glasses tft display manufacturer

In Taiwan. It was formed in 2001 by the merger of Acer Display Technology Inc and Unipac Optoelectronics Corporation. It has G3.5 to G8.5 production lines.

In Korea and China. It is used to be the 2nd biggest TFT LCD manufacturers. LG also planned to stop the production but delayed the plan after the price increased. LG has G7.5 and G8.5 (Guangzhou) production lines.

In Korea. It used to be the biggest TFT LCD manufacturers before it was dethroned by BOE in 2019. Because of tough competition, Samsung planned to stop the production in 2021 but delayed because the price increase during the pandemic. Samsung has G7 and G8.5 production lines.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

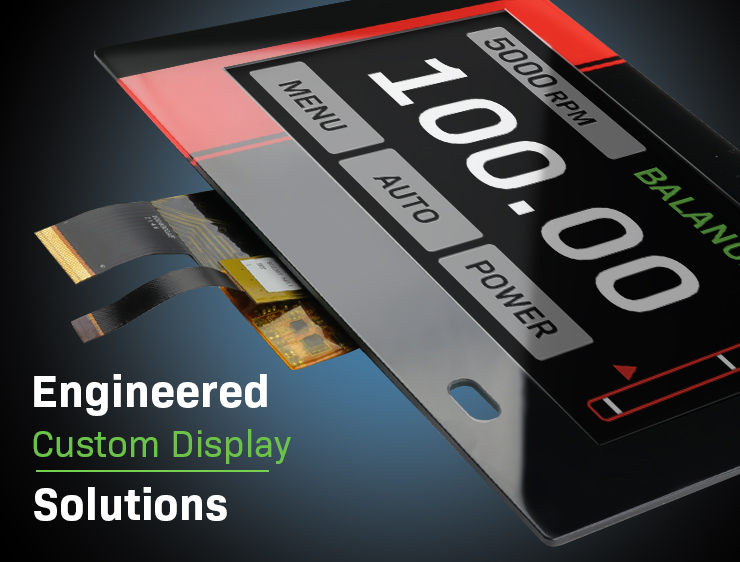

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

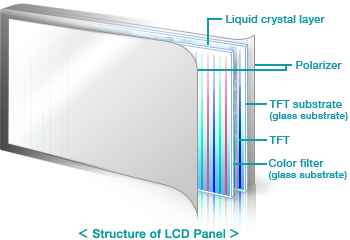

“LCD glass substrate” is a generic term for the special glass used for thin-film transistor (TFT) LCDs which form the display area of products including LCD televisions, personal computers and mobile phones. An LCD panel consists of various components stacked in a number of layers. These components include a polarizer, a color filter and a liquid crystal layer, with the glass substrate being the most important. Glass substrates are extremely thin – typically about 0.3-0.7 mm – and 8th-generation glass substrates (2,200 x 2,500 mm) are as large as three tatami mats in size.

In order to accurately display beautiful, high-definition images, LCD glass substrates must have super-smooth surfaces with irregularities reduced to the nano-level. It is also necessary to avoid the formation of internal bubbles and the intrusion of foreign matter (dust) too minute for the naked eye. Smooth and scratch-free glass substrates with the ultimate precision represent the maximum quality AvanStrate aims for.

One of the things that sets us apart from other touchscreen display manufacturers is the level of customization we offer. Our product portfolio includes a wide range of TFT & Monochrome LCDs, OLED, touch sensor and glass technologies, which we can provide stand-alone or integrated into complete assemblies.

Our custom display, touch and cover lens solutions are used in a variety of end-user applications. For example, our touchscreens are used in many vehicle infotainment systems and dashboard controls. We also provide custom touch displays for popular marine applications such as watercraft navigation screens and fish finders. For consumer electronics, we manufacture custom touchscreen display solutions and smartphone screen protectors. Whether your application will be used in the great outdoors, a construction site, or a hospital operating room, we can build a custom, all-in-one solution for your needs.

Our strength as a custom display company comes from the extensive technical expertise of our engineering team. The approach our engineers take is always based on experience and data-driven decisions that help you find the right solution for your application. In addition, our extensive manufacturing capabilities enable us to deliver quick design cycles, cost-effective solutions, and high-quality products that will meet your specifications even in the harshest conditions. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

Welcome at Riverdi University. In this lecture we’ll talk about different kinds of glass in TFT LCD displays and surfaces that we use to protect displays, or we can use to protect with the glass the entire devices

We will talk about different types of glass in TFT LCD displays, then the surface treatments, what we do to achieve different parameters of glass surfaces, about the hardness – important when we want to protect something, then about painting the glass, how we do it and what we can achieve, IK rate, how much mechanical impact we can place on the glass, and will it withstand this still and at the end about laminated glass, why we laminate glass and what we can achieve by doing that.

The most important thing with the glass in TFT LCD displays is to protect the display, but not only. As you can see on the pictures above, glass is an element of the design of the devices. It makes devices look better and can be designed in a way that protects not only the display, but the entire surface of a device, like for example for the coffee machine on the picture above, where we have a display with some additional graphic that covers the whole front of the device. Glass is one of the best materials that we use in electronics to protect screens, because it is very hard and it is hard to scratch. It is mechanically strong, cheap, and exceptionally good in optics. For glass, the transparency rate is typically more than 90% or even 95% percent. It is widely available, we know a lot of techniques how to manufacture it and how to prepare it for some special advanced designs as we can change the shape of glass quite easily nowadays.

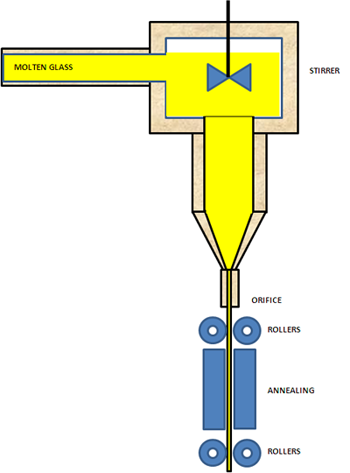

Now we will talk about types of glass that we use to protect screens and devices. Mainly we use two types of glass in TFT LCD displays, one is chemically strengthened glass, that we call CS type glass, the other is thermally tempered glass, hardened glass where we use hot temperature to make it stronger. For our standard products we typically use on the touch screens chemically strengthened glass. Our standard thickness is 1.1-millimeter thickness. This kind of glass is pretty strong, comparing to the regular glass. Chemical strengthening means that we treat the surface with ions, usually silver ions. We increase the strength of the surface of the glass because glass usually breaks when the surface breaks. We do not change the glass internally with chemical strengthening, we just change the surface hardness, and it is enough to make the glass much stronger.

Another property or type of glass that we will talk about is Optiwhite and Float. Float is the most common glass that we use in architecture designs, but also in many touchscreens. The float glass is the most common, most popular and the cheapest, but sometimes we have specific requirements. We sometimes need to have very good color reproduction, especially light colors, white color. Then we use glass called Optiwhite. To achieve that we need to remove the iron from the glass. Float glass has a little bit of iron which makes it green or greenish. If we look straight through the glass, we may not see that but if we look like from an angle, we can see the green color. If we put a white background, we will also see this greenish color a little bit. So, if there are specific requirements, we use Optiwhite, it is especially worth considering if you have a white background. Usually, the Optiwhite is a little bit more expensive, so it is worth checking with the manufacturer of the display what we can use in our case.

Now let us talk about hardness of glass in TFT LCD displays. Of course, to talk about hardness we need to measure it. For that we have the Mohs scale where we have 11 different levels of hardness. Like you see on the picture above, the 10th is diamond and the 1st is talk. What we normally use is glass with hardness between 5 and 7. In some cases we also use Gorilla glass with hardness 9. It is used on our phones or tablets. As you can see, we can achieve hardness 7 with chemically strengthened glass and usually 6 with thermally strengthened glass. Gorilla glass is also chemically strengthened glass, patented by the Corning company and it is the strongest that we can achieve in the cover glass to protect the screen.

Now let us talk about the painting. We know the types of glass that we use in TFT LCD displays, we know how to make the glass stronger, we know the surface treatments, how to make the glass less reflective or anti-fingerprint or antibacterial, but it is not enough because glass will only be transparent. If we want to cover it, we need to paint it. Typically, we paint glass with the technique called Screen Printing. It is the most popular, cheapest and fastest technique.

We laminate glass mainly because of two reasons. One is mechanical strength and impact. We use it even in our homes. Many windows used nowadays are anti-vandal and that means they are laminated glass, and they are extraordinarily strong. The other reason to laminate glass is to put a film inside with some properties, usually to block the UV or IR light. IR means infrared so heat and UV means ultraviolet, short wavelength, extremely dangerous for electronics. When we have an outdoor application, some customers want to protect the displays, touchscreens or the e-paper displays also against UV. Then we use laminated glass and as you can see on the chart above the IR cut film and UV cut film are both transparent for visible light. We can see everything through them, but what is higher and what is lower is cut by UV and IR films. Most often we use only UV cut film because UV is more dangerous, for example it makes the film sensors for capacitive touchscreens turn yellow or it can decrease the contrast of the TFT (Thin Film Transistor) display by damaging the polarizer or color filters. The IR film is used in some applications to protect the display from heat. If we add it, we can decrease the temperature of the display surface. In another video we were talking about High-TN, so liquid crystals that can work in very high temperatures. For this kind of liquid crystals, we usually do not need to decrease the temperature of the surface because they can go up to 100 or 110 degrees, but regular displays can work up to 50- or 70-degrees maximum temperature. Using the IR cut film can solve the problem with blackening and increasing the display temperature too much.

With the rapid development of my country’s display industry, the global display industry structure has undergone major changes. At present, the LCD industry is mainly concentrated in China, Japan and South Korea. With the release of new production capacity of mainland panel manufacturers, mainland China will become the world’s largest LCD panel production area in the near future. So, what are the top ten LCD screen manufacturers in the world and how do they rank?

LG Display is currently the world’s No. 1 LCD panel manufacturer, affiliated to LG Group, headquartered in Seoul, South Korea, with R&D, production, and trading institutions in China, Japan, South Korea, and the United States and Europe.

LGDisplay’s customers include Apple, HP, DELL, SONY, Toshiba, PHILIPS, Lenovo, Acer, and other world-class consumer electronics manufacturers. Apple’s iPhone4, iPhone4S, iPhone5, iPad, iPad2, TheNewiPad, and the latest iPad mini all use LG Display’s liquid crystal display panel.SAMSUNG

Innolux is a professional TFT-LCD panel manufacturing company founded by Foxconn Technology Group in 2003. The factory is located in Shenzhen Longhua Foxconn Technology Park, with an initial investment of RMB 10 billion. Innolux has a strong display technology research and development team, coupled with Foxconn’s strong manufacturing capabilities, and effectively exerts the benefits of vertical integration, which will make a significant contribution to improving the level of the world’s flat-panel display industry.

AU Optronics was formerly known as Daqi Technology and was established in August 1996. In 2001, it merged with Lianyou Optoelectronics and changed its name to AU Optronics. In 2006, it acquired Guanghui Electronics again. After the merger, AUO has a complete production line for all generations of large, medium and small LCD panels. AU Optronics is also the world’s first TFT-LCD design, manufacturing and R&D company to be publicly listed on the New York Stock Exchange (NYSE). AU Optronics took the lead in introducing an energy management platform, becoming the world’s first manufacturer to obtain ISO50001 energy management system certification and ISO14045 eco-efficiency evaluation product system verification, and was selected as the Dow Jones Sustainability World in 2010/2011 and 2011/2012. Index constituent stocks set an important milestone for the industry.

Founded in April 1993, BOE is the largest display panel manufacturer in China and a provider of Internet of Things technology, products, and services. Core businesses include display devices, smart systems, and health services. Display products are widely used in mobile phones, tablet computers, notebook computers, monitors, TVs, vehicles, wearable devices, and other fields; smart systems build IoT platforms for new retail, transportation, finance, education, art, medical, and other fields, and provide ” “Hardware products + software platform + scenario application” overall solution; the health service business is combined with medicine and life technology to develop mobile health, regenerative medicine, and O+O medical services, and integrate health park resources.

Sharp is known as the “Father of LCD Panels.” Since its establishment in 1912, Sharp Corporation has developed the world’s first calculator and liquid crystal display, represented by the invention of the live pencil, which is the origin of the current company’s name. At the same time, Sharp is actively expanding into new areas to improve the living standards of human beings and the society. Contribute to progress.

Established in 1971, Chunghwa Picture Tubes is committed to the development of display technology. From continuous innovative design and research and development, it has introduced high-quality innovative products to meet human needs for visual enjoyment.

Toshiba is a well-known multinational enterprise group with a history of 130 years, with a wide range of business, involving social infrastructure construction, household appliances, digital products, electronic components and other business fields, covering almost all aspects of production and life. Toshiba has the largest R&D institution in Japan. Through unremitting innovation and development, Toshiba has always been at the forefront of world science and technology. From launching Japan’s first washing machines, refrigerators and other household appliances, to developing the world’s first notebook computer, the first 16MB flash memory, the world’s smallest 0.85-inch HDD; creating advanced HDDVD technology; researching and manufacturing new SED displays, Toshiba has created many “world firsts” and has contributed to changing people’s lives through continuous technological innovation. Recently, Toshiba is gradually withdrawing from the home appliance and electronic product market and developing into industries with higher technological content.

Tianma Microelectronics was established in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is an innovative technology company that provides display solutions and fast service support for global customers.

The company independently masters leading technologies including LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and IN-CELL/ON-CELL integrated touch control. The company has a national engineering laboratory for TFT-LCD key materials and technology, a national-level enterprise technology center, a post-doctoral mobile workstation, and undertakes many major national-level special projects such as the National Development and Reform Commission, the Ministry of Science and Technology, and the Ministry of Industry and Information Technology. The company’s strong technology and scientific research capabilities have become the cornerstone of the company’s sustainable development.

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Front Cover Glass for TFT Display, Microscope Slides Cover Glass, Light Cover Glass, Glass Kitchen Scale,Touch Light Switch. Welcome to set up long-term relationship with us. Best Price For Good Quality in China. The product will supply to all over the world, such as Europe, America, Australia,Swiss, Malta,Netherlands, Somalia.Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

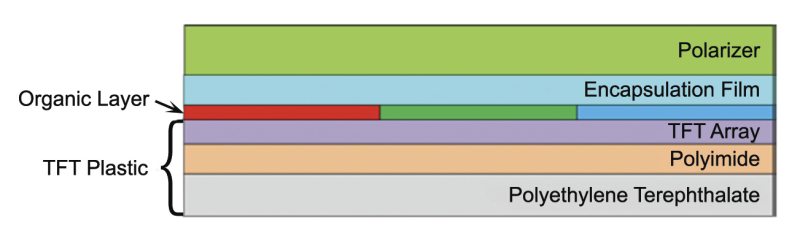

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Full Line of LCD Products. SKY technology has a full line of LCD glass and modules, including TN, HTN, STN, FSTN, CSTN and TFT LCD panles OLED , 3D-glassed LCD modules. We lead the industry in making high-resolution, mid- to large-size LCD panel, which not only supports our own LCD module production, but also is supplied to other module assemblers. We also make LCD panels and modules with non-regular shapes, with specialized fluid and parameters, and for special applications.

Wide Application. SKY technology"s products have been widely used in digital multimeters, electronics testers and equipment, fax machines, telephones, electronic scales, digital clocks and watches, charge meters of taxis, display panels of hi-fi audio systems, POS, air conditioners, various remote controls, digital calendars, temperature/humidity displays, control boards of automobiles and motorcycles, digital meters and messaging systems, GPS devices, PDAs and mobile computers.

Timely customer service and technical support. Our customer service representatives and technical support staff in SKY Display"s headquarters, manufacturing facilities and all the branch offices are always ready to help the customers with any questions about our products and possible problems involved in using the products.

IVO industrial TFT LCDs – IVO are a Chinese TFT manufacturer, offering very competitively priced panels. They have a small line up, focused on industrial applications but are looking to expand their range in the near future. TFT panel driver boards for IVO industrial TFT LCDs are available – VGA, DVI and video input cards to drive a wide range of TFT panels. IVO is an innovative and renowned manufacturer of high-quality TFT LCD panels and displays, which CDS has added to our product range. Our IVO TFTs in sizes from 7″ to 27″ (17.78 to 68.59 cm) are characterized by their wide, symmetrical viewing angles and a high resolution, which ensures a very detailed image reproduction.

IVO provide an excellent price performance ratio and CDS offers long-term available industrial TFTs with integrated LED converter in the sizes listed, plus for easy installation CDS offers these TFTs as a complete VIDEO/HDMI/VGA/DP kit solutions. For the MIPI TFT displays. Plus CDS also has matching resistive analog and PCAP (I²C or USB) touch screens, including customised touchscreen solutions. For other manufacturers we have Public Information Displays (PID) for advertising and infotainment which are available in sizes from 29″ (72.64 cm) to 85″ (215.9 cm), with various brightness levels up to 4500cd/m² and can be used in 24/7 permanent operation. The displays provide excellent value for money and long-term availability.

VIS050IPS03T is an LCD panel module model that adopts a 5 inch IPS type LCD with 800*480 resolution. CTP (Capacity Touch Panel) and CG(Cover Glass) can be added according to user requirements. Based on the substantial and long-term shipments of 5 inch LCD panels, we can guarantee a stable supply of this 5″ LCD display panel module throughout the life cycle of your product.

Based on the panel’s high-cost performance and excellent storage and operating temperature range, this type of LCD display module can be widely used in smart homes, pos machines, industrial instruments (meters), and small medical equipment and other products.

Powertip has grown to become a leading manufacturer of small to mid-size full color TFT and monochrome displays as well as resistive and capacitive touch panels. Powertip is headquartered in Taichung, Taiwan with production facilities located in Taiwan and Nanjing, China. Powertip’s product offerings address major industries to include medical, industrial, automotive, consumer, white goods, communications, test and measurement and gas pumps / parking meters.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey