making lcd screen quotation

Any kind of quote will do, but because the picture frame scrolls through the images that will contain the quotes it works best if you keep the quotes short. Longer quotes, although interesting, may not remain on screen long enough to be read. If you have a number of longer quotations, see "Some Final Notes" at the end of this instructable for tips that you can consider for longer display times.

Look at the sample images stored on your LCD picture frame. For my frame, all of the sample images were 856x480 pixels. To determine this, right click on the image file, and select Properties. You should see a number of tabs, one of which should be called “Details.” Click on the details tab; under Image you should see a width and height. Write this down or keep the window open, because we will use it to set up PowerPoint.

Take the smaller of the two numbers (usually the height), and divide that by the larger number. In my case, 480/856=0.5607. Checking the table below (which shows common screen image ratios), I can see that the native images on my LCD picture frame are just about in 16:9 format.

Open PowerPoint, and start a new presentation. On the ribbon, click Design, Page Setup. In the setup dialog box, select the image format that matches the native format of your LCD picture frame. We do this because it helps prevent the software driving the frame from cropping or stretching the images unnecessarily. Click Home on the ribbon.

At this point, your presentation should have two slides: The initial default title slide, and your newly inserted blank slide. Click on the first slide (the title slide), click your right mouse button, and select delete. You should be left with a single blank slide in your presentation, sized to the native image size of your LCD picture frame.

In many cases, the picture won’t fill the slide because it’s in a different format than the native format for the LCD picture frame. Thus, we’ll need to resize the image to fit. At the same time, we don’t want to distort the image either. Here’s the most straightforward approach:

4. My LCD picture frame doesn’t let you change the display time for pictures, and some of the transitions happen too quickly to allow you to read the entire quote. You can do what I did, which was to make two copies of every slide. PowerPoint is creative in its naming; the slides are called Slide1.jpg, Slide2.jpg, et cetera. I named my copies Slide1a.jpg, Slide2a.jpg. The file system sorts the original and the copy together when the files are named this way, so every quote is displayed twice with an intervening transition.

5. If you don’t have a lot slides suitable for quotes, consider visiting a site like Interface Lift, which has a wide range of images in a variety of formats for desktop wallpapers. Chances are, you’ll be able to find images in a format suitable for the native format of your LCD picture frame.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

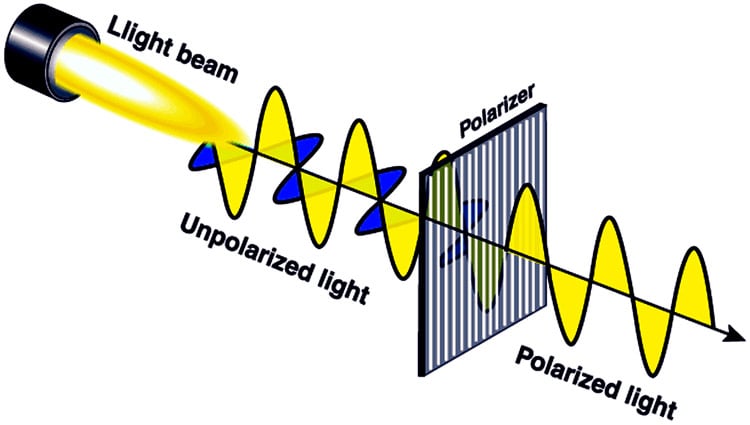

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

The Canadian mechanical engineering student hacked the dashboard display screen in his car, so it’s now displaying funny quotes from Reddit. Specifically, it’s displaying those weird “Shower Thoughts” — the headlines from Reddit’s forum for the brilliant one-off insights that pop into your head at random moments.

“I have no programming experience other than a few Arduino projects around the house,” De Mel wrote in a blog post, “so my code is definitely not optimal.” But within one month, he’d already finished the project, and shared its Python code on GitHub. “Hopefully, this will at least give you some kind of starting point for your own project, and you will be able to see the underlying process for making this work.”

Luckily, all the digital devices in his 2012 Hyundai Genesis Coupe were connected using a fairly common standard — the “Controller Area Network bus” (or CAN bus). So Harin grabbed one of his Arduino’s — plus a cheap SPI CANBUS circuit board — and just started doing some experiments. When he first installed his Arduino circuit board into the dashboard, the LCD began showing the time of day — every ten milliseconds — and any new messages that he sent to the screen were simply being wiped out when the system re-transmitted. But Harin had already built up a strong motivation to keep moving forward, according to a recent write-up in Make: magazine, because “I hated that stupid little blue LCD. It would just sit there staring at me brightly with the words ‘AUX’…”

So he re-routed the LCD’s input. And fortunately, Harin’s other Raspberry Pi board could accommodate a WiFi dongle. By using an iPhone for connectivity, it was now able to draw down the funny Reddit quotes. And Make: also reported that his next project may be to install a router directly into his car.

Harin’s even mounted his Nexus 7 Android tablet into his car’s dashboard and is using it to play music. In the comments on his blog, he talks about one day transmitting the “now playing” information from the tablet to the LCD. Somewhere in the mix, there’s even an SQL database. “My main script retrieves the top post from Shower Thoughts and converts the characters to their hexadecimal equivalents, adds the message ID and row identifier, and stores it in an SQL database.”

There’re two more scripts just for retrieving the quote from the database and display it on the screen, which Harin says will be building blocks for more features down the road. “Eventually, I’ll be able to screen the messages intended for the LCD on the primary [CAN bus] network and add the ones I want to keep to the SQL database while removing the ones I don’t need anymore.”

Now instead of seeing the external temperature on his display, he sees bits of mind-blowing amateur philosophy. But maybe it goes to show you that if you’re going someplace strange, your journey there can be just as unpredictable. According to his blog post, the screen was originally intended for displaying song information (title and artist) for Sirius XM.

Because of this, the Reddit quotes were originally preceded by a musical note, and one screenshot makes it look like he’d been listening to a song titled “Being a cop must be awful…”

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

Looking at Future, they do seem to have a few LCDs quoted on their site, however it is certainly not a comprehensive list. If you contact a sales rep (there or anywhere) and provide them your requirements, they may come back with additional parts that their manufacturers produce that better fit your need.

Unless your volumes are going to be in the millions, let me dispel any thoughts you have of "Why not just talk to (LCD mfc) directly?". Said manufacturers will not care about you, and the premium they will charge to deal with you (if they bother at all) will be higher than what a typical distributor would, because, frankly, they do not want your direct business. Use the middlemen. They will make specifying, finding, and sourcing LCD panels vastly easier and cheaper.

LCD panel prices have risen for 4 months in a row because of your home gaming? Since this year, the whole LCD panel market has smoked. Whether after the outbreak of the epidemic, LCD panel market prices rose for four months, or the panel giants in Japan and South Korea successively sold production lines, or the Chinese mainland listed companies frequently integrated acquisition, investment, and plant construction, all make the industry full of interesting.

LCD panel prices are already a fact. Since May this year, LCD panel prices have risen for four months in a row, making the whole industry chain dynamic. Why are LCD panels going up in price in a volatile 2020? The key factor lies in the imbalance between supply and demand.

The price of LCDS for large-size TVs of 70 inches or more hasn’t budged much. In addition, LTPS screens and AMOLED screens used in high-end phones have seen little or no increase in price.

As for October, LCD panel price increases are expected to moderate. The data shows that in October 32 inches or 2 dollars; Gains of 39.5 to 43 inches will shrink to $3;55 inches will fall back below $10; The 65-inch gain will narrow to $5.

During the epidemic, people stayed at home and had no way to go out for entertainment. They relied on TV sets, PCS, and game consoles for entertainment. After the resumption of economic work and production, the market of traditional home appliances picked up rapidly, and LCD production capacity was quickly digested.

However, due to the shutdown of most factories lasting 1-2 months during the epidemic period, LCD panel production capacity was limited, leading to insufficient production capacity in the face of the market outbreak, which eventually led to the market shortage and price increase for 4 consecutive months.

In fact, the last round of price rise of LCD panels was from 2016 to 2017, and its overall market price has continued to fall since 2018. Even in 2019, individual types have fallen below the material cost, and the whole industry has experienced a general operating loss. As a result, LCD makers have been looking for ways to improve margins since last year.

A return to a reasonable price range is the most talked about topic among panel makers in 2019, according to one practitioner. Some manufacturers for the serious loss of the product made the decision to reduce production or even stop production; Some manufacturers planned to raise the price, but due to the epidemic in 2020, the downstream demand was temporarily suppressed and the price increase was postponed. After the outbreak was contained in April, LCD prices began to rise in mid-to-late May.

In fact, the market price of LCD panels continued to decline in 2018-2019 because of the accelerated rise of China’s LCD industry and the influx of a large number of local manufacturers, which doubled the global LCD panel production capacity within a few years, but there was no suitable application market to absorb it. The result of excess capacity is oversupply, ultimately making LCD panel prices remain depressed.

Against this background, combined with the impact of the epidemic in 2020, the operating burden of LCD companies in Japan and South Korea has been further aggravated, and it is difficult to make profits in the production of LCD panels, so they have to announce the withdrawal of LCD business.

business in June 2022. In August, Sharp bought JDI Baishan, a plant in Ishikawa prefecture that makes liquid crystal display panels for smartphones. In early September, Samsung Display sold a majority stake in its SUZHOU LCD production plant to Starlight Electronics Technology, a unit of TCL Technology Group. LGD has not only pulled out of some of its production capacity but has announced that it will close its local production line in 2020. According to DSCC, a consultancy, the share of LCD production capacity in South Korea alone will fall from 19% to 7% between 2020 and 2021.

It is worth mentioning that in industry analysis, in view of the fact that Korean companies are good at using “dig through old bonus – selling high price – the development of new technology” the cycle of development mode, another 2020 out of the LCD production capacity, the main reason may be: taking the advantage of China’s expanding aggressively LCD manufacturers, Korean companies will own LCD panel production line hot sell, eliminating capacity liquid to extract its final value, and turning to the more profitable advantage of a new generation of display technologies, such as thinner, color display better OLED, etc. Samsung, for example, has captured more than 80% of the OLED market with its first-mover advantage.

From the perspective of production capacity, the launch of LCD tracks by major manufacturers in Japan and South Korea must reduce some production capacity in the short term, which to some extent induces market price fluctuations. In the long run, some of the Japanese and Korean LCD production capacity has been bought by Chinese manufacturers, coupled with frequent investment in recent years, the overall capacity is sure to recover as before, or even more than before. But now it will take time to expand the production layout, which more or less will cause supply imbalance, the industry needs to be cautious.

The LCD panel industry started in the United States and then gradually moved to Japan, South Korea, China, and Taiwan. At present, the proportion of production capacity in The Chinese mainland has reached 52% in 2020, and there are leading LCD panel products in China represented by BOE, Huxing Optoelectronics. Meanwhile, the production capacity layout of BOE, Huike, Huxing Optoelectronics, and other manufacturers has been basically completed, making industrial integration a necessity.

On the one hand, South Korean enterprises out of the LCD track, the domestic factory horse enclosure, plant expansion action. While LCDs may not sell as well as “upstart” flexible screens, respondents believe they are still strong enough in the traditional home appliance market to warrant continued investment. Zhao Bin, general manager of TCL Huaxing Development Center, has said publicly that the next-generation display technology will be mature in four to five years, but the commercialization of products may not take place until a decade later. “LCD will still be the mainstream in this decade,” he said.

On the other hand, there is no risk of neck jam in China’s LCD panel industry, which is generally controllable. In mainland China, there will be 21 production lines capable of producing 32-inch or larger LCD panels by 2021, accounting for about two-thirds of the global total. In terms of the proportion of production capacity, the Chinese mainland accounted for 42% of the global LCD panel in 2019, 51% this year, and will continue to climb to 63% next year.

Of course, building factories and expanding production cannot be accomplished overnight. In the process of production capacity recovery, it is predicted that there will be several price fluctuations, and the cost may be passed on to the downstream LCD panel manufacturers or consumers when the price rises greatly, which requires continuous attention.

A lot of consumers wonder how manufacturers determine the LCD display panel prices. After all, display solutions such as TFT LCDs and HMI touch screens do not always come cheap. And sometimes, a few products that can indeed be purchased for lower prices may come with several quality issues.

Hence, we’ve rounded up a list of factors that influence how to display modules such as TFTs, LCD, and touch screens are priced. You can also use these factors to evaluate to whom you should place your next orders for your display solutions.

LCD fluids are used in altering the light orientation passing through glass substrates. Hence, this causes the panel’s active pixels to darken. Different kinds of LCD panel fluids provide unique characteristics and change a panel’s viewing angle, temperature range, and display clarity.

Another characteristic of this fluid is that it works well even in colder temperatures. It’s because TN fluid has the quickest response time among the other LCD fluid types.

TN fluid is considered the cheapest LCD fluid type. However, this doesn’t mean that TN isn’t widely used. The display technology is greatly utilized in digital clocks, pagers, and gas pumps.

LCD modules with STN fluid enjoy a wider display angle, greater multiplexing, higher image contrast, and sharper response than devices using TN fluids. However, modules with STN fluids may have slower response times when used in lower temperatures due to the fluid freezing inside the device.

STN fluid falls under the moderately cheap LCD module price. Furthermore, STN fluid is widely utilized in several monochrome LCD devices such as POS machines, inexpensive feature phones, and informational screens of some devices.

CSTN is a bit pricier than TN and STN fluids. But it’s a good choice if you need to display color images on your LCD device. In fact, a lot of color feature phones use CSTN as an alternative to the TFT displays, saving almost half the manufacturing costs.

In terms of cost, the LCD display module price of a unit with FSTN is higher compared to TN and STN. But this is concerning the better visual quality that FSTN offers.

To cap off this part, the fluids used in a screen is a big factor in determining the overall LCD screen display panel price. As you can see, the four fluid types often used in LCD screens rise in costs with respect to the visual quality produced by each technology.

The temperature range in which LCD screen displays may work varies intensely. Some displays continue to work at optimal performance even when used in cold or hot outdoor temperatures. Lower-quality LCD panels may start having glitches at the slightest change of temperature and humidity. Hence, the temperature range may have a huge impact on the LCD display panel price as well.

In hot environments– The liquid crystals may begin to deteriorate, while the electrical components will start overheating and cause damage to the display screen performance.

Now, most LCD screen panels don’t experience such temperature extremes. In fact, a typical LCD TV can operate properly between approximately o°C and 32°C (32° – 90° F). Meanwhile, other screen modules (usually the industrial-grade ones) have unique capabilities to work in even more extreme ends of the temperature scale.

If you want to look for the most cost-effective type of LCD panel for your device, then you must consider the following standard LCD unit temperature types:

Normal temperature units work well in environments that have indoor temperatures at approximately 20-35°C (68-95°F). Some LCD modules may work well above up to 50°C (122°F). Such LCD modules can be used in daily settings by the typical consumer public.

LCD units under this type are made to withstand lower and higher temperature ranges. Extreme operating temperatures may range anywhere from -30°C to 85°C (-22-185°F). Most LCD modules with wide/extreme temperature capabilities are used in extremely cold areas such as Artic places and ski resorts, as well as humid and moisture-rich hot outdoor areas.

Generally, the LCD module price goes up if the entire display unit can withstand higher temperature ranges. Those who can operate under normal temperature ranges only are usually cheaper.

Hence, you must consider the places where you’ll be installing your LCD display devices. You can’t just use cheaper LCD modules for an industrial-grade display machine. Treat your LCD panel as an investment and select a panel that will yield better screen performance that’ll last several years for you and your business.

Color LCDs have three subpixels that hold red, blue, and green color filters. Each subpixel can have as much as 256 color shades, depending on the variation and control of the voltage applied to it.

Now, when you combine 256 shades of both red, blue, and green subpixels, color LCDs can display a color palette of up to 16.8 million colors. And all these are made possible by millions of transistors etched onto the glass modules.

Display size also plays a large role in an LCD device’s color capability. Smaller screens need fewer pixels and transistors since they have smaller display sizes. These screens are also less costly to make. Now, larger screens with high color resolution and huge display sizes require more transistors and pixels, justifying the higher prices of such monitors.

A touch screen display module is more costly than a non-touch monitor module. Touch capability is integrated into Human Machine Interface (HMI) modules and is generally used in kiosks, bank ATMs, hospital equipment, and similar devices in other industries.

HMI touch screen price is also dependent on what kind of touch screen technology it uses. Here are some of the common touch technologies integrated to HMI touch screen devices:

This type of touch screen technology is made up of a top polythene layer and a glass-bottom layer separated by microdots or an air gap. This module is then attached to a touch screen controller.

Resistive touch screen panels are used in most bank ATMs and some older models of cellular phones. They carry the lowest HMI touch screen price among all other touch screen technologies.

Capacitive touch screens are the most common in the display industry today. This technology uses transparent conductors, insulators, and glass to create the panel. An electrostatic field change in the screen’s module happens when a human finger touches the screen surface. This ultimately creates signals that are sent to the touch screen controller for processing.

In general, capacitive touch screens are the most cost-effective choice for HMI machines. Since they are considered the gold standard of commercial touch screen technologies, they do come with a high price tag.

Infrared grid technology uses photodetector pairs and X-Y infrared LED components to allow sensors to pick up the touch and its exact location. Infrared grids have been used in several touch screen modules before the capacitive touch screen technology took over.

We’ve explained the following factors at length for both public consumers and business clients to understand the variations in TFT, LCD, and HMI touch screen prices.

Cheap doesn’t necessarily mean low-quality. Also, expensive options aren’t always a wise choice, either. You can maximize your buying or manufacturing options if you know how to compare LCD modules and panels depending on the specifications you truly need for your display machines and devices.

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

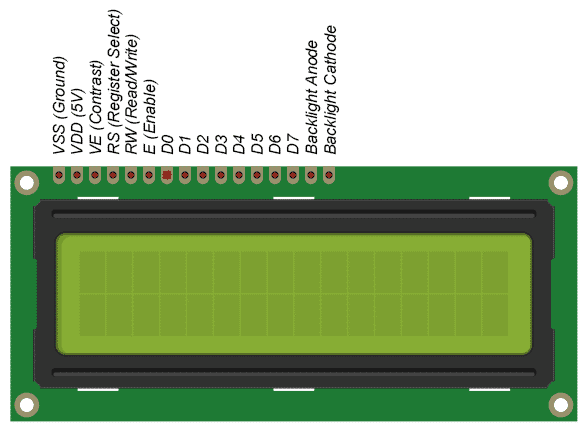

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

Now we’re ready to get into the programming! I’ll go over more interesting things you can do in a moment, but for now lets just run a simple test program. This program will print “hello, world!” to the screen. Enter this code into the Arduino IDE and upload it to the board:

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

This function places the cursor in the upper left hand corner of the screen, and prints any subsequent text from that position. For example, this code replaces the first three letters of “hello world!” with X’s:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

I always finding it interesting when a new customer of ours calls to let us know that they can find cheap LCD displays, the same LCD we supply, for almost half the price. After all, cheap LCD displays are the same no matter where you purchase it. Right?

Let me assure you that the phrase, ‘You get what you pay for’ is just as true for LCD displays as it is for insurance, fine jewelry, car repairs and open heart surgery. You will always be able to find a lower cost product or service, but many times you are not comparing apples to apples.

There is a reason why some things cost more, you are buying the quality and support that come with the set of wrenches or tires or whatever the product. It may sound a bit capitalistic, but if the manufacturer is not making a solid profit, then there is a good chance they will not be around in a year to support you.

The word “cheap” is so polarized in that in one instance you can revel in the victory of finding that super low price and yet simultaneously it is no victory at all if someone looks at your product and says, “Wow, that looks cheap.” So, let’s talk about Cheap LCD displays.

The long and short of it is that LCD’s are in investment. In many cases, they are the most expensive component in your product, but you need to balance that with the fact that they are also what the customer looks at the most. If you are building a hand held device that measures the PH of pool water, it’s a safe bet that people will be looking at the display far more than the battery compartment on the back of the unit. The cheap LCD display may save you a fraction of what other suppliers are quoting, but what is it costing you? Return customers. Good online reviews. Word-of-mouth advertising.

There is a rule of thumb statistic that says it costs a company 7 times more money to earn a new customer, than it does to keep a current customer. So why would you save 20% or even 40% off the cost of an LCD and in return lose your current customers. The savings will not offset the increased advertising cost to bring in new customers.

There are three main fluids used in a monochrome LCD module. They are TN, STN and FSTN. Each fluid has its own niche in which it operates well. One of the main factors impacted by the different fluids is acceptable viewing angle of the display.

LCD displays are quite diverse when it comes to the temperatures in which they can operate well. Some even have as much and more than 100 degrees window of successful operation. There are three main temperature ranges of an LCD unit:Normal temperature (indoor temps—think of your living room)

Take for instance one customer of ours who needed the display to work properly on oil rigs near the North Pole. Their product monitors the safety equipment on the rig. Is it worth spending the extra $5 on a display that can survive working in all conditions? Is the LCD display an investment or expendable?

The engineer took our price and specs and called back a few days later saying that another LCD vendor came in with a similar product that would cost in the low $5 range. Red flags immediately went up in my mind. Something was not right about this cheap LCD display. The display was similar, but upon inspection there were some ‘strings’ attached.

This is critical if you plan to build your product for the next few years. You will need to purchase more of these exact LCD displays in the future. When that time comes and you find out that the LCD modules are discontinued, you are in deep trouble. Your only option is to redesign your product for the current LCD.

Keep in mind that if you plan to repair your customer’s product, it is critical to have a supply of the original LCD. You cannot use a new LCD in an old product in the same way you cannot use a VHS tape (for those of you over the age of 20) in a blue ray player.

A simple tip is to do a little research on the product. Google can be your best friend. When someone offers you a screaming deal on a cheap LCD display, type in the part # and manufacture into Google; you may quickly find out why the prices are so cheap.

There are companies that contact us to buy our surplus/returns. These companies are providing a valuable service by keeping displays out of the landfills. If you need to be able to purchase the exact same LCD in the future, stay away from refurbished units. Once they are gone, there are no rain checks. Many of these displays can be found on eBay and other online auctions.

That engineer quickly realized that asking the three critical questions makes all the difference in the price of the product! Getting cheap LCD displays is not always a mistake, just remember to ask questions and really think through whether this is an investment or an expendable item.

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

Alibaba.com offers 3315 diy lcd screen products. About 8% % of these are lcd modules, 1%% are other machinery & industrial equipment, and 1%% are paper crafts.

A wide variety of diy lcd screen options are available to you, You can also choose from original manufacturer, odm and agency diy lcd screen,As well as from tft, ips, and standard.

Liquid Crystal Display (LCD) screens are a staple in the digital display marketplace and are used in display applications across every industry. With every display application presenting a unique set of requirements, the selection of specialized LCDs has grown to meet these demands.

LCD screens can be grouped into three categories: TN (twisted nematic), IPS (in-plane switching), and VA (Vertical Alignment). Each of these screen types has its own unique qualities, almost all of them having to do with how images appear across the various screen types.

This technology consists of nematic liquid crystal sandwiched between two plates of glass. When power is applied to the electrodes, the liquid crystals twist 90°. TN (Twisted Nematic) LCDs are the most common LCD screen type. They offer full-color images, and moderate viewing angles.

TN LCDs maintain a dedicated user base despite other screen types growing in popularity due to some unique key features that TN display offer. For one,

VA, also known as Multi-Domain Vertical Alignment (MVA) dislays offer features found in both TN and IPS screens. The Pixels in VA displays align vertically to the glass substrate when voltage is applied, allowing light to pass through.

Displays with VA screens deliver wide viewing angles, high contrast, and good color reproduction. They maintain high response rates similar to TN TFTs but may not reach the same sunlight readable brightness levels as comparable TN or IPS LCDs. VA displays are generally best for applications that need to be viewed from multiple angles, like digital signage in a commercial setting.

IPS (In-Plane Switching) technology improves image quality by acting on the liquid crystal inside the display screen. When voltage is applied, the crystals rotate parallel (or “in-plane”) rather than upright to allow light to pass through. This behavior results in several significant improvements to the image quality of these screens.

IPS is superior in contrast, brightness, viewing angles, and color representation compared to TN screens. Images on screen retain their quality without becoming washed out or distorted, no matter what angle they’re viewed from. Because of this, viewers have the flexibility to view content on the screen from almost anywhere rather than having to look at the display from a front-center position.

Based on current trends, IPS and TN screen types will be expected to remain the dominant formats for some time. As human interface display technology advances and new product designs are developed, customers will likely choose IPS LCDs to replace the similarly priced TN LCDs for their new projects.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey