lcd screen uv light manufacturer

The LightSources and LightTech group have become the world leading UV light suppliers by offering OEMs the largest selection of specialty UVC germicidal lamps with patented, proprietary technologies. Our group has the expertise and state-of-the-art resources to design, engineer and test as well as to deliver UV lamps that meet the most stringent requirements. We have modern manufacturing facilities along with sales and distribution locations in North America and Europe and a sales office in China. This provides us with the capability to efficiently serve OEMs of any size and with any type of need.

As a global UV light supplier, we have the expertise and resources to provide high-quality standard and customized products with unmatched flexibility and manufacturing turnaround. With over three decades in the industry, many of our innovative products are proprietary and exclusive to the LightSources group.

The LightSources group is committed to supplying ecologically-sound solutions worldwide as we strive to contribute to balance public safety and environmental protection with the need for effective disinfection. We will continue to develop the technologies that are vital for the current and future health of the earth’s indispensable resources for clean water and air.

LightSources and our affiliated companies, LCD Lighting, Voltarc along with strategic partners LightTech, and Cerlux represent the leading high-tech designers and manufacturers in the lamp industry today. In addition to our high-quality standard lamps and components, we specialize in customizing the best solution and technology to meet our partner’s unique needs. Contact us for more information on our inclusive services from the world’s leading UV light suppliers.

LightSources and our European partner, LightTech, are the industry’s top UV lamp manufacturers and offer OEMs the best quality and selection of standard and customized UV lamps for virtually any application. Our customers benefit from our extensive experience and combined resources. Together, LightSources and LightTech are world market leaders in producing low pressure tanning lamps and UVC quartz germicidal lamp technologies. Our portfolio includes: UVC germicidal lamps, amalgam lamps, HID-MPUVA & MPUVC, specialty UV lamps, low pressure fluorescent and high pressure facial tanning lamps, swirl, dual and triple-phosphor tanning lamps, medical lamps, collagen fluorescent lamps, and eco-friendly UV lighting solutions.

As the world’s top UV lamp manufacturer, we are committed to engineering the highest quality of standard, specialty and proprietary lamps that meet the requirements of our clients. We accomplish this by operating state-of-the-art manufacturing facilities on two continents that keep production running smoothly and benefit from the combined efforts in research and product development and supply chain activities. Our clients benefit by getting a flexible supply and the best turnaround services compared to any other manufacturer worldwide.

Furthermore, we strive to balance concerns for public safety and environmental protection with the ongoing need for effective disinfection. The ecologically-sound technologies that LightSources and LightTech continue to develop offer critical solutions for the current and future health of the earth’s indispensable resources, such as clean water and air.

LightSources and our affiliated companies, LCD Lighting, Voltarc along with strategic partners LightTech, and Cerlux are the leading high-tech designers and manufacturers in the lamp industry today. In addition to our high-quality standard lamps and components, we specialize in customizing the best solution and technology to meet our partner’s unique needs. Please contact us to learn more about the world’s top UV lamp manufacturers.

Liquid Crystal Display (LCD) technology and display quality continues to evolve, while prices for LCDs have declined dramatically in the last few years. These two factors have helped to increase demand for LCDs in a variety of new and challenging applications, such as outdoor displays, where environmental conditions such as high ambient light and heat build-up can affect display quality. This has created a need for unique solutions to help extend the lifetime and display quality of LCDs in these conditions. One such solution is the use of UV blocking glass.

LCDs utilize organic components that are susceptible to ultraviolet degradation, which can manifest as a shift in color or a washed out look. Displays used in outdoor environments or in close proximity to Fluorescent black lights and other long wave UV emitters are at considerable risk of Ultraviolet degradation. Outdoor LCD devices are at high risk, but with more indoor UV emitter applications being developed it has become apparent that sunlight based ultraviolet radiation is not the only concern. Indoor UV emitter applications are being developed or are currently in use by medical and forensics groups for example.

The atmosphere itself blocks a significant portion of sunlight Ultraviolet radiation up to 280 nm, which is the top end of the UV C range. Oxygen is the primary element responsible for the atmospheres filtering effect on UV C. Indoor UV C emitters are in relative close proximity to the LCDs they would potentially affect and thus are not likely to benefit as much from the filtering effects of the atmosphere. UV C is also damaging to people and so high intensity emitters use protective barriers to contain the UV C radiation. For this reason, LCDs within the application would need a protective UV Blocking Glass.

UV B is less blocked by the atmosphere, but is still significantly blocked by ordinary glass (although this is not generally true for Silica or quartz glass). In situations where an application uses UV B radiation, it is recommended that the application be sealed to prevent excessive human exposure. Any application that needs an LCD to be exposed to UV B radiation regularly should utilize a UV Blocking Glass coating to ensure that the LCD does not degrade.

While ordinary glass blocks a significant portion of UV B this still leaves a significant portion of the UV A range that permeates the front of an LCD. It is this UV A range that has often eluded efforts to prevent ultraviolet degradation. Its effects are often not as obvious, but can be seen in many everyday situations where carpet, drapes or other natural and synthetic polymer objects are left in a window for long periods of time. They fade, crack or disintegrate due to the unblocked UV A radiation that passes through ordinary glass.

ZC&R’s UV Blocking Glass solutions act as a mirror to ultraviolet radiation. In combination with a hot mirror (IR Reflector), this coating helps preserve the performance of an LCD exposed to unfiltered broadband lighting while retaining the visibility and clarity of the display.

Before we get into specifics about how this would work, it is important to understand that liquid crystal display panels and polarizers utilize organic compounds that are susceptible to high heat and light energy stress. These organic compounds will eventually break down if deployed in high stress environments. One such contributing factor to LCD panel failure is the use of a high energy unfiltered illuminator. The near IR and shorter UV wavelengths not only add excess heat that may overheat the liquid crystal and prevent them from working properly, but they also add UV band energy that is destructive to organic compounds.

Over time the UV and IR will degrade and damage the LCD panel and polarizers to the point that they produce an unacceptably poor performance. In most applications this is observed to be color shift, washed out images and an observable raise in the darkness levels produced by a damaged LCD panel.

In order to help prolong the onset of such damage a set of UV and IR band filters and mirrors can be used to minimize the amount of harmful energy that is conveyed to the LCD panel from the illuminator. In order to determine what combination of filters and mirrors are best for any particular application it is important to know how each material reacts to the various intensities of bandwidths emitted by your chosen illuminator.

Frequently the Illuminators used in LCD systems are gas discharge lamps such as xenon arc lamps and metal halide light sources. A standard hot mirror that reflects energy between 750 and 1200 nm can be used to mitigate the majority of IR energy being conveyed to the LCD panel. In addition a UV blocker can be used to mitigate the damage from energy below 400 nm.

Other thin film coatings and substrates can be utilized to reduce the IR and UV damage to an LCD panel. Any solution must be well researched to minimize concerns so that a sufficient cooling mechanism is planned and allowed for in the application.

Manufacturer of ultraviolet (UV) curing equipment for DVD/CD & LCD coating applications. Available as mobile/handheld UV curing systems & UV curing ovens. Types of mobile/handheld UV curing systems include modular UV curing systems, portable UV curing systems & dual-purpose UV curing systems. UV curing ovens such as standard UV curing ovens & 3-D UV curing ovens are available. UV curing systems are used to dry coatings, finishes, adhesives & inks on number of different product surfaces. 5-year parts warranty available.

DoctorUV proudly distributes a full line of Inspection Systems. Thousands of companies worldwide trust our UV blacklight inspection lamps to play an integral role in their processes and products for a wide variety of industries, including:

Professional UV inspection lights make excellent quality control systems, providing fast response times, high resolution, and increased operating ranges. They are designed to be easy-to-use and versatile, making them perfect for a wide range of applications.

UV-A inspection lights are used for highlighting cracks in safety, critical aerospace, and automotive components during dye penetrant and magnetic particle fluorescent processes.

UV fluorescent inspection systems can be combined with fluorescent additives mixed with water, oils, fuels, coolants, and refrigerants to reveal leaks on surfaces, pipework, joints, and coils.

Professional UV inspection lights are used to reveal invisible contamination on surfaces, highlighting areas either missed or not cleaned properly. Ideal for audits, evaluating different cleaning products and training staff.

UV light inspection equipment is used for quality control of textile materials and products. Applications include identification of fiber yarn mixes within a cone, cloth or beam. This also includes contamination of raw materials such as cotton, or oil stains on carpets from weaving and tufting machines and particulates in medical non-woven fabrics.

UV blacklights are used in combination with UV reactive materials for creating spectacular special effects, including single and dual image, 3D, invisible/UV revealing and Trompe-l’oeil. Applications include entertainment, promotion and advertising materials.

UV inspection lamps are used for quality control inspection of free-range eggs to detect evidence of washing or wiping and highlighting spoilage by bacteria and mold. Currently used by DEFRA egg inspectors, hatcheries, egg packing centers, wholesalers and food processors.

UV blacklight inspection lamps are used to reveal security markings on items such as currency, credit cards and security documents for verification purposes.

At DoctorUV, we offer a one-stop-shop for all your UV equipment needs, offering a cost-effective, versatile UV system for your manufacturing processes. Whether you’re in the medical device or automotive industry, we provide the highest quality products and most extensive knowledge available.

Using its proprietary optical technology cultivated from the development of automotive headlamps, Stanley entered the ultraviolet lamp market in 2010. We have so far made progress with deep ultraviolet (UV-C) by fully utilizing our strength of having both lamp and LED-based devices and units. Stanley Electric will continue to develop UV-C light sources and products that apply this technology to provide a safe and secure society using light for the people of the world in the “with Corona” and “after Corona” era as it is sometimes called in the coming years.

Bacteria and viruses are lurking everywhere in our daily lives, in the air and on the surface of objects. The risk of infection increases as the number of so many people come into contact or touch these areas. Irradiating with UV-C can reduce this risk of infection.

AℓNUV is a brand of disinfection products that use ultraviolet technology from Stanley Electric. We provide ultraviolet devices that meet the needs of our customers through AℓNUV and are expanding on the application of this technology with the aim of achieving a world in which everyone can live each day safely.

We have a range of UV-C light sources including a 265 nm wavelength UV-C LED, which has the greatest disinfection effect, and long-life compact ultraviolet lamps. We also have a lineup of light sources installed on AℓNUV products.

If you have burned, scrated or caused any general damage to your polarizer then this film will be the replacement for your existing damaged one. The polarizer is needed to make the images on the LCD visible. KOOCU P -Series is developed by Monoshot Mobile Resource Shenzhen with rich experience and technology.

Try using lcd uv glue light found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd uv glue light to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd uv glue light are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd uv glue light at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd uv glue light on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Ultraviolet Light Resistant Resistive Touch Screen. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer"s demands are met.

The D4 Premium is VIQUA’s latest innovation, combining the reliable D4 system with the new LCD Interactive Controller, for flow rates up to 12 gpm (45 lpm).

APO/FPO, Afghanistan, Albania, Algeria, American Samoa, Andorra, Angola, Armenia, Azerbaijan Republic, Bahrain, Bangladesh, Belarus, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Brazil, Burkina Faso, Burundi, Cameroon, Cape Verde Islands, Central African Republic, Central America and Caribbean, Chad, China, Colombia, Comoros, Cook Islands, Côte d"Ivoire (Ivory Coast), Democratic Republic of the Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Gabon Republic, Gambia, Georgia, Ghana, Gibraltar, Greenland, Guam, Guernsey, Guinea, Guinea-Bissau, Guyana, Iraq, Jersey, Jordan, Kazakhstan, Kenya, Kiribati, Kyrgyzstan, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Macedonia, Madagascar, Malawi, Maldives, Mali, Marshall Islands, Mauritania, Mauritius, Mayotte, Micronesia, Moldova, Mongolia, Montenegro, Morocco, Mozambique, Namibia, Nauru, Nepal, New Caledonia, Niger, Nigeria, Niue, Oman, Pakistan, Palau, Papua New Guinea, Paraguay, Republic of Croatia, Republic of the Congo, Reunion, Russian Federation, Rwanda, Saint Helena, Saint Pierre and Miquelon, San Marino, Senegal, Serbia, Seychelles, Sierra Leone, Solomon Islands, Somalia, Sri Lanka, Suriname, Svalbard and Jan Mayen, Swaziland, Tajikistan, Tanzania, Togo, Tonga, Tunisia, Turkey, Turkmenistan, Tuvalu, US Protectorates, Uganda, Ukraine, Uzbekistan, Vanuatu, Vatican City State, Venezuela, Wallis and Futuna, Western Sahara, Western Samoa, Yemen, Zambia, Zimbabwe

Ultraviolet (UV) light-emitting diode (LED) curing offers many benefits for bonding and coating applications in the touchscreen manufacturing segment. It provides a more consistent and reliable process without damaging or discoloring heat-sensitive components.

UV curing is a photopolymerization process that uses UV energy to change a liquid to a solid. Upon absorption of the UV energy, the photoinitiator (PI) produces free radicals that initiate crosslinking with binders (monomers and oligomers) in a polymerization reaction to cure or solidify the ink, coating, or adhesive, usually in a few seconds (see Figure 1).

Originally introduced in the 1960s, today’s manufacturers use UV curing for a variety of applications—from graphic arts printing to automotive headlamp coating and more. In fact, the UV curing market continues to grow as it displaces water- and solvent-based thermal drying processes due to increased productivity, higher quality and performance, and environmental benefits.

LEDs for UV curing applications generate UV energy in an entirely different way. As an electric current (electrons) moves through a semiconductor device called a diode, it emits energy in the form of photons. The specific materials in the diode determine the wavelengths of these photons. In the case of UV LEDs, the output is typically in a very narrow band (± 10 nm). Figure 2 compares the output of a 395-nm UV LED lamp with a typical mercury arc lamp. It is important to note the difference in intensity and wavelength of the output—both are important to understanding a UV curing process.

UV LEDs have been commercially available for more than 10 years. However, their unique output characteristics require newly formulated UV chemistries in order to take advantage of UV LED’s many benefits. For efficient and effective UV curing of an ink, coating or adhesive, the formulator needs to overlap the UV lamp output with the spectral absorption of the photoinitiator. A very efficient cure is possible with a formulation designed specifically for UV LED curing using a photoinitiator with concentrated absorption in the UV-A range.

UV chemistries for electronics applications are typically acrylates, silicones or epoxy formulations; acrylates are the primary choice because they generally cure more quickly. Many formulations are one-part, which makes handling and application simple. Most UV formulations are 100% solids with no solvent emissions, and are available in a range of viscosities depending on application needs. Shelf life varies from six months to several years.

Some UV formulations, especially those for bonding or encapsulating (where the UV energy cannot reach everywhere due to shadow areas) use dual-cure mechanisms such as UV with heat or moisture curing. UV adhesives can adhere dissimilar materials, such as metal, glass and plastics, with precision dispensing via syringe.

The touchscreen market continues to grow; uses include smart phones, tablets, eBook readers, mobile game consoles, and in-car navigation systems. Asia-Pacific is the largest and fastest growing regional market for touchscreen manufacturing.

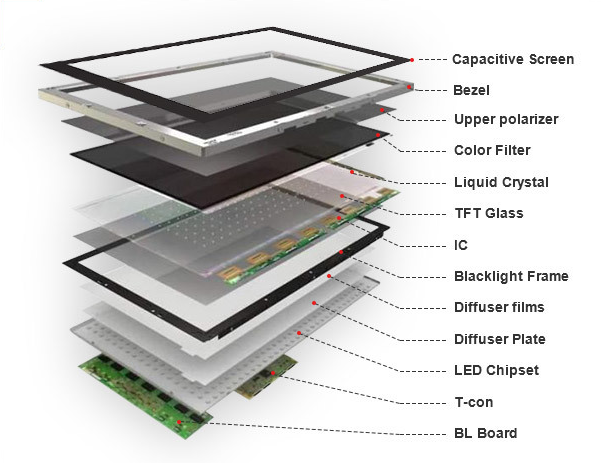

A touchscreen display is an assembly of many different layers, such as the liquid crystal display (LCD) or organic light emitting diode (OLED), glass, conductive and non-conductive layers, and a protective flexible layer. Each of these layers needs a liquid optically clear adhesive (LOCA) to provide a strong bond, a protective seal from moisture, and desirable optical properties while withstanding sunlight.

UV LED-curable adhesive formulations are typically acrylic or epoxy cured at 365 nm, and deliver excellent optical properties such as light transmission, reduced reflections, anti-fogging, and impact and scratch resistance. They are easy to dispense and provide high flexibility without shrinkage or tension between layers, which could cause image distortion.

The manufacture of LCD and OLED displays also uses UV LED curing prior to assembly into a touchscreen. The low heat and on-demand curing using UV LED lamps is especially advantageous for preventing damage to sensitive components and delivering a consistent, high-speed process. One specific application is the edge sealing of OLEDs, which uses an epoxy resin and spot-curing UV LED system to deliver a precise and efficient cure that effectively seals out moisture. UV LED curing offers many benefits to electronics manufacturing, most notably improved yield, process stability and better adhesion.

Yield is improved with UV LED curing systems by providing consistent UV output over long periods of time. The display material receives a homogenous dose of UV energy consistently across the surface with no “hot” or “dead” spots that would lead to rejects.

UV LED systems provide stable output over long periods of time, typically greater than 20,000 hours. At the low power levels needed for display manufacturing, it is conceivable that the UV LED systems would last beyond 40,000 hours, with the only maintenance being monthly checks of air filtration and ensuring the emitting window is clean. Being semiconductor devices, UV LED systems can be turned on and off instantly with no damage to the light source. No warm-up or cool-down period is required.

The consistent output and long life lead to process stability, a key requirement for high-volume manufacturing. Knowing the equipment is consistently producing the same UV output allows vendors to focus their resources on other parts of the manufacturing process. Process stability is further aided by the fact UV LED systems only produce output in the UV-A range, typically 365 nm, to match with the acrylic adhesive being used. Since no UV-C or infrared is being produced, the adhesive and surrounding transport are only receiving the amount of dose in the wavelength required. This UV LED “cold cure” again improves process stability by not damaging the electronic components while the UV adhesive is being cured.

Since UV LEDs provide energy in a narrow band, a wavelength-optimized adhesive can be formulated to ensure deep-through curing and attachment to display surfaces. The adhesive manufacturer can depend on UV LED’s consistent output at a specific wavelength to develop a formulation that is highly reactive to the UV energy and thus shorten the curing time. Future developments of UV adhesives may also mean less adhesive is used for each display screen, leading to an additional cost savings to the manufacturer.

UV LED curing offers electronics manufacturers higher yield rates and productivity due to a consistent and stable process with less damage to heat-sensitive components. UV LEDs require very little space, making them easy to integrate into small spaces. Since UV LEDs produce no ozone emissions or hazardous waste concerns, they are environmentally friendly and safe.

Electronics adhesives and coatings suppliers have formulations available for use with UV LED curing that are easy to handle and apply in the precision, high-speed processes that are so common in electronics manufacturing. Many electronic product manufacturers are already reaping the benefits of using UV LED curing to improve their manufacturing processes.

Kyocera"s UV LED Light Sources are developed by using optical simulation to optimize irradiance, focus distance, and surface uniformity as well as fluid simulation to optimize the characteristics of heat dissipation and the positioning of components.

of high heat dissipation ceramic substrate and optimizing the design of the heat sink to maximize energy efficiency. Capable of achieving 270mJ/cm2 (at 50m/min) dose, which is comparable to the dose level provided by water-cooled UV LED light source.

Compact (80.3 × 88.0 × 150.5mm) and lightweight (1.0kg) design allow more flexibility when incorporating this UV LED Light Source into a system. The G5A Light Source"s ability to achieve high-irradiance with air-cooled design eliminates the need for a water-cooling system (chiller) which is required for water-cooled high-irradiance light sources.

The G5A UV LED Light Source is scalable in 80mm increments to a maximum irradiation width of 1,600mm to meet various curing job requirements. Serial communication with external devices along with ON/OFF power switching at 26.5mm units is available, allowing optimization of the irradiation area.

Monitoring functions: LED temperature, LED current, fan operating hours, and accumulated LED lighting hours. Alert functions: System error, LED lighting error, air filter replacement, etc.

The G5H UV LED Light Source is scalable in 80mm increments to a maximum irradiation width of 1,600mm to meet various curing job requirements. Serial communication with external devices along with ON/OFF power switching at 26.5mm units is available, allowing optimization of the irradiation area.

The G5AP UV LED Light Source is scalable in 120mm increments to a maximum irradiation width of 2,400mm to meet various curing job requirements. Serial communication with external devices along with ON/OFF power switching at 40.0mm units is available, allowing optimization of the irradiation area.

Have you ever experienced "We considered the introduction of a UV LED light source, but abandoned the idea because of insufficient curing with existing inks"? It may be due to "oxygen inhibition" caused by the combination of radicals generated by UV irradiation with atmospheric oxygen.

Kyocera has developed a UV LED Light Source that realizes excellent curing performance without relying only on power such as irradiance and integrated (or accumulated) light amount, in particular, against "oxygen inhibition" known as poor curing of the ink surface.

Excellent curing performance even for inks and resins that are difficult to cure with conventional UV LED light source, such as low migration inks, coat varnishes, and inks for metal halide lamps.

Unlike the conventional nitrogen purging system that requires an enclosed space, G5AN/G5HN can efficiently flow nitrogen and reduce oxygen concentration in UV irradiation area simply by installing it in the system. No major modification to the system is required to create an enclosed space. A separate nitrogen supply source such as a nitrogen generator is required.

OSRAM HBO® Mercury short-arc lamps with power between 200W and 25,000W are used primarily as UV light sources in the manufacture of microchips, Liquid Crystal Displays (LCDs) and Printed Circuit Boards (PCBs). As a result of the continuous cooperation between ams OSRAM, as the lamp manufacturer, and the device manufacturers or the local users, a wealth of mercury short-arc lamps and their variants have been developed to ensure the right radiation for virtually any application. ams OSRAM also produces Infrared (IR) lamps for Rapid Thermal Processing (RTP) offering high quality performance to the meet the critical demands of the semiconductor industry.

HBO® lamps for UV exposure lithography of integrated circuits use the “i-line” of the emission spectrum (365nm),” g-line” (436nm), or deep UV emission (254nm).

HBO® lamps for UV exposure of packaging, MEMS, and LED lithography, are used for mask aligners, advanced packaging, and wafer inspection, with lamp wattages ranging from 350W to 2,500W.

Is there a type of digital display that can work to let sun through it, so that the dark pixels block the UV, and transparent pixels let the UV through?

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey