rs lcd displays free sample

How many times did you start to plan a project and thought to yourself “if only I had a display that can fit within this design”? How many times did you alter the whole design because there were no displays available on the market that went with your idea?

What flavor of serial do you need? Crystalfontz has just about every type of serial character lcds you could ever want. All of the character lcd solutions on this page are capable of communicating using the RS232 protocol. Many of our intelligent character lcds can support multiple protocols/interfaces depending on their configuration. Contact our phenomenal support if you need more information about our RS232 character lcds. We"re here to help!

Do you need a serial LCD display? Our graphic serial LCDs and serial character LCD modules can connect and communicate with almost any host system (microcontrollers, microprocessors, PCs, etc.) and make it easier than ever to include an LCD in your product design.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

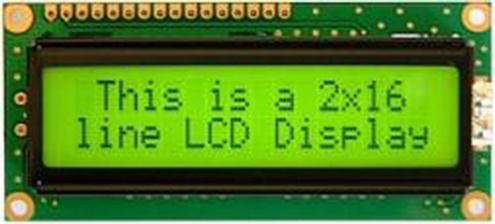

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

Liquid Crystal displays or LCDs have been used in electronics equipment since the late 1970s. LCD displays have the advantage of consuming very little current And they are ideal for your Arduino projects.

In this article and in the accompanying video I’ll show you how easy it is to add an LCD display to your next Arduino design. I’ll also show you a very popular Arduino Shield that has a keypad which you can use in your projects as well.

Today LCD displays are used in a variety of items from test equipment to televisions. They’re inexpensive and versatile, this makes them ideal for all sorts of designs.

LCD displays do not emit light. Instead they block the passage of light, like little windows which open and shut the let light through. The liquid crystals used inside LCD displays are sandwiched between two layers of polarized material. By changing the orientation of the liquid crystals they allow light to pass or they block the light entirely.

Because transmissive LCD displays (the type we will be using) work by blocking light they require a backlight. Several methods have been used to create back lights including electroluminescent panels and fluorescent tubes. these days the most common form of backlight is an LED, in fact so-called LED televisions are usually just LCD screens with an LED backlight system.

Another type of LCD display, the passive-matrix display, does not require a backlight, it works using reflected light. This type of display is often found in digital watches.

The principles of liquid crystals were discovered in the late 1880s but work on Modern LCD displays did not begin until the mid-1960s. a number of patents were filed in the early 1970s and in 1973 the Sharp Corporation introduced LCD displays for calculators.

The first color LCD displays were developed in the early 1980s but production units were not commonly available until the mid-1990s. By the late 1990s LCD displays were quite common.

A number of LCD displays are available for experimenters. These low-cost monochrome displays are ideal for use with microcontrollers like the Arduino and micro computers like the Raspberry Pi.

These displays are available in a number of different configurations. The part number for the display generally relates to the number of rows and columns in the display.

Common display configurations include 16 x 2, 16 x 4 and 20 x 4. All of these displays are used in a virtually identical fashion the only difference being the number of columns and rows they have.

The LCD1602 display module is a very popular and inexpensive LCD display. It is available in a number of different colors such as blue yellow and green and can easily be connected to an Arduino or Raspberry Pi.

In operation data is sent down the parallel data lines for the display. There are two types of data that can be sent to the display. The first type of data are the ASCII characters which are to be displayed on the display. The other type of data are the control characters that are used to activate the various display functions.

Because the LCD module uses a parallel data input it requires 8 connections to the host microcontroller for the data alone. Add that to the other control pins and it consumes a lot of connections. On an Arduino Uno half of the I/O pins would be taken up by the display, which can be problematic if you want to use the I/O pins for other input or output devices.

We will begin our experiments by hooking up the LCD1602 to an Arduino Uno and running a few of the example sketches included with the Arduino IDE. This will allow you to get familiar with the display without needing to write any code.

We need to hookup our LCD display to our Arduino. The display can use any of the Arduino digital I/O pins as it has no special requirements, but if you hook it up as I’ve illustrated here you can run the example sketches without needing to make any modifications.

In addition to the LCD1602 display ands the Arduino Uno you will need a 10K trimpot ot potentiometer, this is used a s a brightness control for the display. You’ll also need a 220 ohm resistor to drop the voltage for the displays LED backlight.

The sketch starts with a number of credits and a description of the required hardware hookup. You’ll note that this is the same hookup you just performed on your Arduino and LCD module.

We then initialize an object that we call “lcd” using the pinouts of the LCD display. If you decide to hook up your display to different pins then you’ll need to modify this section.

In the beginning of the loop we set our cursor to the first position in the second row. Note that the row numbers start with zero so the second row is row 1.

The second example we will try isthe Scroll sketch. Scrolling is a useful technique when you can’t get your text to fit on one line of the LCD display.

Custom characters are useful when you want to display a character that is not part of the standard 127-character ASCII character set. Thi scan be useful for creating custom displays for your project.

A character on the display is formed in a 5 x 8 matrix of blocks so you need to define your custom character within that matrix. To define the character you’ll use thecreateCharfunctionof the LiquidCrystal library. You are limited to defining a maximum of eight characters.

To usecreateCharyou first set up an array of bytes with 8 elements. Each element in the array defines one row of the character in the 5 x 8 matrix. You then use createCharto assign a number from 0 to 7 to that array.

As with the previous sketches we examined this one starts by loading theLiquidCrystallibrary and defining an object calledlcdwith the connection information for the display. It then moves on to define the custom characters.

The last two arrays,amsUpandarmsDowndefine the shape of a little “stickman”, or “stickperson” if you want to be politically correct! This is done to show how we can animate a character on the display.

Then the five custom characters are assigned a unique integer using the createChar function. Remember, you can define a maximum of eight custom characters in a sketch.

Finally the setup routine ends by printing a line to the first row of the LCD display. The line makes use of two of the custom characters, the “heart” and the “smiley”.

One thing you may have noticed about using the LCD display module with the Arduino is that it consumes a lot of connections. Even in 4-wire mode there are still a total of seven connections made to the Arduino digital I/O pins. As an Arduino Uno has only 14 digital I/O pins that’s half of them used up for the display.

But there is another solution. Use the I2C bus adapter for the LCD display and connect using I2C. This only consumes two I/O pins and they aren’t even part of the set of digital I/O pins.

The I2C or IIC bus is theInter Integrated Circuitbus. It was developed by Philips Semiconductors in 1982 for use in the television industry. The idea was to allow the integrated circuits in televisions to “talk” to one another using a standard bus.

The bus has evolved to be used as an ideal method of communicating between microcontrollers, integrated circuits, sensors and micro computers. You can use it to allow multiple Arduinos to talk to each other, to interface numerous sensors and output devices or to facilitate communications between a Raspberry Pi and one or more Arduinos.

The I2C Adapter for the LCD display is a tiny circuit board with 16 male header pins soldered to it. These pins are meant to be connected directly to the 16-pin connection on the LCD1602 display (or onto other displays that use the same connection scheme).

The device also has a 4-pin connector for connection to the I2C bus. In addition there is a small trimpot on the board, this is the LCD display brightness control.

Most of these devices have three jumpers or solder pads to set the I2C address. This may need to be changed if you are using multiple devices on the same I2C bus or if the device conflicts with another I2C device.

Most Arduino Unos also have some dedicated pins for I2C, these are internally connected to A4 and A5 and are usually located above the 14 digital I/O pins. Some models of the Uno have additional I2C connectors as well.

Not all I2C adapters have the same I2C address, Most have address 0x20 but some use address 0x27 or 0x3F. You can change the address of your adapter by shorting some of the solder pads on the board.

Load this sketch into your Arduino then open your serial monitor. You’ll see the I2C address of your I2C LCD display adapter. You can then make note of this address and use it in the sketches we’ll be looking at now.

In order to run the subsequent sketches you’ll need to install another library. This is theNewLiquidCrystallibrarywhich, as its name implies, is an improved version of the LiquidCrystal library packaged with your Arduino IDE.

This library includes libraries for running the I2C adapter, which is why we are going to use it. But ist also can be used as a replacement for the original LiquidCrystal library and it offers improved performance over the original.

Remember that you’ll need to know the address of your I2C adapter before you run this sketch, so if you don’t know it go back and run Nick Gammon’s I2C Scanner first.

On the next line we define the connections to the LCD display module from the I2C Adapter,. Note that these are NOT the connections from the Arduino, they are the connections used by the chip on the adapter itself.

In setup we set the size of the display and then print “Hello world!” on the first line in the first position. After a short delay we print “How are you?” on the second line.

The first demo flashes the backlight on and off four times by alternating the use of thebacklightandnobacklightfunctions. When we are done we turn the backlight on again.

The next demo uses theautoscrollfunction to scroll some text. We first print the text “Scroll demo – “ and then implement a counter to count from 0 to 9 while scrolling the text.

The sketch is similar to our demo sketch in that it creates an “lcd” object with the I2C and display connection information. It also defines a couple of parameters for the DHT22 sensor, as well as some floating variables to hold the temperature and humidity values.

Note that this displays the temperature in Celsius. If you want to change this to Fahrenheit its a simple matter of using some math. The formula( temp * 1.8 ) + 32will convert the results to Fahrenheit.

So far we have used the LCD1602 display module for all of our experiments. For our final demonstration we’ll switch to a popular Arduino shield that contains a LCD1602 along with some push buttons.

The LCD Keypad Shield is available from several different manufacturers. The device fits onto an Arduino Uno or an Arduino Mega and simplifies adding an LCD display to your project.

Pressing each button will send a voltage to the analog A0 pin. Because of the arrangement of the resistors each button will send a different voltage to the analog pin. By measuring the voltage level you can determine which button was pressed.

Note that the LCD is being used in 4-wire mode. The LCD itself is the same one used on the LCD1602 module, so all of the code for that module will work with the LCD Keypad Shield as well.

Now that you know how the LCD Keypad module works and which Arduino pins it uses all that remains is to install it onto your Arduino and load the demo sketch.

One thing – once the shield is installed on the Arduino you won’t have easy access to the unused I/O pins to connect any sensors or output devices you may want to use (although the demo sketch doesn’t need anything else connected). There are a couple of ways to get around this:

Use a shield that exposes the pins for prototyping before you install the LCD Keypad shield. In the video associated with this article I use a “Screw Shield” that brings all of the Arduino I/O pins out to a series of screw connectors. There are other similar shields. Using one of these shields is the easiest way to work with the LCD Keypad shield, as well as other Arduino shields.

The sketch begins by including theLiquidCrystallibrary. You can use the original one or the one includes with theNewLiquidCrystallibrary. We then set up an object with the LCD connections, note that these are just hard-coded as they won’t change.

We then define two variables. The first one holds the value of the selected pushbutton, the second holds the analog reading from port A0 where the push button input is detected.

After that we define a function calledread_LCD_buttons(). This function reads the value on analog port A0 and returns an integer corresponding to the button integers we defined earlier. Note that the function adds approximately 50 to each of the manufacturers specified values to account for intolerances in the resistors in the voltage divider.

We start the loop by placing the cursor 9 spaces over on the second line. We then use themillisfunction to display a counter that counts the time since the Arduino was reset. This is to test the Reset button.

We then call ourread_LCD_buttons()function and use it to display the value of the push button, right before the counter. Then we end the loop and do it again.

As you can see LCD displays are pretty simple to use thanks to the availability of some excellent libraries for the Arduino. As these displays are also very inexpensive they will make an ideal addition to many of your Arduino projects.

And finally the LCD Keypad Shield is a convenient method of adding both a display and a simple keypad to your project, no wiring or soldering required.

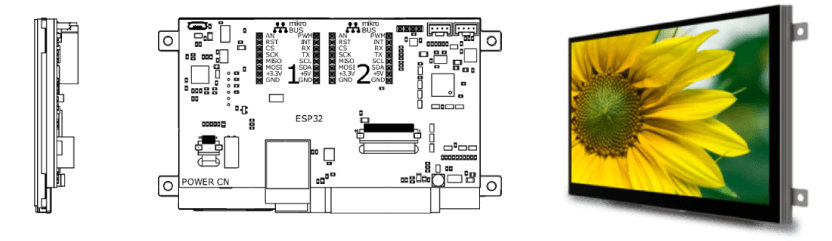

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

The speed of playing all the GIF files are edited and we made them faster or slower for better understanding. The speed of motions depends on the speed of your processor or type of code or size and thickness of elements in the code.

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

If we take a closer look at the display we can notice that there are small rectangular areas composed of 5×8 pixels grid. Each pixel can light up individually, and so we can generate characters within each grid.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

Next is the E pin which enables the writing to the registers, or the next 8 data pins from D0 to D7. So through this pins we are sending the 8 bits data when we are writing to the registers or for example if we want to see the latter uppercase A on the display we will send 0100 0001 to the registers according to the ASCII table. The last two pins A and K, or anode and cathode are for the LED back light.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

Here’s a simple code through which we can explain the working principle of the Liquid Crystal library. This is the code of the first example from the video:

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

In case we have a text with length greater than 16 characters, we can scroll the text using the scrollDisplayLeft() orscrollDisplayRight() function from the LiquidCrystal library.

We can choose whether the text will scroll left or right, using the scrollDisplayLeft() orscrollDisplayRight() functions. With the delay() function we can set the scrolling speed.

The first parameter in this function is a number between 0 and 7, or we have to reserve one of the 8 supported custom characters. The second parameter is the name of the array of bytes.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

The resistor in the diagram above sets the backlight brightness. A typical value is 220 Ohms, but other values will work too. Smaller resistors will make the backlight brighter.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

This function places the cursor in the upper left hand corner of the screen, and prints any subsequent text from that position. For example, this code replaces the first three letters of “hello world!” with X’s:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

This function takes a string of text and scrolls it from right to left in increments of the character count of the string. For example, if you have a string of text that is 3 characters long, it will shift the text 3 spaces to the left with each step:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

Liquid Crystal Display(LCDs) provide a cost effective way to put a text output unit for a microcontroller. As we have seen in the previous tutorial, LEDs or 7 Segments do no have the flexibility to display informative messages.

This display has 2 lines and can display 16 characters on each line. Nonetheless, when it is interfaced with the micrcontroller, we can scroll the messages with software to display information which is more than 16 characters in length.

The LCD is a simple device to use but the internal details are complex. Most of the 16x2 LCDs use a Hitachi HD44780 or a compatible controller. Yes, a micrcontroller is present inside a Liquid crystal display as shown in figure 2.

Power & contrast:Apart from that the LCD should be powered with 5V between PIN 2(VCC) and PIN 1(gnd). PIN 3 is the contrast pin and is output of center terminal of potentiometer(voltage divider) which varies voltage between 0 to 5v to vary the contrast.

Liquid crystal displays (LCD) come in two main types that are of interest to hobby and DIY makers; Character LCD displays and pixel / graphic LCD displays. This intro “How To” will be covering the more popular and less expensive character LCD displays based on the very common Hitachi HD44780 controller.

LCD displays come in many sizes most often named by the number of rows and then the length of the display line. For example a 1x16 LCD display will have one row of sixteen characters and a 4x20 LCD display will have four rows with twenty characters in each.

LCDs can be have backlighting or be reflective (think calculator). In either case the programming that goes into working these displays is the same. LCDs with backlight normally use two pins to provide power to the backlighting.

2x16 character LCD with backlighting. Note, screen is all black, but to display characters the crystals move to allow the backlighting to show through.

Most LCDs that are being made now come with one row of sixteen pins. The first fourteen pins are used to control the display and the last two are for the backlighting (if the display has backlighting).

Older LCDs sometimes came with two rows of seven making a fourteen pin connector. These fourteen pins, most often, have the same signals on them that the 1x16 pin displays do. For example, pin #1 on the 2x7 connector is the same signal as pin #1 on the 1x16 connector, they are just arranged differently. If you have a 2x7 pin display but need to connect it to a 1x14 (1x16) backpack or device, the basic

LCDs based on the Hitachi HD44780 controller must be initialized after they are powered-up. The reason that the LCDs must be initialized is because there are a few critical options that the display must “know” before it can work or communicated properly.

The most import of which is wether to use an eight or four bit data interface. Hitachi and compatible LCDs can be set to use either 8 or 4 of the data pins to communicate with the host controller that is driving it. Using a four pin data bus lets you save on pins, but your controller must divide each instruction into two four bit segments and then send them one at a time to the display. So the trade off is less pins versus more programming and slower communication. (The reduced speed of having to send data twice has little effect on the display, but it does busy your processor for a longer amount of time.)

Ok, so you initialized your new 1x16 display and cleared it so that the cursor is at the first character position. Now you start sending your “Hello World” message to the screen.

When you send the LCD a character to display, you are not actually sending it to the screen part of the display, but rather a memory location that the display uses to know what to display on the screen. The problem here is that the memory location and the mapping to positions on the screen are not always sequential.

The “Hello World” example above is often what gives people trouble using a 1x16 LCD for the first time. Here the “r” “l” “d” went into memory address 0x88,0x89 and 0x8A which are not visible on this display !

Here is a short list of popular display sizes and the memory mapping that we have found in them. Note: not all displays will necessarily have the same mapping, even when they are the same size. Use this a “Quick Start” reference when working on your own.

When it is actually time to use an LCD you have a few choices of how to do it. You can connect it directly to your Arduino or micro-controller (MCU) and use a lot of pins and wires or your could use a backpack.

Using a backpack has a few advantages over connecting the LCD directly to your micro-processor. Besides using less wires, (and pins) some backpacks take over the entire job of driving the display. All your code has to do is send the text out of the appropriate interface, I2C, serial, SPI etc ... This can save your micro-controller a lot of memory, and processor time. And, it also lets you get your projects working sooner, since you do not have to code and debug software to drive the display on top of the rest of your project.

B. Backpacks that reduce the pin-out burden on your MCU. With this type of backpack, your MCU still initializes and drives the LCD, but through an interface with fewer wires.

Most displays work with the standard 128 ASCII characters. Often times, the displays are also able to display other characters, these include Asian characters and other special symbols and icons.

But, you can only send a single digit at a time to the display. So if you have the value of 139 to display, first it must be chopped into “1”, “3”, and “9” then you must add 48 to each before sending them to the display to convert the value into ASCII.

The Model 3030 Alpha-Beta Sample Counter incorporates an internally housed ZnS(Ag) plastic scintillator detector with shielded 5.1 cm (2 in.) diameter stainless steel sample tray into the Ludlum Model 3030 Scaler. This combined system supplies independent backlit LCD readouts to support discriminated alpha and beta sample counting. Key features include background subtraction, crosstalk correction, separate alpha/beta alarms, cpm/dpm operating modes, and a pre-scripted QC function with automatic reminder timer.

The instrument supports both 110 and 220 Vac operation, and includes a trickle charged gel-cell battery for portable offsite use for up to eight hours. A wide-range high voltage power supply supports virtually any detector. Status indicators located along the front panel inform the operator when a QC check is required, if the detector is non-functional, if it is operating in dpm or cpm mode, and if either an alpha or beta alarm setpoint has been exceeded.

The count time is selected via a front-panel rotary switch that enables count times ranging from 0.1 to 60 minutes, or some other prescribed value as set up via a link to a PC. Other controls include a start count button, audio volume rotary adjustment, and instrument on/off switch. An RS-232 output from the rear panel supports connection to either a printer or PC. Included in the price is PC-control software, which is a Windows application that supports setup of the system, as well as collecting and logging all count results from the 3030.

9-pin RS-232 port for connection to PC for data download and adjustment of setup parameters. A one meter RS-232 to USB adapter cable is included. PC interface software is available for download here.

Computer based software to perform setup and calibration routines including: background subtract, crosstalk correction, cpm/dpm modes, daily QC check parameters, alarm levels, and automatic plateaus.

All parameters are stored in the instrument in non-volatile memory. The supplied software is capable of logging and storing the following: Sample Number, Sample Date, Sample Time, Alpha Count, Beta Count, Sample Type, Comments.

PC interface software and the driver needed to use the RS-232 to USB adapter cable are available for download on the Software & Firmware Downloads page.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey