imaging technology tft lcd quotation

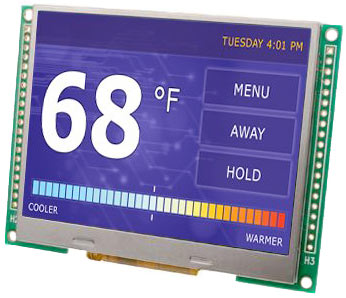

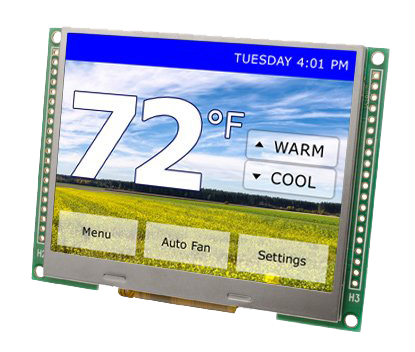

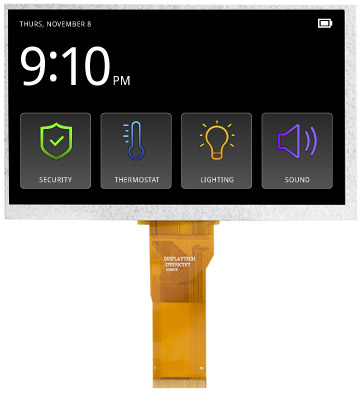

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

We have over two dozen TFT LCD display modules to choose from. All of them are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for imaginative user experiences. Thin and light, these are ideal for handheld devices, communications equipment, information displays, and test and measurement equipment.

Listed by the diagonal size of the active area (the usable area for lit pixels), our TFT display sizes range from 1.3 inches to 10.1 inches. Choose from six different interfaces, many of our TFT modules have more than one interface available. Arduino users should select modules with SPI for fast and easy communications to add color graphics to their projects.

Contrast ratio is the difference between a pixel that is lit or dark. Standard STN LCD displays typically have a 10:1 contrast ratio while TFT displays are 300:1 and up, so details stand out and text looks extra sharp. For standard STN displays, you must choose a display limited to a specific viewing angle (12, 3, 6 or 9 o"clock) while TFTs can have a viewing cone greater than 160 degrees.

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

Improve your product design by adding the DT010ATFT: a small, simple 1” TFT LCD with IPS technology. This mini TFT display is perfect as a status indicator presenting graphic icons or simplified information. The IPS technology included in this display allows your content to be crisp and clear no matter what angle your user is viewing it from. The ST7735S driver IC provides on-chip storage and power system. This IC allows for fewer components and a simple design to easily integrate the DT010ATFT into your next product.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Digimax distribetes a wide range of professional LCD monitors and large format displays for digital signage applications manufactured by Philips: one of the world"s largest manufacturers of TFT monitors, recognized for quality products and cutting-edge solutions.

Digimax also features touch display options with integrated touch technology thanks to multi-touch with 10 touch points, plus anti-reflective glass provides an even more immersive touch experience.

TFT LCD, acronym for Thin Film Transistor Liquid Crystal Display, is a technology developed for improve image quality and has countless consumer and industrial uses.

Specifically, within TFT monitors, liquid crystals allow faster and smoother state transitions while saving power, resulting in high image quality on the display, which appears without flickering or bright irregularities (unlike simpler LCD screens).

TFT screens can be of different sizes, ranging from small 3.5" screens to large displays, and can also be identified by their area of use or by certain special features and applications, such as multitouch.

TFT displays are always clearly visible in sunlight, making them particularly suitable for outdoor use. This type of display is also particularly light, thin and energy-efficient, as well as being relatively inexpensive in relation to the technical features offered.

Digimax has an extensive catalogue ofTFT screens from 7" to 23", LCD displays and professional monitors capable of handling a high number of pixels to enable high image quality, high resolution and a screen without glare or flicker.

TFT technology is now a consolidated reality for the choice of monitors, screens and industrial displays: following this market evolution, Digimax offers the latest generation of TFT touch screen solutions, multi touch monitors and transparent displays able to offer the right option for every need.

We offer both standard and customised TFT LCDs through strategic partnerships with leading international suppliers and brands: Ampire displays, Raystar monitors and DLC screens, as well as RockTech, RockTouch and AUO touch screens.

Together with Digimax consultancy, a specific service is also available to configure TFT kits consisting of a TFT LCD monitor and matching PC board: it is possible to customise CPU and coverlens, touch technology used and connection wiring between motherboard and display.

The liquid crystal display (LCD) technology has been used in several electronic products over the years. There are more reasons for LCDs to be more endearing than CRTs.

Capacitive Touchscreen TFT LCD Displays, Displaytech. The Displaytech range of projected capacitive (PCAP) touch screen LCDs are fully integrated with both LCD and PCAP driver ICs to reduced design time and BOM count. PCAP touch input enables you to integrate multi-touch gestures and proximity sensing into your design. Offering up to 5-finger multi-touch and high accuracy which ensures your design is responsive and intuitive to your customers. Add modern and intuitive controls used on most smartphones to your product such as swipe, pinch-to-zoom, drag and rotate. They are available in a range of sizes: 2.8 Colour LCD Display with PCAP – DT028ATFT-PTS – RS ; 915-6455 915-6455 3.5 Colour LCD Display with PCAP – DT035ATFT-PTS – RS ; 915-6458 915-6458 4.3 Colour LCD Display with PCAP – DT043BTFT-PTS – RS ; 915-6452 915-6452 7 Colour LCD Display with PCAP – DT070ATFT-PTS – RS ; 915-6461 915-6461

and added a reference:B.J.Lechner, "History Crystallized_A First-Person Account of the Development of Matrix-Addressed LCDs for television at RCA in the 1960s",Information Display 1/08 p26-27

I tried to pay due respect to RCA LCD group I admire the most: their LCD research work on TV finished in 1969, according to Lechner"s account, when I was still in the university, and I joined SHARP CRL in 1971 and started research on LCD for mini-calculator; on TFT-LCD for TV in 1984.

TFT-LCD technology is based on semiconductor IC manufacturing processes, and is unique in that it uses glass substrates rather than traditional silicon wafers. For the TFT manufacturing process, thin film formation, such as CVD and PVD processes, is a very important part. The ODF process has been developed for the assembly of color filters and TFT substrates, and is used in large size LCDs.

First of all, the movement and arrangement of liquid crystal molecules need electrons to drive, so in the carrier of liquid crystal – TFT glass, there must be able to conduct the part to control the movement of liquid crystal, here will use ITO (Indium TIn Oxide, transparent conductive metal) to do this thing. ITO is transparent, also known as thin film conductive crystal so that it will not block the backlight.

The different arrangement of liquid crystal molecules and the rapid movement changes to ensure that each pixel accurately display the corresponding color, and the image changes precisely and quickly, which requires precision control of the liquid crystal molecules. ITO film requires special processing, as if printed circuitry on a PCB board, drawing conductive lines throughout the LCD board.

For array panels with back-channel etched TFT structure.The main process can be divided into 5 steps (5 lightings) according to the sequence of the layers to be made and the interrelationship between the layers.

The process includes: PECVD triple layer continuous film formation, island lithography, island dry lithography and other processes. After these processes, the final amorphous silicon island for TFT is formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

PVD (Physical Vapor DeposiTIon), i.e. physical vapor deposition, is an advanced surface treatment technology widely used in the international arena. Its working principle is to use gas discharge to partially dissociate the gas or evaporated material under vacuum conditions, and to deposit the evaporated material or its reactants on the substrate while the gas ions or the evaporated material ions bombard the action. At present, the most used PVD technology on the market is mainly divided into three categories: magnetron sputtering plating, multi-arc ion plating and evaporation plating.

Specific processes include: S/D metal layer sputtering into a film, S/D lithography, S/D wet lithography, channel dry lithography and other processes. After these processes, the source, drain, channel and data lines of the TFT are finally formed on the glass substrate. At this point, the TFT has been produced. The graphics obtained after the process is completed are shown in the following figure.

The process includes PECVD, photolithography, and dry lithography of vias. After these processes, the final TFT channel protective insulation layer and guide through the hole are formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Color filters can be produced by various methods; photolithography is a typical method. In photolithography, color filters are produced by exposing a glass substrate coated with a photographic color resist through a photomask. The resist is hardened to form the RGB pattern of the LCD.

When making LCD panels it is impossible to produce them one by one, which is too inefficient, so multiple pieces are processed at once and separated by cutting.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey