tft lcd display projects factory

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

In this Arduino project, a TFT display will be used, which is essentially another screen like an OLED or a common LCD display to show information, graphics or animations as well. Since you will just be getting introduced to this TFT display module which is made into a shield form to perfectly fit an Arduino Uno, the sketch which we will be using will display a simple demo program to show its quality, resolution and ability to show multiple colours as well. Additionally, this module has a resistive touch feature, where the whole screen can be used to play games or to work as an automation system control with interactive buttons. However, this is not a capacitive touch screen so it will defer in sensitivity when compared to your phone, as resistive touch screens rely on mechanical pressure as opposed to natural conduction from your body. For this project, here are the components which you will need:1 2.8" 240x320 TFT LCD Display Module with Resistive Touch

This project"s circuit is by far, the easiest to mount as this shield comes prepared to be fitted onto an Arduino Uno. Each pin on this shield should go into every pin on the Arduino perfectly and I recommend that you line it up carefully before applying pressure to press the display down into each of the pins. However, this LCD module also has a 6-pin ICSP (In-Circuit Serial Programmer) header which matches the male ICSP header pins on the Arduino, thus, ensuring that you match those pins up as well is critical to making sure that you mount this module correctly. Remember, don"t use too much force on the module as it may damage the pins or the display itself, so be careful! Then, once this module has been mounted on to your Arduino board, plug in your USB cable and you are now ready to go. For this project, you will not be importing files into the SD card, so taking out the SD card from this module is not necessary.

With DisplayModule"s DMTFTLibrary, the software part of this project is made 10x easier due to no manual coding needed for each function performed. DisplayModule has also already written the main part of the code, so that will save you some time if you need to use this code again. Firstly, the code starts by defining some libraries used: we declare the SPI (Serial Peripheral Interface) library for communication between the TFT and the Arduino, the DMTFTIli934 library, which is used to drive the TFT with an Arduino and the BubbleDemo library, which is basically the library which stores all the code for this program. Then, we define some pins which aid in the software communication to the TFT display. We mention the TFT chip select pin on pin 10, the SD chip select pin on pin 8, the flash chip select pin on pin 6 and the touch screen chip select pin on pin 4. After that, we now add in a line where we declare the TFT being used with the chip select pin on pin 10 and the data/command (DC) pin being on pin 9 and on the following line, we mention that the bubble demo program will be used, which will consume the whole TFT display"s length and width. Now, thevoid setupsection is present, where we set theTFT_CS,T_CS,SD_CSand theF_CSpins as output pins, so that data will be fed into the Arduino from the TFT display. Next, we declare the same set of pins high, meaning that they will be turned on, active and performing their individual function during this sketch. We then also initialise the display to start it up, which transitions us to thevoid loopsection, with one command only. This command is to basically run thebubbleDemoprogram for 750 loops with a delay time of 20 milliseconds. Now, the software part has been already done and your program should be up and running fine!

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

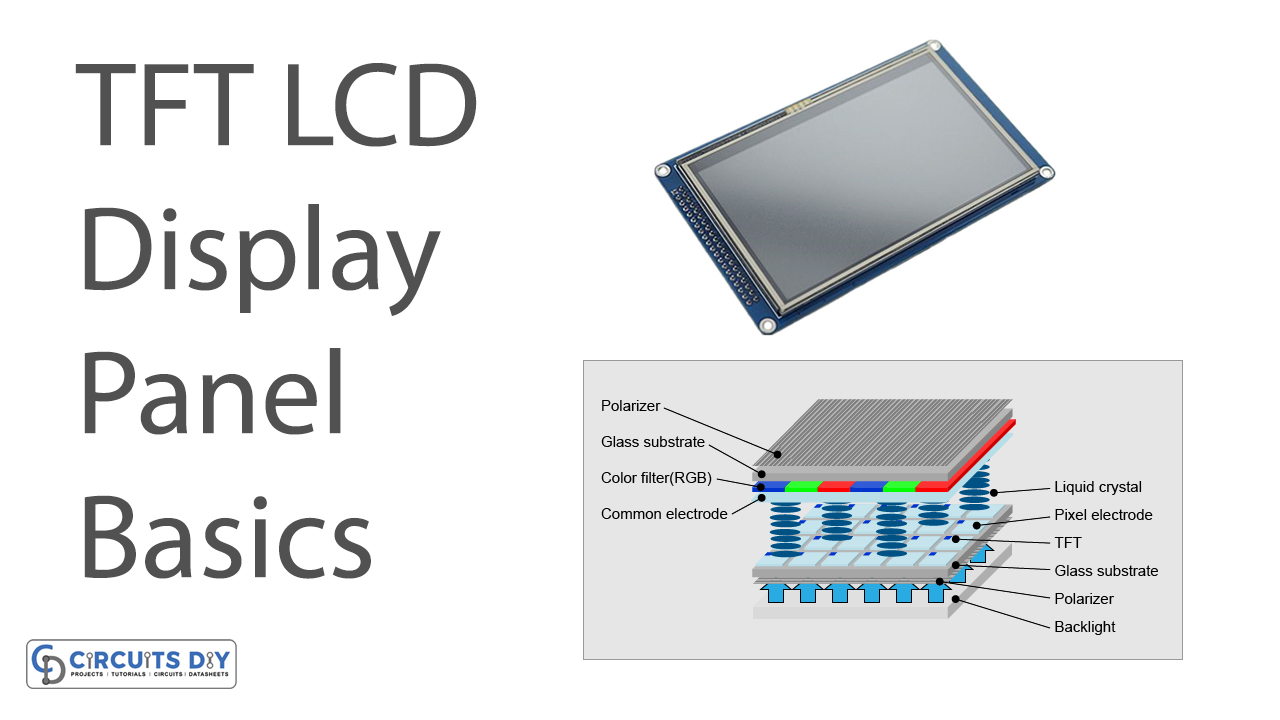

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

To interface TFT LCD Display with Arduino, for designing custom HMI TFT LCD Display provide rich colours, detailed images, and bright graphics with their full-colour RGB mode it comes in different pixels 128 x 160 pixels, 320×240 pixels and many more.

In this tutorial, we’ll interface the 1.8 TFT LCD display with Arduino Uno. You’ll learn how to interface the TFT LCD with Arduino to write text on this LCD. This tutorial presents the coding, wiring diagram and components list required for the LCD display.

Creating an interface between the user and the system is very important. This interface can be created by displaying useful data, and menus. There are several components to achieving this. LEDs, 7-segments, OLEDs, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, and the type of user interaction.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. In the case of Arduino, the processor frequency is low. So it is not possible to display complex and high-speed motions. Therefore, full-colour TFT LCDs can only be used to display simple data and commands. This TFT has 128 x 160 pixels. 1.8 TFT display can load images from an SD card. It has an SD card slot at the back. You can see the front and back views of the TFT LCD in the figures below.

TFT is an abbreviation of “Thin Film Transistor”. It has transistors made up of thin films of Amorphous silicon. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. The working principle is very simple the TFT LCD composes of many pixels that can emit light of any colour. The desired image achieves by controlling each pixel to display the corresponding colour. In TFT LCD, the backlight technology is generally used. In order to accurately control the colour and brightness of each pixel, it is necessary to install a shutter-like switch after each pixel. When the “blinds” are opened, light can pass through them. When the shutters are closed, light cannot pass through them.

This is the section before setup which uses for globe variables defining and libraries additions. TFT.h is the library for TFT LCD Display and uses for writing and drawing on the display. The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library.

This is the setup section in which Serial.begin(9600) initialize. TFTscreen.begin() is use to initialize the library. TFTscreen.background(0, 0, 0) is use to customize the screen background color here TFTscreen.background(0, 0, 0) means the background colour is black. TFTscreen.setTextSize(2) is use to set the font size.

In the loop section first, we will print the “Hi_peppe8o!” in the centre of the LCD and this will be in three different colours (Red, Green, Blue) you can choose any colour using the different colour codes. After 300 milliseconds a straight line will be displayed, after 300 milliseconds a square will be displayed, after 300 milliseconds a circle will be displayed, and after 300 milliseconds screen will be black/ erase and these all shapes and the text will be repeated in the void loop.

The LCD displays the text of “Hi_peppe80” and after that displays the line, square, and circle and then erases everything after completing this sequence. The command used for clearing all the data is TFTscreen.background(0,0,0):

(Yicai Global) Aug. 11 -- Electronic display giant BOE Technology Group Co. [SHE:000725] has signed an agreement with the municipal government of Wuhan, in China"s central Hubei province, to invest CNY46 billion (USD6.9 billion) to build a factory for 65-inch LCD TFT-LCD display modules and related projects in the city, BOE said in a press briefing on Aug. 10.

Beijing-based BOE plans to start construction in the fourth quarter of this year and finish within two years. The facility will produce 120,000 displays per month.

module could be customized made. there are many standard tft lcd sizes for your choices, we don"t have to total custom make tft lcd, a semi-custom tft would be economy and feasible way. the standard tft sizes can be from 0.96", 1.1",1.3", 1.54", 1.77", 2.0", 2.2", 2.4" 2.6",2.8", 3.0", 3.2",3.5", 4.3", 5", 7", 8", 9", 10.1" 10.4",12.1", 13.3", 15", and up to 86" tft panel available. display resolution can be : 80x160 pixels, 160x128, 176x220, 240x320, 320x480, 480x272, 640x480, 800x480, 1024x600, 1280x800 pixels etc.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

In October, Wisconsin denied Foxconn subsidies because it had failed to build the LCD factory specified in its contract with the state. As The Verge reported, it had created a building one-twentieth the size of the promised factory, taken out a permit to use it for storage, and failed to employ anywhere near the number of employees the contract called for. Nevertheless, Foxconn publicly objected “on numerous grounds” to Wisconsin’s denial of subsidies.

Documents obtained through a records request show Foxconn’s rationale: it doesn’t think it was specifically promising to build an LCD factory at all. According to a November 23rd letter to the Wisconsin Economic Development Corporation (WEDC), Foxconn does not think the factory specified in the contract, an enormous Generation 10.5 LCD fabrication facility, was actually a “material” part of the contract. (“Material” is a legal term that means relevant or significant.)

“As you confirmed on November 10, 2020, the only reason the WEDC made the determination that the Recipients are ineligible for tax credits is because the WEDC believes the Recipients have failed to carry out the ‘Project,’” Foxconn wrote. “Thus, WEDC’s determination of ineligibility is based off its belief that the Generation 10.5 TFT-LCD Fabrication Facility is a material term of the Agreement.”

“Thus, WEDC’s determination of ineligibility is based off its belief that the Generation 10.5 TFT-LCD Fabrication Facility is a material term of the Agreement.”

WEDC is standing by its denial of subsidies. In a letter dated December 4th, the agency wrote that the definition of the project as a Gen 10.5 LCD factory was in fact central to the contract, calling Foxconn’s claim that jobs and investment were the only terms that mattered “incomplete and flawed in several respects.” (It also noted that Foxconn hasn’t performed on the jobs or investment parts of the contract, either.)

The contract explicitly defined the project as a Gen 10.5 LCD factory, and its enormous size and economic impact was the justification for the record-breaking subsidy package Foxconn received, WEDC pointed out, as it has numerous times before. “Without a Generation 10.5 TFT-LCD Fabrication Facility, there is no justification, or consideration, for the enormous tax credit incentives or expense to Wisconsin taxpayers,” WEDC wrote.

WEDC ended the letter by reiterating it was open to amending the contract to reflect Foxconn’s current plans. There are signs that such an agreement might be close. After claiming the specifics of what it was building were never important, Foxconn added that it does wish to discuss amending the contract to “lower the taxpayer liability in exchange for a flexible business environment in Wisconsin.” Foxconn has previously expressed interest in an amendment only to revert to insisting it was building an LCD factory after all, but it’s possible that with President Trump exiting the White House, the company will feel less pressure to maintain the facade that it’s building the project Trump touted.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey