tft lcd ips vs gorilla glass made in china

IPS-LCDs are costlier than normal TFT LCD and hence are found only on higher end smartphones. A higher resolution (640 x 960 pixels) version of IPS LCD is used in Apple iPhone 4 and is called Retina Display because of its brilliant picture quality.

It is a special alkali-aluminosilicate glass shield with exceptional damage resistance that helps protect mobile displays from scratches, drops, and bumps of everyday use. Many companies like Motorola, Samsung and Nokia are now using Gorilla Glass to make their mobile displays more durable and reliable. It is always better to go for a smartphone with Gorilla Glass for that added protection and peace of mind.

LCDs use a simple grid to supply the charge to a particular pixel on the display. Creating the grid is quite a process! It starts with two glass layers called substrates.

AMOLED Display and Gorilla Glass Has Been Popular Out of Marketing by the Companies. What Are AMOLED Display and Gorilla Glass of Smartphones? In very short – AMOLED Display is a display technology like OLED, TFT-LCD are display technologies. Basic is any type of LED display is one multi color RGB LED controlled by a programmable micro-controller, multiple RGB LED controlled via multiplexing. Up to RGB LED display is what we can do with Arduino to built DIY color display unit. After that, the individual units become too small SMD components. As they many a times AMOLED Display and Gorilla Glass co-exist in advertisements for the display units of modern Android smartphones, we thought to discuss them together in one article divided in two sub-headers.

Corning Inc is an 167 years old company who manufactures patented glass related things like yellow colored headlamp lenses of automobile. Today after 100 years, that yellow colored headlight seems ordinary. Corning is a glass expert company themselves with huge resources :

Gorilla Glass is a branded toughened or tempered glass. Tempered glass glasses upon fracture stress does not splinter into jagged shards plate glasses but cause the glass to crumble into small granular chunks. These glasses are most susceptible to breakage due if extra stress applied to the edge of the glass. But shattering can also occur in the event of a hard impact in the middle of the glass.

Gorilla Glass is simply a branded scratch resistant touchscreen glass. Corning is manufacturing similar tempered glass since 1960s, which are used for both industrial and commercial fields. In 2005, 2008 they introduced newer type of tempered glass. Gorilla Glass is an alkali-aluminosilicate thin glass designed to function as protective cover glass for smartphone display (in our current context). That Gorilla is made by a proprietary process named Corning’s fusion draw. Gorilla Glass does not interfere with Capacitive Touch Screen. Gorilla Glass has versions and Gorilla Glass 5 is towards latest version. Corning has full lists unless smartphone manufacturer not allowed to publish :

2.5D glass is kind of generic version of toughened glass for smartphones which can have edges like Gorilla Glass. There are 3D Curved Surface Tempered Glass for J7 Max with videos on YouTube. That will give you an idea of “curved edges”.

Samsung, LG are working on plastic screens which can be folded and are lighter than Corning’s products. Gorilla Glass is exactly like Corning’s yellow colored headlamp lenses of automobile. It is important now, sells well; may be outdated in future.

Next we talk about the technology behind your display screen. There are different types of technologies that are used to make smartphone display screen which generally includes TFT LCD, IPS LCD, AMOLED / Super AMOLED.

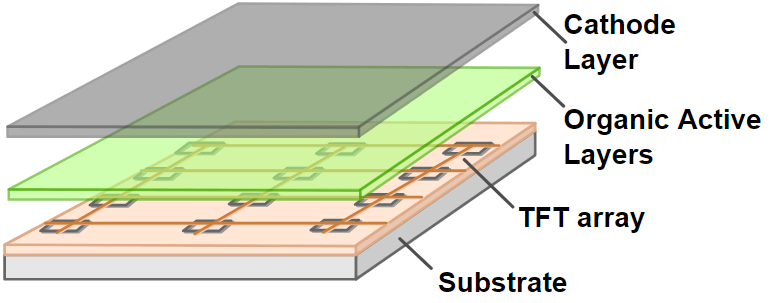

Thin Film Transistor Liquid Crystal Display or TFT LCD is a relatively older type of display screen technology that is cheap to manufacturer and is used in budget smartphones, TVs, computer monitors, handheld video games, cameras, navigation systems, projectors etc. It is a variant of traditional LCD display technology and TFT LCD uses thin film transistors (TFT) to improve the image quality and contrast of a regular LCD screen.

IPS (In-plane switching) is also a technology for LCDs or Liquid Crystal Displays. This display technology is used in iPhones and many other current mid to high-end smartphones. IPS LCD offers most accurate color reproduction, clear images and stable response time. They require relatively more power to operate as compared to AMOLED and TFT LCD screen.

This layer of Protection Glass sits above the display screen and it protects your display screen from getting damaged. The two most widely used protection glass are Gorilla glass and Dragontrail glass. Fully Laminated OGS or One Glass Solution is another technology that integrates touchscreen device and protection glass in one unit to provide thinner screen with vibrant colors and richer display with excellent visibility. The most common example of fully laminated OGS technology is Concore glass from Corning.

Welcome at Riverdi University. In this lecture we’ll talk about different kinds of glass in TFT LCD displays and surfaces that we use to protect displays, or we can use to protect with the glass the entire devices

We will talk about different types of glass in TFT LCD displays, then the surface treatments, what we do to achieve different parameters of glass surfaces, about the hardness – important when we want to protect something, then about painting the glass, how we do it and what we can achieve, IK rate, how much mechanical impact we can place on the glass, and will it withstand this still and at the end about laminated glass, why we laminate glass and what we can achieve by doing that.

The most important thing with the glass in TFT LCD displays is to protect the display, but not only. As you can see on the pictures above, glass is an element of the design of the devices. It makes devices look better and can be designed in a way that protects not only the display, but the entire surface of a device, like for example for the coffee machine on the picture above, where we have a display with some additional graphic that covers the whole front of the device. Glass is one of the best materials that we use in electronics to protect screens, because it is very hard and it is hard to scratch. It is mechanically strong, cheap, and exceptionally good in optics. For glass, the transparency rate is typically more than 90% or even 95% percent. It is widely available, we know a lot of techniques how to manufacture it and how to prepare it for some special advanced designs as we can change the shape of glass quite easily nowadays.

Now we will talk about types of glass that we use to protect screens and devices. Mainly we use two types of glass in TFT LCD displays, one is chemically strengthened glass, that we call CS type glass, the other is thermally tempered glass, hardened glass where we use hot temperature to make it stronger. For our standard products we typically use on the touch screens chemically strengthened glass. Our standard thickness is 1.1-millimeter thickness. This kind of glass is pretty strong, comparing to the regular glass. Chemical strengthening means that we treat the surface with ions, usually silver ions. We increase the strength of the surface of the glass because glass usually breaks when the surface breaks. We do not change the glass internally with chemical strengthening, we just change the surface hardness, and it is enough to make the glass much stronger.

As you can see in the table above, with chemical strengthening we can make glass even 6 or 8 times mechanically stronger than the regular one. This is a very long process; it can take several hours, and we need hot temperature, 400 or more degrees. Thermally tempered glass is a separate way of strengthening glass. We use hot temperature and very fast cooling to make the glass stronger. We need a higher temperature, 700 degrees in this process, but it is much faster, it takes just several minutes, and we achieve strong glass, 4 to 5 times stronger than regular float glass. Thermally tempered glass is not as strong as chemically strengthened glass. It is cheaper, but we cannot use it for thin glass. The thinnest glass that we can thermally temper is 3-4 millimeter. If the glass is thinner, with hot temperature it starts floating and the surface will not be flat again. So, if we have a thick glass, it would be cheaper to use the thermally tempered solution. That is why it is more popular. For thinner glass we use chemical strengthening, because we cannot use the thermally tempered solution.

Now we will talk about the other difference between these two methods of strengthening glass. On the left side of the picture above, you can see chemically strengthened glass broken, and on the right side there is thermally tempered glass broken. Chemically strengthened glass breaks like regular glass because we do not change the internal part of the glass. We only make the surface stronger, but inside the glass is the same as regular float glass, and it breaks just like it. Thermally tempered glass changes the internal structure of the glass and it breaks into very small pieces. In many cases it is better because it is safer for humans, that is why we normally use thermally tempered glass in cars or in places where broken glass may injure people.

Another property or type of glass that we will talk about is Optiwhite and Float. Float is the most common glass that we use in architecture designs, but also in many touchscreens. The float glass is the most common, most popular and the cheapest, but sometimes we have specific requirements. We sometimes need to have very good color reproduction, especially light colors, white color. Then we use glass called Optiwhite. To achieve that we need to remove the iron from the glass. Float glass has a little bit of iron which makes it green or greenish. If we look straight through the glass, we may not see that but if we look like from an angle, we can see the green color. If we put a white background, we will also see this greenish color a little bit. So, if there are specific requirements, we use Optiwhite, it is especially worth considering if you have a white background. Usually, the Optiwhite is a little bit more expensive, so it is worth checking with the manufacturer of the display what we can use in our case.

Now we know how glass is made, how it is being strengthened, how it breaks and what types of glass, Float and Optiwhite, we have. To continue, we will talk about surface treatments other than strengthening. The other treatments that we use are anti-glare, anti-fingerprint, anti-reflective and anti-bacterial. About anti-reflective treatment we have talked in another video about

On the picture above there are examples of glass. One of them is a little bit blurry, it is anti-glare and the other one is clear – it is anti-reflective. In the past, anti-glare glass was more popular and used in some commercial devices, but later manufacturers have found that devices with anti-glare are being sold less frequently than the glare ones. It is because as humans we think that there is something wrong with a little bit blurry image even if the reflections are lower. When we are in a shop and looking at phones, we do not see the image clearly and we think that there is something wrong and we do not want this device. That is why we do not see any more anti-glare glass in consumer products. Everything is glare in consumer products, it could be anti-reflective or could be only regular without any surface treatment. But in the professional market that we are working on, like medical devices, military devices, we have many projects where we use anti-glare and anti-reflective treatments, both solutions to reduce reflections and increase contrast.

Now let us talk about hardness of glass in TFT LCD displays. Of course, to talk about hardness we need to measure it. For that we have the Mohs scale where we have 11 different levels of hardness. Like you see on the picture above, the 10th is diamond and the 1st is talk. What we normally use is glass with hardness between 5 and 7. In some cases we also use Gorilla glass with hardness 9. It is used on our phones or tablets. As you can see, we can achieve hardness 7 with chemically strengthened glass and usually 6 with thermally strengthened glass. Gorilla glass is also chemically strengthened glass, patented by the Corning company and it is the strongest that we can achieve in the cover glass to protect the screen.

This scale is about surface hardness – how hard is it to scratch the surface. As you know, even glass with hardness 9 can be scratched, everybody has some scratches on their phone because this hard layer is very thin – 10 micrometers only. If we put enough force and break this barrier, then we have soft glass with hardness 6 or even lower, that is why we have the scratches.

A couple more words about Gorilla glass. Now there is the sixth generation of Gorilla Glass on the market. The goal for Corning company and Gorilla Glass is to make the glass as strong and as light as possible, because most of the cases are handheld devices, where we want the glass to be light, that is why we want to make it very thin. We have also other companies that are making equivalents of Gorilla Glass, like Dragontrail from AGC or Xensation from Shott. They are not so popular but in many mobile phones or tablets on the market you can find these types of glass.

Now let us talk about the painting. We know the types of glass that we use in TFT LCD displays, we know how to make the glass stronger, we know the surface treatments, how to make the glass less reflective or anti-fingerprint or antibacterial, but it is not enough because glass will only be transparent. If we want to cover it, we need to paint it. Typically, we paint glass with the technique called Screen Printing. It is the most popular, cheapest and fastest technique.

When we do the Screen Printing, we need a screen for each color, so to minimize cost, we try to reduce the number of colors to 2–4, like the background and the colored logo. Each color is a different process, we need to wait until the previous painting dries and then we need to put another screen and print another color. More colors mean a longer process and of course a higher cost. Of course, we can change the shape of the glass, we can make rounded corners or custom design of the glass, but it is expensive because first it is just the rectangular piece, then you need to go to the CNC machine to make the proper shape of the glass.

Now we will talk about mechanical impact protection. It is different than the surface hardness we talked about before. On the picture above, we have the test and scale to measure the mechanical strength of glass, that means how much energy we can put on the glass before it breaks. It is measured in IK rate. IK rate is a scale where we have different levels and different energy that will boost. For example, if we want to test IK 9, we need to take 5-kilogram mass from 200-millimeter height. The mass is kept above the tested glass using an electromagnet, then we just drop it, and we see if it breaks or not. If not, of course the test is passed.

If the glass has not passed the test, we can try to change the glass type from thermally tempered to chemically strengthened or go to a thicker glass.

The last point in this article is laminated glass. We laminate glass because of a few reasons. First, what is laminated glass. Laminated glass is like putting the film inside two glass sheets. This process is expensive, we need pressure, we need temperature, we need time, and we need an exceptionally clean environment, because when we laminate together two sheets of glass, we need to be sure that no particles get inside. This kind of process needs to be done in a Clean Room, so it is expensive, but as you see on the picture above, even if the glass is broken, it still holds up because of the laminated film inside.

We laminate glass mainly because of two reasons. One is mechanical strength and impact. We use it even in our homes. Many windows used nowadays are anti-vandal and that means they are laminated glass, and they are extraordinarily strong. The other reason to laminate glass is to put a film inside with some properties, usually to block the UV or IR light. IR means infrared so heat and UV means ultraviolet, short wavelength, extremely dangerous for electronics. When we have an outdoor application, some customers want to protect the displays, touchscreens or the e-paper displays also against UV. Then we use laminated glass and as you can see on the chart above the IR cut film and UV cut film are both transparent for visible light. We can see everything through them, but what is higher and what is lower is cut by UV and IR films. Most often we use only UV cut film because UV is more dangerous, for example it makes the film sensors for capacitive touchscreens turn yellow or it can decrease the contrast of the TFT (Thin Film Transistor) display by damaging the polarizer or color filters. The IR film is used in some applications to protect the display from heat. If we add it, we can decrease the temperature of the display surface. In another video we were talking about High-TN, so liquid crystals that can work in very high temperatures. For this kind of liquid crystals, we usually do not need to decrease the temperature of the surface because they can go up to 100 or 110 degrees, but regular displays can work up to 50- or 70-degrees maximum temperature. Using the IR cut film can solve the problem with blackening and increasing the display temperature too much.

In recent years, smartphone displays have developed far more acronyms than ever before with each different one featuring a different kind of technology. AMOLED, LCD, LED, IPS, TFT, PLS, LTPS, LTPO...the list continues to grow.

There are many display types used in smartphones: LCD, OLED, AMOLED, Super AMOLED, TFT, IPS and a few others that are less frequently found on smartphones nowadays, like TFT-LCD. One of the most frequently found on mid-to-high range phones now is IPS-LCD. But what do these all mean?

LCD means Liquid Crystal Display, and its name refers to the array of liquid crystals illuminated by a backlight, and their ubiquity and relatively low cost make them a popular choice for smartphones and many other devices.

LCDs also tend to perform quite well in direct sunlight, as the entire display is illuminated from behind, but does suffer from potentially less accurate colour representation than displays that don"t require a backlight.

Within smartphones, you have both TFT and IPS displays. TFT stands for Thin Film Transistor, an advanced version of LCD that uses an active matrix (like the AM in AMOLED). Active matrix means that each pixel is attached to a transistor and capacitor individually.

The main advantage of TFT is its relatively low production cost and increased contrast when compared to traditional LCDs. The disadvantage of TFT LCDs is higher energy demands than some other LCDs, less impressive viewing angles and colour reproduction. It"s for these reasons, and falling costs of alternative options, that TFTs are not commonly used in smartphones anymore.Affiliate offer

IPS technology (In-Plane Switching) solves the problem that the first generation of LCD displays experience, which adopts the TN (Twisted Nematic) technique: where colour distortion occurs when you view the display from the side - an effect that continues to crop up on cheaper smartphones and tablets.

The PLS (Plane to Line Switching) standard uses an acronym that is very similar to that of IPS, and is it any wonder that its basic operation is also similar in nature? The technology, developed by Samsung Display, has the same characteristics as IPS displays - good colour reproduction and viewing angles, but a lower contrast level compared to OLED and LCD/VA displays.

According to Samsung Display, PLS panels have a lower production cost, higher brightness rates, and even superior viewing angles when compared to their rival, LG Display"s IPS panels. Ultimately, whether a PLS or IPS panel is used, it boils down to the choice of the component supplier.

This is a very common question after "LED" TVs were launched, with the short answer simply being LCD. The technology used in a LED display is liquid crystal, the difference being LEDs generating the backlight.

One of the highlights from TV makers at the CES 2021 tradeshow, mini-LED technology seemed far removed from mobile devices until Apple announced the 2021 iPad Pro. As the name implies, the technique is based on the miniaturization of the LEDs that form the backlight of the screen — which still uses an LCD panel.

Despite the improvement in terms of contrast (and potentially brightness) over traditional LCD/LED displays, LCD/mini-LEDs still divide the screen into brightness zones — over 2,500 in the case of the iPad and 2021 "QNED" TVs from LG — compared to dozens or hundreds of zones in previous-generation FALD (full-array local dimming) displays, on which the LEDs are behind the LCD panel instead of the edges.

AMOLED stands for Active Matrix Organic Light-Emitting Diode. While this may sound complicated it actually isn"t. We already encountered the active matrix in TFT LCD technology, and OLED is simply a term for another thin-film display technology.

OLED is an organic material that, as the name implies, emits light when a current is passed through it. As opposed to LCD panels, which are back-lit, OLED displays are "always off" unless the individual pixels are electrified.

This means that OLED displays have much purer blacks and consume less energy when black or darker colours are displayed on-screen. However, lighter-coloured themes on AMOLED screens use considerably more power than an LCD using the same theme. OLED screens are also more expensive to produce than LCDs.

Because the black pixels are "off" in an OLED display, the contrast ratios are also higher compared to LCD screens. AMOLED displays have a very fast refresh rate too, but on the downside are not quite as visible in direct sunlight as backlit LCDs. Screen burn-in and diode degradation (because they are organic) are other factors to consider.Affiliate offer

OLED stands for Organic Light Emitting Diode. An OLED display is comprised of thin sheets of electroluminescent material, the main benefit of which is they produce their own light, and so don"t require a backlight, cutting down on energy requirements. OLED displays are more commonly referred to as AMOLED displays when used on smartphones or TVs.

Super AMOLED is the name given by Samsung to its displays that used to only be found in high-end models but have now trickled down to more modestly specced devices. Like IPS LCDs, Super AMOLED improves upon the basic AMOLED premise by integrating the touch response layer into the display itself, rather than as an extra layer on top.

Resolution describes the number of individual pixels (or points) displayed on the screen and is usually presented for phones by the number of horizontal pixels — vertical when referring to TVs and monitors. More pixels on the same display allow for more detailed images and clearer text.

Speaking of pixel density, this was one of Apple"s highlights back in 2010 during the launch of the iPhone 4. The company christened the LCD screen (LED, TFT, and IPS) used in the smartphone as "Retina Display", thanks to the high resolution of the panel used (960 by 640 pixels back then) in its 3.5-inch display.

As a kind of consolation prize for iPhone XR and iPhone 11 buyers, who continued relying on LCD panels, Apple classified the display used in the smartphones with a new term, "Liquid Retina". This was later applied also to the iPad Pro and iPad Air models, with the name defining screens that boast a high range and colour accuracy, at least based on the company"s standards.

TFT(Thin Film Transistor) - a type of LCD display that adopts a thin semiconductor layer deposited on the panel, which allows for active control of the colour intensity in each pixel, featuring a similar concept as that of active-matrix (AM) used in AMOLED displays. It is used in TN, IPS/PLS, VA/PVA/MVA panels, etc.

LTPS(Low Temperature PolySilicon) - a variation of the TFT that offers higher resolutions and lower power consumption compared to traditional TFT screens, based on a-Si (amorphous silicon) technology.

IGZO(Indium Gallium Zinc Oxide) - a semiconductor material used in TFT films, which also allows higher resolutions and lower power consumption, and sees action in different types of LCD screens (TN, IPS, VA) and OLED displays

LTPO(Low Temperature Polycrystaline Oxide) - a technology developed by Apple that can be used in both OLED and LCD displays, as it combines LTPS and IGZO techniques. The result? Lower power consumption. It has been used in the Apple Watch 4 and the Galaxy S21 Ultra.

Among televisions, the long-standing featured technology has always been miniLED - which consists of increasing the number of lighting zones in the backlight while still using an LCD panel. There are whispers going around that smartphones and smartwatches will be looking at incorporating microLED technology in their devices soon, with it being radically different from LCD/LED displays as it sports similar image characteristics to that of OLEDs.

In the case of LCD displays, the main advantage lies in the low manufacturing cost, with dozens of players in the market offering competitive pricing and a high production volume. Some brands have taken advantage of this feature to prioritize certain features - such as a higher refresh rate - instead of adopting an OLED panel, such as the Xiaomi Mi 10T.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

Over time, the purpose of using mobile phones or Smartphones has changed. Comparatively, it has now become a basic necessity of every individual. Smartphone has dramatically transformed the lives of individuals. It has now become a mini-computer that everyone carries in their pocket. Instead, you can have multiple things at your fingertips in a few seconds. While there are plenty of things to look for, AMOLED vs OLED is also a part of it.

This article will introduce you to AMOLED vs OLED display technologies. Then, we will discuss the properties of both display technologies, followed by the difference between AMOLED vs OLED.

AMOLED stands for Active Matrix Organic Light Emitting Diode. This type of display is generally for large platforms. It contains TFT, which further consists of a storage capacitor. It also works on the same principle as OLED displays.

AMOLED offers no restriction on the size of the display. The power consumption of AMOLED is much less than other display technologies. The AMOLED provides incredible performance. It is thinner, lighter, and more flexible than any other display technology like LED, or LCD technology.

The AMOLED display is widely used in mobiles, laptops, and televisions as it offers excellent performance. Therefore, SAMSUNG has introduced AMOLED displays in almost every product. For example, Full HD Super AMOLED in Samsung Galaxy S4 and Samsung Galaxy Note 3, Super AMOLED in Samsung Galaxy S3, HD Super AMOLED in Samsung Galaxy Note, and HD Super AMOLED Plus in Samsung Galaxy S3. Apart from this, it is also used in AMOLED vs OLED creating the following:

OLED comprises thin layers of the organic component, which emits light when the current passes through it. In this technology, each pixel transmits its own light. On the other side, AMOLED consists of an additional layer of thin-film transistors (TFTs). In AMOLED, the storage capacitors are used to maintain the pixel states.

While the technology is different among various manufacturers, Samsung’s edge AMOLED displays use plastic substrates with poly-Si TFT technology similar to how LG uses it in their POLED technology. This technology is what makes the possibility to build curved displays using an active-matrix OLED panel.

OLED display much deeper blacks as compared to the AMOLED displays. You cannot see the screen in AMOLED display under direct sunlight. The AMOLED display quality is much better than the OLEDs as it contains an additional layer of TFTs and follows backplane technologies.

These organic compounds are present between the protective layers of glass or plastic. Comparatively, AMOLED comprises an active matrix of OLED pixels along with an additional layer of TFTs. This extra layer is responsible for controlling the current flow in each pixel.

OLED displays are comparatively much thinner compared to the LCDs. Hence, it provides more efficient and bright presentations. In addition, OLED offers support for large display sizes compared to the traditional LCDs. AMOLEDs remove the limitation of display sizes. one can fit it into any display size.

The Xiaomi Mi 11 Lite runs on Snapdragon 732G chipset bundled with Adreno 618 GPU and up to 8GB RAM. The display front comes with a 6.55-inch AMOLED display with HDR 10+ support and 402 PPI.

OPPO has recently launched the Oppo Reno 6 Pro with MediaTek’s Density 1200 chipset coupled with Mali-G77 MC9 GPU and up to 12GB of RAM. In addition, it comes with a 6.55-inch curved AMOLED FHD+ display with support for HDR 10+ and an Oleophobic coating.

Major smartphone manufacturers attempt to provide their consumers with the most delicate devices possible that incorporate the most up-to-date technologies. In AMOLED vs OLED, AMOLED is a type of OLED and a more prominent example of both OLED and POLED, so there’s no debate about which is superior.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

tempered glass monitors, on the other hand, are a great choice for customers looking to add a wider variety of tempered glass monitors to their applications.

tempered glass makes it a good choice for windows or doors. Wholesalers on Alibaba.com offer a wide variety of tempered glass monitor, for example, a bathroom tempered glass monitor, or a bathroom tempered glass monitor. When buying large bulk for your customers, it would be a good idea to stock a variety of tempered glass monitor.

Find a tempered glass monitor for your customers" needs, Alibaba.com offers a wide variety of tempered glass monitors to meet the wholesale needs of your customers. Commercial tempered glass monitors are usually made in glass or plastic to provide a wide variety of advantages and disadvantages.

Check out the wide variety of tempered glass monitors from Alibaba.com ’ s computer suppliers to offer you a wide choice of wholesale tempered glass monitors at Alibaba. Wholesale tempered glass monitors for sale are easy to find and buy the products that your business will need.

![]()

LCD TV Panel Prices Headed for One “L” of a Recovery in Q4Flat Panel Display Revenues Falling 19% in 2022, but Revenues Will Recover to $153 Billion in 2026LGD, AUO Fall to Losses in Q2Samsung Continued to Ride Semi Strength to Profitable Q2

Apple Reports 2% Y/Y Growth – Expects Revenue Growth to Accelerate Despite Pockets of SoftnessQualcomm Revenue Increases 36% Y/Y - Downgrades Outlook on Challenging Macroeconomic EnvironmentMotorola to Announce Razr 2022 and New Flagship on August 2ndAsus and Vivo Announce New AMOLED SmartphonesIntel and MediaTek Form Foundry PartnershipSamsung Trademark Hints at a 450MP Smartphone Image Sensor

DSCC Report Reveals Advanced Tablet Market Rose 99% in 2021, Apple Dominates, MiniLED Supply Chain and Product UpdatesLCD TV Panel Price Declines Moderating Further in MarchDSCC’s Display Capacity Outlook Falls Slightly on Cancellations/Delays/Downsizing

Sony Officially Unveils 2022 TV Line Up – Adds 42” and 48” OLED TVs and 55” and 65” QD-OLED TVsLGD is Investigating a 55” Transparent OLED Display for the Consumer Market

59 New POs and Awards Last WeekNotion Systems Installs IJP System at ITRI Plus Company UpdateChina FPD Construction Weekly UpdatesFlexEnable Raises $11M to Bring Flexible LCD and Optical Films to Mass Production

Price Declines Hit Top & Bottom Lines for AUO and Innolux in Q4Taiwan Panel Maker Revenues Fell in JanuaryJDI Continued Progress Towards Profitability in Q4Glassmaker Q4 Earnings – NEG, AGC and ComparisonTEL Enjoys Record Results and Beats Consensus EstimatesV Technology Misses as Both Display and Semiconductor Revenues Fall

New MicroLED TVs Announced at CES 2022More OLED and MiniLED Notebooks and Monitor IntroductionsAsus Announces 17.3” Foldable Notebook to Launch in Q2’22

Corning Opens Mass Production at Guangzhou Gen 10.5 Glass Substrate PlantSummersprout, Chinese OLED Maker, Completes Series D FinancingETRI Develops World"s First Commercialization of Low-Temperature Photoresist for Displays.

SCHOTT Challenges Corning’s Dominance of Cover Glass with Launch of “Nearly Unbreakable” Xensation αApple iPhone 13 Updates – Are Volumes Constrained? Did BOE Win More Business?Samsung Launches Higher Priced Z Fold 3 Variant, the W22, in China for $2650Samsung Unpacked Part 2 SpeculationNew AMOLED Smartphones from OnePlus and Xiaomi

Smartkem and RiTdisplay Sign Joint Development Agreement on OTFT-Based AMOLEDs for Small DisplaysTianma: More Incentives Gained & Change of Company ProfileTCL Tech Gained 100% Control of T10, Previous SDC Suzhou Plant

Kriya Materials Sets New Standard and Introduces Its State-of-the-Art Multi-Functional Coating for Rollable/Foldable Displays Providing Glass Like Surfaces with Low Light Reflection

Skyworth Introduces a 55” OLED TV for $1199 – Joins LG With the Lowest Price for a 55” OLED TVSkyworth Releases New Glass Based MiniLED TV and OLED TVUS TV Price Inflation Continued to Surge in August

More Glass Lines Are Coming: Caihong Plans to Invest in More Glass Lines in Shaanxi, ChinaKorea’s Olum Material Develops New FMM Mask Approach for G8.5

Amazon Enters the TV Market with the Fire TV 4 Series and Fire TV Omni Series of LED TVsNanosys Announces Mass Production for Breakthrough in “Air Stable” Quantum Dots

BOE Presents its Product Roadmap for MiniLED LCDInterview: Nanosys CEO on the Acquisition of MicroLED Developer GlōRecent Mini/MicroLED Activities in China: Skyworth, Refond, Focus Lighting and BTMC

Coming in Hot: TCL Announces T8 and T9 ProjectsHas Visionox V2-2 Been Canceled?Permission Granted: EverDisplay Is One-step Away From an IPO, But Next Fab DelayedDisplay Highlights from Applied Materials’ Investor Event65 New POs and Awards Led by Large-Gen LCDAixtron Supplies MOCVD Reactor to US LED Manufacturer for MicroLED Production

DSCC Launches Quarterly Advanced Smartphone Features Report, Provides Share & Forecasts on 5G, Refresh Rate, Notch Type, Chipset, Touch, Cameras, Price Band and Much More

DSCC’s Latest Display Capacity Forecast Shows China’s Share Surging Even Higher, LCD Capacity Declines for the First Time and OLED Capacity Growing Rapidly

DSCC Reveals Quarterly Display Equipment Revenues/Market Share for Over 130 Different Companies in New Report, Downgrades 2019-2020 Equipment Spending on LCD Weakness

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey