patents tft lcd globally free sample

[1] The present invention relates to a cutting method of a large size TFT-LCD panel and a liquid crystal display unit to enhance a simplicity of process facility and a speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of respective sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size. Background Art

[5] Most of all as an outline, one pixel (composed of R. G. B. three sub-pixels) in the thin film transistor (TFT) - LCD is approximately as fine as 0.3 mm wide.

[6] Of course, the TFT included in the pixel is smaller than the pixel. Moreover, in order to meet a resolution of 1600x1200, 1,920,000 pixels are required and 5,760,000 TFTs are necessary if the sub-pixels are considered. Therefore, an overall process is very precise and demands a level of semiconductor process.

TFT process, a color filter (CF) process, a cell process and a module process. The cell process makes one panel with two glasses undergone the TFT process and the CF process. Then, the module process completes the manufacturing process by mounting the one TFT-LCD panel undergone the cell process in a real monitor or TV.

[8] First, the TFT process is the most basic core process for forming the most basic electrodes that provides an electrode for each cell. The process includes five process steps in order of forming a gate electrode, an insulating film, a semiconductor film, a data electrode, a protective film, and a pixel electrode that requires one or more pattern processes for each process step. Not only this pattern process that may be called a core

process in the processes of manufacturing the TFT-LCD panel is necessary in the TFT process but also a similar pattern process is necessary in the CF process.

TFT-LCD panel formed as hereinabove, the TFT-LCD panel is completed by providing a polarized plate on a surface of the TFT substrate and the CF substrate.

[11] The TFT-LCD panel of size demanded by a user may be produced in a large amount but the other TFT-LCD panel of less demand may be produced in only a limited amount since various sizes of the TFT-LCD panels completed as hereinabove require a difference in production line and in each process of the production line dependent on the sizes of the TFT-LCD panels. Disclosure of Invention Technical Problem

[13] The cutting method of a large size TFT-LCD panel of the present invention, provided to solve the hereinabove problems, has an object of enhancing a simplicity of process facility and speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of different sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size.

[14] The cutting method of a large size TFT-LCD panel formed as hereinabove can devise a simplicity in process and a profitability through solving a spatial enlargement and other costs increase due to an increase of facilities by equipping a facility"s process dependent on a size according to a production of TFT-LCD panels in various sizes, having an advantage of possibly producing a various size of the TFT-LCD panel asked by a user purpose or a user taste in a simple and convenient way, and solving an abandonment and reduction of the facilities due to a change in consumption dependent

[18] FIG. 4 illustrates a state of a scribe line set into a mid-depth of a color filter substrate and a thin film transistor substrate by diamond wheel in the cutting method of a large size TFT-LCD panel of the present invention.

[20] FIG. 6 illustrates a state completed after processing sealing a cut portion in the cutting method of a large size TFT-LCD panel of the present invention.

[27] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate below the TFT substrate, a polarized plate stripping step that removes a portion of a predetermined width to be cut from the each polarized plate provided on a surface and an opposite surface of the large size TFT-LCD panel, a cutting location setting step that sets a portion not damaging a gate line and a data line of the TFT substrate through investigating a portion stripped in the polarized plate stripping step by microscope, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning

over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth in the stripped polarized plate portion along the portion set in the cutting location setting step which precisely corresponds with the set first scribe line using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step, and

[28] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth along the portion set in the cutting line setting step which precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may accomplish the present invention object.

[29] Further, the present invention comprises a scribe line setting step that sets scribe lines simultaneously cutting the CF substrate and the TFT substrate into their mid-depths along the portions set in the cutting location setting step using a diamond wheel.

[30] The cutting method of a large size TFT-LCD panel further comprises a blocking off a light illuminated from a backlight through attaching a light blocking tape along a cut portion selected between the CF substrate and the TFT substrate or the both substrates or between the polarized plates located above the CF substrate and below the TFT substrate or the both polarized plates.

LCD panel 100 is formed in structure sequentially coupled of, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14.

[36] In order to cut the large size TFT-LCD panel 100 completed as hereinabove, a polarized plate stripping step is initially performed that removes a portion of a predetermined width to be cut from the each polarized plate 10 provided on a surface above the CF substrate 11 and an opposite surface below the TFT substrate 13.

[38] The TFT substrate 13 is exposed if the polarized plates 10 and 14 around the cutting portion are removed by its lengthwise direction. Since gate lines transferring a scanning signal and data line transferring a screen image signal are configured by innumerably crossing with each other and difficult to perceive by naked eyes, a cutting location setting step sets a portion not damaging the gate line and the data line of the TFT substrate through investigating a portion stripped on the polarized plate stripping step by microscope.

[43] To process a side opposite from a side where a portion of the first scribe line is set, the present step turns over the large size TFT-LCD panel 100 after chucking one end of the large size TFT-LCD panel 100.

[45] The present step sets a 2nd scribe line setting step cutting the TFT substrate 13 into its mid-depth in the portion of the stripped polarized plate 14 bonded with the TFT substrate 13 below along the portion set in the cutting location setting step which

precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100. This step is also difficult and requires a skill of high precision to correspond with the set first scribe line.

[48] A natural crack is made if tempered for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100. Then, the air flows into a liquid crystal layer 12. If there is the air flow into the liquid crystal layer 12, the liquid crystal layer 12 is temporarily restricted from flowing out by the flowed in air.

[50] After the 30 minutes tempering step, the CF substrate 11 and the TFT substrate 13 are naturally cracked along the first scribe line and the second scribe line and the present step externally applies a certain amount of force in order to cut the large size TFT-LCD panel 100 along the scribe lines.

[52] The present step is the last step that applies a sealant 30 on a cut portion in the large size TFT-LCD panel 100 and the present invention is completed by applying the sealant 30.

[53] Through undergoing the process hereinabove, the large size TFT-LCD panel 100 is possible to be cut into a plural or multiple numbers without a many numbers of equipment and to meet a desired size of a demander or an operator.

[56] That is, in a large size TFT-LCD panel 100 completed of forming sequentially coupled, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14 below the TFT substrate 13, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate 11 into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel 100 to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel 100, a scribe line setting step that sets a second scribe line cutting the TFT substrate 13 into its mid-depth along the portion set in the cutting location setting step corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100, a tempering step that tempers for

30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100, a cutting step that cuts the CF substrate 11 and the TFT 13 substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may configure the present invention.

[59] For example, after undergoing the sequentially processed cutting location setting steps of the first or the second exemplary embodiments through the polarized plate stripping step that removes a corresponding portion of a predetermined width to be cut from the polarized plates 10 and 14 provided on a surface of the CF substrate 11 and an opposite surface of the TFT substrate 13 like the first exemplary embodiment or without the polarized plate stripping step like the second exemplary embodiment, a scribe line setting step sets scribe lines simultaneously cutting the CF substrate 11 and the TFT substrate 13 into their mid-depths along the portion set in the cutting location setting step using a diamond wheel.

TFT substrate 13 by applying the same scribe line depth and the like enables not only an abridgement of the operation process but also a precise setting job.

[61] The present exemplary embodiment may or may not include the polarized plate stripping step like the first or second exemplary embodiment, and the subsequent steps may proceed in the same sequence as tempering step for the natural crack, cutting step cutting the CF substrate 11 and the TFT substrate 13 and sealing process step .

[62] Meanwhile, when a light from the backlight unit through the TFT-LCD panel 100 processed by the respective exemplary embodiments is illuminated to display a corresponding image, the image may be displayed with an image quality relatively unclear at a portion corresponding to the cutting portion.

[64] Here, the light blocking tape 20 may be attached in a range covering any cut portions of the CF substrate 11 and the TFT substrate 13 or the both substrates 11 and 13 as shown in FIG. 7.

10 bonded above with the CF substrate 11 or at a periphery of the polarized plate 14 bonded below with the TFT substrate 14 which are removed with the set cutting portion, may maximize a clearness of the screen quality when the light from the back light unit is illuminated on the cut portion of the TFT-LCD panel 100 completed by cutting into a desirable size.

[67] Meanwhile, as shown in FIG. 9 of other exemplary embodiment, a transparent tape is used to cover an outer peripheral edge of the CF substrate 11 and the TFT substrate 13 after sealing the outer peripheral edge with an ultraviolet sealant 31 while the CF substrate 11 and the TFT substrate 13 are in bonded state.

[68] Further, though not shown in the drawings, the peripheries of the CF substrate 11 and the TFT substrate 13 may be covered by tape-processing or may be fixed by clipping and the like.

[70] Further, FIG. 10 and FIG. 11 illustrate an application of the TFT-LCD panel according to the cutting method provided by the present invention. FIG. 10 is a brief exploded perspective view of a liquid crystal display unit. FIG. 11 is a brief cross sectional view of FIG. 10.

[71] As shown in FIG. 10 and FIG. 11, the cut processed TFT-LCD panel 100 equipped with the backlight unit (not shown in drawing) below undergoes a series of course coupling a top sash 2 corresponding to an upper frame with an accommodating frame 3 accommodating the TFT-LCD panel 100 and the backlight unit to be used for the liquid crystal display unit.

[72] Here, when the TFT-LCD panel 100 cut processed in a desired size according to the present invention is received in the top sash 2 and the accommodating frame 3, a realization of a clear screen may be difficult since a slight difference may be produced, not accurately fixing the TFT-LCD panel 100, and producing a flowing phenomena because of the internal difference.

[74] Accordingly, in order to prevent the flowing phenomena, that is the flowing phenomena of the received TFT-LCD panel 100, attaching a plurality of both-faces tape 4 at the outer peripheral edge on the top sash 2 surface and attaching a plurality of both-faces tape 4 at the outer peripheral edge on the accommodating frame 3 surface as well is preferable to completely prevent the flowing phenomena.

[76] Therefore, since a large size TFT-LCD panel may be miniaturized for an application to various video games, monitors or cell phone liquid crystal displays through cut processing the large size TFT-LCD panel without a separate manufacturing line for manufacturing process according to present invention, an industrial applicability expecting an effective reduction of manufacturing facility and its value may be recognized.

Thin film transistor-liquid crystal display (TFT-LCD) is known as the display required for the high pixel density and quality. In general, the TFT-LCD includes a bottom plate formed with thin film transistors and pixel electrodes and a top plate formed with color filters. The liquid crystal is filled between the top plate and the bottom plate. In each unit pixel, a capacitor and a further capacitor are provided which are formed by virtue of the TFT serving as the switching element of the unit pixel. In the operation, a gate signal voltage is applied to the TFT that is the switching element of each unit pixel. The TFT receives the gate signal voltage, it is turn on so that data voltage carrying image information can be applied to the corresponding pixel electrode and the liquid crystal via the TFT. When the data voltage is applied to the TFT, the arrangement of the liquid crystal moleculers is change, thereby changing the optical properties and displaying the image. Supplying of voltage to each pixel electrode is carried out via a single line by a corresponding thin film transistor which is switched by a gate voltage supplied via a gate bus line.

In U.S. Pat. No. 5,166,086 proposed by Takeda et al., he disclosed a method to form a TFT-LCD. In the patent, Takeda provides a TFT array with reduced parastic capacitances. Further, Possin et al. disclosed a method to form a TFT-LCD by using back-side photoresist exposure. Please refer to U.S. Pat. No. 5,010,027. Possin teaches a method for forming a self-aligned thin-film transistor which controls the overlap width of the gate electrode with each source and drain electrode to an optimum distance.

Typically, the channel region of the self-aligned TFT-LCD is defined by the gate structure as a mask. The lightly doped drain (LDD) region or the offset structure is formed by a further photomask. The object of the present invention is to provide a method to form the offset structure without a further photomask as aforesaid.

The present is to form a TFT-LCD having a offset structure. The present invention includes patterning a metal layer on a glass substrate for serving as the gate electrode. The metal layer can be chosen from the group of chromium (Cr), tungsten (W), titanium (Ti), tantalum (Ta) or molybdenum (Mo). Next, a dielectric layer is formed on the gate for isolation. An amorphous silicon layer having hydrogen ions (a-Si:H) is subsequently formed on the dielectric layer. A first positive photoresist is formed on the amorphous silicon layer. Then, a back-side exposure is used using the gate electrodes as a mask. A bake step is performed at a temperature 140 to 150 degrees centigrade for about 20 to 30 minutes to expand the lower portion of the photoresist. Next, a second positive photoresist layer is formed on the amorphous silicon layer and the residual first positive photoresist layer.

A method is disclosed to form a TFT-LCD. The present invention provides a method to form a TFT-LCD having a offset structure. Back-side exposure technique is used to eliminate the misalignment induced by the photolithography process. Further, at least two photoresist layers are used to construct the offset structure. As will be seen below, this technique can be used for the formation of a TFT device. Referring to FIG. 1, in the preferred embodiment, a glass substrate 2 or the like is used as an insulating transparent substrate. In a preferred embodiment, the substrate 2 is chosen from glass or quartz. Subsequently, still referring to FIG. 1, a metal layer 4 for the gate electrode is formed by using physical vapor deposition (PVD). The metal layer 4 can be chosen from the group of chromium (Cr), tungsten (W), titanium (Ti), tantalum (Ta) or molybdenum (Mo). A Cr/Al (chromium/aluminum) composition layer can also be used for serving as the gate electrode 4. The metal layer 4 is then patterned on the substrate 2. The thickness of the metal layer 4 is approximately 1500-3000 angstroms. Next, a gate isolation (dielectric) layer 6 is formed on the gate 4 for isolation. An amorphous silicon layer 8 (a-Si:H) is subsequently formed on the gate isolation layer 6. In a case, the amorphous silicon layer 8 is about 300 to 600 angstroms in thickness.

As shown in FIGS. 10, the amorphous silicon layer 8 is patterned. A further dielectric layer 16 for isolation is formed on the patterned amorphous silicon layer 8. Via holes are created by etching to expose a portion of the amorphous silicon layer 8. Next, a conductive layer 18 formed of metal, polysilicon or alloy are patterned on the dielectric layer 16 and in the via holes to contact with the amorphous silicon layer 8. The conductive layer 18 acts as the source and drain electrodes of the TFT. Referring to FIG. 10, subsequently, a passivation layer 20 formed of silicon nitride layer is deposited on the source and drain 18. Preferably, the thickness of the silicon nitride layer is about 3000 to 6000 angstroms. In a case, the silicon nitride layer can be amorphous silicon nitride having hydrogen dopant (a-SiNx :H).

The present invention relates to a pixel structure, and particularly to a pixel structure for a transflective thin film transistor (TFT) liquid crystal display (LCD) for improving efficiency in backlight utilization.

Since the first cathode ray tube (CRT) television was invented, display technology has developed rapidly. However, CRT displays have obvious disadvantages such as large size, heavy weight, high radiation and poor pixel quality, and therefore various flat display panels are explored and introduced. Among them, LCDs, with advantages such as compact size, power consumption, no radiation, full color display, and portability, have become the most developed and popular products. LCDs are used in various applications including cellular phone, electronic dictionary, digital camera, digital camcorder, personal digital assistant, notebook computer and desktop computer.

TFT LCDs can be generally categorized into transmissive type, reflective type and transflective type, according to the light source and array substrates used. A typical transmissive TFT LCD uses a backlight source, and employs transparent electrodes as pixel electrodes of the TFT array substrate for allowing backlights to transmit through. A typical reflective TFT LCD uses a front-light source and/or ambient lights as a light source, and employs metal or other reflective material as reflective electrodes for reflecting the front-lights or the ambient lights. A typical transflective TFT LCD can be viewed as a combination of a transmissive TFT LCD and a reflective TFT LCD, taking advantages of the backlight source and the front-light source or the ambient lights for display.

In the conventional transflective TFT LCDs, the reflective layers are usually designed to have rough surfaces for obtaining widely distributed reflected lights. However, the process to make the surfaces rough increases production costs. Further, when the backlight source provides backlights for display, only those radiating on the transparent electrodes rather than those radiating on the reflective layer can be used. Therefore, such a conventional transflective TFT LCD has lower utilization efficiency of lights provided by the backlight module. SUMMARY OF THE INVENTION

Therefore, an object of the invention is to provide a pixel structure for a transflective TFT LCD panel, adapted for improving efficiency in backlights utilization of the TFT LCD.

Another object of the invention is to provide a method for fabricating a transflective TFT LCD panel having higher efficiency in backlights utilization.

According to the foregoing objects and others, the present invention provides a pixel structure for a transflective TFT LCD. The pixel structure includes a transparent substrate, a TFT, at least one reflective structure, a passivation layer, a pixel electrode and a reflective layer. The TFT is disposed in a reflective region of the transparent substrate. The reflective structure is configured at one side of the TFT and located in the reflective region of the transparent substrate. The passivation layer is disposed over the transparent substrate and covers the TFT and the reflective structure. The pixel electrode is disposed above the TFT and the reflective structure, and at least is located in a transparent region. The pixel electrode is electrically connected to the TFT. The reflective layer is disposed above the TFT and the reflective structure, and is located in the reflective region.

According to an embodiment of the pixel structure for a transflective TFT LCD panel, the TFT includes a gate electrode, a gate insulating layer, a semiconductor layer and a source/drain electrode. The gate electrode is disposed on the transparent substrate. The gate insulating layer is also disposed over the transparent substrate and covers the gate electrode. The semiconductor layer is disposed on the gate insulating layer and above the gate electrode. The source/drain electrode is disposed on the semiconductor layer and above the gate electrode.

According to an embodiment of the pixel structure for a transflective TFT LCD panel, the reflective structure includes a first metallic layer. The first metallic layer and the gate electrode are of a same film layer, for example. The first metallic layer is lodged into a depression of or protrudes from the transparent substrate surface, for example. Furthermore, the gate insulating layer extends outside the TFT for example, and covers the first metallic layer.

TFT LCD panel, the first metallic layer and the source/drain electrode for example are of a same layer. The gate insulating layer for example extends outside the TFT and is disposed between the first metallic layer and the transparent substrate. The first metallic layer for example is lodged in a depression of the gate insulating layer surface.

TFT LCD panel, the reflective structure for example further includes a second metallic layer. The second metallic layer is disposed on the first metallic layer. The first metallic layer and the gate electrode for example are of a same film layer, and the second metallic layer and the source/drain electrode for example are of a same layer. Furthermore, the gate insulating layer for example extends outside the TFT, and the gate insulating layer for example is disposed between the first metallic layer and the second metallic layer.

According to an embodiment of the invention, the pixel structure for a transflective TFT LCD panel further includes a flatting layer, disposed between the pixel electrode and the transparent substrate, and covering the TFT and the reflective structure.

The present invention further provides a method for fabricating a pixel structure for a transflective LCD panel. The fabricating method includes the steps of: providing a transparent substrate; then forming a TFT and configuring a reflective structure on the transparent substrate, wherein the reflective structure is located at one side of the TFT; forming a passivation layer over the transparent substrate, wherein the passivation layer covers the TFT and the reflective structure; forming a pixel electrode above the TFT and the reflective structure, wherein the pixel electrode and the TFT are electrically connected to each other; then forming a reflective layer above the TFT and the reflective structure.

According to an embodiment of the method for fabricating a pixel structure for a transflective LCD panel, the step of forming a reflective structure for example includes forming a first metallic layer on the transparent substrate, wherein the first metallic layer for example is formed simultaneously with the gate electrode. Further, before the first metallic is formed, a lithographic process and an etching process are performed on the transparent substrate to form a first depression, the first depression being adapted for receiving the first metallic layer. Also, the gate insulating layer for example covers the first metallic layer.

According to an embodiment of the method for fabricating a pixel structure for a transflective LCD panel, the method of forming a reflective structure for example is by forming a first metallic layer on the transparent substrate, simultaneously with the gate electrode. Further, before forming the first metallic layer, the method includes conducting a lithographic process and an etching process to form a first depression for receiving the metallic layer therein; and thereafter, forming the gate insulating layer covering the first metallic layer.

According to an embodiment of the method for fabricating a pixel structure for a transflective LCD panel, the first metallic layer for example is formed simultaneously with the source/drain electrode. Further, before the first metallic layer is formed, a lithographic process and an etching process are performed on the gate insulating layer to form a second depression, the second depression being adapted for receiving the first metallic layer.

According to an embodiment of the method for fabricating a pixel structure for a transflective LCD panel, the step of forming a reflective structure for example further includes forming a second metallic layer above the first metallic layer. The first metallic layer for example is simultaneously formed with the gate electrode, and the second metallic layer for example is simultaneously formed with the source/drain electrode. Further, before the first metallic layer and the gate electrode are formed, a lithographic process and an etching process are performed on the transparent substrate to form a first depression, the first depression being adapted for receiving the first metallic layer. Furthermore, after the gate insulating layer is formed and before the second metallic layer is formed, a lithographic process and an etching process are performed on the gate insulating layer to form a second depression, the second depression being adapted for receiving the second metallic layer.

According to an embodiment of the invention, after the passivation layer is formed and before the pixel electrode is formed, a flatting layer is formed for covering the TFT and the reflective structure.

When forming a TFT, a reflective structure is simultaneously formed on at least one side of the TFT. There is no extra processing needed to form the reflective structure. Further, this reflective structure is adapted for improving efficiency in backlights utilization of the TFT LCD. BRIEF DESCRIPTION OF THE DRAWING

FIGS. 1A through 1E schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the first embodiment of the invention.

FIGS. 2A through 2E schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the second embodiment of the invention.

FIGS. 3A through 3D schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the third embodiment of the invention.

FIGS. 4A through 4D schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the fourth embodiment of the invention.

FIGS. 5A through 5D schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the fifth embodiment of the invention.

The following embodiments illustrate different types of pixel structures for a transflective LCD. The pixel structure mainly includes a transparent substrate, a

TFT, at least one reflective structure, a pixel electrode and a reflective layer. The TFT is disposed on the transparent substrate, and is located in a reflective region. The reflective structure is configured at one side of the TFT on the transparent substrate, and located in the reflective region. The pixel electrode is disposed above the TFT and the reflective structure, and at least is located in a transparent region. The pixel electrode is electrically connected to the TFT. The reflective layer is disposed above the TFT and the reflective structure, and is located in the reflective region. Detailed structures accompanying with the manufacturing process thereof will be described in the following embodiments. The First Embodiment

FIGS. 1A through 1E schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the first embodiment of the invention. First, the step shown in FIG. 1A, includes providing a transparent substrate 100, and simultaneously forming a gate electrode 110 and a metallic layer 122 on the transparent substrate 100, wherein the metallic layer 122 is formed at one side of the gate electrode 110 for configuring a reflective structure 120. According to the first embodiment, the reflective structure 120 for example can be either sawtooth-shaped or block-shaped. Further, the transparent substrate 100 for example is a glass substrate. The reflective structure 120 and the gate electrode 110 are made of a same material.

Then, the following step shown in FIG. 1C includes forming a semiconductor layer 140 above the gate electrode 110. The method for forming the semiconductor layer 140 includes: forming an amorphous silicon layer 142; then forming an ohmic contact layer 144 on the amorphous silicon layer 142, wherein the ohmic contact layer 144 is made of N+doped amorphous silicon, for example; and thereafter, forming a source electrode 152 and a drain electrode 154. The source electrode 152 and the drain electrode 154 for example are made of a material selected from a group consisting of copper, tungsten, chromium, aluminum or a combination thereof. The gate electrode 110, the semiconductor layer 140, the source electrode 152 and the drain electrode 154 constitute a TFT 160.

Then, the following step shown in FIG. 1D includes optionally forming a passivation layer 170 over the transparent substrate 100, the passivation layer 170 covering the TFT 160; forming a flatting layer 180; then patterning the flatting layer 180 and the passivation layer 170 to form an contact hole 182 of the flatting layer 180 and the passivation layer 170.

Then, the following step shown in FIG. 1E includes: forming a pixel electrode 190, and forming a reflective layer 192 on the pixel electrode 190. The pixel electrode 190 is electrically connected with the drain electrode 154 via the contact hole 182 of the flatting layer 180 and the passivation layer 170. The area of the pixel structure of the transflective LCD panel covered by the reflective layer 192 is a reflective region 101 b,and the area not covered thereby is a transparent region 101 a. According to an aspect of the embodiment, the pixel electrode 190 covers the entire flatting layer 180, while according to other aspects of the embodiment, the pixel electrode 190 can be located within the transparent region 101 a,being adjacent to the reflective layer 192.

It is to be noted that the TFT 160 and the reflective structure 120 are simultaneously configured according to the first embodiment, while in other embodiments, they are individually configured. For example, the TFT 160 is configured at first, and thereafter the reflective structure 120 is configured at one side of the TFT 160, or the reflective structure 120 is configured at first and then the TFT 160 is configured.

According to the first embodiment, the reflective structure 120 is simultaneously formed at one side of the TFT 160, when the gate electrode 110 is formed. In operation, a backlight module (not shown) provides a backlight, the backlight including a light L1 incident to the transparent region 101 aand a light L2 incident to the reflective region 101 b. The light L1 is adapted for passing through the transparent region 101 afor display, and the light L2 is reflected by the reflective layer 192 to the reflective structure 120, wherein the reflective structure 120 reflects the light L2 out of the panel. Therefore, the efficiency in backlights utilization can be improved. The Second Embodiment

FIGS. 2A through 2E schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the second embodiment of the invention. First, the step shown in FIG. 2A includes providing a transparent substrate 200, conducting a lithographic process and an etching process to form a depression 202 at the surface of the transparent substrate 200. The transparent substrate 200 for example is a glass substrate, and the etching liquid used for etching the transparent substrate 200 for example is a hydrogen fluoride solution.

Then, the following step shown in FIG. 2D includes: forming a semiconductor layer 240 on the gate insulating layer 230 and above the gate electrode 210. The method for forming the semiconductor layer 240 includes: forming an amorphous silicon layer 242; then forming an ohmic contact layer 244 on the amorphous silicon layer 242, wherein the ohmic contact layer 244 for example is made of N+ doped amorphous silicon; and thereafter, forming a source electrode 252 and a drain electrode 254. The source electrode 252 and the drain electrode 254 for, example are made of a material selected from a group consisting of copper, tungsten, chromium, aluminum or a combination thereof. The gate electrode 210, the semiconductor layer 240, the source electrode 252 and the drain electrode 254 constitute a TFT 260.

Then, the following step shown in FIG. 2E includes optionally forming a passivation layer 270 over the transparent substrate 200, the passivation layer 270 covering the TFT 260; forming a flatting layer 280; then patterning the flatting layer 280 and the passivation layer 270 to form an contact hole 282 of the flatting layer 280 and the passivation layer 270. The step shown in FIG. 2E further includes forming a pixel electrode 290 and forming a reflective layer 292 on the pixel electrode 290. The pixel electrode 290 is electrically connected with the drain electrode 254 via the contact hole 282 of the flatting layer 280 and the passivation layer 270. The area of the pixel structure of the transflective LCD panel covered by the reflective layer 292 is a reflective region 201 b, and the area not covered thereby is a transparent region 201 a. According to an aspect of the embodiment, the pixel electrode 290 covers the entire flatting layer 280, while according to other aspects of the embodiment, the pixel electrode 290 is located within the transparent region 201 a, adjacent to the reflective layer 292.

According to the second embodiment, a plurality of depressions 202 are formed at the surface of the transparent substrate 200 for the reflective structure 220 to be formed therein when the gate electrode 210 is formed. The reflective structure 220 for example is block-shaped. The reflective structure 220 configured at one side of the TFT 260 is adapted for improving the efficiency in backlights utilization. The Third Embodiment

FIGS. 3A through 3D schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the third embodiment of the invention. First, the step shown in FIG. 3A includes providing a transparent substrate 300, and forming gate electrode 310 on the transparent substrate 300.

Then, the following step shown in FIG. 3C, includes: forming a source electrode 352, a drain electrode 354, and at the same time forming a metallic layer 322 at one side of the source electrode 352 and the drain electrode 322. The gate electrode 310, the semiconductor layer 340, the source electrode 352 and the drain electrode 354 constitute a TFT 360, and the metallic layer 322 functions as a reflective structure 320. The reflective structure 320 for example is sawtooth-shaped or block-shaped. Further, the reflective structure 320, the source electrode 352 and the drain electrode 354 are made of a same material.

Then, the following step shown in FIG. 3D, includes: optionally forming a passivation layer 370 over the transparent substrate 300, the passivation layer 370 covering the TFT 360 and the metallic layer 322; forming a flatting layer 380; then patterning the flatting layer 380 and the passivation layer 370 to form an contact hole 382 of the flatting layer 380 and the passivation layer 370. The step shown in FIG. 3D further includes forming a pixel electrode 390, and forming a reflective layer 392 on the pixel electrode 390. The pixel electrode 390 is electrically connected with the drain electrode 354 via the contact hole 382 of the flatting layer 380 and the passivation layer 370. The area of the pixel structure of the transflective LCD panel covered by the reflective layer 392 is a reflective region 301 b, and the area not covered thereby is a transparent region 301 a. According to an aspect of the embodiment, the pixel electrode 390 covers the entire flatting layer 380, while according to other aspects of the embodiment, the pixel electrode 390 is located within the transparent region 301 a, adjacent to the reflective layer 392.

According to the third embodiment, a reflective structure 320 is configured on the gate insulating layer 330 at one side of the TFT 360, when the source electrode 352 and the drain electrode 354 are formed. The reflective structure 320 is adapted for improving the efficiency in backlights utilization. The Fourth Embodiment

FIGS. 4A through 4D schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the fourth embodiment of the invention. First, the step shown in FIG. 4A includes providing a transparent substrate 400, and forming gate electrode 410 on the transparent substrate 400.

Then, the following step shown in FIG. 4C, includes: conducting a lithographic process and an etching process to form a depression 432 on the gate insulating layer 430; then simultaneously forming a source electrode 452, a drain electrode 454 and a metallic layer 422, wherein the source electrode 452 and the drain electrode 454 are located on the gate electrode 410, and the metallic layer 422 is lodged in the depression 432 for configuring a reflective structure 420. The gate electrode 410, the semiconductor layer 440, the source electrode 452 and the drain electrode 454 constitute a TFT 460. The reflective structure 420 for example is sawtooth-shaped or block-shaped. Further, the reflective structure 420, the source electrode 420 and the drain electrode 454 are made of a same material.

Then, the following step shown in FIG. 4D includes: optionally forming a passivation layer 470 over the transparent substrate 400, the passivation layer 470 covering the TFT 460 and the metallic layer 422; forming a flatting layer 480; then patterning the flatting layer 480 and the passivation layer 470 to form an contact hole 482 of the flatting layer 480 and the passivation layer 470. The step shown in FIG. 4D further includes forming a pixel electrode 490, and forming a reflective layer 492 on the pixel electrode 490. The pixel electrode 490 is electrically connected with the drain electrode 454 via the contact hole 482 of the flatting layer 480 and the passivation layer 470. The area of the pixel structure of the transflective LCD panel covered by the reflective layer 492 is a reflective region 401 b, and the area not covered thereby is a transparent region 401 a. According to an aspect of the embodiment, the pixel electrode 490 covers the entire flatting layer 480, while according to other aspects of the embodiment, the pixel electrode 490 is located within the transparent region 401 a, adjacent to the reflective layer 492.

According to the third embodiment, the depression 432 is formed on the gate insulating layer 430 for configuring a reflective structure 420 lodged in the depression 432 of the gate insulating layer 430 at one side of the TFT 460, when the source electrode 452 and the drain electrode 454 are formed. The reflective structure 420 is adapted for improving the efficiency in backlights utilization. The Fifth Embodiment

FIGS. 5A through 5D schematically illustrate a flow chart of fabricating a pixel structure for a transflective LCD panel, according to the fifth embodiment of the invention. First, the step shown in FIG. 5A includes providing a transparent substrate 500, and forming gate electrode 510 and a metallic layer 522 on the transparent substrate 500, wherein the metallic layer 522 is located at one side of the gate electrode 510. According to an aspect of the embodiment, a method for forming the metallic layer 522 is by directly forming a patterned metallic layer on the transparent substrate 500 as shown in FIG. 1. Another method for forming the metallic layer 522 can be, as shown in FIG. 2, by conducting a lithographic process and an etching process to form a depression (not shown) for receiving the metallic layer 522 when forming the gate electrode 510.

Then, the following step shown in FIG. 5C includes: forming a source electrode 552, a drain electrode 554, and at the same time forming a metallic layer 522, wherein the source electrode 552 and the drain electrode 554 are above the gate electrode 510, and the metallic layer 524 is above the metallic layer 522. The gate electrode 510, the semiconductor layer 540, the source electrode 552 and the drain electrode 554 constitute a TFT 560, and the metallic layer 522 and the metallic layer 524 function as a reflective structure 320. Further, the metallic layer 522 and the gate electrode 510 are made of a same material, while the metallic layer 524 and the source electrode 552, the drain electrode 554 are made of a same material. The metallic layer 522 and the metallic layer 524 for example are sawtooth-shaped or block-shaped.

Then, the following step shown in FIG. 5D includes: optionally forming a passivation layer 570 over the transparent substrate 500, the passivation layer 570 covering the TFT 560 and the metallic layer 522; forming a flatting layer 580; then patterning the flatting layer 580 and the passivation layer 570 to form an contact hole 582 of the flatting layer 580 and the passivation layer 570. The step shown in FIG. 5D further includes forming a pixel electrode 590, and forming a reflective layer 592 on the pixel electrode 590. The pixel electrode 590 is electrically connected with the drain electrode 554 via the contact hole 582 of the flatting layer 580 and the passivation layer 570. The area of the pixel structure of the transflective LCD panel covered by the reflective layer 592 is a reflective region 501 b, and the area not covered thereby is a transparent region 501 a. According to an aspect of the embodiment, the pixel electrode 590 covers the entire flatting layer 580, while according to other aspects of the embodiment, the pixel electrode 590 is located within the transparent region 501 a, adjacent to the reflective layer 592.

According to the fifth embodiment, the reflective structure 520 for example is a dual-layer structure configured simultaneously with the gate electrode 510, the source electrode 522 and the drain electrode 554. The reflective structure 520 is located at one side of the TFT 560 for improving the efficiency in backlights utilization.

According to the above-described embodiments, combined with an optical mask processing, the present invention is adapted for fabricating a reflective structure at one side of a TFT, for improving the efficiency in backlights utilization. The reflective structure can be formed simultaneously with the gate, and can either protrude from or lodge into the substrate surface. Further, the reflective structure can also be formed simultaneously with the source/drain electrode, and can either protrude from or lodge into the substrate surface. Furthermore, the reflective structure can also be a dual-layer structure, or even a combination of the above-mentioned types.

In summary, the pixel structure for a transflective LCD panel and the fabricating method thereof according to the present invention have at least the following advantages and features: 1. A reflective structure is disposed on at least one side of the TFT, thus improving the efficiency in backlights utilization;

2. The reflective structure is formed at one side of the TFT while the TFT is formed, thereby excluding additional optical masks and process, and saving production cost.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

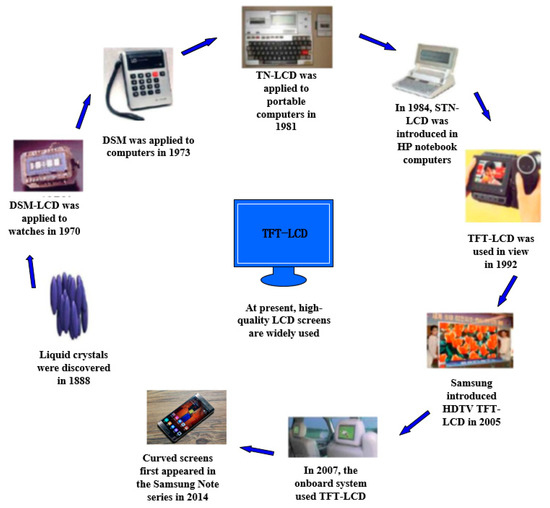

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Global Thin Film Transistor (TFT) Display Market, By Technology (Plasma Display (PDP), Organic Light Emitting Diode (OLED), Other), Type (Twisted Nematic, In-Plane Switching, Advanced Fringe Field Switching, Multi-Domain Vertical Alignment, Advanced Super View, Cell Technology), Panel Type (A_MVA, ASV, MVA, S_PVA, P-IPS), End Use (Domestic Use, Industrial Use) – Industry Trends and Forecast to 2029

Global Thin Film Transistor (TFT) Display Market was valued at USD 270.26 million in 2021 and is expected to reach USD 968.64 million by 2029, registering a CAGR of 17.30% during the forecast period of 2022-2029. Twisted Nematic accounts for the largest type segment in the respective market owing to its low cost. The market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

A thin-film-transistor display refers to a form of LCD that uses TFT technology for enhancing image quality including addressability and contrast. These displays are commonly utilized in mobile phones, handheld video game systems, projectors, computer monitors, television screens, navigation systems and personal digital assistants.

The increase in the smartphone and tablet proliferation acts as one of the major factors driving the growth of thin film transistor (TFT) display market. Technological advancements are leading a radical shift from traditional slow, bulky and imprecise resistive mono touch to highly sensitive multi-touch capacitive screen have a positive impact on the industry.

The increase in application areas of large e thin film transistor (TFT) display due to the advantages offered by these paper displays in terms of user experience, manufacturing cost, readability, and energy consumption further influence the market.

Additionally, rapid urbanization, change in lifestyle, surge in investments and increased consumer spending positively impact the thin film transistor (TFT) display market.

On the other hand, high cost associated with the manufacturing is expected to obstruct market growth. Also, lack of awareness and low refresh rate are projected to challenge the thin film transistor (TFT) display market in the forecast period of 2022-2029.

This thin film transistor (TFT) display market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on thin film transistor (TFT) display market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The COVID-19 has impacted thin film transistor (TFT) display market. The limited investment costs and lack of employees hampered sales and production of electronic paper (e-paper) display technology. However, government and market key players adopted new safety measures for developing the practices. The advancements in the technology escalated the sales rate of the thin film transistor (TFT) display as it targeted the right audience. The increase in sales of devices such as smart phones and tablets across the globe is expected to further drive the market growth in the post-pandemic scenario.

The thin film transistor (TFT) display market is segmented on the basis of technology, type, panel type and end-use. The growth amongst these segments will help you analyze meager growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

The thin film transistor (TFT) display market is analysed and market size insights and trends are provided by country, technology, type, panel type and end-use as referenced above.

The countries covered in the thin film transistor (TFT) display market report are U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA).

North America dominates the thin film transistor (TFT) display market because of the introduction of advanced technology along with rising disposable income of the people within the region.

The thin film transistor (TFT) display market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies" focus related to thin film transistor (TFT) display market.

In China. The biggest LCD panel manufacturer in the world now. BOE has G4 (Chengdu), G5 (Beijing), G5.5 (Ordos), G6 (Hefei, Chengdu, Mianyang, Dalian), G8 (Beijing, Hefei, Chongqing), Fuqing, Dalian, Chongqing) and 10.5 (Hefei) production lines.

In Taiwan. One of the daughter company of Foxconn/Hon Hai. In 2010, it bought the then famous LCD manufacturer, ChiMei, then changed its name to Innolux. It has G7.5 production lines.

In Korea and China. It is used to be the 2nd biggest TFT LCD manufacturers. LG also planned to stop the production but delayed the plan after the price increased. LG has G7.5 and G8.5 (Guangzhou) production lines.

In Korea. It used to be the biggest TFT LCD manufacturers before it was dethroned by BOE in 2019. Because of tough competition, Samsung planned to stop the production in 2021 but delayed because the price increase during the pandemic. Samsung has G7 and G8.5 production lines.

In Japan and China. The pioneer and queen of LCD industry. Because of high cost and tough competitor, Sharp was acquired by Foxconn/Hon Hai in 2016. Sharp has G8, G8.5(Suzhou), G10, G10.5 (Guangzhou) production lines.

This article is not about freedom-to-operate analyses. Rather, it is primarily intended for people who operate at the intersection of science, technology, and business, and who see patents as one (but not the only) source of information.

There are a number of free services you can use to find patents. Google Patents, for example, or Espacenet, which is operated by the European Patent Office, or EPO. The EPO has the biggest patent database in the world. Its database collects and aggregates patent documents from patent offices worldwide.

Mergeflow gets its patent data from the EPO. Our algorithms include several analytics capabilities that the free services mentioned above do not have. For instance, Mergeflow tags all incoming patents with a range of emerging technologies from across several technology sectors and industries. I will come back to this below.

Furthermore, since Mergeflow collects and analyzes a range of other data sets across science, technology, and business, you get an “un-siloed” view. For example, if you f

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey