4th dimensional innovations tft display manufacturer

Leveraging 50 years of presence in avionic cockpit lighting we provide the ultimate display solutions. Cevians has rapidly become the fastest-growing privately owned company offering fully customized TFT-LCDs. Our highly vertically integrated technological foundation, from material science, thin-film coatings, optical designs, electronics and electro-mechanical designs to system engineering, makes Cevians’ capabilities and product offerings truly unique and the natural partner for Tier 1 OEMs.

Understanding the diverse industry ecosystem, we offer the level of product that integrates perfectly in each customer’s base model, from supplying custom TFT-LCD to LCD modules, display head assemblies (DHA), and fully ruggedized display systems. This flexible strategy allows our customers to efficiently use their resources for core competencies.

Displays with curvature not only look special, but also offer clear advantages for some applications. Compared to conventional displays, curved displays offer a slightly spatial and thus more immersive image impression. Our symmetrically curved display (C-type) with a curvature radius of 1500R generates a completely new picture experience. Immerse yourself!Landscape format ideal for immersive HMI and digital signage systems

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

Get started quickly on your new user interface with our HMI development kits. The display, the processor and the OS work together out of the box with optimised QT GUI images. We"ll then optimise the kit to meet exactly your system requirements with our design services.

At Anders we understand that no two customers are the same, which is why we specialise in custom display solutionsand offer unique productstailored to your end application.

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

We aim to offer reliable and long-term solutions to our B2B customers. If you are a business and would like to discuss your display and/or embedded system requirements please contact us below

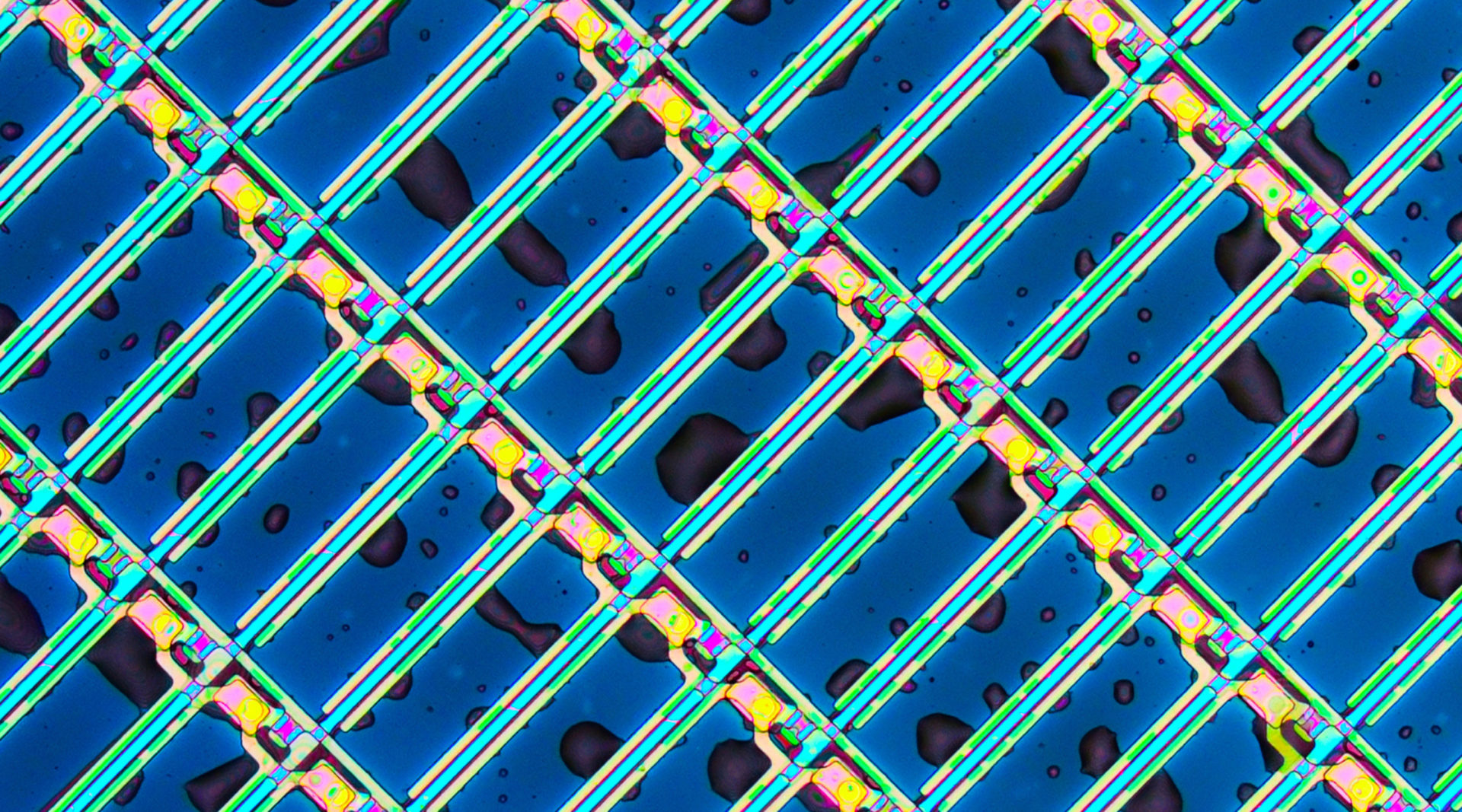

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

Superior materials and modern technology are adopted for tft panel. The raw materials vary with items. The first step in a procedure is frequently the most essential. Therefore, manufacturers in this industry pay great attention to raw materials and never spare raw materials. Changes in the quality of the raw materials used in production often result in changes in the quality of the final product.

Interaction with the pillar-to-pillar display is supported by an integrated control display, that appears, as if by magic, only when it is needed. This unique display solution prevents unnecessary information from distracting the driver. The panel can also be used to conveniently control areas that are out of arm’s reach for the user. The haptic feedback of the panel makes it possible to operate the pillar-to-pillar display without having to take your eyes off the road. Covered by a semi-transparent surface the invisible display is integrated seamlessly into the interior design surface, both visually and haptically. When the display is not needed, it is invisible. It does not appear as an empty black space, instead it merges with the decorative surface to form a single unit, in a wood, carbon or any other premium look and feel. In addition, a special matrix backlight is used. This lighting technology allows content to be displayed in the required brightness and with the highest possible contrast in any lighting situation, without a visible background (also known as the “postcard effect”).

“The combination of our In2visible Technology with the Curved Ultrawide Display is unique because it solves the problem of how to keep the growing screens in the cockpit operable. Pillar-to-pillar displays in particular present a challenge of finding operating solutions that allow the driver and front passenger to reach the entire screen. The seamlessly integrated control panel, within the driver’s reach, solves this problem in the most elegant manner while also granting the request of many drivers to operate the display via touch control,” said Kai Hohmann, product manager Display Solutions at Continental.

WINSTAR Display as a TFT LCD Display manufacturer has devoted itself to develop innovative TFT-LCD display new series including Winstar Q Series and P Series. Winstar Display TFT Q Series Family (TFT Panels with SSD1963 TFT LCD Controller Board) is featuring an important key element of having an integrated 36-pinout connecter on the SSD1963 controller board. The Q Series TFT modules are derivative products from Winstar standard TFT modules which unified the pin assignment into 36 pins on board. The TFT Q Series is optional in 8 bit or 16 bit and already defined pin no. 33 ~ 36 as backlight supply; therefore, the customers no need to design extra backlight circuit. Winstar Q series is support with Solomon SSD1963 Which has the traditional inputs and drive TFT by VESA signal. The customers don’t need to design T-COM circuit on board. Winstar have integrated all functions including TFT connection, backlight driver, and touch panel (capacitive touch screen / resistive touch screen) into one controller board.

The modules of Winstar TFT P Series (TFT Panels with RA8875 Controller Board) are similar to TFT Q series which are also featured with an integrated 36-pinout connector on board. The P Series TFT modules are derivative products from the Winstar standard TFT modules which unified the pin assignment into 36 pins on a RA8875 controller board. The P Series is support with 8 bit or 16 bit options and also already defined pin no. 33 ~ 36 as backlight supply; therefore, the customers no need to design extra backlight circuit. Winstar TFT P series supports many import function including Chinese character display, backlight brightness adjustment, Flash Memory and touch panel driver, etc.

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

Industrial LCD manufacturer KOE (Kaohsiung Opto-Electronics) have announced the introduction of a new high performance 5.7” TFT display module. The TX14D203VM0BAA display features VGA resolution (640x480px), a 4:3 aspect ratio, and the latest IPS (in-plane switching) technology which delivers exceptional optical performance.

Additionally, the new 5.7” TFT display module also provides a fully compatible, performance upgrade for the existing KOE 5.7” VGA TX14D23VM5BAA display.

The new KOE TX14D203VM0BAA provides the ideal display solution for use in process control systems, industrial HMI and medical monitoring equipment. Featuring the latest IPS display technology, the 5.7” display delivers excellent colour saturation and image stability, high contrast and highly saturated black levels. Exceptional all-round viewing angles of up to 170° are enabled (left/right, up/down).

The 5.7-inch display module provides exceptional optical performance, with a contrast ratio of 1000:1 and a white LED backlight with a specified brightness rating of 800cd/m². These key features ensure that display images are bright, concise and exhibit high accurately colour reproduction.

Benson Huang, Marketing Manager, KOE said: "The 5.7-inch VGA TFT display is a very popular display format and is widely used across the electronics industry. The development and introduction of a further medium-sized display module demonstrates and maintains KOE"s commitment to supporting the industrial market with a product line-up of premium, high quality display modules that are suitable for a wide range of diverse applications.”

The 5.7” module has mechanical outline dimensions of 131.0x102.2x7.6mm and an active display area of 115.2x86.4mm. A storage and operating temperature range of -30 to +80°C is supported.

The TX14D203VM0BAA display module provides a direct, plug-in enhancement for the existing KOE 5.7” VGA TX14D23VM5BAA TFT display. Both display modules feature the same mechanical outline dimensions and an identical, fully compatible 40-pin CMOS data interface. 6-bit RGB colour data enables a colour palette up to 262K colours. KOE will also shortly be introducing a LVDS interface version of the new 5.7” VGA display.

With continuity of supply essential for many industrial equipment and systems, KOE is fully committed to developing and manufacturing premium, high quality display modules, and ensuring long-term product availability.

KOE"s new TX14D203VM0BAA can now be sourced and supplied for a minimum period of five years. The KOE 5.7” TX14D203VM0BAA TFT display module is available from KOE"s worldwide sales channel and distribution partners.

• (2.4", 2.8", 3.2", 3.5", 4.3", 5.0", 7.0")• TFT 65K RGB Resistive Touchscreen• Onboard Processor and Memory• Simple ASCII Text Based Instruction Set• The Cost-effective HMI Solution with Decreased

Nextion is a Human Machine Interface (HMI) solution combining an onboard processor and memory touch display with Nextion Editor software for HMI GUI project development.

Using the Nextion Editor software, you can quickly develop the HMI GUI by drag-and-drop components (graphics, text, button, slider, etc.) and ASCII text-based instructions for coding how components interact on the display side.

Nextion HMI display connects to peripheral MCU via TTL Serial (5V, TX, RX, GND) to provide event notifications that peripheral MCU can act on, the peripheral MCU can easily update progress, and status back to Nextion display utilizing simple ASCII text-based instructions.

Nextion is available in various TFT LCD touchscreen sizes including 2.4”, 2.8”, 3.2”, 3.5”, 4.3”, 5.0”, 7.0”, 10.1” . With a large selection to choose from, one will likely fit your needs. Go Nextion Series and Product Datasheets.

Easy-to-use components, touch event programming and customized GUI at screen side allow you to develop projects rapidly in cost-effective way. The TTL serial Nextion display is the best balance HMI solution between cost and benefit with low and decreased learning curve. See Nextion Editor Guide and Instruction Set.

Display as a TFT LCD Display manufacturer has devoted itself to develop innovative TFT-LCD display new series including Winstar Q Series and P Series. Display TFT Q Series Family (TFT Panels with SSD1963 TFT LCD Controller Board) is featuring an important key element of having an integrated 36-pinout connecter on the SSD1963 controller board. The Q Series TFT modules are derivative products from standard TFT modules which unified the pin assignment into 36 pins on board. The TFT Q Series is optional in 8 bit or 16 bit and already defined pin no. 33 ~ 36 as backlight supply; therefore, the customers no need to design extra backlight circuit. Q series is support with Solomon SSD1963 Which has the traditional inputs and drive TFT by VESA signal. The customers don’t need to design T-COM circuit on board. Products have integrated all functions including TFT connection, backlight driver, and touch panel (capacitive touch screen / resistive touch screen) into one controller board.

The 10.1” WXGA (TCG101WXLP) TFT-LCD display features 1280 x 800 resolution, with a brightness of 500cd/m2 and a 800:1 contrast ratio. Viewing angle is 80-degree in all directions: left, right, top and bottom. Powered with high-efficiency LED backlights the total power consumption is only 4.46W.

The 12.1” WXGA (TCG121WXLP) TFT-LCD display features 1280 x 800 resolution, a brightness of 500cd/m2 and a contrast ratio of 750:1. Powered with Kyocera’s Advanced Wide View (AWV) technology, providing a wide, 85-degree viewing angle in all directions: left, right, top and bottom with no colour inversion.

No additional components are required to drive the backlights as Kyocera’s LED driver circuit is integrated into both the 10.1” and 12.1” LCD modules. The new TFT-LCDs are designed with a standard LVDS interface and offer a wide operating temperature range of -20º to 70º C.

“Kyocera brings almost 40 years of experience in LCD technology innovation, helping to make the company a preferred supplier of displays for industrial applications as well as automotive and medical equipment,” said Eberhard Schill Sales Manager Distribution & Marketing at Kyocera Display Europe GmbH. “We continue our commitment to developing environmentally friendly products.”

Tianma P-series (Professional series) TFT displays have been designed and developed to deliver exceptional optical performance and meet the demanding requirements of the industrial and medical display markets and applications where reliable and consistent operation is considered essential.

The 12.1-inch display module exhibits exceptional optical performance with a contrast ratio of 1000:1 and a high brightness, long-life LED backlight providing a brightness specification of 1100cd/m² which creates display images that are bright, colourful, and concise.

SFT (Super Fine TFT) technology is Tianma’s implementation of IPS (in-plane switching) technology, where optical performance, colour saturation and image stability are significantly improved over standard TFT display technology – where brightness and colour will change with respect to viewing angle. Viewing angles of 88 degrees in all directions (up/down, left/right) can be achieved with SFT.

Justin Coleman, displays division manager, RDS said: “P-series display modules from Tianma have been designed and developed for use in a wide range of human-machine interface (HMI) applications where guaranteed, long-term operation in challenging application environments is a necessity. Offering a technical specification that provides excellent optical performance, the Tianma 12.1-inch P-series display delivers bright, saturated colour display images that can be easily observed from all viewing directions.”

The new 12.1-inch TFT display module is suitable for use in a wide range of industries including construction, agriculture, medical, factory automation, manufacturing, and in-vehicle systems.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

Universal Display Corporation is a developer and manufacturer of organic light emitting diodes (OLED) technologies and materials as well as provider of services to the display and lighting industries. It is also an OLED research company. Founded in 1994, the company currently owns or has exclusive, co-exclusive or sole license rights with respect to more than 3,000 issued and pending patents worldwide for the commercialization of phosphorescent based OLEDs and also flexible, transparent and stacked OLEDs - for both display and lighting applications. Its phosphorescent OLED technologies and materials are licensed and supplied to companies such as Samsung, LG, AU Optronics CMEL, Pioneer, Panasonic Idemitsu OLED lighting and Konica Minolta.

UDC is working with many other companies, including Sony, DuPont and Novaled. Back in 2009 UDC claimed that "virtually all AMOLEDs on the market use our technology". Based in Ewing, New Jersey, with international offices in Ireland, South Korea, Hong Kong, Japan and Taiwan, Universal Display works with a network of organizations, including Princeton University, the University of Southern California, the University of Michigan, and PPG Industries.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing,plasma displays. However, fabrication of the OLED substrate is more costly than that of a TFT LCD, until mass production methods lower cost through scalability. Roll-to-roll vapour-deposition methods for organic devices do allow mass production of thousands of devices per minute for minimal cost, although this technique also induces problems in that devices with multiple layers can be challenging to make because of registration, lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. As the substrate used can be flexible such as polyethylene terephthalate (PET),

OLEDs also can have a faster response time than standard LCD screens. Whereas LCD displays are capable of between 1 and 16 ms response time offering a refresh rate of 60 to 480 Hz, an OLED theoretically can have a response time less than 0.01 ms, enabling a refresh rate up to 100,000 Hz . OLEDs also can be run as a flicker display, similar to a CRT, in order to eliminate the sample-and-hold effect that creates motion blur on OLEDs.

While an OLED will consume around 40% of the power of an LCD displaying an image that is primarily black, for the majority of images it will consume 60–80% of the power of an LCD. However, an OLED can use more than three times as much power to display an image with a white background, such as a document or web site.

According to OLED Display "Samsung Display uses different Sub Pixel Matrix technologies for their smartphone Super-Amoled Displays. For the Galaxy S4 and S5 they use the Diamond Pixel Matrix."

Universal Display"s OLED screens currently feature in Samsung"s Galaxy S, S II and S III, S IV and S V smartphones. The Galaxy S3 sold 10 million units in the first three months after its launch in April 2012. Also, their Galaxy Note has sold 10 million units since launch.

Universal Display reported that Samsung Display Corporation (SDC) adopted UDC"s green PHOLED (host and emitter) in the 5" Full-HD Super AMOLED display used in the GS4 smartphone. This is a significant development as the green PHOLED increases energy efficiency of displays by up to 25%

In October 2013, Samsung released the first ever curved display smartphone called the Galaxy-Round. Samsung also introduced the "Roll Effect" where when the phone"s screen is off and is rolled, it displays basic information like time or battery percentage.

Cnet also reviewed the Galaxy Note 3 and had this to say about the AMOLED screen:"Trust me when I say that the Samsung Galaxy Note 3"s screen is simply gorgeous. Measuring a vast 5.7 inches across, the AMOLED display has an ultracrisp full HD resolution (1,920x1,080 pixels) which translates into an amazingly sharp 385ppi. That"s a level of detail that puts the smaller screens of the iPhone 5S (4-inch, 326ppi) and Samsung"s own Galaxy S4 (5-inch, 441ppi) to shame."

On September 3, 2014, at IFA Berlin, Samsung unveiled a successor to the Galaxy Note 3, the Galaxy Note 4. The new model introduced a new design with a plastic leather backing and metal frame, a 5.7-inch (145 mm) QHD display, a 16MP camera with OIS, improved S-Pen, an upgraded digitizer with 2,048 levels of pressure sensitivity and expanded functionality, fingerprint scanner, and other features taken from the Galaxy S5.

Samsung and LG-Display showed 55-inch OLED-Television devices at CES-2012. But both companies had to delay their mass production. Also AUO, Sony and Epson will start AMOLED-TV production in 2014.

With the arrival of Quantum Dot LCD displays, LG released an article describing why they still see OLED as the future of Television displays: "In fact, OLED technology is the technology that is so much advanced that it should not be compared to an LCD based QD. Hence, even though LG already has the technology to create QD backlighting, it is focusing on developing OLED".

In January 2015, LG Display signed a long-term agreement with UDC for the supply of OLED materials and the right to use their patented OLED emitters. LG is the leader in the push for OLED Televisions.

The Korea Times claims that Google"s next gen Google Glass HMD (or "wearable computer") will use OLED microdisplays made by Samsung Display, with licensed technology from Universal Display.

OLEDs enable screens to be made in curved or flexible format. Samsung"s flexible AMOLEDs will be fabricated on a plastic (Polyimide) substrate and will be able to withstand high temperature (up to 350-400 degrees). The displays can be bendable - but since the first products will use them inside rigid glass cases - so it"ll actually be "curved" displays and not flexible ones. A plastic based AMOLED will be shatterproof, and will also be lighter and thinner compared to glass based OLEDs.

OLED Info reports that for flexible displays on plastic, UDC"s UniversalBarrier single-layer encapsulation technology is being evaluated by Samsung. UDC has a working 6" R&D deposition machine for the encapsulation layer.Corning Glass have developed a flexible glass to help speed up the adoption of bendable OLED screens. "On Aug. 28 2013, Corning and AU Optronics announced that Corning is an important and strategic highperformance display glass collaborator for AUO’s line of AMOLED panels. AUO selected the Corning Lotus Glass platform based on the glass substrate’s outstanding thermal and dimensional stability. This aids AUO with efficient manufacturing during the high-temperature processes that are required to develop its AMOLED panels." Corning is also developing a Roll to Roll manufacturing process that will greatly reduce costs of mass-producing flexible displays.

UBI Research published a new report on flexible OLED displays, forecasting a very fast growth: from 20 million units in 2012 to 150 million units in 2013. UBI sees $6.3 billion in flexible OLED revenues in 2017. This is far more optimistic than the recent report by Markets&Markets who see the entire flexible display market at $3.2 billion in 2017.

The Flexible Display Center announced that it has successfully manufactured the world"s largest flexible color AMOLED prototype using advanced mixed oxide thin film transistors (TFTs). Measuring 7.4 diagonal inches, the device was developed at the FDC in conjunction with Army Research Labs scientists. It also meets a critical target set by the U.S. Department of Defense to advance the development of full-color, full-motion video flexible OLED displays for use in thin, lightweight, bendable and highly rugged devices.

"This is a significant manufacturing breakthrough for flexible display technology," said Nick Colaneri, director of the FDC. "It provides a realistic path forward for the production of high performance, flexible, full color OLED displays, accelerating commercialization of the technology in the process."

Universal Display"s Sid Rosenblatt talking about the future of OLED technology was quoted as saying: "Samsung is going to introduce flexible screens, but the flexible plastic substrates are difficult to manufacture. Plastic is porous and oxygen with moisture causes OLEDs to degrade. [However]...These kind of displays are unbreakable, flexible on stainless steel foil. It would result in a thinner device because you don’t have the pieces of glass. It could conform around the sides, so you can show information on the sides. It would be lighter. So you can either make it smaller or thinner or you can make a larger battery so that it lasts longer. The challenges are encapsulation, so you need an encapsulation process. The temperature is too high to deposit them directly to the plastic, so they do is they literally deposit them on glass." Further SID Rosenblatt thinks that flexible OLEDs will be initially a niche market for the high end.

iSuppli, a market research firm, sees the flexible OLED display market growing significantly from 2013 to 2020. Their estimates are from a market value of $21 million in 2013 to $100 million in 2014 and reaching $12 billion by 2020. IHS says this will bring about "unprecedented change(s) in flat displays".LG and Samsung believe that flexible displays will make up as much as 40% of the Smartphone maker by 2018.

At the Flextech Conference in Phoenix, Arizona, Plastic Logic and Novaled demonstrated a new, really bendable, and completely organic AMOLED display. OLED News said: "This is a very important technological advance. For the first time we have an entirely plastic AMOLED with backplane electronics manufactured in a special low temperature process. The industrial techniques applied open up real prospects of mass producing these displays at a very competitive unit cost." Plastic Logic CEO, Indro Mukerjee, spoke of 2014 as the year when wearable technology is going to really take off. He described the advance that has been made in the following: "Flexible electronics is a reality, already proven through the development and manufacture of plastic, bendable displays and sensors. For the first time a fully organic, plastic, flexible AMOLED demonstration has been achieved with a real industrial fabrication process. This marks the start of a revolution in wearable products, the next frontier in consumer."

Apple began using OLED panels in its watches in 2015 and in its laptops in 2016 with the introduction of an OLED touchbar to the MacBook Pro.iPhone X with their own optimized OLED display licensed from Universal Display Corporation.All subsequent iPhones have had OLED displays.

According to OLED-Display.net "OLED technology has been found useful in creating new forms of lighting. Because of the potential inherent with OLED technology in terms of its flexibility, transparency and thickness, a myriad of new possibilities exist for OLED illumination, lighting and light display shows. The potential is almost infinite, because OLED technology has proven to show lifetimes over 50,000 hours and because it burns at rates that surpass the efficiency of halogen and can reach up to 150 lm/W. In addition, OLED lighting utilizes less CO2, requires less energy and contains no toxic substances. This opens up a revolutionary concept of lighting displays and light based art conceptions."

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey