lcd screen pressure marks quotation

Pressure damage is just like it sounds. Too much pressure was on the laptop"s display causing the LCD to crack. This could happen by holding the laptop too tightly when carrying it. If you put the laptop into a bag when transporting it, then anything else in the bag could put pressure on the display and cause the LCD panel to crack. Neither of these would leave any external marks or signs. You do have to be a bit more careful with the Retina models since their displays are extremely thin and a bit more fragile.

If there are multiple cracks in the glass or the LCD panel, then Apple considers it accidental damage even if there are no signs of impact or external damage.

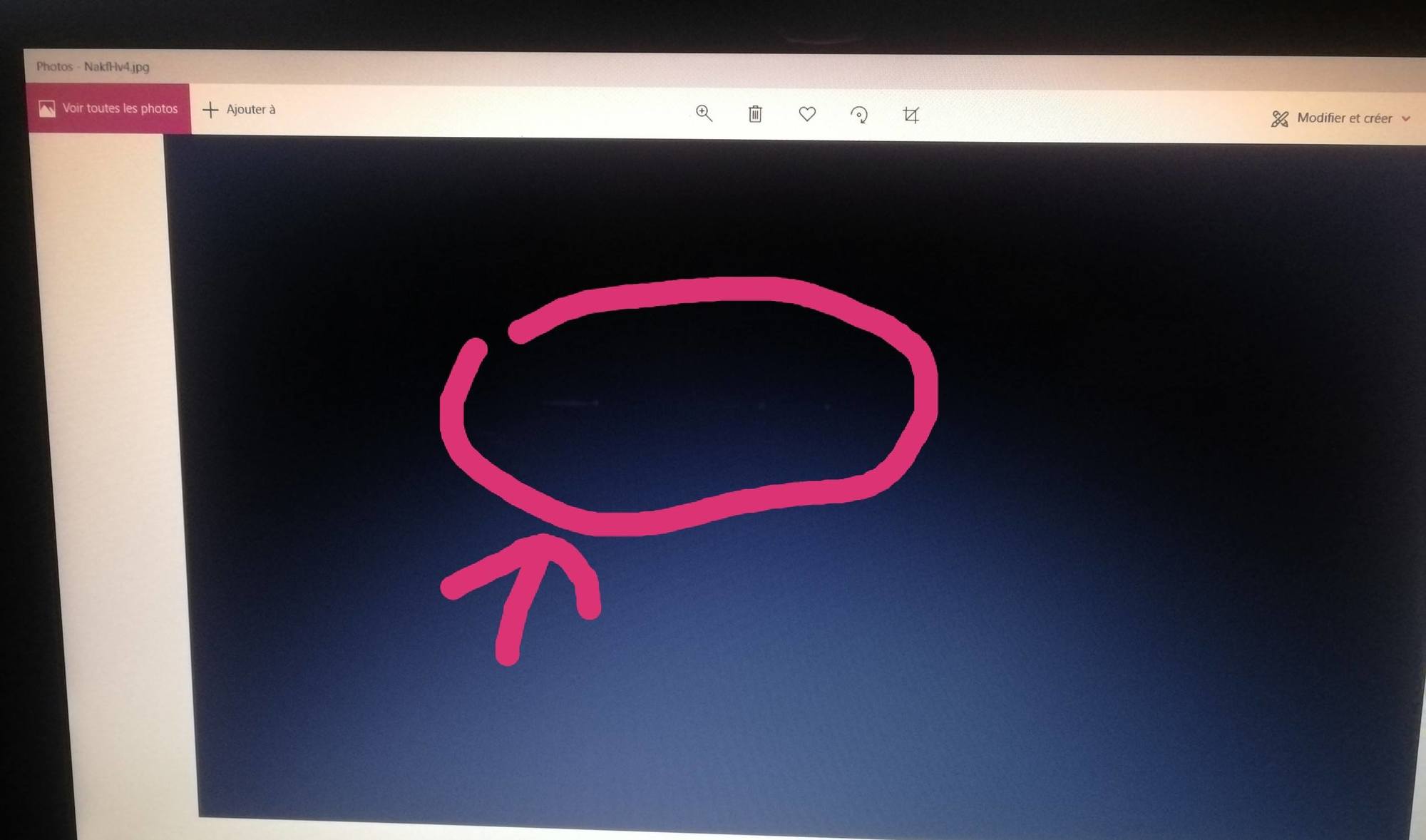

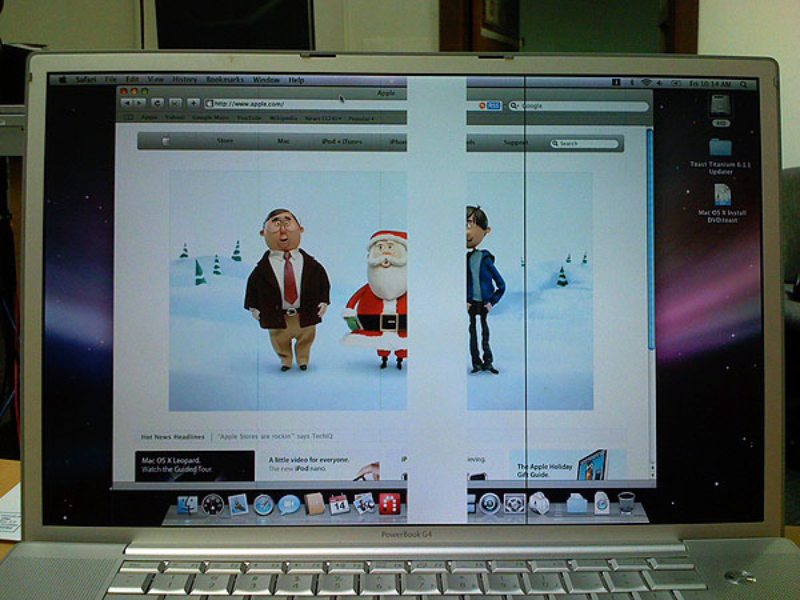

When used to display different things (text, graphics etc), nothing is notcieable, just with a dark blank screen (like a dark blue) are some pressure marks notcieable.

The most annoying thing about laptop damage is having a problem with its screen. It is not enough to have the laptop in good working condition. Rather, it is best if the laptop looks perfect on the outside too.

Some laptop problems do not need an expert to fix, you can do it as a DIY project. Find out how to remove pressure marks on LCD screens as explained in this article.

Pressure marks, despite how nasty they can be, unfortunately, have no specific fixing techniques. You might be lucky if you manage to remove the damage without interfering with your laptop’s part.

Liquid crystal displayis a technology used in making many electronics’ screens. Mostly found on monitors, TV screens, and even phone screens, the technology creates images by illuminating light through multiple liquid crystals.

Pressure application is the major cause of damage to these screens. This is because these screens are very sensitive. The liquid crystal, in the LCD screen, is fixed between two glass sheets.

After purchasing a good LCD screen, usually, you feel so contented; not knowing with time some problems may arise. The most common issues experienced are:

The mark does not damage your screen, although it can be frustrating seeing it there. There is software to solve this. They work by forcing the area with the dead pixel to experience a rapid change of colors.

This is a layer of a crushed crystal, found between two glasses that makes the screen. They form due to physical pressure exerted on the screen. The pressure forces the crystal to lose its solid properties.

To prevent it, you will require less pressing of the screen. Avoid unnecessary holding of the screen, not unless it’s a touch screen that is designed to withstand pressure.

This should also apply when you are wiping the screen or other sensitive laptop parts like the touchpad. Ensure you do it lightly and gently. While traveling, ensure your laptop is closed properly without having any object that will exert pressure between the keyboard and screen.

Pressure marks are a result of physical force that occurs when a laptop is mishandled, example when you bring the laptop to a plane. Therefore it will require physical fixing attention.

Physically fixing the screen also is not a 100 percent guarantee of solving the problem. It may even result in worse damages since it will require opening the laptop parts.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure, and is therefore not covered under the standard warranty of the LCD-Monitor. Such damage is most often the result of a drop or an impact to the LCD screen or any other part of the product which may render the device.

In light of this, the first thing we did was come up with a concept for the final project- here we decided to make a prototype toy, that when you played with it nicely would be affectionate towards you, but if too rough or hit, it would express its unhappiness. The idea for this was to use the skills that we had learnt in the Arduino software using pressure sensors, LCD screens and altering coding etc. After the idea was decided upon, we drew up a rough plan of what needed to be done during the following weeks.

We started by learning to use LCD screens, as the pressure sensors were relatively easy to get our heads around due to the other work we had done on Arduino and in connecting components together.

First, we connected the LCD screen to the Arduino Board using a white lead that we connected to the I2C adapter and a jumper wire from the LED pin on the I2C adapter to pin 12 on the Arduino Board along with other connections (GND-GND/VCC-5V etc.)

Next we downloaded the LCD library and found the address of the I2C device by downloading I2C scanner code. Then connected the set up Arduino Board (already connected to the LCD Screen) to the computer and clicked upload. After this, we opened the serial monitor and set the Baud rate to 115200 to match the code and then noted down the Hexadecimal number for coding later on.

From here, we created the code, by downloading a previously written code and changing the Hexadecimal number, then pressed upload. Now, we could change the text in the quotation marks within the code, and display them on to the LCD screen.

From here, we combined the code for both components- the pressure sensor and the LCD screen, so that different messages would appear when different pressures were exerted on to the sensor. – When there was a ‘big squeeze’ that showed you were being to rough by displaying a clearly annoyed message, whereas, with a ‘small squeeze’ the LCD would show an affectionate message. Next, we connected this to a battery pack to make it more portable (In the proper toy, the other wires and connections would be made smaller and more secure).

The LCD liquid crystal display screen brought a massive change in the latest technology because we left the TV and monitor screens and got a sleek design screen.

The main problem with LCD screens and LCD pressure marks is that they get pressure spots; here in this article, we will explain what the pressure spots and black dots are and how to get rid of them.

It is not easy to remove pressure marks from the LCD screen, as you think that if your screen got damaged, you could easily replace it by changing your hardware or software spare parts.

So there is no permanent method to get rid of these pressure spots; you only need to change your screen; however, you can follow some things to free your screen from the pressure spot.

If you try to fix your screen pressure, your screen gets harmed, so be careful while selecting your pressure spots on your screen. The only way to fix this issue is to ask a professional repairer to change the screen.

Some people say that their screen automatically after a long time, but what can you wait for a long time? If you do not change it otherwise, it will also increase the pressure spot area.

Some common problems with LCD screens appear on your screen due to negligence and careless use. Here we discuss some of these problems and proven ways how to remove pressure marks from your LCD screen.

Some people also said that applying pressure on the dotted area can solve this issue, but this is not working for all the screens; maybe your screen gets more damage, so don’t use these tricks.

The crack is also a common issue that we face because of the physical damage; the screen is falling from the table, and you’re accidentally through the liquid on your screen.

Sometimes the child hits a sharp thing on the screen, so you need to change your screen in these situations because there is no way to fix this issue.

Did you notice you are working on your computer or laptop and hear some sounds from the screen’s backside? This problem mostly happens with the old computers because they used fluorescent lighting tubes and caused the sounds.

There is also a big reason for these white dots: when the micromirrors are stuck in between the screen and stop the signals from reflecting, sometimes they become permanent if you did not repair this issue in time.

Sometimes the stains are also a hurdle between you and the TV screen. But this problem is not as serious as the others. You can get rid of this problem by cleaning your screen. You can use a soft cloth and chemical cleaner to clean laptops, mobiles, and computer screens.

You can only prevent your screen from getting pressure, white dots, or vertical lines is care because many of us use the laptop without any attention and keep heavy things on the computer screen.

Yes, you can fix and remove pressure marks from LCD screen, laptop and phone screen by using wipes and chemical cleaners which are available in market.

You can also use the same method and treatment which you use for LCD, laptop and phone screen. Use wipes and chemical cleaners available in market to get rid of marks and spots on your TV.

If you are facing pressure marks on phone screen, you don’t need worry. Use wipes and chemical cleaners to remove pressure marks on phone screen as well.

Bruising screen of phone, laptop and LCD may happen when glass of screen is cracked and there are spots of different colors. This is difficult to fix bruising screen as the damage may be permanent and difficult to repair.

If you have pressure marks on monitor and want to remove spots, You can also use wipes with dry and anti-static LCD cleaning cloth to remove the dust and the stain. You can also use wipes and chemical cleaner as well.

Getting pressure marks, and white and black dots on your screen is a ubiquitous thing nowadays, and this is the only reason for our use. Some laptops getheat when we overuse them, and heat-affected screens in different ways.

Here in this article, we discuss some of the common problems of screen issues and ways how to remove pressure marks from LCD screens. We also highlight some methods and techniques that you can follow to prevent these issues.These methods will help you out to get pressure marks from the screen.

Are you looking for how to get rid of those irritating spots on your phone screen? This article shows you everything you need to know on how to fix pressure spots on LCD screens and how to prevent them in the future.

One of the deadliest and most frustrating issues you could have with your mobile phone is screen damages. And for pressure spots on LCD screens, it"s somewhat annoying than breaking the whole screen itself, as it requires going for replacement in most cases.

As its name implies, pressure spots on phone screens can render the display useless (or irritating, based on how you see it) by creating spots of different shapes and styles on the screen. These spots show continually, and most times, permanently on the display and can obstruct your viewing or cause other problems such as dead pixels, flickering, or blurriness.

When you apply too much pressure on your phone’s display – whether accidentally, intentionally, or carelessly, it damaged the LCD components, hence creating different spots on the display.

Pressure spots on LCD screens can come in different forms and shapes depending on the density of pressure applied. Sometimes, the spots can be whitish, deep black, or come in various colors depending on what’s currently showing on the screen.

Unfortunately, learning how to fix pressure spots on LCD screens isn"t the same as learning how to fix simple hardware and software issues. Simply put, there is no way to repair a phone screen that was damaged by pressure.

Attempting to get rid of pressure spots on LCD screens can cause more harm than good. Hence, you had better find a professional phone repairer to help you with screen replacement.

Meanwhile, some users reported that the pressure spots on their phone screen got healed after a few years. But do you want to keep seeing the same issue on your screen for years? So, a screen replacement is the only way out.

Fortunately, if you use a TECNO, Infinix, or itel smartphone, Carlcare Service is the best bet for you when it comes to replacing your damaged screen and fixing other issues on the device. We"re the official after-sales service provider to render professional repair and customer services for these brands.

And if you’ve bought our extra Screen Protection Plan for your TECNO, Infinix, or itel device earlier, you might be able to replace your screen for free, or better still, get huge discounts on-screen replacement at Carlcare.

Also, if you notice pressure spots on your Syinix TV, the best thing to do is bring it down to our service centre for proper screen replacement with genuine stock parts.

Paying for screen replacement from your own pocket (especially when you don’t have any form of screen insurance or protection plan), can be a pain in the ass. However, there’s probably nothing you could have done better than learning how to protect your phone screen from pressure spots in the future.

Pressure spots on LCD screens (or any screen in general) occur accidentally or carelessly. The only way to avoid such damage in the future is to handle your phone carefully. Try as much to shun applying much pressure on the screen while playing games and performing other tasks.

Overall, the only way to prevent your phone screen from getting pressure spots in the feature is to handle it carefully whenever and wherever possible. If you ever come across the need to drop your phone somewhere, ensure you don’t place anything on it.

Taking these few things into consideration would help you protect your phone screen from pressure spots in the future, rather than looking for how to fix pressure spots on LCD screen when it happens.

Now, if you’ve accidentally applied much pressure on your phone’s screen and some spots are showing on it when you turn it on, the best thing you can do is to visit the official service provider for your device for a screen replacement. Trying to shift the spots away or performing some DIY tricks may cause more harm than good.

Is your obsessive side getting twitchy yet? Before we discuss upping your Xanax prescription, let"s review how the DSE demon begins its possession of your beloved screen.

Still, DSE may afflict cheaper versions, particularly if the anti-reflective coating on the glass that overlays the screen is of low quality or poorly applied. Furthermore, as the display ages, the phosphors in the screen may begin to wear out or malfunction, all of which can contribute to less uniform images, which is often apparent particular in scenes with fast panning shots.

In LCD and LED TVs, DSE is typically a bigger issue, one that"s due to the way these units are illuminated. Before we proceed, it"s worth mentioning that although marketing-speak often treats LED and LCD TVs as completely different technologies, they"re not different beasts.

LED units could be more accurately described as "LED-backlit LCD televisions," but salespeople and consumers alike are too lazy to utter that tongue-wearying phrase while haggling in a big-box store. What"s important to realize is that both categories rely on LCDs (liquid crystal displays), which act as shutters that either block light or allow it to pass, depending on the image that"s being rendered on the screen.

There are a variety of factors that affect LCD quality, notably illumination source. Older LCD TVs, for example, used multiple cold cathode fluorescent lamps (CCFL) to light LCDs from the rear. They provide generally smooth and even illumination, but they make the final product rather bulky.

More modern TVs rely on LEDs (light-emitting diodes) as a light source. Some models have what"s called full-array backlighting, in which the LEDs are stationed in regular intervals behind the screen, creating even lighting and excellent picture quality.

Other models incorporate what"s called edge lighting, which positions the LEDs along the edges of the screen. In general, the overall picture quality isn"t quite as good as a backlit screen, but manufacturers still use it because it allows them to build substantially slimmer TVs.

If you"ve ever pressed a little too hard on your smartphone or computer screen, you"ve likely witnessed a bit of discoloration, clear evidence of how sensitive LCDs are to physical pressure. Now, picture a huge manufacturing facility that cranks out thousands of these units per week. It"s easy to see how a bit of mishandling could alter the screen"s consistency.

The same goes for shipping. Some units travel long distances in cargo boxes, and then take bouncy rides in your car to their final resting place on your living room wall. That"s a lot of opportunities for tiny mishaps to affect LCD uniformity.

You may experience a stuck pixel on a new or used LCD screen. If your monitor’s warranty has expired, or the manufacturer won’t replace the monitor because it considers one or two stuck pixels as acceptable, there are a few things that you can do.

You’ll find that many of them run with Flash, which is no longer available – fortunately, here’s one that you can still rely on – JScreenFix. JScreenFix is a free online service that can solve your problem of stuck pixels. You don’t have to download anything, so it’s not invasive nor harmful.

Visit the website jscreenfix.com and scroll down to find the Launch JScreenFix button – click on it. It will open a black screen with a square full of flickering pixels. The instructions pop up right there – however, what you’re meant to do is drag this square to the area where the stuck pixel is. Then, leave it for at least ten minutes.

Any technique that implies applying pressure to fix a stuck pixel can potentially make more damage than good. Here you’ll find some precautions you should take to minimize these chances.

However, if you decide to do this, it’s at your own risk. Turn on your computer screen or monitor as the pixel needs to be working for the pressure methods to stand a chance.

Determine if you have hot, stuck or dead pixels – if you don’t know the difference among these, read the next section first. Only if the pixel is stuck, you’ll have a chance at fixing it with a pressure method.

Open a black image as background in full-screen mode or use a black browser window such as this. Either way, don’t just leave a blank signal. This again has to do with the fact that you need the pixel to have the backlight on. Make sure the screen is clean to avoid confusing dust with bad pixels.

Get a Stylus or Touch pen to put pressure on the monitor without damaging it. Otherwise, you can try using your finger wrapped with a microfiber cloth.

Some people recommend a heat method where you use a hairdryer to warm the spot while you’re putting pressure on the monitor to fix a stuck pixel. Others suggest using a hot water damp cloth to apply the heat directly.

However, you could end up with something worse than a stuck pixel. The pressure method already represents a small risk of damaging your monitor – if you add heat, you’re increasing that risk.

To understand the possible pixel problems that you can face – and whether or not you can fix them – you need to know that an LCD screen is made by pixels. Three sub-pixels form each pixel – one is red, one is green, and one is blue (RGB).

LCD stands for liquid crystal display. These monitors are made with multiple layers. In the far back, they have the light source that illuminates the screen with white even light.

The reason why we don’t see a fully white screen all the time is that there’s also a layer with color filters. This layer has a red, green and blue filter per pixel (RGB) – each of those would be a sub-pixel.

Anyway, all this explanation is to tell you that stuck or dead pixels often happen because there is a broken transistor that fails to supply voltage to a certain pixel or sub-pixel. Keep in mind that there are two types of LCD monitors: TN (Twisted Nematic) and IPS (In-Plane Switching). On TN monitors, the default without voltage is on. So, if the transistor is not supplying power, the pixel won’t be dead (black) but hot (white). On IPS monitors, it works the other way around.

So, you can use a dead pixel test. There are some free ones online such as the one from LCD Tech. You simply need to click on the Start Test button, and it will automatically enter full-screen mode in complete white.

Make sure your monitor is clean to identify dead pixels better. Because the screen will be completely white, you can also use this to find stuck pixels. On the other hand, a hot pixel won’t be visible – for these, you would need a dark screen.

Keep in mind that these are just good practices that can extend the life of your LCD screen. Unfortunately, there isn’t a full-proof method to avoid getting stuck pixels.

If you abort a BP measurement by pressing the Start/Stop button, you will hear one short beep. Then after the pressure has been completely dumped from the cuff, you will hear one long beep.

The ability to measure MAP must be turned on using the Advanced Configuration Application. It is turned off by default at the factory. If MAP is enabled, the results will alternate with heart rate results on the display screen. Note that MAP results are only validated for use outside of the United States.

If the LCD of your phone is fully functioning then it can be renewed or reprocessed. Mostly broken LCDs with working screens can be fully renewed and returned to a new state. Considering it is quite a difficult process because it requires a highly technical machine and expertise. IspeakPhone has technicians with over 10 years of experience with a great customer satisfaction. We offer you a high tech renewal program in order to give you the best service and quality. If you have a working iPhone or Samsung displays with cracked screen, and you are likely to use them again, why not send them to us for the renewal process. The quality and service we are providing is far greater than aftermarket screens. Usually when the screen gets cracked, it’s basically the exterior glass that has been damaged, and the original LCD continue to work as normal. Therefore the original LCD of your mobile will not be replaced, meaning you can get your mobile phone as good as new.Aftermarket LCD screens in comparison to IspeakPhone renewed LCD screens When your mobile phone has a broken LCD and you want it fixed as soon as possible and as cheaply as possible. Mostly, consumers don’t have any idea about how many components make up a single mobile screen and how does those components affect the quality of your mobile screen. IspeakPhone Renewed LCD screens has quite a few advantages over Chinese LCD screens. Undoubtedly aftermarket parts are of no substitute for original parts. How we do value add-on is that the original LCD remains the same and only the glass is replaced, the quality of the screen remains the same as compared to aftermarket replacement. Whereas in Chinese LCD the glass and LCD both are replaced.

LCD screen: LCD basically shows the retina display and it has the digitizer attached which controls the touch screen. LCD of the mobile phone is attached to the glass screen internally.So, LCD is a major component and if it’s broken it is irreplaceable. Therefore we renew LCDs in a working condition and replace glass only. Aftermarket companies replace LCDs and the quality of the screen is not as good as the original one and they often have problems with touch screen.

Glass and frame: LCD is the far most important component of any mobile phone, nonetheless glass and frame are also very significant and not surprisingly there are also copies of glass and frame used by aftermarket which vary in quality. The aftermarket screens normally come up with a lower glass quality. The display may break again due to the low glass quality. While renewing LCD we pay close attention to the quality of the glass and frame.

Battery: The aftermarket LCD screens can affect your battery life, as the screen is not original it can cause battery to deteriorate faster. Whereas we are keeping original LCD so that will have no effect on the battery as compared to aftermarket LCD screens.

Color differences: Aftermarket phone screens has a color difference that is quite noticeable. If you compare both the screens, aftermarket screen tend to have slightly dull blue color as compared to the original one. Whereas screen will work properly and it will look just like normal phone, but the difference will be there. Therefore IspeakPhone provides you mobile with original look and feel with no difference due to its original LCD. Thickness: As aftermarket screens replace the glass as well as LCD, they use a thicker LCD with many layers causing LCD screen to look thick. The difference will be slightly noticeable.

Polarizer issues:LCDs use a polarizer film and if installed incorrectly it will make the screen dimmer, causing ambiguity to see the screen through polarized sun glasses.

Step4: LCD’s are returned Now you must be thinking what our renewal process is and how we do it? Here’s the renewal process: Once we receive your screens we test each screen to make sure that the LCD is in a working condition, or there are no damaged pixels or pressure marks visible on the screen. Normally people continue using their mobile phones with a cracked or a broken glass for a longer period of time that causes pressure marks on the screen. Pressure marks basically shows itself as green, White, red or blue marks that are only possible to see in the dark. Therefore we perform test by turning off the lights in order to check the pressure marks.

Glass removal: We basically separate the screen using cutting wire so that we can retain the original backlight. Once we remove the glass we also remove the polarizer. Some companies use thin wire to separate the glass in order to save the original polarizer, but we replace it.

Building new glass and polarizer: After the detailed cleaning of the screen we move on to replace the glass. There is no risk of the screen lifting from the frame because we are using original frame, glass and polarizer.

That is not normal in that it wouldn’t be made that way, but it’s normal since it’s understandable how it could happen. That is a cosmetic issue with the LCD panel. Without a physical inspection or examining the panel, my best guess is the layers are compressed physically. No need to repair it until you can’t or won’t abide by the color shift or the area just stops working.

As to the coming and going, If you carry your Mac in the book bag or it could be getting otherwise squeezed, that would explain why the color moves around in the dissipates as the glass and plastic layers reset themselves. Like a thin film of oil or soap on water, you are seeing a rainbow of diffraction and refraction as the light and LCD interact with each other.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey