elaborated in popular analysis, and also provide an update to the material presented 5yrs ago at the Bay-Area SID (Society for Information Displays), on why this technology, is so different, so disruptive, and how it will reach far beyond even the wildest market projections. But for a background on the basics of how & why, vision, the brain and displays work, recommend an easy to digest, and popular, book by Mark Changizi: The Vision Revolution. There are also excellent industry analysts, who cover displays professionally, and in much finer-grain detail, such as Yole Development (thanks to Eric Virey for source graphics) and DSCC (thanks to Ross Young & team for references, and feedback).

Firstly, to be clear: the flat-panel display industry is a semiconductor industry. This is the critical "border", where electrons of digital information, are turned into photons of visual information. And the pixels you see, while reading this article, are driven by transistors - Thin-Film Transistors (TFT) - somewhere between 3 and 12 transistors per pixel, depending on the type of display (OLED needs more than LCD), and the maker. The Transistor, Resistor, Capacitor circuits are built by nano-scale material deposition processes, on a glass substrate (the backplane), via semiconductor manufacturing equipment, from suppliers including US"s Applied Materials, Japan"s Canon Tokki, Korea"s SNU Precision, Wonik IPS and more. Yet it has not attracted the same strategic interest from within the US, as other semiconductor industry segments e.g. processor chips. While there is a drive to increase the number of (existing) semiconductor chip fabs on US soil, the fact is that the US has no significant domestic display manufacturing capability at all, effectivelyzero. And the same is true for most of the technology ingredients comprising the display, such as the film layers, LED’s & OLED and their ingredient materials, and the controller & driver chips - which is dominated entirely by non-US companies you probably never heard of, such as Taiwan Novatek (the 13th largest semi maker, worldwide), Taiwan Himax, Taiwan Parade, and Japan"s Renesas. That is, until one of them has a problem.

So if the geopolitical semiconductor war gets any rougher, you might be wondering, where is this chip (that Biden is holding) going to display it"s output ? On an etch-sketch ? (perhaps the only display device still made in the US ?)

Since more than 40% of our brain is devoted to vision, more than all of the other senses combined, this would seem an important gap. After all, light, color and contrast are the fundamentals of art, literature, civilization, as well as your next Zoom virtual meeting. Of course we need to see the results of the computation of AI, CPU, Memory, GPU, Network, 5G ... processors, appear on some display eventually, right ? So this article also aims to provide some more insights on key factors in the previous transition, what"s going on now, why it"s important, and how it may matter in real-life terms.

Secondly, (and this an easy bet) you’re more likely reading this article on an LCD flat-panel Display, rather than OLED or ePaper. But all 3 have been transformational technologies of the 21st century. Could modern society continue to communicate effectively, presenting a person in front of you from anywhere/anytime, productivity continuing virtually, during a Global Pandemic ? What would it have been like if we were still sharing the 20th century family’s TV ? (recap for millennials: the Cathode Ray Tube TV was a 50 ~ 100 lb, X-Ray-emitting, monster appliance, using electron beam scanning technology from the 1920"s, and with coarse interlaced video rendering designed to save 6MHz (3 Mbit/s by modern standards) of precious radio-frequency bandwidth). Even the 12yr old iPhone 3GS could muster more than that, on a bad day.

As for myself, am writing this article across two of my favorite consumer flat-panel devices: a newer 15” Retina MacBook Pro and an older 17” MacBook Pro. Partly because both are still the best, un-compromised, example of the portability & performance enabled by the Hybrid Graphics technology, a Display & GPU technology, drove across the laptop industry while working at NVIDIA. But mostly because Apple consistently aims for excellence in their displays. Am enjoying a large, bright, 300 “nit” (candela/meter2) LCD screen, an excellent 900~1000:1 contrast ratio, a full DCI-P3 color gamut, and sharp 220 ppi "retina" resolution that renders crisp text and beautiful images. The recurring theme: light, color, contrast.

However, at the 2019, 2020 and 2021 CES, Micro-LED and Mini-LED began appearing across more and more applications (e.g. TV, AR, Monitors, Digital Signage), and demo"s like the Samsung Wall and Sony MicroLED continue to attract the largest, most excited crowds, have ever seen at CES (before it went virtual). Back in 2017, I wrote this article about Micro-LED & Mini-LED"s, talking about potential applications, and specifically about the key challenges to this visual revolution, that PixelDisplay set out to solve: in the color conversion material needed to more economically create Red & Green from the high efficiency Blue. In November 2020, PixelDisplay publicly disclosed details of NanoBright™solution, at the Phosphor & QD Summit, and is now offered for sale on PixelDisplay.com

In the Mini-LED ecosystem, the role of NanoBright is often used the same as per regular white LED"s, which in 2018 PixelDisplay estimated to be worth $750m/yr, but this market is now projected to be worth $5b, for Mini-LED"s overall, by 2025. The color converter can be simply coated on the Mini-LED and surrounding backplane (providing a high efficiency, bright-contrast, High-Dynamic-Range with DCI-P3 wide-color gamut), but there are more interesting benefits e.g. eliminating existing LCD films to make thinner, borderless and more efficient.

But to put this in larger perspective, here"s the role NanoBright™fills in the Micro-LED ecosystem, as described in DSCC"s ( @Guillaume Chansin) excellent LinkedIn article.

But why should this Micro-LED technology be of any broader importance ? Why is it any different than OLED, or LCD ? How is it a disrupting technology ? What difference does it have from any of the other opaque display industry machinations that means it will have significant impact in our lives? It"s a great test to ask: "would my mother care ?".

To start with how it"s different, and how it is disruptive, we need to recap on how we got here on the glass backplane of LCD and OLED. And to fully appreciate the magnitude of the disruption represented by the Micro-LED revolution, we have to also understand the scale of the investment behind the commercializing flat-panel glass, and to the display TFT semiconductor industry.

Am not going to cover the long sordid history of display technologies, nor the detailed lineage of LCD, or OLED. But it is worth noting that both technologies were born in the US, the LCD from RCA, and the OLED from Kodak - and ironically, both pioneering companies are now just brands - non practicing entities. But there are other pioneers, such as UDC, who have persisted, and remain necessary ingredients in the ecosystem (we"ll touch on "why ?" later). But instead, will identify two key elements from the 1990"s, that were the major accelerators flat-panel displays to escape velocity in 2000"s, launched the FPD revolution into orbit, and led to the proliferation of what we enjoy today:

1) TFT follows Square-Rule Growth:To understand the explosion in the economics of producing glass flat panel displays covered in TFT pixels, we can start with the size increases of the glass processing fabrication itself. The term, "Gen" refers to the size generation, the capability of the TFT panel fab, by the dimensions of the glass sheet that it can process, which typically entails creating deposition layers stacked layer-by-layer, to build the TFT pixels - whether OLED or LCD, it starts with TFT pixels on a sheet of glass. In the late 90’s, massive government investments spurred the creation of ever larger display fabrication facilities, with ever larger deposition equipment based on the successful A-Si (amorphous Silicon) process, which grew quickly from Gen 3.5 (0.62 x 0.75m) to Gen 5 (1.1 x 1.3m) to Gen 6 (1.5 x 1.85m) glass substrates, in just a handful of years. Every sheet of glass processed in an LCD production line is cut into smaller panels, making TV’s, Monitors, laptops, tablets and phones.

But unlike Moore’s Law (which doubles transistors every 18months), the glass panel area increase (width x height) results in a faster, power-of-2 square-rule, increase in the number of pixels, and thus the number of TFT transistors. In fact, the number of semiconductor transistors on glass TFT was increasing at 2.5x Moore’s Law, during the last decade. While it took 10 years to go from 5mil transistors in Intel’s Pentium Pro 1995, to 169 mil transistors in the Prescott CPU 2005 – the LCD display industry made the same increase in the number of TFT transistors for 8K resolution, in roughly 5 years (from the PixelDisplay presentation at the 2018 DSCC Future Display Technology Conference).

By early 2000"s, Plasma was beyond hope, the transition from CRT"s was in full-swing, the IBM Thinkpad was a staple of corporate life, and laptops had crossed the 8hr battery-life mark thanks to display efficiency improvements (as we"ll discuss later the display is the key enabler of longer battery-life). The LCD plants were pumping out everything from laptop screens, to LCD monitors, to 60" large-screen LCD TV"s, at lower-and-lower price-points - from fabs based in Japan, then Taiwan, and Korea. By the late 2000"s, the Fab-depreciation (eff. cost of borrowed capital) was the most significant component of the LCD panel prices, and panel makers squeezed the margins out of everyone in the supply chain including films, LED, controller and driver chips. Major winners were the materials suppliers: Corning Inc (the Glass), Merck (the LCD material itself), Nichia (the backlight LED"s), and Canon Tokki & Applied Materials (TFT-glass deposition equipment).

Meanwhile in the US, Intel made a huge bet in 2001, that LCD would not scale, and that LCOS would provide solutions, and enable larger-screen, like the earlier (CRT-based TV) projection displays. But in just 3~4 years, it became clear the LCD square-rule economies were different, ever-larger ever-cheaper LCD panels seemed to be viral, ramping to fill the large-screen TV market. The LCOS & DLP were relegated to the projector market, and Intel exited LCOS in late 2004. It"s worth noting Intel has gradually become more active in the display industry, and Intel Capital has made multiple investments in the Micro-LED partnerships for GaN-on-Si (and we"ll come back to that later).

Outside the US, the display industry has been the target of massive strategic investments for Asia for over 3 decades. Starting with Japan government forcing the collaboration of Sony, Hitachi and Toshiba to create JDI (which made the first iPhone and iPad screens), and the INCJ (a government investment consortium) of Japan, then Korea and Taiwan Governments, and then China. Today this industry is dominated by China, as per the reports from analysts e.g. this one from Display Supply Chain Consultants. The government of China and private investors, aggressively funded the rise of China from sub 10% a decade ago, to owning more than 63% of the world’s display production. By 2017, the Taiwan government had publicly stated they were no longer going to invest in more LCD fabs, and in 2018 the chairman of LG got up in front of the entire company taking a sledge hammer to smash an LCD TV, in a symbolic communication of the company"s shift in focus to the highly profitable OLED (not facing competition from China) - the fate of LCD flat-panels was sealed.

One example of China"s investment in display leadership is Beijing Opto Electronics (BOE). And I have visited BOE’s Gen 6, 8.5, and 10.5 (2.9m x 3.4m) fabs in HeFei and Beijing. This picture below is a panorama I took standing outside one of the older (smaller, older) Gen 8.5 Fab"s from a visit to the BOE facility in HeFei. At the time, they had built a Gen 10 behind it, and building another beside that.

But when you’re outside looking at a factory that is literally over 1.3 kilometer per side, the staggering magnitude of China"s investment in display leadership, is simply breathtaking. The first Gen 10.5 fab located in Sakai Japan, was also Japan"s last one. But at last count there are seven (7) Gen 10.5 fabs in Mainland China, and still more are being built. There is no questioning China’s intent to seize control over the majority of eye-balls, from the source.

2) Inorganic Solid-State gives 4x increase in efficiency: The second important innovation was the In/GaN-based Blue LED. Invented in Japan (ironically, US-based CREE had a blue LED earlier, but failed to productize until much later), from which Nichia made White LED’s, by adding yellow-emitting YAG:Ce inorganic phosphor, they had left over from their CRT phosphor business. It was a cheap trick to synthesize something that looked White, from a psycho-visual hack of using two complementary colors: Blue + Yellow. But in short, the poor color was an acceptable tradeoff for higher-efficiency, smaller size, more robust inorganic solid-state solution. LED backlights quickly transformed the industry from (thicker, bulky, and very fragile) fluorescent tube (CCFL) backlights, into thin/efficient LED backlights, in the early-mid 2000"s. And the lead inventors, including Shuji Nakamora of Nichia, won the 2014 Nobel prize for the work on GaN LED.

This was an important step forward in the story. Originally, the CCFL backlit display was 70~80% of the total power consumption of an idle Laptop. In fact, back in 2001 while at Intel, together with Ying Cui we invented and implemented Intel’s Backlight Modulation Technology (called DPST(tm)) which was like an inverse-High-Dynamic Range, it proportionally increased pixel contrast, in order to allow decreasing the CCFL backlight brightness and provide huge system power-savings. That was the star feature of Intel’s EBL (Extended Battery Life) initiative, saving more system power than other, more publicized, Intel CPU features (e.g. Geyserville aka "SpeedStep"). For me, that was a first introduction to the value and importance of the flat-panel display technology, as the essential ingredient in portable platforms. But LED"s further helped enable the "implosion" of visual-compute portability into sub-8lb / sub-1inch Laptops. And the displays that appeared in Phones and Tablets, were using LED"s that are only 0.4~0.6 mm tall, fitting in the edge of the panel.

Today, LED efficiency is over 200 lm/W (4x the efficiency of older CCFL), but efficiency improvements in processor and memory technology means the display is still typically 50~70% of total system power for phone or laptop, and this is worse for OLED (than LCD) because of how poorly OLED technology handles mostly-white backgrounds (e.g. of browsers, text & productivity applications).

The LED industry has also been a source of massive investment and deeply geopolitical rifts as Japan (e.g. Nichia) vs Korea (e.g. Seoul Semi Conductor) vs Taiwan (e.g. Foxconn/AOT, LiteOn, Epistar) vs China (e.g. CSOT, SanAn). Initially dominated by IP held by Nichia, CREE and Osram, those players now have diminished roles, but it has remained a complex ecosystem.

Tiny efficient LED"s enable 2D-array backlighting on LCD to achieve HDR (High-Dynamic-Range). Higher-end LCD TV"s were the first consumer displays to use LED"s with better R-G Phosphors to create a wider DCI-P3 color gamut. Firstly, arranging the Edge-Backlight LED"s to control 1-Dimensional regions, from along the edge. And then advancing into 2D-array of LED"s, to create active-region backlight. This enabled LCD"s to increase the contrast ratio beyond 1000:1, and peak brightness beyond traditional edge illumination, creating the High-Dynamic Range (HDR) experience first popularized by BrightSide (later acquired by Dolby, to form DolbyVision, and which is now licensed-technology on the iPhone). Today HDR content leverages individual screen-region lighting, to create brighter highlights, and the deeper-blacks to create a more realistic and dynamic experience. In summary, HDR LCD TV with 2D backlight became commercially practical as a result of small (less than 3.0 x 3.0 mm) LED"s with over 220 Lm/W efficiency - 13x more efficient than incandescent bulbs Brightside originally used, which had required huge exotic water cooling solution.

Challenges of the "Crystal Cycle":the size of these glass-processing fab investments is so large, and the equipment CapEx expenditures are so huge, that this leads to massive disconnect between supply and demand, causing large cyclical swings in pricing, which became known as the "Crystal Cycle"

To ride the economies of scale requires increasing the glass handling size, which requires ever larger investments, just as the second of Moore’s Laws predicts. For example, BOE’s invested US$7 billion to make a Gen 10.5 fab. And in an interesting geopolitical twist, after the Taiwan (once a former colony of Japan) government declared they were not investing anymore in the LCD business, Terry Guo (Taiwan Foxconn CEO), acquired a majority of Sharp, and their huge LCD display production lines in Kameyama (which made the innovative IGZO-based LCD panels, which enabled the thinner/more-efficient iPhone 6, and iPad Air), and Japan’s only Gen 10.5 plant in Sakai, which is making 8K TV’s (was spun-off into Sakai Display Corporation). Foxconn was already a large player in the display industry owning Taiwan’s #2 maker, Innolux Optoelectronics. Far beyond merely being “the sport of king’s”, the display industry has been “the sport of nations”.

OLED is doubly challenged: and it has not become progressively cheaper with economies-of-scale as many expected. In LCD only a tiny current is needed to flip a pixel, all of the light is produced from a thin string of backlight LED"s. Whereas in OLED, every pixel is itself a light emitting organic-LED, with many orders of magnitude higher current required at every pixel. The high contrast emissive pixel design of OLED displays provides excellent contrast, but typically requires the use of the more expensive and complex LTPS (low-temperature polycrystalline silicon) process to produce the active TFT driving backplane. LTPS involves a more complex 11-step process, with much higher-temperatures that only a few materials (glass, clear polyamide) can sustain. LTPS requires a high-power excimer laser to anneal the surface, forming the layer of polycrystalline silicon - this is slow, and does not scale well into larger sizes. The OLED fabs have thus been limited to Gen 6 (1.5 x 1.85m) or smaller, in glass size. Even though this is big enough to make a few TV"s, the smaller starting glass size means the cost-curve is sub-optimal, unless partitioned into many smaller panels e.g. the higher-cost has lower impact for smaller smartphone screen. While an oxide deposition process called LTPO (a simpler Oxide process, borrowing from the IGZO process that delivered LCD efficiency improvements in iPhone 6 & iPad Air), offers some hope in the future, there’s another additional challenge.

The complexities of driving a large number of emitters from a thin layer on glass backplane has also meant limits on full-screen brightness, and limited ability to address higher resolutions. A full screen of white does not occur often on a OLED TV, as it does on an Tablet or Laptop, but if you do witness a larger amount of white (as in productivity apps on a Laptop) you"d notice the whole OLED screen goes dimmer, this is done in order to limit the total current across the thin conductor traces that feed the pixels on the glass.

Unlike LCD TFT (which only requires a single transistor and storage capacitor), a typical OLED driving circuit can have 3~6 transistor (and similar number of capacitors) per color i.e. 9~18 transistors per pixel. This driving complexity also limits the net active emitting area of the pixel, versus the inactive driving circuit, also called the "Fill-Ratio". And that"s part of the reason why the Oculus and Samsung Gear VR headsets look like watching everything through a thick fly-screen mesh - the amount of non-emitting "dark-area" per pixel is huge (much larger than LCD). Laying out complex circuits naturally extends the non-emitting pixel-area, horizontally outwards in width & length, that is of course a limitation of thin deposition layers on glass. This limits both the ability to go into finer pitch (>1000ppi and 40Kx16K resolution is the ultimate goal for x-Reality displays), and also to create larger emitters for higher brightness.

Furthermore, the front-plane of an OLED panel requires ultra-precise patterning with emissive organic phosphor materials, with tightly controlled size & depth-tolerances. This has switched from vapor deposition, to inkjet patterning to save some cost, but because of the non-uniformity it is limited in ability to go into very fine pitch, retina-quality displays. But either way, the OLED materials themselves remain very expensive, with Universal Display Corp (UDC) maintaining a tight grip on the materials supply chain, thanks to a portfolio of significant & early IP. The alternatives to UDC patents, such as HF (Hyper fluorescence e.g. KyuLux) or TADFL (thermally activated delayed fluorescence e.g. Cynora) are really 5~10yrs out, and merging QD on OLED aka "QD-OLED (e.g. Nanosys & Samsung) has consistently missed every promised demo/roll-out, and feels more like either a science project, or a ploy for negotiating UDC pricing.

But since OLED breaks-down with age, and even faster with moisture, heat, and higher-energy blue/uv photons (reminder, the “O” in OLED, stands for Organic), the use of glass (or expensive polyamide materials) with low gas & moisture permeability remains a requirement, since lifetime & brightness remain the bigger issues for OLED. In the phone industry, key manufacturers came to embrace OLED since it looks fantastic but wears out - after-all consumers are more motivated to buy a new phone, if it looks noticeably brighter and sharper, than the worn-out 2-year-old one in hand. While higher production costs, aging and burn-in problems of OLED have been acceptable (even desirable) in the phone business, they have hampered the progression of OLED into IT and Automotive applications. And while OLED came with the promise of more freedoms than LCD, in creating foldable and flexible displays, the fact remains: it lasts longer when hermetically encapsulated in glass the best barrier protecting from oxygen and moisture.

While OLED has not enjoyed the same cost-reduction curve, as in the LCD proliferation, the higher-end and visually-satisfying (initial) experience continue to feed hope & investment. Glass TFT has both enabled, and limited OLED"s ability to achieve higher brightness, and higher resolution. There"s frequently news of better OLED solution coming down the research pipeline, and we"ve already touched on the bigger ones (e.g. Hyperfluorescence, Thermally Activated Delayed Fluorescence, Quantum Dot on OLED), but the reality has fallen far short, nor is there anything helping to break-free from the most expensive TFT processes. OLED is very likely to continue to service the small display markets, products that have a shorter life expectancy, and only need a lower-brightness display (e.g. TV"s, which only need 100nits of brightness).

The industry is ripe for disruption from a brighter, more robust inorganic solution, that comes with a better (near-term) ability to reduce cost as it scales.

Unmet needs, in important niche markets: is the essential formula, for the beginning of disruption, as outlined by Clayton Christensen. Who described the formula for disruption as essentially: a niche market (of future importance) with unmet needs, that can afford to adopt a more expensive solution, where that solution has an ability to scale and leverage the niche-win to expand into broader markets, displacing incumbent technologies. Some example display niche markets:Automotive and Smartwatches displays have been over 1,000 nits for some time, but need much more to compete with typical daylight glare.

Autonomous vehicles (e.g. robo-taxis) are on the horizon, but pause for a moment to consider how they will visually communicate to passengers & pedestrians, when no human is present ? No driver to confirm name or usher in passenger, or gesticulate with body language to other less-patient human drivers. The solutions are being developed right now (and PixelDisplay is involved), they of course need to operate in bright daylight, and be colorful & robust as the painted bumper panel or shatter-resistant safety-glass, they"ll be integrated-into.

When the HDR standards were formed, they included a high peak-brightness of 10,000 nits (far beyond wildest dreams of OLED and Quantum Dots), and real-world contrast ratio"s (>10x that available on LCD with edge backlight). And studio-grade content-authoring displays can do well over 4,000 nits, but need constant recalibration to account for non-uniformity from wear, and sometimes replaced after only a year. We can expect this to migrate into more consumer displays over the next 5yrs, and the Gaming/TV/Video/Movie content standards (BluRay-UHD, VESA DisplayHDR and the Hollywood UHD-Alliance) already integrated that support.

These are markets that will pay for a more expensive solution, that can deliver unmet needs of bright, high (HDR) contrast, deep-black and defined shadows, and crisp-rich colors (like OLED), in a thin form-factor, but with higher brightness and longer lifetime (like LED-backlit LCD).

The value of the Flat Panel Display: the industry is worth over $120 billion (3x the value of the GPU market), and is project to grow to well over $200 billion by 2025. Yearly production (rough numbers): over 1.8 billion smartphone panels, 300 million laptop and tablet panels. This thin, complex, glass-stack, in the flat-panel module, still represents the single most expensive component in the phone & tablet (and many laptops also).

In the iPhone BOM, the display has, at times, been more than 2~3x the cost of the SoC (CPU & GPU) and RF BaseBand chips, combined. And in the iPhone 12, the new OLED display is responsible for 35% of the BOM cost increase vs iPhone 11. It should then, be unsurprising that Apple (unlike Intel, NVIDIA, AMD, DELL or any other OEM that I know), has multiple (large) divisions devoted just to display technology - one in each of their business verticals. Staffed with display architects, and engineers refining technologies, sourcing core materials (even the phosphors), creating new designs. Even custom-designing the display controller and driver chips, for the panel makers to insert inside displays made - exclusively for Apple - that are not available to any other panel customers. Perhaps because it is the most critical border of the Visual Information Age, and obviously because it is necessary to control the border to control your future, right ?

In summary,during this pandemic we"re able to adapt and continue our communications visually; collaborating, pitching, working efficiently, and remotely from anywhere; thanks to the internet, wireless connectivity, and the glass flat-panel visual interface. Long Zoom sessions can be taxing, but imagine if this had happened in the 1950"s, 1970"s or 1990"s ? Would our children have been able to engage in school remotely ? Would we have remained as connected, and as productive ?

The technology innovations may have US origins, but the major enablers of the last visual revolution were: a) execution driven by massive investments in manufacturing & commercialization from: Japan, Taiwan, Korea and China in flat-panel display leadership, b) faster than Moore’s Law growth in the economies-of-scale of glass-substrate TFT pixels, and c) the shift to cheaper/smaller/robustsolid-state In/GaN semiconductor LED technology.

Now there’s a another shift happening. With the Micro-LED & Mini-LED generation, there"s a new, and very different, formula. Unlike the past display technologies: Micro-LED are innately decoupled from the glass backplane, and that changes everything.

In the next article,more details of how this visual revolution is progressing, firstly re-igniting LCD 2.0 with Mini-LED"s, and breaking through the glass-barrier with Micro-LED"s, and what displays of the future will look like.

Before you get a new monition for your organization, comparing the TFT display vs IPS display is something that you should do. You would want to buy the monitor which is the most advanced in technology. Therefore, understanding which technology is good for your organization is a must. click to view the 7 Best Types Of Display Screens Technology.

Technology is changing and becoming advanced day by day. Therefore, when you are looking to get a new monitor for your organization, LCD advantages, and disadvantage, you have to be aware of the pros and cons of that monitor. Moreover, you need to understand the type of monitor you are looking to buy.

Now, understanding the technology from the perspective of a tech-savvy person may not be the ideal thing to do unless you are that tech-savvy person. If you struggle to understand technology, then understanding it in a layman’s language would be the ideal thing to do.

That is why it is important to break it down and discuss point by point so that you can understand it in a layman’s language devoid of any technical jargon. Therefore, in this very article, let’s discuss what exactly TFT LCDs and IPS LCDs are, and what are their differences? You will also find out about their pros and cons for your organization.

The word TFT means Thin-Film-Translator. It is the technology that is used in LCD or Liquid Crystal Display. Here you should know that this type of LCD is also categorically referred to as active-matrix LCDs. It tells that these LCDs can hold back some pixels while using other pixels. So, the LCD will be using a very minimum amount of energy to function. TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the display monitor functions by using a very small amount of energy without running out of operation.

Now, it is time to take a look at its features that are tailored to improve the experience of the monitor users significantly. Here are some of the features of the TFT monitor;

The display range covers the application range of all displays from 1 inch to 40 inches as well as the large projection plane and is a full-size display terminal.

Display quality from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, the high response speed of a variety of specifications of the video display models.

No radiation, no scintillation, no harm to the user’s health. In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of a paperless office and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be normally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can not only be used as a mobile terminal display, or desktop terminal display but also can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and good characteristics of large-scale industrial production. TFT LCD industry technology is mature, a mass production rate of more than 90%.

It is a perfect combination of large-scale semiconductor integrated circuit technology and light source technology and has great potential for further development.

TFT LCD screen from the beginning of the use of flat glass plate, its display effect is flat right angles, let a person have a refreshing feeling. And LCDs are easier to achieve high resolution on small screens.

The word IPS refers to In-Plane-Switching which is a technology used to improve the viewing experience of the usual TFT displays. You can say that the IPS display is a more advanced version of the traditional TFT LCD module. However, the features of IPS displays are much more advanced and their applications are very much widespread. You should also know that the basic structure of the IPS LCD is the same as TFT LCD if you compare TFT LCD vs IPS.

As you already know, TFT displays do have a very quick response time which is a plus point for it. But, that does not mean IPS displays a lack of response time. In fact, the response time of an IPS LCD is much more consistent, stable, and quick than the TFT display that everyone used to use in the past. However, you will not be able to gauge the difference apparently by watching TFT and IPS displays separately. But, once you watch the screen side-by-side, the difference will become quite clear to you.

The main drawback of the TFT displays as figured above is the narrow-angle viewing experience. The monitor you buy for your organization should give you an experience of wide-angle viewing. It is very much true if you have to use the screen by staying in motion.

So, as IPS displays are an improved version of TFT displays the viewing angle of IPS LCDs is very much wide. It is a plus point in favor of IPS LCDs when you compare TFT vs IPS. With a TFT screen, you cannot watch an image from various angles without encountering halo effects, blurriness, or grayscale that will cause problems for your viewing.

It is one of the major and remarkable differences between IPS and TFT displays. So, if you don’t want to comprise on the viewing angles and want to have the best experience of viewing the screen from wide angles, the IPS display is what you want. The main reason for such a versatile and wonderful viewing angle of IPS display is the screen configuration which is widely set.

Now, when you want to achieve wide-angle viewing with your display screen, you need to make sure it has a faster level of frequency transmittance. It is where IPS displays overtake TFT displays easily in the comparison because the IPS displays have a much faster and speedier transmittance of frequencies than the TFT displays.

Now the transmittance difference between TFT displays and IPS displays would be around 1ms vs. 25ms. Now, you might think that the difference in milliseconds should not create much of a difference as far as the viewing experience is concerned. Yes, this difference cannot be gauged with a naked eye and you will find it difficult to decipher the difference.

However, when you view and an IPS display from a side-by-side angle and a TFT display from a similar angle, the difference will be quite evident in front of you. That is why those who want to avoid lagging in the screen during information sharing at a high speed; generally go for IPS displays. So, if you are someone who is looking to perform advanced applications on the monitor and want to have a wider viewing angle, then an IPS display is the perfect choice for you.

As you know, the basic structure of the IPS display and TFT displays are the same. So, it is quite obvious that an IPS display would use the same basic colors to create various shades with the pixels. However, there is a big difference with the way a TFT display would produce the colors and shade to an IPS display.

The major difference is in the way pixels get placed and the way they operate with electrodes. If you take the perspective of the TFT display, its pixels function perpendicularly once the pixels get activated with the help of the electrodes. It does help in creating sharp images.

But the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

As you already know the features of both TFT and IPS displays, it would be easier for you to understand the difference between the two screen-types. Now, let’s divide the matters into three sections and try to understand the basic differences so that you understand the two technologies in a compressive way. So, here are the difference between an IPS display and a TFT display;

Now, before starting the comparison, it is quite fair to say that both IPS and TFT displays have a wonderful and clear color display. You just cannot say that any of these two displays lag significantly when it comes to color clarity.

However, when it comes to choosing the better display on the parameter of clarity of color, then it has to be the IPS display. The reason why IPS displays tend to have better clarity of color than TFT displays is a better crystal oriental arrangement which is an important part.

That is why when you compare the IPS LCD with TFT LCD for the clarity of color, IPS LCD will get the nod because of the better and advanced technology and structure.

IPS displays have a wider aspect ratio because of the wide-set configuration. That is why it will give you a better wide-angle view when it comes to comparison between IPS and TFT displays. After a certain angle, with a TFT display, the colors will start to get a bit distorted.

But, this distortion of color is very much limited in an IPS display and you may see it very seldom after a much wider angle than the TFT displays. That is why for wide-angle viewing, TFT displays will be more preferable.

When you are comparing TFT LCD vs. IPS, energy consumption also becomes an important part of that comparison. Now, IPS technology is a much advanced technology than TFT technology. So, it is quite obvious that IPS takes a bit more energy to function than TFT.

Also, when you are using an IPS monitor, the screen will be much larger. So, as there is a need for much more energy for the IPS display to function, the battery of the device will drain faster. Furthermore, IPS panels cost way more than TFT display panels.

1. The best thing about TFT technology is it uses much less energy to function when it is used from a bigger screen. It ensures that the cost of electricity is reduced which is a wonderful plus point.

2. When it comes to visibility, the TFT technology enhances your experience wonderfully. It creates sharp images that will have no problems for older and tired eyes.

1. One of the major problems of TFT technology is that it fails to create a wider angle of view. As a result, after a certain angle, the images in a TFT screen will distort marring the overall experience of the user.

Although IPS screen technology is very good, it is still a technology based on TFT, the essence of the TFT screen. Whatever the strength of the IPS, it is a TFT-based derivative.

Finally, as you now have a proper understanding of the TFT displays vs IPS displays, it is now easier for you when it comes to choose one for your organization. Technology is advancing at a rapid pace. You should not be surprised if you see more advanced display screens in the near future. However, so far, TFT vs IPS are the two technologies that are marching ahead when it comes to making display screens.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The LCD module is very suitable for industrial control equipment, medical instru

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey