led lcd panel repairing free sample

Disclaimer And/ Or Legal Notices The reader is expressly warned to consider and adopt all safety precaution that might be indicated by the activities herein and to avoid all potential hazards. This E-Book is for INFORMATIONAL PURPOSES only and the author do not accept any responsibilities or liabilities resulting from the use of this information. While every attempt has been made to verify the information provided here, the author cannot assume any responsibility for any loss, injury, errors, inaccuracies, omissions or inconvenience sustained by anyone resulting from this information. Most of the repair tips and solution given should only be carried out by suitable qualified electronics engineers/technicians. Please be careful as all electrical equipment is potentially dangerous when dismantled. Any perceived slights of policy, specific people or organizations are unintentional.

All these tools and equipments will help you in troubleshooting and repairing the electronics devices. http://www.LCDRepairGuide.com/screen-repair-v2/

Isolate the LED/LCD TV Screen Problem Made Easy ....................11 The Good Tools .......................................................................................11 The Knowledge of How to Troubleshoot and Repair TV Panel…... .13

Types of LCD/LED TV Screen Problem............................................... 13 How to Use the LCD/LED Panel Tester Correctly ............................ 16 How to Know Which LVDS Cable is Suitable to this TV Panel? ......18

You Must Know Why Repair LED TV Screen Unsuccessfully ....19 A Good Workbench and Tools will Help to Increase Successful Repair Rate........................................................................................................20

Terminology of the T-CON Board and LCD/LED Panel PCB .....21 Procedure to Repair Samsung LCD/LED Panel without External Gate COF......................................................................................................... 27 About Samsung Panels...........................................................................27 General Considerate Regarding Samsung Panel by Disconnecting Gate Drivers Signals .........................................................................................31 Steps You Have To Do When Repairing a Samsung Panel................34 Samsung Panel Screen Repair Case .....................................................35 (4.1) Panel Screen: LTA260AP02 T-CON: 260AP02C2LV0.2 Level Shifter IC: IC8-AG32AE2 ......................................35 (4.2) Panel Screen: LTA320AB02 and LTF320AB01 T-CON: 320AB02CP2LV0.3 http://www.LCDRepairGuide.com/screen-repair-v2/

V2-LCD/LED Screen Panel Repair Guide Level Shifter IC: 2x AG16BG...........................................38 (4.3) Panel Screen: LTJ400HM03 B T-CON: S100FAPC2LV0.3...............................................39 (4.4) Panel Screen: LTF320AP11 T-CON: S100FAPC2LV0.3 Processor: BD8193MWV, Gamma MAX9694E .............41 (4.5) Panel Screen: LTJ400HM07 T-CON: S100FAPC2L v0.3 (BN41-01687A) ...................43 (4.6) Panel Screen: LTF400HM03 T-CON: S100FAPC2L v0.3...............................................46 (4.7) Panel Screen: LSF320HJ01 T-CON: 2013_TCON_FOX_FT1 (BN41-01939) ............47 (4.8) Panel Screen: LTY320AP04 and LTZ320AP04 TCON: 320AP04S4LV1.5 and 320AP04S4LV1.7...........50 (4.9) Panel Screen: LTA400HW03 J TCON: SH120PMB45V0.3................................................52 (4.10) Panel Screen: LSY320AN02 TCON: 320KSB_S2LV0.2.................................................55 (4.11) Panel Screen: LTJ400HM05 T-CON: 400HR42S4LV0A, 400HR42S4LV0B ...............59 (4.12) Panel Screen: LTF320HM01, LTA320HM03 T-CON: LJ94- 03256H (F 60M B4C2LV0. 6) ................64 (4.13) Panel Screen: LTJ400HV01-J T-CON: SH120PMB4SV0.3 ..............................................67

V2-LCD/LED Screen Panel Repair Guide COF BoardView List (aka COF Bypass Modification) ...................70 LCD Panel TAB/COF Equivalent List ..................................................94 T-CON Board P-GAMMA IC & DC-DC IC Programming Method............................................................................................................ 104 How do I know the GAMMA IC & DC-DC IC is programmable type? .................................................................................................................105 How to Programming/Write the T-CON Board P-GAMMA & DCDC IC?..............................................................................................................106 These 5 Pins of T-CON Board P-GAMMA & DC-DC IC You Must Know.................................................................................................................107 T-CON Board P-GAMMA & DC-DC IC Programming Tutorials.108 RT809F Software Programming Programmable IC Process ..........114 T-CON Board P-GAMMA & DC-DC IC Read/Write Pins List .....115 Download the T-CON Board P-GAMMA IC & DC-DC IC Data/Firmware ................................................................................................117

Troubleshooting & Repairing Hisense RSAG7.820.5129 T-CON Board............................................................................................................... 119 T-CON Board Circuit Structure.........................................................119 Panel Control Signals & Mini-LVDS Timing Chart Waveform .....120 Control Signals DC Voltage Range.....................................................121 Critical T-CON Board Output Voltage Values .................................121 RSAG7.820.5129 T-CON Board Module Features ...........................121 Introduce Module Features & Their Common Faults in T-CON ..123 Other Common Faults in this T-CON Board ...................................128

V2-LCD/LED Screen Panel Repair Guide BONUS-A: LG LED/LCD TV Interconnect Schematic Diagrams 32LS3500-Interconnect_2012_Interconnect ………….………..148 37LK450-Interconnect_2011_Interconnect ……………….……155 42CS560-Interconnect_2012_Interconnect ……….…….………163 42LG60-Interconnect2_2008_Interconnect …………….………170 42LG60-Interconnect_2008_Interconnect ………………….…..172 43LJ5000-Interconnect-Mainboard_2017_Interconnect ……….174 47LV4400-Interconnect_MB Built-In T-con_Interconnect…… 178 49UH6100-Interconnect_2016_Interconnect ……………………184 55UF7600-Interconnect-Mainboard_2015_Interconnect ……....185 65UH5500-Interconnect-Mainboard_2016-2017_Interconnect…191

BONUS-A: T-Con Board Schematic/Circuit Diagrams HISENSE RSAG7.820.5129 T-CON Board Schematic………..….….195 HISENSE RSAG7-820-4159 T-CON Board with LED32K16 TV HE315DH-B11…………………………………..……………….203 SKYWORTH 5800-TCON6-0P10 T-CON Board Schematic………..208

V2-LCD/LED Screen Panel Repair Guide Highly recommended other great related repair information for you: With all these great repair information, it will help and improve your skills in troubleshooting and repairing OLED/LED/LCD/Plasma TV quickly and easily: (Please click on the ebook cover to get more details)

http://www.LCDRepairGuide.com http://www.LCD-Television-Repair.com (LCD/LED TV service manuals & etc) http://www.Plasma-Television-Repair.com (Plasma TV service manuals & etc) Other Great Electronic Repairing Ebooks:

How to Use This Repair Guide 1) Yes, this repair guide not only can save you time and money, it also can help to earn more profit from repairing LCD/LED panel. Because of LCD/LED Panel is the most expensive spare part inside the TV and Monitor. If we can repair it, so the profit is quite high to compare repairing other section like PSU in TV. 2) With the help of LCD/LED Screen Panel Repair Guide (V1), when you read this ebook, it will improve your knowledge and repairing skills quickly and easily. Because all the basic theory of how Panel working was written inside the LCD/LED Screen Panel Repair Guide (V1). Highly recommend to grab this ebook too. 3) If you don’t want to start from the basic theory, but just want to solve your TV display problem, you can direct refer to the chapter you’re interesting. So it will directly to show you what’s wrong on this type of display symptom. Also the LCD and LED Backlight is not writing in this ebook, because I had wrote a lot this title in my V2, V3, V4 and V5 LED/LCD TV Repair Tips ebook series. 4) When I’m mention “LCD” word in this ebook, actually it is included the “LED” at the same time. So I don’t write too many LED word in this ebook to save more space and reduce some file sizes in this ebook. 5) After you have finished reading this repair guide, I believe that you will have the confident to repair LCD/LED TV Panel now. It is because of we know how the LCD/LED Panel is working, why this display symptom is occur and also know how to troubleshooting it! The LCD/LED Screen is the most expensive cost of the TV. Normally when the Panel is beyond repair, this TV will no point to continue repair. Either replaces a new or working Panel with reasonable price, or just selling their PCB board as it to the used spare part market. Nowadays, repairing the LCD/LED Panel has a high profit margin in TV or Monitor repair!

Isolate the LED/LCD TV Screen Problem Made Easy How to isolate the LED/LCD TV screen problem easily? I’ve received lots of this type of question from the TV repairer. And my answer is:

1) The Good Tools a) LCD/LED Panel Tester - A tester to test the T-con + Panel is working or not. So this tester can generate and send the Testing Color Bar to the Panel through T-con Board. The tester like picture below:

b) LVDS convert to VGA Tester - This type of tester have two design, one is their tester build in the LCD screen and another one is need to connect to a monitor to see the video output is normal or not. Normally, this tester can test Mainboard output video signals LVDS to VGA and see the result on its own LCD screen or connect it to a monitor to see the display result. This tester is looks like the picture below:

c) V-by-One converts to LVDS (also to VGA) for 4K TV Mainboard. - This type of tester is more expensive than the above two. Because of this tester can support to the latest 2K~4K TV Panel. It also same as the LVDS convert to VGA Tester, the display result can see on its own LCD screen or connect to a VGA monitor. Please see on the picture below:

V2-LCD/LED Screen Panel Repair Guide 2) The Knowledge of how to Trobleshoot and Repair TV Panel So from the TV screen symptom, you will know what the TV or panel problem is. All these knowledge you can learn from my previous ebooks like: V3 & V4 LED/LCD TV Repair Tips and LCD/LED Screen Panel Repair Guide. For more details of these ebooks, please visit to http://www.LCDRepairGuide.com .

Types of LCD/LED TV Screen Problem 1) No Display (Grey Screen: you can feel that their backlight is lit) This type of screen problem, you need to see their backlight is lit or not. If the backlight lit but no display, then use the volt meter to check their T-con board VCC supplies input voltage. If the Vcc has 12V or a similar voltage, that’s mean the problem is on T-CON board or Panel. If the T-con VCC input voltage missing, you need to trace it back to mainboard. We can use the LCD/LED Panel Tester to checking their T-con + Panel are working or not. So to confirm the problem is on Mainboard or Panel. Also we can use the other two testers too. 2) Display Upside Down & Painting Display Problem Normally this type of problem is causing by their setting in between Mainboard and their T-con board. So the solution is to login to TV service mode (Mainboard) to change their Panel setting. Or you can modify their T-con like inside the LCD/LED Screen Panel Repair ebook. If cannot modify, then change the T-con board to solve this problem. 3) White Display Normally this type of problem is the T-con or Panel damage. If you use the LVDS convert to VGA Tester, the TV Mainboard can output a perfect display on its LCD screen there.

V2-LCD/LED Screen Panel Repair Guide 4) Display Slow Motion Normally this type of problem is the T-con or Panel damage. If you use the LVDS convert to VGA Tester, the TV Mainboard can output a perfect display on its LCD screen there. 5) Display Double Images/ Jittering or Jumping Normally this type of problem is the T-con or Panel damage. If you use the LVDS convert to VGA Tester, the TV Mainboard can output a perfect display on its LCD screen there. 6) Whole Screen of Vertical Colors Lines (Static or Dynamic) Most of the time, this type of screen problem is causing by their T-con. If you’re not sure, you can call out their TV OSD Menu. It is also same problem too. If their OSD Menu can show a perfect image on the screen, that’s mean the problem is in the Mainboard there. Or just use the LCD Panel Tester to testing it, you will know the result directly. 7) Screen Display Divided to Several Section or Display Content Opposites This type of problem is causing be their T-con board EEPROM firmware abnormal. 8) One or Several Horizontal/Vertical Bar or Lines on Screen Normally this type of problem is causing by their TV Panel. 9) Abnormal Display (Not mention the above) This type of screen symptom, you can try call out their OSD Menu to see it is normal or not. If OSD Menu normal, that’s mean the problem is on the Mainboard. If still same problem, then you needs to use the LCD Panel Tester or another two testers to testing this TV.

V2-LCD/LED Screen Panel Repair Guide Notes: If these voltage lines abnormal on T-CON Board, what will happen on TV Screen? a) Vin (12V), VDD (3.3V), VAA/VDA(~17V) If these voltage missing or abnormal, the screen will no display. b) VGH, VGL If these voltage missing or abnormal, the screen will become slow motion or abnormal display. c) Vcom If this voltage missing or abnormal, the screen will flashing or display not sharp (like low level contrast screen).

How to Use the LCD/LED Panel Tester Correctly Nowadays, the LCD/LED Panel Tester is a must have tool to repair an LCD/LED TV. It is cheaper than the LVDS Convert to VGA & V-By-One Panel Testers. So lots of the TV repairer purchased this type of Panel Tester. Unfortunately, they bought the wrong package of this LCD/LED Panel Tester. Please look at the picture below:

The above LCD Panel Tester is a standard package only. The seller put their advertisement say this Tester can support LCD Panel from 10 inches until 55 or higher inches too! But from the above picture to see that, it is not user friendly for the TV repair!! When you bought the above LCD Panel Tester package, this tester will not help much in TV Panel repair. Because of the seller not put all type of the LVDS cables to standard package of LCD/LED Panel Tester. When you want to testing the 32, 37, 39, 40, 42, 47, 50, 55 inches TV panel with this tool, you will feel the lack of the LVDS cables to testing the above TV Panel. So I will recommend you when purchase this type of LCD/LED Panel, you must ask the seller to purchase extra LVDS cables like: 8-bits Single & Dual Channels types, and also for the 10-bits Single & Dual Channels LVDS cables. http://www.LCDRepairGuide.com/screen-repair-v2/

V2-LCD/LED Screen Panel Repair Guide How to Know Which LVDS Cable is Suitable to this TV Panel? That’s easy to just refer to back to their LCD Panel specification sheet, and then you will know what type of LVDS cable of this Panel (T-con board) use. Below is an example Panel datasheet of AUO T315XW02 VC. Inside the “”General Description” section there, it is shows their cable type already is 8-Bits and 1 Channel LVDS cable like picture below:

Important Note: 1) Make sure that the T-CON Vcc input voltage pins are connected correctly to LCD/LED Panel Tester. 2) Also choose the correct LCD Panel voltage values for the TV Panel need to test. If just wrong doing the above either one, it can damage and burn the LCD/LED TV Panel!!! So be careful on this part, if not, afterward you will regret. One more thing is make sure the TV backlight is working properly. If not you can’t see anything on TV screen.

You Must Know Why Repair LED/LCD TV Screen Unsuccessfully Repair LCD/LED TV Panel is a challenging job. So we always need to find and learn the good & helpful TV Panel repairing information to improve our skills. When the skills improved, that’s mean repair the TV Panel successful rate will increase at the same time too! But I received several members email said they hard to successful repair the TV Panel. Finally, I found that they have a same mistake to learn the knowledge of repair TV Panel. For example: An LCD TV with display slow motion problem. Normally it is causing by their abnormal VGH voltage. So the member emails me about this problem and I told him to checking the VGH voltage. After next day, he replied my email and said all voltages on the T-CON board are normal. I asked him, did you check the VGH voltage until to the X-COF pin there? He said no. Then I asked him to check again. But I forgot to tell him that LCD Panel has 3 x external Gate COF and also need to check too. So next email, he told me that the VGH voltage normal even measure until the X-COF pins there. So he feels like this TV Panel is beyond repair and need to return back to customer. So I encourage him try again. Because he never finish check the VGH yet. Luckily, when he check the Gate COF-1 (COF BoardView or my previously call it as Bypass Modification) and found that VGH voltage missing! So he connects a wire from T-con board VGH point to the Gate COF-1 VGH point. Finally, his TV Panel problem solved! From the above story, we know that different people even learn from a same book, but get a different result! Hopefully, the entire TV repairers don’t do this mistake again.

V2-LCD/LED Screen Panel Repair Guide A Good Workbench and Tools will Help to Increase Successful Repair Rate Yes, a good environment workbench with the entire necessary tools standby to use will help to increase the successful TV panel repair rate. These things and tools will helps to you: 1) 2) 3) 4) 5) 6) 7) 8)

A clean workbench with the proper lighting. Magnifier LCD/LED Panel Tester LCD & LED Backlight Tester Sharp & Fine tip Needle Soldering Iron Universal ISP Programmer Good sharp knife and etc accessories. TV Panel repairing information like: Panel datasheet specification info, Panel schematic diagram and my ebooks: V3, V4, LCD/LED Screen Panel Repair Guide (V1.0) and this ebook also.

This VGH (VGate High) voltage was generated by DC-DC circuits. And their voltage is about 20V ~30V but it will depends on the T-con board design. The feature of VGH voltage is to supply to the Gate Driver Board as a “Switch ON” feature. It can switch on the TFT cells in LCD Panel and display shows.

CKV( Clock Signal)- High-Voltage Scan-Drive Output. When enabled, CKV1 toggles between its high state (connected to VON) and its low state (connected to VOFF) on each falling edge of the CPV1 input. Further, CKV1 is high impedance whenever CPV1 and STV are both low.

High-Voltage Scan-Drive Output. When enabled, CKV2 toggles between its high state (connected to VON) and its low state (connected to VOFF) on each falling edge of the CPV2 input. Further, CKV2 is high impedance whenever CPV2 and STV are both low.

High-Voltage Scan-Drive Output. When enabled, CKV3 toggles between its high state (connected to VON) and its low state (connected to VOFF) on each falling edge of the CPV3 input. Further, CKV3 is high impedance whenever CPV3 and STV are both low.

In order to solve the problem of image-retention effect of TFT-LCD, the technique of XAO function (power off control) is mostly used at present. XAO function means that XAO is set to low level when the display is turned off. For example, the logic low level is set to 0˜3.3 v, and thus all outputs of the gate driver will be shifted to high level at the same time and all TFT will be turned on. The charge stored on the CS can thus be discharged and the imageretention effect can be eliminated. However, the common method of using XAO function is to send XAO signal into logic control circuit and to convert low level to high level output through level shifter. After the display is turned off, much charge on the capacitor will be discharged since the voltage of power supply is maintained only by the capacitor and all TFT at low level will function at the same time. Therefore, when the pulse of XAO reaches, the gate voltage of all TFT are all shifted to VGH, and thus a large current is produced at the moment in which the gate of TFT on gate driver circuit is activated. This large current may cause the trace on gate driver circuit to burn. Furthermore, VDD voltage will also decrease rapidly and

Procedure to Repair Samsung LCD/LED Panel without External Gate COF This chapter will help you repair a Samsung 2008-2013 type panel screens that use gate circuits embodied in glass screen cell (chip on glass COG). But the knowledge you learn from this chapter, also can apply to other brands of panel repair. The procedure has a rate of success of 0-90%, but it will depend on your screen panel type, the tools you use and the knowledge you’ve learn from my previous ebook (Also included this chapter too). You have to accept that sometimes, even the screen panel will work but a thin line may appear randomly on screen. Also, sometimes, the screen will not respond to any procedure described here. In this file, I will refer only on repairing gate problems of fault in Samsung screen panels.

1. About Samsung Panels A display device includes multiple pairs of field generating electrodes and an electro-optical active layer interposed there between. Generally, one of the pair of field generating electrodes is connected to a switching element to receive an electric signal and the electro-optical active layer converts electric signal into an optical signal to display images. The display device typically includes a gate driver and a data driver. The gate driver applies to a gate line a gate signal that turns a pixel on and off, and the data driver converts image data into data voltages and then applies the converted data voltage to a data line.

“We are interested only in gate signal circuit, this is the one that faults and need to be fixed” The gate signals are processed by the scan driver circuits and amplified by the level shifter to analog signals, which are outputted as the gate pulses for scanning the display panel. Gate driving circuits can be mounted - (TCP) tape carrier package or printed on glass - (COG) chip on glass. On Samsung panels, gate driving circuits were replaced since 2008-2009 with gate drivers on glass mounted transistors, using ASG technology (Amorphous Silicon Gate).

Each gate line has a block circuit glass mounted transistors called SR, made using ASG technology. The gate driver receives clock signals CKV and CKVB and the start signal STVP, and sequentially apply on voltages to gate lines G1Gn.

V2-LCD/LED Screen Panel Repair Guide Cp. As show below, the gate lines G1-Gn, and the liquid crystal capacitor CIc and storage capacitor Cst , respectively have the resistance and capacitance, and the sum thereof is represented by one resistor Rp and one capacitor Cp. The gate voltage output from each line block SR1-SRn is analog transmitted through the gate line corresponding. The SR blocks are connected between, with glass printed connections, and when a component of one SR block faults, owing to the fact that is on glass, the repair is impossible.

The fault can be visible on whole screen, half of screen, so we need to cut in either signals sets, or one by one, depending on each situation. On large screen panels, starting with 32 inch, there are gate drivers on both sides of the screen, and we can have 2, 3 or 4 sets of signals. In this case, the command of 4 blocks gate drivers (CKV1.....CKV4, etc) are made in various ways, one way it is as below: - First gate signal will command upper side of screen odd lines, second gate signal - lower side of screen odd lines, third gate signal will command upper side of screen even lines, fourth gate signal lower side of screen even lines. A fault screen will display in many ways: - Doubled image on all screen, on vertical, or image stop. - Half of screen, upper or lower, doubled or static image, the other half will be correct displayed. - On whole screen are horizontal lines where image is reversed or static. - A part of the screen is darker and with lines. - Vertical flickering image on all screen or upper or lower half of the screen - In an area of the screen, the image has lines on it. - On area where image is not right, can also to have a certain color or fail of color.

2. General Considerate Regarding Samsung Panel by Disconnecting Gate Drivers Signals This method also called as “Cut-Off Modification” in my previous ebook “LCD/LED Screen Panel Repair Guide”. (2.1) The generating circuit for gate drivers, called LEVEL SHIFTER or SCAN DRIVER, can be mounted on T-CON drivers, on PCB (printed wire board) connected to screen, or in glass screen. (2.2) When level shifter is in glass cell, you cannot disconnect it, but you can try to disconnect the input signal – CPV, STV and OE. This signals will go on both sides of the screen, thru left and right PCB, you can disconnect one side first,

V2-LCD/LED Screen Panel Repair Guide check if any improvement, and if not, disconnect other side and re-connect first one. (2.3) First of all you have to check is: where is the LEVER SHIFTER IC, by finding check points CKV CKVB and STVP. Usually the LEVER SHIFTER is on TCON board or on T-CON PCB attached to the screen glass cell. (2.4) When you cut CKV, CKVB and STVP signals on printed wire circuit, you have to be sure that the disconnection will be made to screen direction, there are several situations when connection with level shifter is between check points and screen, so cutting the printed wire circuit near this check points to be with no result. (2.5) The T-CON processor generates only low voltage gate signals, like CPV, STV and OE, the level shifter circuit is not integrated in t-con processor, is a separate IC. (2.6) Sometimes there are 2 or 3 LEVEL SHIFTER IC, like in picture below:

V2-LCD/LED Screen Panel Repair Guide (2.7) Generally, if screen configuration permits, you have to check the printed wire circuit from T-con to both left/right PCBs, in connection to panel for all signals CKV, CKVB and STVP. The best way to repair is to cut the signals near screen, on left/right PCB, or left/right connection to screen on PCB (if only one board attached to screen cell). (2.8) Sometimes, cutting some signals only from left or right will solve the image problems but cutting same signals from both right / left connection to screen to generate more errors. (2.9) If you have a T-con apart from screen cell, first step is to find which part of the screen is fault. Disconnect left FFC between T-con and left PCB and power the tv. If you have now on right part of the screen a normal image, means that you have a fault in left side of the cell. If still a fault image, re-connect the left FFC and disconnect right FFC between T-con and left PCB and power the tv. If you have now on left part of the screen a normal image, means that you have a fault in right side of the cell. (2.10) On some screens, Level Shifter IC have on outputs, some zero ohms resistors, so, you can first remove this resistors and check if any improvements. You should remove on signal groups, for example, when you remove output of CKV2, you have to remove also CKVB2 signal. (2.11) Sometimes, you have on left/right PCB, some zero ohms resistors that connect Level Shifter to right/left screen cell. In this case, just remove those resistors for groups that fault. In example below, RM1 connects to screen the STVP signal, RM2 connects to screen CKV1 signal, RM3-CKV2, RM4-CKV3, RM5-CKVB1, RM6-CKVB2, and RM7-CKVB3 .

V2-LCD/LED Screen Panel Repair Guide (2.12) As I explained in previous presentation, the CKV, CKVB and STVP signals scan between positive voltage VONE and negative voltage VOFFE. Sometimes, a small raise of VOFFE negative voltage will remove faults of the screen.

3. Steps You Have To Do When Repairing A Samsung Panel (3.1) identify the Level Shifter generator, by finding the inputs CPV, OE and STV check points, or finding the outputs CKV1...CKVn, CKVB1...CKVBn, and STVP1...STVPn check points. (3.2) Check the VONE and VOFF voltages and note the values. (3.3) First, disconnect the CKV1, CKVB1 and STVP signals, after that CKV2, CKVB2, and so on. (3.4) Disconnections will be made so the wires from screen panel to be “on air” (3.5) when disconnect the printed wire board near screen entrance, by cutting the printed circuit, you have to be sure that you will be able to solder this wires, so the cut has to be made with some distance from data driver flexible circuit. (3.6) First disconnect, CKV1 and CKVB1- if image still have thin lines, just strap the wires coming from screen panel CKV1 and CKVB1 with a thin wire. (3.7) After connecting CKV1 and CKVB1 with a thin wire, try also to ground this 2 points, or try to connect to VOFF. (3.8) If no improvements, try to disconnect CKV2 and CKVB2 (with STVP disconnected) and make same steps as for CKV1 and CKVB1 (3,6 and 3.7). (3.9) If we have also CKV3, CKVB3 and CKV4 and CKVB4, make the same procedure as CKV1 and CKVB1, described on 3.6-3.7.

V2-LCD/LED Screen Panel Repair Guide (3.10) If, for example, by disconnecting CKV3 and CKVB3 we have a normal screen display, re-connect the former signals to panel screen, one by one in pairs (CKV1 and CKVB1, and so on). (3.11) It is possible that, sometimes only by disconnecting pair 1 and 4 to have a normal screen, but by disconnecting all 4 pairs to have a fault image. (3.12) Sometimes, even the image is correct displayed, you"ll have a thin line in the area where gain glass circuit is failure - this cannot be repairable. You have to advice the client about this, and ask him to put in balance the final result of this procedure against the cost of a new panel screen.

4. Samsung Panel Screen Repair Case (4.1) Panel Screen: LTA260AP02 T-CON: 260AP02C2LV0.2 Level Shifter IC: IC8-AG32AE2 Level shifter receives from processor this low voltage signals: OE, STV and CPV1, CPV2, and from DC-DC source, VON and VOFF voltages Output signals that controls 2 gate drivers are CKV1, CKVB1 and STVP1, respectively, CKV2, CKVB2 and STVP2.

Clock signals are starting from T-con Board, and you don"t have to open the screen panel. First, cut and disconnect on printed side, where indicated in picture, CKV1 and CKVB1, strap on the check point on component side only CKV1 and CKVB1

V2-LCD/LED Screen Panel Repair Guide (4.2) Panel Screen: LTA320AB02 and LTF320AB01 T-CON: 320AB02CP2LV0.3 Level Shifter IC: 2x AG16BG On this panel, we have 2 versions of repairing it. a) On T-con board: There are 2 gate drivers and clock signals are outputted by 2 level shifter IC"s, ICS1 and ICS2, located on T-con board. First, cut the circuits between ICS1 - CKV1 and CKVB1, right near resistors, as shown in image below. If image still fault, try to strap CKV1 and CKVB1, connect to the ground, or connect with an wire to Voff. ATTENTION! Make sure the connection between check point and ICS1 is opened with diode instrument, before strapping CKV1 and CKVB1. If there is still connection to the level shifter IC, you can burn it by connecting to the ground or Voff. If image still faults, make a similar procedure with ICS2, by disconnecting CKV2 and CKVB2. Reconnect CKVB1 and CKVB2 to ICS1, and follow the same procedure.

If image is correct, but on still images there are some white vertical artifacts’, you have to connect strapped pair to VOFF, instead of GND. b) On PCB connected to glass screen panel Cut the connections CKV1, CKVB1, CKV2, CKVB2 and STVP1 (2) on side with gate block fault (left or right) . You can see where the fault is by checking left/right margin of the screen with a magnifier lens, or a microscope. You will see a burned glass circuit, in the area where screen faults.

(4.4) Panel Screen: LTF320AP11 T-CON: S100FAPC2LV0.3 Processor: BD8193MWV, Gamma MAX9694E Panel screen used in Samsung LE32D450G1W TV VONE = 28v, VOFFE= -11,5v Gain signals CKV1, CKVB1, CKV2, CKVB2 and STVP are outputted to screen cell thru 4 resistors, 0 ohms, as in image below:

V2-LCD/LED Screen Panel Repair Guide When all image is colorless or with hue of green/red pale, the fault is from NVM EEPROM IC, 24C64WP. Replace it, with another one, need to use the Universal Programmer to write the good firmware into it before solder back to PCB. A very often fault found with this type of panel: Image is ok only on lower part of the screen, and upper side is discolored and full of visible horizontal lines, as in picture below:

(4.5) Panel Screen: LTJ400HM07 T-CON: S100FAPC2L v0.3 (BN41-01687A) Fault: The thin horizontal stripes were at the top of the screen. Cause of the defect: burned SR block in the higher right/left corner of the panel.

V2-LCD/LED Screen Panel Repair Guide Repair procedure: Disconnect left FFC between T-con and left PCB and power the tv. If you have now on right part of the screen a normal image, means that you have a fault in left side of the cell. If still a fault image, re-connect the left FFC and disconnect right FFC between T-con and left PCB and power on the tv. If you have now on left part of the screen a normal image, means that you have a fault in right side of the cell. The right side (with problems) resistors are RM2, RM3, RM4, RM5 RM6 and RM7. You will have a normal picture now, but sometimes, you will have, on side with problems, a little ODD/EVEN lines distance. Strap with a wire, on check points, CKV1 with CKVB1, see if lines are now correct displayed. If not, strap with a wire, on check points CKV2 with CKVB2, check, and repeat procedure with CKV3 with CKVB3. Now you will have a clean image. Sometimes, if you have a bigger problem on SR circuit, the image will be correct but a / some thin line (s) will be displayed sometimes on screen, noticeable on lighter/darker images. Check if any improvements if connect all pairs of check points on fault side on GND or Voff.

V2-LCD/LED Screen Panel Repair Guide (4.6) Panel Screen: LTF400HM03 T-CON: S100FAPC2L v0.3 Fault: 15 - 30 minutes of good image, begins to trembling, double vertically. If you check on strips of glass with your fingers, you will find that hot broken drivers are on one of the left/right bar. Repair procedure: Disconnect left/right FFC cable between T-con and left/right PCB one by one, and check which part is fault. Remove on pairs (CKV1 and CKVB1 and so on), the 7 resistors from fault side RM1-RM7. If needed, strap pairs coming from screen, on check points (CKV1 with CKVB1, CKV2 and CKVB2, and so on). You can also try to strap pairs to GND or Voff and see if better picture. Left PCB:

(4.7) Panel Screen: LSF320HJ01 T-CON: 2013_TCON_FOX_FT1 (BN41-01939) Fault: Horizontal lines are partial or whole of the screen. Repair procedure: Disconnect one by one the left/right FFC cable between T-con and left/right PCB and start the tv, this way you can easy check which part is fault. Level shifter IC is connected to left/right gate blocks, thru some zero ohms resistors fitted on T-con, thru left/right FFC cable, thru left/right PCB and extreme left/right flexible data driver circuit.

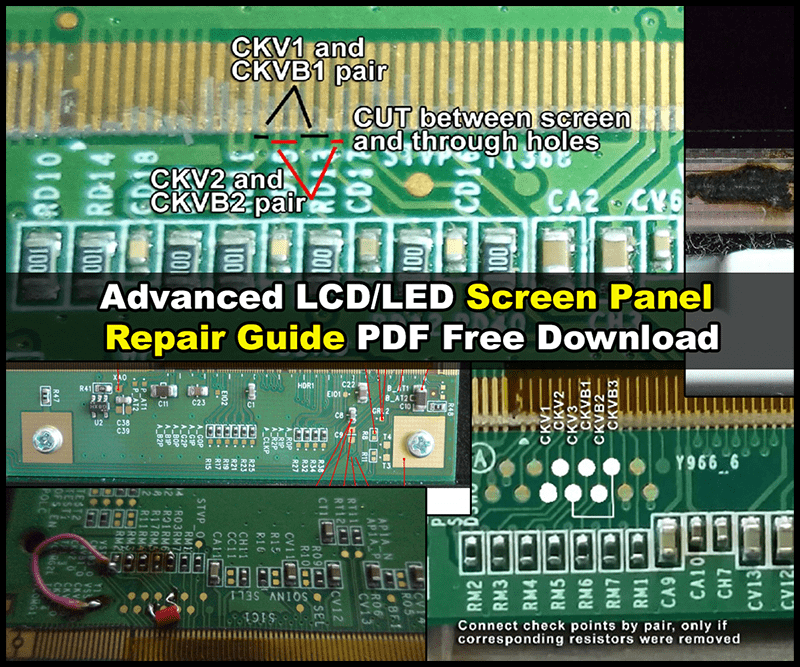

V2-LCD/LED Screen Panel Repair Guide The clock signal pairs CKV1-CKVB1, CKV2-CKVB2, CKV3-CKVB3 and start signal STVP have check points on each side, but they are covered with paint and are very close to PCB"s through-holes, so cutting the circuits is an hard operation.

V2-LCD/LED Screen Panel Repair Guide The easiest way to repair the panel is to cut all 7 signal connectors from FFC cable, only on the side with fault, on T-con side.

V2-LCD/LED Screen Panel Repair Guide (4.8) Panel Screen: LTY320AP04 and LTZ320AP04 TCON: 320AP04S4LV1.5 and 320AP04S4LV1.7 Fault: Image trembling, double vertically, horizontal lines are partial or whole of the screen.

T-CON board is not detachable, and signals to left/right gate blocks, is transmitted thru left/right flexible data driver circuits. So, it"s almost impossible to check which gate is fault. Usually, the right part faults more often, so you can start to disconnect signals from there. You must cut the connections between PCB"s through-holes and check points, so the check points to remain connected to panel, as in picture.

V2-LCD/LED Screen Panel Repair Guide Disconnect first the pair CKV1-CKVB1 and STVP and power the tv and check if any improvement. If not, try to strap CKV1-CKVB1. Check again. Try to connect CKV1- CKVB1 to GND. Disconnect the pair CKV2-CKVB2 and power the tv and check if clear display. If not, try to strap CKV2-CKVB2. Try to connect CKV2-CKVB2 to GND. If CKV2-CKVB2 faults, try to rebuild connection for pair CKV1-CKVB1. Your goal is to have best image you can achieve. Sometimes a thin horizontal line will be displayed even you have a perfect image. You can not eliminate this failing. The line is not noticeable from normal view distance, but its position depends on the position of faulty SR gate block. On image below, the line is very close to lower part of the screen.

V2-LCD/LED Screen Panel Repair Guide (4.9) Panel Screen: LTA400HW03 J TCON: SH120PMB45V0.3 Fault: Image trembling, double vertically, horizontal lines are partial or whole of the screen.

V2-LCD/LED Screen Panel Repair Guide You will have a normal picture now, but sometimes, you will have, on side with problems, a little ODD/EVEN lines distance. Strap with a wire, on check points, CKV1 with CKVB1, see if lines are now correct displayed. If not, strap with a wire, on check points, CKV2 with CKVB2, check, and repeat procedure with CKV3 with CKVB3. In example bellow, the pair CKV3- CKVB3 was strapped Connect check points by pair, but only if corresponding resistors were removed, or else you can burn the LEVEL SHIFTER IC from T-CON.

(4.10) Panel Screen: LSY320AN02 TCON: 320KSB_S2LV0.2 Fault: Screen is flickering, have a part/whole of the screen with doubled image, white ghosting on part / whole screen. T-CON board is not detachable, and signals to left/right gate blocks, is transmitted thru extreme left/right flexible data driver circuit. It"s only one data driver flexible circuit, so, it"s almost impossible to check which gate is fault (left/right).

The connections from LEVEL SHIFTER and left/right gate blocks are made thru some 10 ohms resistors, RD10, RD14, RD9, RD11, RD13, RD12 and RD40, as in picture. CKV1 and CKV2 have 2 outputs on each side to double the current and to avoid LEVEL SHIFTER overheating. Repair Procedure: On fault side, you must cut the connections to left/right side, between PCB"s through-holes and panel, so the check points to remain connected to working side of the panel, as in picture. PCB"s through-holes, connects the other side of the cell with gate signals, so cutting the connections between resistors and through-holes, will cut signals on both sides of the screen. If no burned circuits http://www.LCDRepairGuide.com/screen-repair-v2/

V2-LCD/LED Screen Panel Repair Guide on reverse side of the cell, first try to find out which pair creates problems on screen. First, remove RD10, RD14 and RD13, and check if CKV1- CKVB1 pair creates problems. If not, solder back the resistors, and remove RD9, RD11 and RD 12, and see if CKV2-CKVB2 pair creates problems. Cut only pair with problems, as in picture:

V2-LCD/LED Screen Panel Repair Guide (4.11) Panel Screen: LTJ400HM05 T-CON: 400HR42S4LV0A, 400HR42S4LV0B Fault: Screen is flickering, have a part/whole the screen with doubled image, upper side is discoloured and have visible horizontal lines. First step is to find which part of the screen is fault. This operation is very hard and the t-con is attached to cell glass thru data drivers. We don"t have resistors on CKV-CKVB left-right pair signals, so we have to make a big effort to find out where is the fault. If you have a point where fault starts, you can try to see if a burned SR block can be seen on fault side. You can detach and reverse the cell glass, so you will see burned circuits on glass and you can now know which side is fault. There are several connections that you have to cut on fault side: CKV1-CKVB1, CKV2-CKVB2, CKV3-CKVB3 and STVP.

V2-LCD/LED Screen Panel Repair Guide b) We know now which pair creates the fault on screen, solder back all resistors and let"s find on what side (left or right) is the defective SR block. If, for example CKV1-CKVB1 pair is fault, we will disconnect the signal from left side of the screen (if you could see with a magnifier where is the fault, cut connections on fault side) We will disconnect left side because we have more space to re-connect the signals if there is no problem on this side, and the fault is on the right side. Cut the signals’ corresponding that goes on left side of the screen: IF PAIR CKV1-CKVB1 faults, cut signals as in image below:

(4.12) Panel Screen: LTF320HM01, LTA320HM03 T-CON: LJ94- 03256H (F 60M B4C2LV0. 6) Fault: Image trembling, flickering, double vertically or horizontal lines are on whole/partial of the screen. This panel have 4 pairs of high voltage scan drive gate signals: CKV1-4 and inverse signals CKVB1-4. There are 2 x Level Shifter IC"s, MAX17121E. http://www.LCDRepairGuide.com/screen-repair-v2/

(4.13) Panel Screen: LTJ400HV01-J T-CON: SH120PMB4SV0.3 Fault: Image trembling, double vertically, horizontal lines on all/partial screen USED ON Samsung 3D TV, D series, Class 6-8 (EX: UE40D6530). Repair procedure: First step is to find which part of the screen is fault. Disconnect left FFC between T-con and left PCB and power the tv. If you have now on right part of the screen a normal image, means that you have a fault in left side of the cell. If still a fault image, re-connect the left FFC and disconnect right FFC between T-con and left PCB and power the tv. If you have now on left part of the screen a normal image, means that you have a fault in right side of the cell. On upper image, there is a problem in the right side gate screen driver. NOW WE KNOW WHICH GATE DRIVER FAULTS (LEFT OR RIGHT), so we will step in with repair, only on fault side.

COF BoardView List In my previous ebook: LCD/LED Screen Panel Repair Guide, I called it as: TAB/COF Bypass List. But for more accurate to describe this feature for the TAB/COF photo, I think it is similar like the Laptop schematic BoardView file. So I decided to call it as “COF BoardView”. This repair information is quite important to the TV Panel repairer. Even they have the TAB Bonding Machine in their workbench. If that panel Gate signals & voltage lines opened circuit in the half way of it, the TAB Bonding Machine also cannot help. Especially some panel broken cases, like the panel glass crack their edge side of the Gate lines. Causing some Gate signals & voltage lines broken. So we can use this COF BoardView to connect back their signals and voltage lines from T-con board to their Gate COF. If you need to increase the success rate to repair the panel through this method, you need to have these tools before start to repair the panel: 1) A good and sharp/fine needle tip of Soldering Iron and quality flux. 2) Magnifier- No matter what brands or type of this magnifier, at least it can help you to see the Gate signals & voltage lines clearly. 3) Thin copper wire (0.1mm): Normally use it in Laptop mainboard repair.

LCD Panel TAB/COF Equivalent List This equivalent list is to let you easily find out a replacement TAB or COF IC when the original TAB/COF is not available or no stock. It is a common issue for the TAB Bonding Machine owner. Even they have the expensive TAB Bonding Machine in their workbench, if the failure COF IC is not available or no stock, it will quite frustration. Because we use lots of time to bring in this TV, dismantle the TV cover, PCB board and troubleshooting time, but the part is not available or no stock. So the repairer will waste lots of time and money or even reduce the repair income too. So this TAB/COF Equivalent List is to let repairer easily to find out the suitable replacement TAB/COF IC for their Panel repair. Note-1: 1) Some of the replacement COF maybe a bit longer than original COF. But it can use as an equivalent COF, just need to readjust their pins position to the right place and you need to cut out some unused area before bonding the TAB into glass & PCB board. 2) If after replace one of their Gate COF and showing an abnormal display, a very thin of the horizontal line or half horizontal top more brighter than the bottom half horizontal area, that’s mean, you need to replace the other Gate COF together with the equivalent part number Gate COF. For example, if this TV Panel has 3 Gate COF (Y1, Y2 & Y3), then you cannot just replace one COF only (for example Y1), you need to replace together with another same part number 2 Y-COF (Y2 & Y3) also. If you can find the original part number of this Y-COF, so the other two Y-COF no need to replace. This will also same as the X-COF/TAB (Source Driver Board) too.

V2-LCD/LED Screen Panel Repair Guide How do I know the GAMMA IC & DC-DC IC is programmable type? This is a good question. Every year, the manufacturers will production new part number of P-GAMMA & DC-DC IC. So how do I know which IC is a programmable type P-GAMMA & DC-DC IC? The answer is: 1) Check their IC datasheet file, normally the datasheet IC description there will write it as a “Programmable” xxxxxx IC. 2) The IC datasheet pins description there if you found have these pins: SDA & SCL inside the IC. You can refer to picture below:

V2-LCD/LED Screen Panel Repair Guide 5) If you’ve bought the RT809F programmer, just simply look at the software there. If you found this IC was in the IC list there, that’s mean, it’s a Programmable type IC! Note: These IC are no need to write/programming the firmware into the IC: TPS65160, TPS65161, TPS65162, TPS65167 and so on.

How to Programming/Write the T-CON Board P-GAMMA & DC-DC IC? 1) First, you need to buy a RT809F (or H) ISP Universal Programmer (you can order it at: http://www.lcdrepairguide.com/tools/ ) and install it correct in your computer or laptop. 2) You need to create a “cable” and DIY it to suitable for your Programmer to connect to the T-CON board. Just use the LVDS cable with 51-pins connector like picture below to DIY it:

3) Please prepare the working “firmware” to write it to the IC you want. But the IC firmware must use the same T-CON & Panel. Even the Programmable IC and T-CON board both same, but the T-con Board is using in different inches Panel, so the firmware is cannot be used. Even it is the same programmable IC.

V2-LCD/LED Screen Panel Repair Guide If the programmable IC & T-CON board both same, same Panel size but different Panel model number, then you can give it a try, but not guarantee. So where to get this programmable IC “firmware”? a) You can use the Programmer to copy it from a good T-CON board. b) Ask the other repairer to help on the forum site or social media. c) Buying this “firmware” online, if you can find who are selling it.

T-CON Board P-GAMMA & DC-DC IC Programming Tutorials For the programmable IC pins configuration, please refer to the IC specification datasheet or the list: “T-CON Board P-GAMMA & DC-DC IC Read/Write Pins List”. 1) BUF16821 P-GAMMA IC The T-CON board 6870C-3500C is come with this BUF16821 IC. This T-CON board is usually using in LG 32~55 inches TV. This GAMMA IC inside ROM has two BANKS. Normally just use 1 BANK only. The BUF16821 IC pin-14= SCL and pin-15= SDA usually is connect to the T-con Board LVDS connector pin-4= SDA and pin-5= SCL. IC BUF16821 pin-16= AO must connect to GND (use multimeter/ohm meter to measure it), pin-17= BKSEL (default setting is connected to ground). Use a DIY 51-pins LG32~52 inches LVDS cable with 51-pins connector, one side connect to RT809F programmer socket pin-6= SCL, http://www.LCDRepairGuide.com/screen-repair-v2/

V2-LCD/LED Screen Panel Repair Guide pin-7= SDA, pin-8= GND. Another side is connected to T-CON board LVDS connector (for T-con board 6870C-3500C) pin-4= SDA, pin-5= SCL and connect the GND pins. The DIY LVDS cable Vcc input one side connects to 12V DC Power Supply. Another side is connecting to the T-CON Board LVDS connector VCC input pin/s.

Attention: Actually you can just use the cables direct connect to their IC pins and supply the Vcc 12V to their T-con Vcc input. After that, this cable is connects to the RT809F programmer and do the write/programming IC. So it will depend on which method you’re feeling better to use, and then just use it (also for the other Programmable IC tutorials too). Notes: a) Please refer to their Panel datasheet or T-CON Board LVDS connector for the correct VCC voltage values & pins configuration (also for the other Programmable IC tutorials too).

V2-LCD/LED Screen Panel Repair Guide b) This BUF16821 IC has a limit times to their each BANK to write/programming. Maximum per BANK is limit to 16 times. But read/copy is unlimited times to the IC. When the IC reached 16 times to write/programming, the RT809F software will show “Checksum Error” message on screen and it is because the IC itself has blocking it. If this IC has two BANKS, then we can disconnect their BKSEL pin from ground (GND) and connect it to 3V (active high). The IC will automatically change to another BANK to save the data. So for the new BANK, we can continue to write/programming another 16 times again. c) If unsuccessful to write/programming the IC, please double check the above connection and also their VS and VSD voltage range is in the normal values or not.

2) TPS65178 DC-DC IC The T-CON board 6870C-0401B is come with this TPS65178 IC. This T-CON board is usually using in LG 32~55 inches TV. This DC-DC IC inside has built-in an EEPROM with a limitation allow to WRITE 16 times only. The connection of the T-CON board (SDA & SCL lines) and RT809F Programmer is same as the BUF16821 IC. The TPS65175 & TPS65168 also use the same method like TPS6178 IC to do write/programming the programmable IC. Notes: a) Please refer to their Panel datasheet or T-CON Board LVDS connector for the correct VCC voltage values & pins configuration (also for the other Programmable IC tutorials too).

V2-LCD/LED Screen Panel Repair Guide b) Because of this TPS65178 has 1 EEPROM built-in, so don’t write/programming this IC more than 16 times. If not, it will cause the write/programming fail or checksum error appear and can’t write/programming the new data/firmware into it. But reading IC is unlimited times to use. c) Inside the RT809F software, you will found a button call “Restore”. When this IC TPS65178 connected successfully on RT809F, if click on this “Restore” button, the software can help this IC reset to their default voltage output setting like below: VCC: 3.3V Vcore: 1.8V VDD: 16V VGH: 25.8V VGL: -5V VCOM: 7.3V d) The TPS65168 IC after click on “Restore” button, IC will reset to their default voltage output setting like below: VCC: 3.3V Vcore: 1.0V VDD: 16V VGH: 25.7V VGL: -5.24V VCOM: 8V

V2-LCD/LED Screen Panel Repair Guide 3) ISL24837A P-GAMMA IC The T-CON board: Sharp RUNTK_5317TP_0075FV is come with this ISL24837A IC. This T-CON board also can use the 51-pins LVDS cable to do the write/programming as usually using in LG 32~55 inches TV. This GAMMA IC inside has built-in an EEPROM (260-bits) with a limitation allow to WRITE/PROGRAMMING not more than 300 times only. The connection of the T-CON board (SDA & SCL lines) and RT809F Programmer is same as the BUF16821 IC. But the pin number is a bit different. The DIY 51-pins LVDS cable connector pin-2 is SDA, pin-3 is SCL and pin-1 is GND. Also don’t forget to provide 12V to their VCC input pin/s.

V2-LCD/LED Screen Panel Repair Guide RT809F Software Programming Programmable IC Process 1) Connect the RT809F Programmer with T-CON Board through DIY 51pins LG32~55 Inches LVDS Cable. You can refer to the above Programmable IC tutorial. Double check all the connection and supply the correct voltages to the VCC pin/s. 2) Open RT809F software. 3) Click on the AUTO ISP button, it will detected the programmable IC and it will pop-up a screen with Programmable IC list. 4) Choose the correct Programmable IC part number and click OK. 5) After select Programmable IC, click on the “READ” button to start reading the Programmable IC data/firmware. 6) After finished successful reading the Programmable IC, you can click on the “SAVE” button to copy this data/firmware into your computer or laptop. 7) If you want to WRITE/PROGRAMMING the programmable IC, click on the “OPEN” button and go to the computer folder to select the correct part number (also other part number/model same information). Click on the “WRITE” button to write/programming Programmable IC. 8) If finished successful to write/programming the Programmable IC, it will show “Checksum” ok/success. 9) So you can remove all the cable and connector and put it back the T-CON board to TV and give it a try. Good luck!

V2-LCD/LED Screen Panel Repair Guide Because this type of programmable IC also like the normal EEPROM IC, their data will easy to lost due to any environment issues too.

Download the T-CON Board P-GAMMA IC & DC-DC IC Data/Firmware I’ve attached some of the T-CON Board P-GAMMA IC & DC-DC IC data configuration/firmware files at Bonus-B section there. Here is the firmware list: AUO-G1422.2H_T315HW07_VB BUF8821B_LC320WXN-SBA1_6870C-0238B BUF16821_LG T-CON Board_6870C-3500C BUF16821B_LC320WUD_T-CON_6870C-0249C BUF16821B_LG_LC420WUE Panel PCB CM601_CHIMEI INNOLUX_V390HJ1-CE1_CM2805A CM601_CHIMEI INNOLUX_V420HJ1-P01_REV.C1 CM602_CHIMEI INNOLUX_V236H3-CS3-C_CM602 DS3501_LG LM240WU3-TLC1_6870C-0221A EPM3064A_LC370WX1_T-CON_6870C-0060G ISL24837A_SHARP_RUNTK_5317TP_0075FV_T-CON MAX9668_LC320EXN 6870C-0370A 2010_11_03 MAX9668_LC320EXN_6870C-0370A.BIN MAX9668_LC320EXN-SEA1-K31 6870C-0414A 2011_11_04 MAX9668_LG LC420WUN-SCA1 6870C-0310C 2010_01_19 MAX9668_LG LC420WUN-SCA1_T-CON_6870C-0310C MAX9669_CHIMEI-E150630-V460H1-C11

V2-LCD/LED Screen Panel Repair Guide MAX9674_CHIMEI-E150630-V460H1-CPE5 SM4051D_LG500DUE-SFR1_6870C-0452A SM4053B_LG T-CON Board_6870C-0488A SW508A_LG T-CON Board_6870C-0480A TPS65168_LG Panel with T-CON_6870C-0369C_VER0.2 TPS65175A_LG T-CON Board_6870C-0471D TPS65178A_LG Panel with T-CON_6870C-0401B

ATTENTION: This is very important! Before you do the write/programming programmable IC, you MUST first to “COPY” and save their original data/firmware into your computer/laptop. After that, you can write a new data/firmware into the programmable IC. Also find the data/firmware with correct programmable IC part number, T-CON Board p/n and same “Inches” of the LCD/LED Panel (or model).

Troubleshooting & Repairing Hisense RSAG7.820.5129 T-CON Board This T-CON board schematic diagram was included in this ebook. The RSAG7.820.5129 T-CON board is widely used in these HISENSE TV Model: HE390GF-B51, HE460HFR-B51, HE500HF-B52 and HE500HFR-B52. All the above TV is using this T-CON board, but their program/firmware is different only.

V2-LCD/LED Screen Panel Repair Guide b) 3.3V Voltage out of the normal range: Commonly it’s their CN2 or RN2 failure. 4) Module D & E => Is T-CON IC and DDR buffer IC. T-CON IC

How to know this IC is working or not? Use multimeter/voltmeter to measure the LC_L1 point, if the voltage range is in between 25V and -6V change, that’s mean this IC is working normally. If not, then this IC is abnormal. 6) Module-H => Panel Voltage Generated Circuit (VDDD/AVDDA1/VGL)

V2-LCD/LED Screen Panel Repair Guide Common Fault: a) VDDD/VDDA/VGL no output voltage. The TV screen is no display but the backlight is lit: NN3 IC damage causes the VDDD/VDDA/VGL no output voltage. Check the NN3 pin-15 & 16 both pins is it short circuit. If yes, that’s mean the IC NN3 is damage and need to replace. b) When connect to Panel, the inductor noisy, screen display has horizontal line interference: Normally it is the CN212 failure.

V2-LCD/LED Screen Panel Repair Guide Other Common Faults in this T-CON Board 1) Dry Soldering Joint or Pins Shorted Display Symptom Left side screen no display or abnormal display

V2-LCD/LED Screen Panel Repair Guide 2) Gate/Source COF Problem (Glass Cell Problem) This type of screen problem is not repairable, unless you’ve TAB bonding machine. If their ITO line/s defective inside the screen glass then this type of problem is beyond repair.

This GOA horizontal line evenly spaced (vertical 6 pixels). The Panel itself defective or the T-CON board Module-F (NN19 or NN21- RT8922) failure also can causing this type of screen problem. Check the IC NN19 or NN21 pins have dry soldering joint or not. If soldering ok and just replace this IC.

Mostly, this type of screen problem is causing by the T-CON IC, Especially the production before 1240, their T-CON IC is the common fault. http://www.LCDRepairGuide.com/screen-repair-v2/

V2-LCD/LED Screen Panel Repair Guide This problem is causing by the T-CON IC NT71790. Especially the TCON Board production batch before 1240. 8) No Display/ Grey Display (Backlight Lit) a) The PMU circuit abnormal (Module H), NN3 (AAT1133) abnormal and causing the VDDD/AVDDA1/VGL no output or output abnormal voltages. Replace NN3 IC. b) Gamma circuit abnormal (Module-A). If Gamma IC output voltage abnormal, the output voltage range is about 6.7V~ 7.0V. Replace Gamma IC (iML7991D). c) NN1 dry soldering joint inside the bottom of this T-CON IC. Because of this IC is BGA package type, so we can use the oscilloscope to check their STV, LC, TP, POL & etc control signals waveform to confirm the T-CON IC is ok or not. If these signals got output, then this IC is Ok, if not, then it is T-CON IC failure.

LCD/LED TV Display Problem Repair Tips 1) TV Model: Changhong LT32710 LCD TV T-CON Board: T-con (CHIMEI) section was built-in TV Mainboard Mainboard Chassis: LS23 Symptom: Screen Fully of Vertical Color Bars

Repair/Solution: This LCD TV T-CON section was built-in the TV Mainboard. Check their Tcon section each output voltages from U26: TPS65161 (DC-DC IC) and found their VDD25 output voltage is just 1.36V only. Normally this VDD voltage should be 2.5V. This VDD 2.5V was generate by DC-DC IC U26 pin-18 through D55, L24, CA44 filter and get VDD 2.5V. After that the R339, R348 and R272 is the VDD sampling resistors and feedback to U26 pin-15 to control the VDD voltage output. After checking these component and found the R348 (24K ohm 1%)

V2-LCD/LED Screen Panel Repair Guide ohm values increase to 40K ohm! Replace this resistor and the VDD output voltage is back to normal 2.5V. Finally this TV screen problem solved!

V2-LCD/LED Screen Panel Repair Guide Symptom: Display full of horizontal lines with bright and dark flashing. It also can see some irregular vertical bars. Repair/Solution: This TV backlight is steady lit and no any flashing. Use the LCD/LED Panel Tester check and found that’s the LCD Panel or T-CON board problem. This TV Panel T-con board is using the A60MB4C2LV0.2 like picture below:

V2-LCD/LED Screen Panel Repair Guide Repair/Solution: The TV backlight is lit normally. Check their T-CON board and this PCB board was built-in the Panel glass. Found the VGH voltage line is 0V only! Continue to check their corresponding components especially smd filter capacitor C240, C241, C242, C243 & D2. Found the C240 shorted circuit. After replace with a good SMD capacitor, the TV is back to normal now. Note: VGH voltage abnormal, commonly was causing by MOSFET opened circuit, capacitor shorted/leakage or shorted DC-DCIC.

V2-LCD/LED Screen Panel Repair Guide 5) TV Model: Haier LE32A700, LE32A720, LE32A910, LH32E10 LED TV T-CON Board: HV320WXC-200-X-PCB-X0.0 Panel Model: H320EHC-BB2, H320HC-YB30 Symptom: Display White Screen or Blue Screen without any characters on screen. Repair/Solution: Most of the time this model of Panel come with the problem mention the above is causing by abnormal VGH voltage in VGH line. So first step is check the VGH line until the X-COF contact pin there still has the VGH: 27V. After that check their first Gate COF and found VGH voltage missing. For Gate COF: 8659-F

6) TV Model: Haier LE48A5000, LE48M6000, LE48AL88 & LH48UH3200 LED TV T-CON Board: Samsung 13NVB_S60TMB4C4LV0.0 Panel Model: Symptom: Various problems occur in this T-CON Board.

V2-LCD/LED Screen Panel Repair Guide Repair/Solution: Because of their SMD filter capacitors often have leakage or shorted circuit on the T-CON Board.

V2-LCD/LED Screen Panel Repair Guide Repair/Solution: Use the LCD/LED Panel Tester to testing it and found their screen Panel is ok. So the problem is on the Mainboard. The sound and the other features are working properly. Check their Mainboard LVDS connector output signals with oscilloscope and found several pairs of video signals is missing. Suspect the LVDS connector (XS501) pins dry solder joint problem.

8) TV Model: Skyworth 32L08HR LCD TV T-CON Board: V315B3-L01REV.C1 Panel Model: Symptom: Display become white screen and has some vertical bars. After a while, the vertical bars will slowly increase their quantity. Their vertical bars are not fixed and it will change randomly.

Repair/Solution: Use the LCD/LED Panel Tester testing it and found the problem is on the TCON or Panel. Check the T-CON board each output voltages, and found the VGH is just has 0.44V only! So the problem is on the VGH voltage line.

V2-LCD/LED Screen Panel Repair Guide The VGH voltage is output from the P-Channel MOSFET QP8 pin-D (Drain). Check the QP8 pin-S (Source) has 22.3V and it is normal. From the above schematic diagram, the QP8 pin-G (Gate) is control by QP7 (2N7002DW, 2 x N-Channel MOSFET 6-pins SMD and marking code is: 702). Check the QP7 pin-2 has 2.45V, but QP7 pin-6 has 22.1V! So suspect the QP7 one of the N-Channel MOSFET has opened circuit. Solder a wire from QP7 pin-6 to GND and then power on the TV. All the vertical bars are gone and the TV display back to normal now. So confirm the problem is QP7 one of their MOSFET was opened circuit. Because this QP7 6-pin SMD type is not available in my stock, so just use a normal 3-pin N-Channel SMD 2N7002 solder to the correct pins. Finally this problem solved! Note: This T-CON board their VGHP voltage line filter capacitor CP19 or CP43, when its leakage, it will pull it down 2~3V of the VGHP voltage. And generate the same display problem like the above TV screen problem too.

*For searching the training manuals, service manuals or schematic diagram, please join the LED/LCD Television repair membership, highly recommended: Http://www.LCD-Television-Repair.com

Bonus-A LG OLED/LED/LCD TV Interconnect Schematic Diagrams 32LS3500-Interconnect_2012_Interconnect ………….………..148 37LK450-Interconnect_2011_Interconnect ……………….……151 42CS560-Interconnect_2012_Interconnect ……….……………163 42LG60-Interconnect2_2008_Interconnect …………….………170 42LG60-Interconnect_2008_Interconnect ……………………..172 43LJ5000-Interconnect-Mainboard_2017_Interconnect ……….174 47LV4400-Interconnect_MB Built-In T-con_Interconnect…… 178 49UH6100-Interconnect_2016_Interconnect ……………..……184 55UF7600-Interconnect-Mainboard_2015_Interconnect ……....185 65UH5500-Interconnect-Mainboard_2016-2017_Interconnect…191

T-Con Board Schematic/Circuit Diagrams HISENSE RSAG7.820.5129 T-CON Board Schematic……………...…..195 HISENSE RSAG7-820-4159 T-CON Board with LED32K16 TV HE315DH-B11……………………………………………………..203 SKYWORTH 5800-TCON6-0P10 T-CON Board Schematic…………...208

SMPS TEST 1 : Forcing SMPS On. 22 Remove AC Power. 21 Jumper Disconnect P401 on Main Board. 20 Jump pin 1 (PWR_ON) to pin 9, 10, 11 or 12 . Apply AC Power. This should force the SMPS to 19 the on state. All Voltages should be produced. 18 Test 1 (24V and 12V to Main, 24V to the Backlight LED 17 Driver Board). 41V Backlight Power. 13-16 Backlights are on. 9-12 Disconnect AC Power.

LED BLOCK TEST Using a 220Ω resistor one end on Ground The other end on any of the OUT lines will turn on the backlight block. (Providing the 41V is present J2 pin 1)

LED

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey