tft lcd displays matrix lcds brands

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

What we are talking about TFT LCD, it is a LCD that uses TFT technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments without TFT in each pixel.

The TN type TFT LCD display is one of the oldest and lowest cost type of LCD display technology. TN TFT LCD displays have the advantages of fast response times, but its main advantages are poor color reproduction and narrow viewing angles. Colors will shift with the viewing angle. To make things worse, it has a viewing angle with gray scale inversion issue. Scientist and engineers took great effort trying to resolve the main genetic issues. Now, TN displays can look significantly better than older TN displays from decades earlier, but overall TN TFT LCD display has inferior viewing angles and poor color in comparison to other TFT LCD technologies.

IPS TFT LCD display was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels. Its name comes from its in-cell twist/switch difference compared with TN LCD panels.The liquid crystal molecules move parallel to the panel plane instead of perpendicular to it. This change reduces the amount of light scattering in the matrix, which gives IPS its characteristic of much improved wide viewing angles and color reproduction. But IPS TFT display has the disadvantages of lower panel transmission rate and higher production cost compared withTN type TFT displays, but these flaws can’t prevent it to be used in high end display applications which need superior color, contrast, viewing angle and crispy images.

The mono-domain VA technology is widely used for monochrome LCD displays to provide pure black background and better contrast, its uniformly alignment of the liquid crystal molecules makes the brightness changing with the viewing angle.

MVA solves this problem by causing the liquid crystal molecules to have more than one direction on a single pixel. This is done by dividing the pixel into two or four regions – called domains – and by using protrusions on the glass surfaces to pretilt the liquid crystal molecules in the different directions. In this way, the brightness of the LCD display can be made to appear uniform over a wide range of viewing angles.

This is an LCD technology derived from the IPS by Boe-Hydis of Korea. Known as fringe field switching (FFS) until 2003, advanced fringe field switching is a technology similar to IPS offering superior performance and color gamut with high luminosity. Color shift and deviation caused by light leakage is corrected by optimizing the white gamut, which also enhances white/grey reproduction. AFFS is developed by Hydis Technologies Co., Ltd, Korea (formally Hyundai Electronics, LCD Task Force).

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan’s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation. (Reference)

The AFFS is similar to the IPS in concept; both align the crystal molecules in a parallel-to-substrate manner, improving viewing angles. However, the AFFS is more advanced and can better optimize power consumption. Most notably, AFFS has high transmittance, meaning that less of the light energy is absorbed within the liquid crystal layer and more is transmitted towards the surface. IPS TFT LCDs typically have lower transmittances, hence the need for the brighter backlight. This transmittance difference is rooted in the AFFS’s compact, maximized active cell space beneath each pixel.

From their discovery in 1888 to their first application within displays in the 1960s, liquid crystals have become a mainstream material choice with many impactful applications in the world of electronics.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

TFTs can be formed by amorphous silicon (denoted α-Si TFT), by poly-crystalline silicon (LTPS for Low Temperature Poly Silicon), or by semiconducting metal oxides (Ox-TFT or IGZO-TFT for Indium Gallium Zinc Oxide).

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

The above display technologies have liquid crystal molecules that are aligned nearly parallel to the display surface with more or less twisting when going from one substrate to the other. In VA (also called VAN) displays, the liquid crystal molecules are aligned vertically with respect to the display surface. Applying a voltage causes the molecules to lay flat, with or without twist.

The advantage of this arrangement is a very dark black state with very little light leakage. This allows making displays with a black mask and colored icons or symbols. These displays look like color displays with brilliant colors, however each image element or icon can only have its assigned color or black.

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

The integrated circuit is a patterned piece of silicon or other type of semiconducting material. A modern IC contains millions or even billions of tiny transistors. Their tiny size allows for the fabrication of smaller, faster, more efficient, and less expensive electronic circuits. The driver chips addressing electronics displays are ICs.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

Low Voltage Differential Signaling (LVDS) is an interface to the display, not a display technology itself. This technology is not specific to displays, as it’s used in many other applications as well. It’s a high-speed signal that provides some noise immunity for the display. It also allows for longer distances compared to parallel interfaces.

For product design engineers and manufacturers, a custom display and touch solution is the best approach to meet their unique application needs. Turning to us to be your monochrome LCD manufacturer means you’ll gain the experience and expertise of our in-house engineering team. Our talented engineers can develop customized solutions using a wide range of LCD technologies:Custom TN LCD displays

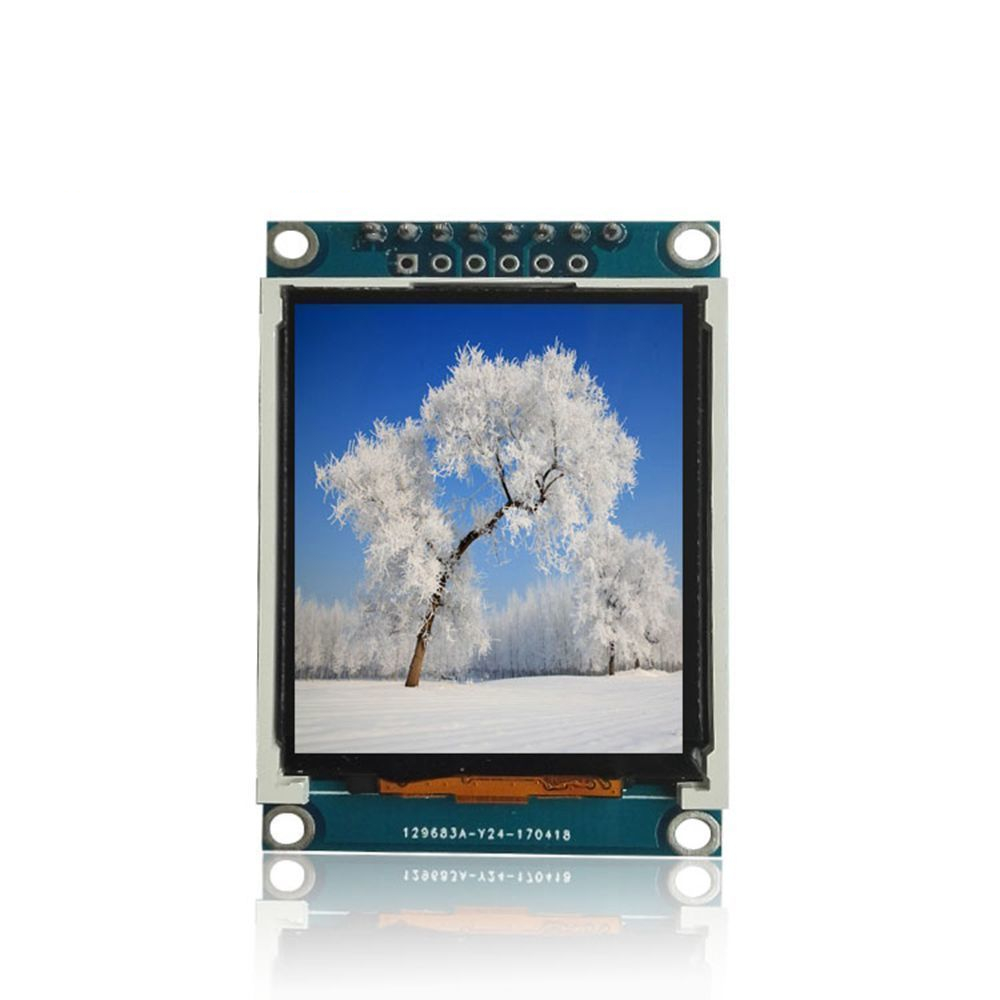

Thin Film Transistor or TFT screens are active-matrix LCDs capable of controlling individual pixels on the screen. Thus, they assure better visibility than other variants. These flat-panel displays are suitable for a variety of applications owing to their wide range of beneficial features.

Round TFT LCDs are gaining popularity as they have become a perfect replacement for analog gauges, and they help make any application look versatile. Microtips Technology has introduced a new 3.4-inch round display, with a high resolution of 800 x 800 pixels.

TFT (Thin Film Transistor) is a thin-film field-effect transistor display that is designed to visualize millions of clear, bright, and high-contrast color pixels. Over the years, this display has gained immense popularity owing to its several benefits.

The 7 inch low-cost color display is one of the most popular touch screen displays available for raspberry pi, HDMI display screen and other mini PCs. Featuring IPS screen with larger visible angle and more clear display effect, this 7 inch display with touch screen can be used in all environmental conditions because of its wide temperature liquid crystal fluid.

Microtips Technology has introduced a high brightness High-Definition Multimedia Interface (HDMI) interface IPS TFT LCD module. These modules are compatible and assure seamless interface with any version of Raspberry Pi Single Board Computers (SBCs), PCs, or devices such as HDTV, DVD player, or any device that is compatible with HDMI.

AMOLED stands for Active Matric Organic Light Emitting Diodes. This technology is environmentally friendly, and commonly used in small but complex electronic devices such as handheld instruments, meters, and smart watches. This technology is a very fine combination or OLED plus active matrix.

AMOLED (stands for Active Matrix Organic Light Emitting Diodes) display is one of the best screen technologies popularly used in today’s laptop screens and PC monitors and high-end smart phones.

The Thin-Film-Transistor display (TFT display) is an active matrix display where each pixel of the flat panel is illuminated individually. In recent times, TFT display is increasingly used in the electronics industry owing to its several benefits.

Microtips Technology, one of the leading 5-inch color TFT display module manufacturers, has introduced the new low-cost 5-inch color TFT display. The thin film transistor (TFT) technology is just another variant of the LCD technology.

Thin-film transistor (TFT) LCD displays assure improved image quality over traditional LCD displays. They offer more control over colors and images, and require less power than other technologies.

Microptips Technology has introduced a 3.9" bar type TFT display that has a high contrast ratio. This panoramic 3.9 inch RGB bar TFT LCD comes with a resolution of 480x128 pixels. This display is suitable for several modern electronic appliances like server and audio systems, auto/marine equipment, advertising displays, drone controls and many more.

Microtips Technology, one of the leading 4.3-inch TFT LCD module manufacturers, has introduced the new low-cost 4.3-inch TFT display. TFT or thin film transistor is primarily a variant of the LCD technology. TFTs are active matrix LCDs, which help improve contrast, color, and picture quality.

Thin-Film- Transistor displays or TFT displays are active matrix LCD displays that assure better color perception than regular Twisted Nematic LCDs. The demand for TFT displays has increased in recent years owing to several advantages they offer. These displays assure a clear view from any angle, and they can display millions of bright color pixels.

Microtips is proud to announce a new line of HDMI Displays designed to work seamlessly with development boards and computers like the Raspberry Pi. This video outlines our current options for these displays...

Microtips is excited to announce our 10.1”, high bright, TFT display with increased resolution and widened viewing angles. This 10.1”, WXGA 1280*800 TFT display is an IPS panel equipped with an HDMI signal input...

Microtips Technology is excited to announce our In-Cell technology for segment type LCDs. This is due to the fact that consumer electronics are becoming thinner and lighter

Simple monochrome displays, like 7 Segments & Icons, have been around for a very long time. These displays are still widely used by customers in wide variety of industries. But have you thought about Color TN Displays instead?

Regional Sales Manager, George, explains OLED Displays, their benefits, and other characteristics that make them better than standard Liquid Crystal Displays for some applications.

TFT or thin film transistor is a variant of the LCD technology. TFTs are active matrix LCDs, which help improve contrast, color, and picture quality. Thin film transistors are used along with capacitors to improve image quality in many electronic devices. Owing to their several advantages, these TFT displays are available in various specifications. The 4.3 inch TFT display is one of the most popular among them. The 4.3-inch TFT LCD display module touch screen has a resolution of 480X272 with an RGB interface. This display finds applications in mobile phones, cars, embedded systems, and certain industrial equipment among others. There are many 4.3-inch TFT LCD module manufacturers making this display; however, certain features may slightly differ based on the manufacturer. However, it is essential that you source it from a reliable manufacturer. Microtips Technology, one of the leading 4.3-inch TFT LCD module manufacturers, offers the new low-cost 4.3-inch TFT display. This post discusses the common features, working, and benefits of using this new low cost 4.3-inch TFT LCD display module touch screen provided by Microtips.

As mentioned, TFT is a subset of the LCD technology. TFT is an active matrix display. There are active matrix displays and passive matrix displays used in LCD flat panels of computers, phones, and so on. The images produced by active matrix are responsive and enable a wider angle of view compared to passive matrix display. Passive matrix displays, on the other hand, use a grid of horizontal and vertical wires to display an image. In this case, the charge of two wires is altered to change a pixel at intersection. The response time of producing an image with the passive matrix technology is much slower than active matrix. Also, at times, the image quality produced by passive matrix is blurred and pixelated. Active matrix, in comparison, offers many more advantages and a fine image quality, and hence is widely used in making 4.3-inch TFT LCD display module touch screens. The pixels on the TFT screen are arranged in a row-column configuration. The glass panel has an amorphous silicon transistor on which the pixels are attached. This enables each pixel to get a new charge and keep it consistent even after the screen is refreshed to load a new image. So, each pixel continues to be in its maintained state when other pixels are being used. This is one reason why this technology is called active matrix.

Interface: The display interface helps humans exchange information with software. For instance, you need to control color, brightness, and other parameters as there are many interface options. This display has RGB interface and a TFT-LCD display type.

Response Time: This indicates the time in which you receive a response on your command, with tough screens it is much faster than typing a command. Once you touch the screen, most 4.3-inch TFT LCD display module touch screens respond in 15ms.

Active Area: Most 4.3-inch TFT LCD module manufacturers make this display with an active area of 95.04X53.86 mm and pixel pitch of 0.198(W) x0.198(H)mm.

Operating Temperature Range: Most displays are designed to function accurately in harsh environments and weather. These displays usually have an operating temperature ranging from -20 to +70 degrees Celsius.

Suited for Advanced Applications: These displays are suitable for car system scree, industrial systems and equipment, and mobile phones among others

Figures 3a–d show optical and SEM (scanning electron microscopy) images of the fabricated CL and CLSE pixel structures. Each structure has the same pixel size (80 μm × 240 μm) and minimum pattern size (5 μm). As shown in Fig. 3d, the white line patterns are the ITO interdigitated pixel and common electrodes. They are well connected to the source electrode and gate line via through holes, and the common electrodes at both ends cover the underlying data lines to prevent electrical noise from being applied to the LC layer. As will be shown later, this noise shield electrode (SE) is what makes the black matrix above the data line unnecessary

Optical and SEM (scanning electron microscopy) images of fabricated (a, b) CL and (c, d) CLSE pixel structures. The five white line patterns in (d) are the ITO interdigitated pixel and common electrodes. (e) Images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel. (f) The three-black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM) and (g) optical images of pixels without BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines).

Figure 3e shows images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel fabricated in our laboratory, (f) the three black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM), and (g) optical images of panel areas without the BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines). As can be seen in the image from the normal direction, the brightness and contrast of the display area with the top BM and middle BM patterns are almost the same, but the contrast of the display area without the BM is relatively lower because of the lower darkness level of the LC off pixels indicating “HITACHI”. As shown in Fig. 3g, this is due to light leaking through the aperture between the data line and adjacent common lines. Therefore, in the CL structure, the BM on the drain line is necessary to obtain a high contrast ratio by shielding light leakage. This is the same as in the conventional structure. On the contrary, there is no light leakage along the gate line through the gaps between the gate line and edges of the pixel/common electrodes, as is clearly shown in Fig. 3g. This is a unique advantage of the CL structure because the conventional structure must shield these gaps with the BM to prevent light leakage. The suppression of light leakage along the gate line in the CL structure is due to the driving scheme (see Fig. 2b,a for a comparison with the conventional structure). During the holding period (tOFF) in the conventional structure, regardless of the pixel voltage, Vp (including Vp = 0), nonzero Vgp and Vgc are always applied to keep the TFT off, and these voltages are applied to the LC layer, inducing light leakage as reported in

Figure 4a shows the gate voltage (Vg) dependence of the panel brightness, while the inset shows that of the TFT current (transfer characteristics). The gray curves are for the conventional IPS TFT-LCD with the TFT before enhancement, the common line, and the matrix BM (MBM) shown at the top of Fig. 3f. The blue curves are for the proposed CL structure with the enhanced TFT and the stripe BM (SBM) shown in the middle of Fig. 3f. In this case, enhanced TFT characteristics were obtained by using an MNOS TFT without back-channel oxidation that was enhanced by the BTS process. In both structures, the threshold voltages for panel brightness, defined by extrapolating the straight part of the brightness curves, reflect those of the TFT transfer curves defined as Vg at a drain current of 10−12 A, and they are well matched to be 4 V and 9 V, respectively. The maximum brightness for the CL structure is 137% higher than that for the conventional structure, which is due to the increase in the aperture ratio from 38 to 52% that results from the elimination of the common line and the BM covering the gate line.

(a) Dependence of panel brightness and TFT current on gate voltage for the conventional pixel structure of 38% aperture ratio (AR) with matrix black matrix (MBM) over both drain and gate lines and proposed CL pixel structure of 52% AR with strip black matrix (SBM) over only the drain lines. Transfer characteristics before and after bias temperature stress (BTS) treatment are shown in the inset. (b) Charging and (c) holding characteristics of enhanced TFT of the CL structure with gate as a common line. Vg and Vd in the TFT ON state are 30 V and +/−7 V, respectively.

To estimate the charging and holding characteristics of the MNOS-enhanced TFT in the panel, the gate TFT ON and OFF time dependences of the panel brightness were measured (Fig. 4b,c). The charging characteristics in Fig. 4b are plotted as a function of tON at tOFF = 16.6 ms, Vg = 30 V, and Vd = ± 7 V. The holding characteristics in Fig. 4c are plotted as a function of tOFF at tON = 34 μs. 95.1% charging at tON = 34 μs and 95.3% holding at tOFF = 16.6 ms indicate that the enhanced TFT has sufficient charging and holding performance to drive a standard VGA (640 × 480 pixels) panel (the number of scanning lines is estimated as tOFF/tON = 16.6/0.034 = 488).

To confirm the driving conditions for the CL structure without the BM along the gate line (with the SBM), the tOFF dependence of the contrast ratio (CR) in the CL panel was further investigated as shown in Fig. 5a, where CR is plotted as a function of tOFF for the CL panels with the matrix BM (MBM) and the strip BM (SBM). The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. The SBM and MBM panels keep CR higher than 240 with tOFF > 16.6 ms, the frame period of a display panel without flicker being noticeable to the human eye. both panels decrease CR when tOFF is less than 16.6 ms; the CR of the SBM panel decreases faster than the CR of the MBM panel. As shown in the inset, the decrease in CR was due to the increase in dark-state brightness with decreasing tOFF as light leakage increases along the gate line. This light leakage is induced by the voltage Vgp = Vgc = VgON = 30 V applied only for 34 μs during the TFT ON (charging) state, which is 1/488th the duration, tOFF = 16.6 ms, of the TFT OFF (holding) state with Vgp = Vgc = VgOFF = 0 V, but the ratio increases with decreasing tOFF and becomes effective enough to switch on LC layer and induce light leakage. However, it should be stressed again that the CL panel with the normal holding (TFT OFF) time of 16.6 ms does not suffer from the light leakage along the gate line, so the aperture ratio can be increased by removing the BM along the gate line.

(a) Contrast ratio (CR) for CL panels with matrix BM (MBM) and stripe BM (SBM) plotted as a function of tOFF. The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. Vd (= VLC) dependence of (b) brightness and (c) contrast ratio of the CLSE panel. Insets of (b): optical images indicating the elimination of the BM from the CLSE structure (upper left) and the MBM in the conventional structure (lower right). Insets of (c): CLSE panel composed of different areas with three different pixel structures and aperture ratios (ARs), i.e., CLSE structure without BM (60%), CL structure with SBM (52%), and conventional structure with MBM (38%).

Figure 6 indicates the effect of bias temperature stress (BTS) on the TFT characteristics. As the stressing time, tS, of the positive gate stress voltage, Vst = + 77 V, increases from 0 to 3600 s, the transfer (Id-Vg) curve shifts in the positive direction (Fig. 6a). Vth is defined as Vg at which Id = 10−12 A and ΔVth is defined as the Vth shift from the initial value via BTS. As shown in Fig. 6b, ΔVth increases logarithmically with increasing tS: ΔVth = 2.17 + 4.93 × log (tS). The mechanism behind the gate-stress-induced Vth shift is electron tunnel injection from the a-Si:H semiconductor into the SiOx gate insulator. For confirmation, ΔVth of MNOS TFTs with different SiOx thicknesses is plotted as a function of the electric field applied to the SiOx layer in Fig. 6c. Here, the thickness of the SiOx was varied (5, 10, 20, 50 nm), while the SiN thickness was fixed at 200 nm. The electric field applied to SiOx, Eox, was calculated using the following equation,

Effect of bias temperature stress (BTS) on TFT characteristics. (a) The transfer (Id–Vg) curve shifts in the positive direction with positive gate bias stress of Vst = + 77 V over the duration of 0–3600 s. (b) ΔVth, defined as the Vth shift from the initial value via BTS, increases logarithmically with increasing tS, following ΔVth = 2.17 + 4.93 × log (tS). (c) ΔVth of MNOS TFTs with different SiOx thicknesses from 5 to 50 nm as a function of the electric field applied to the SiOx layer.

Figure 7a shows the effect of back-channel oxidation (BCO) and passivation (PAS) on the Id-Vg characteristics of the MNOS TFT. The Id-Vg curve with Vth = 5.1 V is further enhanced to Vth = 10.9 V after BCO, although there is a slight degradation of the slope of the current increase in the sub-threshold region. The slope recovers after PAS without any change to the enhanced characteristics

(a) Effect of back-channel oxidation (BCO) and passivation (PAS) on Id–Vg characteristics of MNOS TFT. (b) Vth and Vth standard deviation, σVth, after BTS and after BCO without BTS treatments and (c) SiOX thickness as a function of position along gate-line, x.

The advantage of BCO over BTS is the uniformity of the enhanced characteristics; Fig. 7b shows the distribution of the enhanced Vth as a function of position along gate-line, x, for the MNOS TFTs connected with a 90-mm-long gate line in the TFT substrate after BTS and BCO treatments. The average value of Vth and the standard deviation, σVth, for pristine TFTs before BTS or BCO, are 5.1 V and 0.35 V, respectively. After BCO, Vth is uniformly enhanced, with an average Vth = 11 V and σVth = 0.4 V without increasing σVth. On the other hand, after BTS, Vth is nonuniformly enhanced with an average Vth = 9.3 V and σVth of 1.4 V. In particular, Vth increases linearly as a function of position along gate-line, x. As the gate SiOx thickness linearly decreases, from (54 nm) to (47 nm) with increasing x as shown in Fig. 7c, the increase in ΔVth after BTS with x is due to increase in the electric field applied to SiOx as shown in Fig. 6c and Eq. 1.

It has been shown that the Vth of the MNOS TFT is independent of the gate SiOx thickness when the thickness is more than 5 nm8a, Vth of the MNOS TFT with the BCO treatment becomes almost independent of the BCO SiOx thickness. As shown in the inset, the thickness of BCO SiOx composed of oxidized a-Si:H linearly increases with BCO processing time, and the Vth increase almost saturates at a BCO SiOx thickness greater than 5 nm. Therefore, the enhanced MNOS TFT after BCO has a uniformly high Vth that is robust to thickness fluctuations of the gate and BCO SiOx layers. BCO also has an advantage over BTS in terms of the stability of Vth as shown in Fig. 8b, which plots the annealing time dependence of Vth for BCO and BTS. In this experiment, the stoichiometry (x) of the gate SiOx was 1.78 for BTS and 1.78 and 1.9 for BCO. The annealing temperature in the N2 atmosphere was 200 °C. In the case of BTS, Vth decreased to the pristine value after approximately 5 h of annealing, while Vth decreased more slowly in the case of BCO. In particular, the annealing time required for Vth to fall to 7 V was 7.5 times longer than that of BTS. Increasing the stoichiometry (x) of the gate SiOx dramatically improved the BCO-enhanced Vth to as much as 11 V, which was stably maintained after 24 h of annealing at 200 °C.

(a) Dependence of Vth on thickness of back-channel oxidized (BCO) SiOX. The inset shows the SiOx thickness dependence on the BCO process time for RF powers of 200 W and 500 W. (b) Stability of Vth as a function of annealing time for three different TFTs with gate SiOx stoichiometry, x = 1.78 and bias temperature stress (BTS), x = 1.78 and BCO, and x = 1.9 and BCO. The temperature of annealing in the N2 atmosphere was 200 °C. (c) Band diagram of back-channel oxidized MNOS TFT. The red arrows show the electric dipoles at the SiOX/a-Si:H and a-Si:H/BCO SiOX interfaces.

A schematic band model for the MNOS TFT with the BCO treatment and the sectional structure of the interface between the a-Si:H and gate and BCO SiOx are shown in Fig. 8c. The uniformly high Vth that is independent of SiOx thickness is due to the dipoles generated at the channel and back-channel interfaces between a-Si:H and SiOx8 of reference

These wide viewing angle Small Format TFT LCDs with optional touch are industrial grade and cost competitive. Therefore these products are a popular display choice to integrate in many projects.

Using only high-tech factories that we partner with, we provide clients with the service of designing liquid crystal display panel (LCD) and liquid crystal display module(LCM), and is committed to the customized service, R&D, sales, after-sales service of display products. Our factories have hundreds of engineers focusing on creating the highest quality displays including monochrome LCD (TN, STN), colour LCD (CSTN and TFT), Custom LCD’s, LCD module (both COG* and COB*) which are widely used in mobile phones and many other applications.

Our state of the art factory produces High Resolution TFT glass panel cells, has TN, HTN, STN and TFT technologies for LCD panels. The Factory has class 1000 clean rooms, high accuracy bonding, pre bonding and heat seal machinery, many production lines specifically for TFT production, OCA and OCF bonding machines, In-House LCD glass cleansing process, output thousands of pieces per month.

Touchscreen overlay cover glass only available (so you do not have to purchase the display)These displays can come with: touchscreen components, touchscreen overlays, industrial touch screen,Wide LCDs, LED TFTs, and TFT Colour displays.

Other options are: LCD drivers, LVDS Touchscreen displays, automotive LCD Display, TFT high resolution screens, TFT LCD capacitive touchscreens, TFT capacitive touchscreens, high brightness LCDs, Letterbox Displays, small VGA Displays, LCD panel without backlights,Variations of our Small Format TFT LCDs include: TFT Display touchscreens, TFT IPS Display, monochrome displays, TFT or LCD, embedded components, LCD components, TFT Drivers, industrial range of Displays,

CDS also offers industrial TFT LCDs,Our displays are used in: touch screen vending machines, automotive touch screen displays, vending machine display panel, Touch screen vending, TFT Automotive, LCD Dislay panel kits, Touch screen TFT monitors, LCD Display components, LCD Screen components, and POS LCD Displays.As you can see from the tables above we have sizes including: 8.8 inches, 4.3 inch LCD Display, 10.1″ TFT LCD, 3.5 inch LCD Display, 4.3 inch display, 3.5 inch TFT LCD Display, 4.3″ screen, 7 inch LCD panel, 3 inch LCD Displays, and 4.3″ TFT LCDs as well as other small LCD Display screens.We have options on and equivalents to the following displays and TFT panel manufacturers: Raystar, Kingtech LCD, Digital View, OLED modules, OLED products, Powertip LCD Displays, Data Vision LCD, LG TFT Display, Tianma NLT, Powertip Displays, Mitsubishi LCD Displays, DMC components, Kyocera LCDs, NLT Technologies Ltd, Sharp LCD TFT modules, LCD manufacturers in the USA, PMOLED Displays, innolux display corp, Industrial touchscreens, A Grade TFT LCD Displays, Panoramic TFT Displays, Samsung TFT Displays, Touchscreen components, Transparent TFT Displays, Touchscreen components, TFT LCD controllers, as well as other TFT LCD manufacturers and Liquid crystal Display manufacturers.

CDS offers the widest range of displays and touchscreens including Abon touchscreens, Ampire LCD distributor, alternative Prisma interface baord supplier including Prisma iiia, Solomon Goldentek, Panasonic TFT, Winmate display, USB IO, and Apollo monitors

Our range includes AMOLED, circular displays, circular monitors, circular screens, circular TFT screens, round displays, Round TFT LCD displays, TFT AMOLEDs, TFT and IPS, TFT display interface microcontroller, TFT LCD or AMOLED, TFT LCD super AMOLED, WXGA TFT Displays, and WXGA TFT screens

As well as large format displays CDS also offers DSI TFT Display, large monochrome LCD displays, mono displays, mono OLEDC displays, mono TFT LCDs, monochrome displays, PCT Touchscreens, projected capacitive touch PCT technology, sq monitors and squid IDS.

CDS added a number of additional controller boards nd accessories which include TFT adaptor boards, TFT boards, TFT display controller boards, USB c LCD controller, USB touch kit, resistive touch screen, TFT accessories com, LCD controller board, LCD controller board USB c, LCD controller board, HDMI to MiPi DSI board, HDMI to MiPi DSI bridge, HDMI to MiPi LCD controller board, EDP adaptor bard, elite C microcontroller, Displaylink DL 3000 .

Whether it be bar type LCDs or any of CDS display solutions or many TFT displays we can help with comparing mipi dsi vs lvds interfces or mipi to edp wch can include use on pos shelf displays and rgb epaper for example.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey