super amoled plus vs tft lcd factory

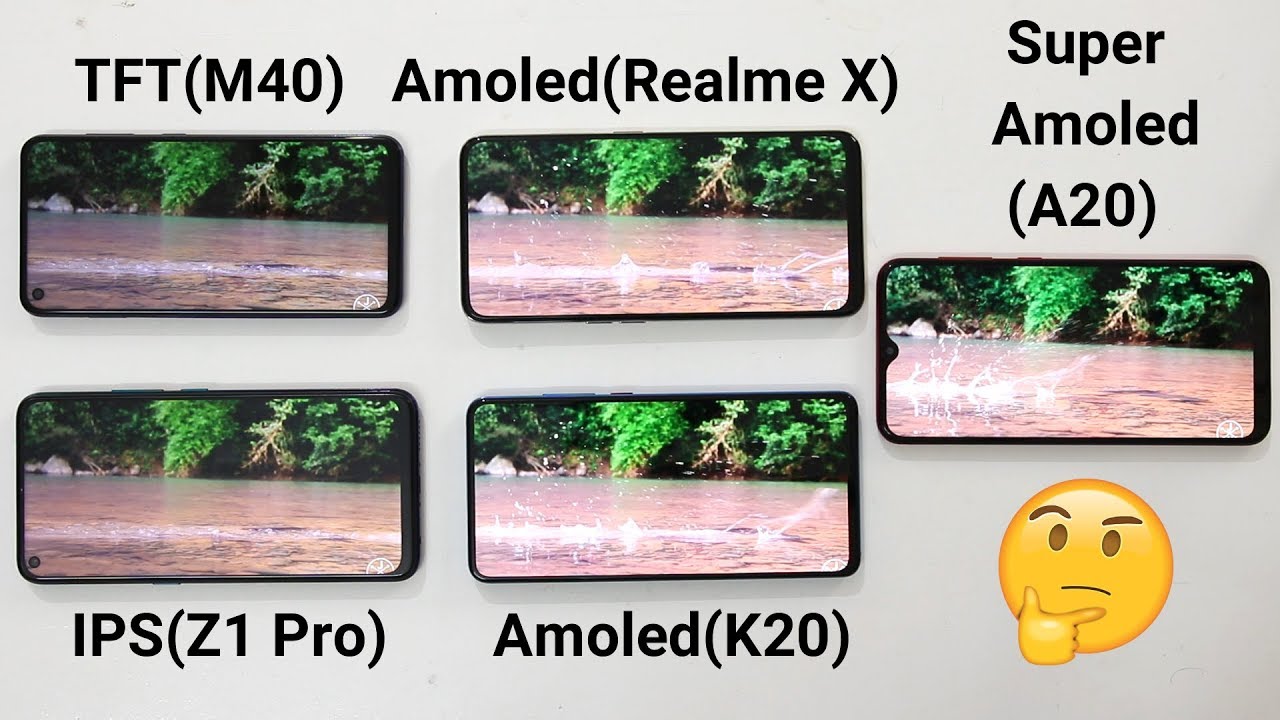

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Thanks for the display technology development, we have a lot of display choices for our smartphones, media players, TVs, laptops, tablets, digital cameras, and other such gadgets. The most display technologies we hear are LCD, TFT, OLED, LED, QLED, QNED, MicroLED, Mini LED etc. The following, we will focus on two of the most popular display technologies in the market: TFT Displays and Super AMOLED Displays.

TFT means Thin-Film Transistor. TFT is the variant of Liquid Crystal Displays (LCDs). There are several types of TFT displays: TN (Twisted Nematic) based TFT display, IPS (In-Plane Switching) displays. As the former can’t compete with Super AMOLED in display quality, we will mainly focus on using IPS TFT displays.

OLED means Organic Light-Emitting Diode. There are also several types of OLED, PMOLED (Passive Matrix Organic Light-Emitting Diode) and AMOLED (Active Matrix Organic Light-Emitting Diode). It is the same reason that PMOLED can’t compete with IPS TFT displays. We pick the best in OLED displays: Super AMOLED to compete with the LCD best: IPS TFT Display.

Tried and trusted TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination.

By contrast the Active Matrix OLED (AMOLED) display requires no backlight and can light up or turn off each of their pixels independently. As the name suggests, they are made of organic material.

An AMOLED display has many other benefits which make it a superior looking display including exceptional vieiwng angles and a display that looks practically black when it is switched off.

So, why use a TFT display? Well, it is a mature technology meaning the manufacturing processes are efficient, yields high and cost much lower than AMOLED.

TFT displays also have a much longer lifespan than AMOLED displays and are available in a far greater range of standard sizes, which can be cut down to fit a space restricted enclosure for a relatively low cost adder.

AMOLED (Active Matrix Organic Light Emitting Diode) and TFT (Thin Film Transistor) are the two types of displays that are used in mobile phones. TFT is actually a process of producing the displays and is used even by AMOLED but for most purposes, TFT is used to refer to LCD displays. The difference between them is the material as AMOLED uses organicmaterials, mainly carbon, while TFT does not.

There are differences between the two that are quite tangible. For starters, AMOLED generates its own light rather than relying on a backlight like a TFT-LCD does. This consequently means that AMOLED displays are much thinner than LCD displays; due to the absence of a backlight. It also results in much better colors than a TFT is capable of producing. As each pixel’s color and light intensity can be regulated independently and no light seeps from adjacent pixels. A side by side comparison of the two displays with the same picture should confirm this. Another effect of the lack of a backlight is the much lower power consumption of the device. This is very desirable when it comes to mobile phones where every single feature competes for the limited capacity of the battery. As the screen is on 90% of the time that the device is being used, it is very good that AMOLED displays consume less. Just how much of a difference is not very fixed though as it really depends on the color and intensity of the image. Having a black background with white text consumes much less energy than having black text on a white background.

The biggest disadvantage that AMOLED has is the shorter lifespan of the screen compared to TFT. Each pixel in the display degrades with each second that it is lit and even more so the brighter it is. Â Despite improvements on the lifetime of AMOLED displays, AMOLED still only lasts a fraction of the lifetime of a TFT display. With that said, an AMOLED display is able to outlast the usable lifetime of the device before parts of it start to degrade.

The main hindrance to the massive adaptation of AMOLED is the low production numbers. TFT has been in production for much longer and the infrastructure is already there to meet the demands.

This rise of small, powerful components has also led to significant developments in display technology. The most recent of which, AMOLED, is now the main competitor for the most common display used in quality portable electronics – the TFT–LCD IPS (In-Plane Switching) display. As more factories in the Far East begin to produce AMOLED technology, it seems likely we will enter a battle of TFT IPS versus AMOLED, or LCD vs LED. Where a large percentage of a product’s cost is the display technology it uses, which provides best value for money when you’re designing a new product?

TFT IPSdisplays improved on previous TFT LCD technology, developed to overcome limitations and improve contrast, viewing angles, sunlight readability and response times. Viewing angles were originally very limited – so in-plane switching panels were introduced to improve them.

Modern TFT screens can have custom backlights turned up to whatever brightness that their power limit allows, which means they have no maximum brightness limitation. TFT IPS panels also have the option for OCA bonding, which uses a special adhesive to bond a touchscreen or glass coverlens to the TFT. This improves sunlight readability by preventing light from bouncing around between the layers of the display, and also improves durability without adding excess bulk; some TFT IPS displays now only measure around 2 mm thick.

AMOLED technology is an upgrade to older OLED technology. It uses organic compounds that emit light when exposed to electricity. This means no backlight, which in turn means less power consumption and a reduction in size. AMOLED screens tend to be thinner than TFT equivalents, often produced to be as thin as 1 mm. AMOLED technology also offers greater viewing angles thanks to deeper blacks. Colours tend to be greater, but visibility in daylight is lower than IPS displays.

As manufacturers increasingly focus on smaller devices, such as portable smartphones and wearable technology, the thinness and high colour resolution of AMOLED screens have grown desirable. However, producing AMOLED displays is far more costly as fewer factories offer the technology at a consistent quality and minimum order quantities are high; what capacity there is is often taken up the mobile phone market Full HD TFT IPS displays have the advantage of being offered in industry standard sizes and at a far lower cost, as well as offering superior sunlight visibility.

The competition between displays has benefitted both technologies as it has resulted in improvements in both. For example, Super AMOLED, a marketing brand by Samsung, involves the integration of a touchscreen layer inside the screen, rather than overlaid on it. The backlight in TFT technology means they can never truly replicate the deep blacks in AMOLED, but improvements have been made in resolution to the point where manufacturers like Apple have been happy to use LCD screens in their smartphones, even as they compete with Samsung’s Super AMOLED.

Aside from smartphones, many technologies utilise displays to offer direct interaction with customers. To decide whether TFT LCD will survive the rise of AMOLED technology, we must first recap the advantages of LCD. The backlit quality means that whites are bright and contrast is good, but this will wear down a battery faster than AMOLED. Additionally, cost is a significant factor for LCD screens. They are cheaper, more freely available and are offered in industry standard sizes so can be ordered for new products without difficulty.

It seems hard to deny that AMOLED will someday become the standard for mobile phones, which demand great colour performance and are reliant on battery life. Where size is an issue, AMOLED will also grow to dominance thanks to its superior thinness. But for all other technologies, particularly in industrial applications, TFT-LCD offers bright, affordable display technology that is continually improving as the challenge from AMOLED rises.

On some lower quality LCD screens, you can see bright spots in the middle or on the perimeters of screens. This is caused by uneven light distribution. The downside to using backlights, is that black is never true black, because no matter what, light has to be coming through, so it will never have as dark of a screen as an AMOLED screen. Its comparable to being able to slow a car down to 2 mph versus coming to a complete stop.

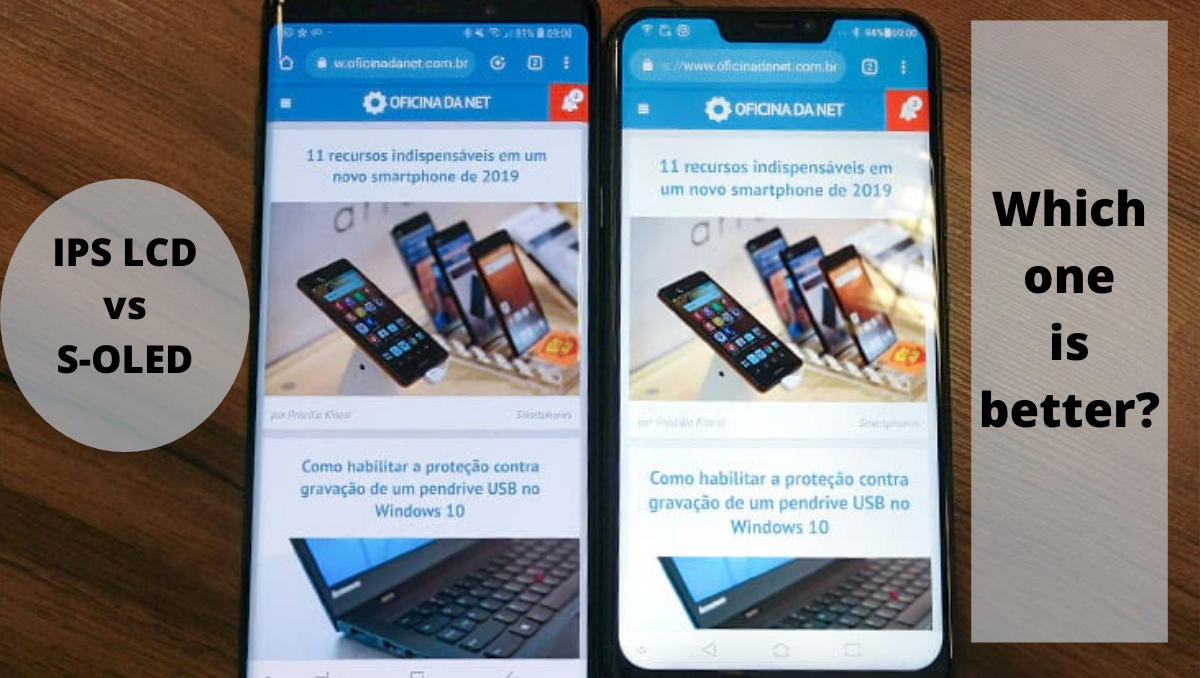

Display technologies are advancing every day. All the major tech giants like Apple, Samsung, One Plus use one among these technologies for building the displays of their Apple phones or Galaxy Notes. Each has its advantages and disadvantages. So which one is better? Is it the AMOLED favored mostly by Samsung? Or is it the IPS LCD favored by Apple for their iPhones? Let us take a detailed look at the features of AMOLED vs IPS display technologies.

AMOLED stands for Active-Matrix Organic Light-Emitting Diode is a type of display used mainly in mobile phones. You might have seen the AMOLED display mentioned in the specifications for smart devices, especially mobile phones. They are also used in smartwatches, laptops, and even televisions. Let’s see what the terms in AMOLED mean.

The Active Matrix technology came about as an improvement on the existing passive matrix technology that used passive components like wires which were arranged vertically and horizontally to control each pixel. The color and brightness of the pixels and thereby the picture can be altered by varying the electrical charge at the given joint of vertical and horizontal wires. The newer Active Matrix uses active electrical components like transistors and capacitors to carry out the same purpose. Instead of varying current at the intersection of wires to control the pixels, this latest technology uses a grid or matrix of thin-film transistors commonly referred to as TFTs and capacitors.

You might be familiar with the giant LED bulbs used at parties or even as indicators on televisions showing the on/off state. These same LED lights are used in AMOLEDs, but of course in the smallest size possible. The LEDs used are in the primary shades namely Red, Blue, and Green, and are grouped in triangle-shaped pixelated forms.

Compared to the LCD and LED displays, the diodes in the OLED display produce light individually meaning they do not need a backlight like their predecessors. OLEDs use lesser electricity and are thinner compared to LEDs. They are also bendable and may even be curved. However, they are much more expensive than LED displays. Hence in the earlier days, it was majorly used for displays for

Now the technologies mentioned above combine to give the AMOLED displays. Here an OLED display is driven with an active matrix control scheme. The TFTs (thin-film transistors) turn on/off each pixel one at a time. The other scheme where the OLEDs are controlled by a passive matrix requires each grid ( rows and lines) to be controlled together. The advanced AMOLED displays allow for higher resolution display with a much bigger physical size.

AMOLEDs have deep black lights. The blacks are darker than LEDs and LCDs because parts of the screen can be switched off altogether. AMOLEDs are also thinner and lighter than LCDs. This feature especially stands out in a dark theater room where OLED displays give a higher contrast ratio compared to LCDs making for an excellent visual experience. This feature of OLED which can work with no backlight makes it better than LCDs whether or not they have an LED backlight.

Since they use Active Matrix technology over the passive matrix version, AMOLEDs have a faster response time. They are up to a millisecond faster and extract less power from your mobile phone’s battery. Extended battery life means major advantages in the portability department. This adding to its high display features leads to them being extensively used. They are preferred over the other versions by major companies like Samsung. Speaking of power, the amount consumed by an OLED display varies according to the brightness and color of the picture displayed.

AMOLEDs have impressive contrast ratios. The contrast ratio is the ratio of the luminance of white color to the black color of a display unit. The high contrast of AMOLEDs is because when the LEDs are off, it gives complete black and since no backlight is used in LEDs, we get deep blacks.

One of the disadvantages the AMOLED had over LCD was the blurriness caused in sunlight which is a result of its lowered peak-brightness values. This issue was corrected in the advanced Super AMOLEDs. In the Super AMOLEDs, the size of gaps between the various layers of the screen namely the cathode layer, anode layer, organic active layer, TFT layer is made narrower than before.

Another problem associated with the AMOLEDs is that the organic materials used in the emissive layer and the conductive layer suffer degradation. This happens comparatively in a short amount of time. As a result, various display problems arise including image persistence, burn-in, etc which are essentially screen burn type problems and color shifts where some colors fade quicker than others. Burn-in is essentially the pixel quality becoming trash after a while because of the degradation of the organic molecules.

Most flagship models of major companies like Samsung, Apple, and One Plus use either super AMOLED or IPS panel premium LCDs. So what exactly is an IPS display? and how does it feature against like the likes of super AMOLEDs?

First, let us understand the basics of a standard LCD. Simply put, when you apply current to some crystals, they may or may not let through the light which comes from a backlight that covers the whole display. In addition to this, there are polarization and color filters present in LCDs which finally give the primary colors Red, Blue, and Green.

Before we get into detailed explanations, you have to keep in mind that for the final end-product that ends up on the market, the quality of the display does not solely depend on whether it is IPS or AMOLED. The companies usually put their tweaks on top of the existing technology before making them available in the market. AMOLEDs are a newer technology than IPS LCD and improve on it in some areas while still lagging in others.

The IPS LCD stands for In-Plane Switching Liquid Crystal Displays. It emerged onto the scene as an improvement on the existing and vulnerable Thin Film Transistor LCD technology commonly referred to as the TFT. Samsung was the leading manufacturer to employ Super AMOLEDs. The IPS display is mainly being used in Apple iPhones. Apple beginning with the iPhone X is switching to AMOLED displays with contrast ratios of 1000000 to 1

As said before, an IPS display is an improved version of the regular TFT LCDs. Here, the difference comes in the way the anode and the cathode are arranged. They are planted as strip electrodes on one of the two glass substrates.

The IPS display scores big time when it comes to offering better viewing angles compared to the other LCD technologies like Twisted Nematic LCD (TN) and Vertical Alignment LCD (VA). The IPS display can be viewed without any color degradation or blurriness at flimsy shallow angles compared to TN and VA displays.

The consistency of colors and clarity of pictures at wider viewing angles is the major advantage of an LCD. IPS displays have higher resolution. They also can display a wide range of colors. These features also make the IPS displays costlier than TN and VA LCDs. Normally IPS monitors allow up to 178 degrees of viewing angles. These displays almost guarantee absolute color accuracy.

For other LCD models, the color and the brightness of an image vary when viewed from different angles. Compared with them, IPS displays are more suited for someone working as a visual/graphic artist. As a regular television, all LCD models are mostly considered equally good. This is because the viewers would mostly be sitting right in front of the screen where these differences between the models do not matter.

IPS displays are capable of displaying a wider spectrum of colors. Considering no monitors can display the entire color spectrum visible to the human eye, IPS LCD panels are the closest things to a perfect display monitor far better than TN and VA LCDs

Image retention is a problem often associated with LCDs. This happens because of the crystal which gets into a particular position for the light to go through stays in that same spot without falling back into its original position. This leads to some parts of the image being left on the screen. This is, however, a temporary problem. The crystal will eventually twist back into the position when the current is applied to it again. When it comes to color accuracy, the previous generation of LCDs was no match for the AMOLED. They had the highest color accuracy among mobile phones. But recent versions of the LCDs have fared much better versus their counterparts.

Large-sized IPS monitors are not affordable for the average customer. They should be avoided since they offer nothing impressive over other LCDs considering the price range. However, if you are a visual artist or a photographer, IPS displays provide the best color accuracy in the market. It would be more beneficial to you compared to an ordinary TN display unit.

AMOLEDs and IPS LCDs are two sides of the same coin in a sense. They both got their advantages and disadvantages. Their disadvantages are mostly overshadowed by the many tweaks installed by the parent companies to ensure customer satisfaction. From high power consumption to ugly blacks, the flaws are minimized in every newer version.

In recent years, smartphone displays have developed far more acronyms than ever before with each different one featuring a different kind of technology. AMOLED, LCD, LED, IPS, TFT, PLS, LTPS, LTPO...the list continues to grow.

As if the different available technologies weren"t enough, component and smartphone manufacturers adopt more and more glorified names like "Super Retina XDR" and "Dynamic AMOLED", which end up increasing the potential for confusion among consumers. So let"s take a look at some of these terms used in smartphone specification sheets and decipher them.

There are many display types used in smartphones: LCD, OLED, AMOLED, Super AMOLED, TFT, IPS and a few others that are less frequently found on smartphones nowadays, like TFT-LCD. One of the most frequently found on mid-to-high range phones now is IPS-LCD. But what do these all mean?

LCD means Liquid Crystal Display, and its name refers to the array of liquid crystals illuminated by a backlight, and their ubiquity and relatively low cost make them a popular choice for smartphones and many other devices.

LCDs also tend to perform quite well in direct sunlight, as the entire display is illuminated from behind, but does suffer from potentially less accurate colour representation than displays that don"t require a backlight.

Within smartphones, you have both TFT and IPS displays. TFT stands for Thin Film Transistor, an advanced version of LCD that uses an active matrix (like the AM in AMOLED). Active matrix means that each pixel is attached to a transistor and capacitor individually.

The main advantage of TFT is its relatively low production cost and increased contrast when compared to traditional LCDs. The disadvantage of TFT LCDs is higher energy demands than some other LCDs, less impressive viewing angles and colour reproduction. It"s for these reasons, and falling costs of alternative options, that TFTs are not commonly used in smartphones anymore.Affiliate offer

IPS technology (In-Plane Switching) solves the problem that the first generation of LCD displays experience, which adopts the TN (Twisted Nematic) technique: where colour distortion occurs when you view the display from the side - an effect that continues to crop up on cheaper smartphones and tablets.

The PLS (Plane to Line Switching) standard uses an acronym that is very similar to that of IPS, and is it any wonder that its basic operation is also similar in nature? The technology, developed by Samsung Display, has the same characteristics as IPS displays - good colour reproduction and viewing angles, but a lower contrast level compared to OLED and LCD/VA displays.

According to Samsung Display, PLS panels have a lower production cost, higher brightness rates, and even superior viewing angles when compared to their rival, LG Display"s IPS panels. Ultimately, whether a PLS or IPS panel is used, it boils down to the choice of the component supplier.

This is a very common question after "LED" TVs were launched, with the short answer simply being LCD. The technology used in a LED display is liquid crystal, the difference being LEDs generating the backlight.

One of the highlights from TV makers at the CES 2021 tradeshow, mini-LED technology seemed far removed from mobile devices until Apple announced the 2021 iPad Pro. As the name implies, the technique is based on the miniaturization of the LEDs that form the backlight of the screen — which still uses an LCD panel.

Despite the improvement in terms of contrast (and potentially brightness) over traditional LCD/LED displays, LCD/mini-LEDs still divide the screen into brightness zones — over 2,500 in the case of the iPad and 2021 "QNED" TVs from LG — compared to dozens or hundreds of zones in previous-generation FALD (full-array local dimming) displays, on which the LEDs are behind the LCD panel instead of the edges.

AMOLED stands for Active Matrix Organic Light-Emitting Diode. While this may sound complicated it actually isn"t. We already encountered the active matrix in TFT LCD technology, and OLED is simply a term for another thin-film display technology.

OLED is an organic material that, as the name implies, emits light when a current is passed through it. As opposed to LCD panels, which are back-lit, OLED displays are "always off" unless the individual pixels are electrified.

This means that OLED displays have much purer blacks and consume less energy when black or darker colours are displayed on-screen. However, lighter-coloured themes on AMOLED screens use considerably more power than an LCD using the same theme. OLED screens are also more expensive to produce than LCDs.

Because the black pixels are "off" in an OLED display, the contrast ratios are also higher compared to LCD screens. AMOLED displays have a very fast refresh rate too, but on the downside are not quite as visible in direct sunlight as backlit LCDs. Screen burn-in and diode degradation (because they are organic) are other factors to consider.Affiliate offer

OLED stands for Organic Light Emitting Diode. An OLED display is comprised of thin sheets of electroluminescent material, the main benefit of which is they produce their own light, and so don"t require a backlight, cutting down on energy requirements. OLED displays are more commonly referred to as AMOLED displays when used on smartphones or TVs.

As we"ve already covered, the AM part of AMOLED stands for Active Matrix, which is different from a Passive Matrix OLED (P-OLED), though these are less common in smartphones.

Super AMOLED is the name given by Samsung to its displays that used to only be found in high-end models but have now trickled down to more modestly specced devices. Like IPS LCDs, Super AMOLED improves upon the basic AMOLED premise by integrating the touch response layer into the display itself, rather than as an extra layer on top.

As a result, Super AMOLED displays handle sunlight better than AMOLED displays and also require less power. As the name implies, Super AMOLED is simply a better version of AMOLED. It"s not all just marketing bluster either: Samsung"s displays are regularly reviewed as some of the best around.

The latest evolution of the technology has been christened "Dynamic AMOLED". Samsung didn"t go into detail about what the term means, but highlighted that panels with such identification include HDR10+ certification that supports a wider range of contrast and colours, as well as blue light reduction for improved visual comfort.

In the same vein, the term "Fluid AMOLED" used by OnePlus on its most advanced devices basically highlights the high refresh rates employed, which results in more fluid animations on the screen.Affiliate offer

Resolution describes the number of individual pixels (or points) displayed on the screen and is usually presented for phones by the number of horizontal pixels — vertical when referring to TVs and monitors. More pixels on the same display allow for more detailed images and clearer text.

Speaking of pixel density, this was one of Apple"s highlights back in 2010 during the launch of the iPhone 4. The company christened the LCD screen (LED, TFT, and IPS) used in the smartphone as "Retina Display", thanks to the high resolution of the panel used (960 by 640 pixels back then) in its 3.5-inch display.

With the iPhone 11 Pro, another term was introduced to the equation: "Super Retina XDR". Still using an OLED panel (that is supplied by Samsung Display or LG Display), the smartphone brings even higher specs in terms of contrast - with a 2,000,000:1 ratio and brightness level of 1,200 nits, which have been specially optimized for displaying content in HDR format.

As a kind of consolation prize for iPhone XR and iPhone 11 buyers, who continued relying on LCD panels, Apple classified the display used in the smartphones with a new term, "Liquid Retina". This was later applied also to the iPad Pro and iPad Air models, with the name defining screens that boast a high range and colour accuracy, at least based on the company"s standards.

TFT(Thin Film Transistor) - a type of LCD display that adopts a thin semiconductor layer deposited on the panel, which allows for active control of the colour intensity in each pixel, featuring a similar concept as that of active-matrix (AM) used in AMOLED displays. It is used in TN, IPS/PLS, VA/PVA/MVA panels, etc.

LTPS(Low Temperature PolySilicon) - a variation of the TFT that offers higher resolutions and lower power consumption compared to traditional TFT screens, based on a-Si (amorphous silicon) technology.

IGZO(Indium Gallium Zinc Oxide) - a semiconductor material used in TFT films, which also allows higher resolutions and lower power consumption, and sees action in different types of LCD screens (TN, IPS, VA) and OLED displays

LTPO(Low Temperature Polycrystaline Oxide) - a technology developed by Apple that can be used in both OLED and LCD displays, as it combines LTPS and IGZO techniques. The result? Lower power consumption. It has been used in the Apple Watch 4 and the Galaxy S21 Ultra.

In 2022, flagship phones started using the so-called LTPO 2.0 tech, whose main advantage is being able to go down to a 1 Hz refresh rate, instead of the 10 Hz available in first-generation LTPO panels. Found in phones like the OnePlus 10 Pro and the Galaxy S22 Ultra, LTPO 2.0 promises even further energy savings.

Among televisions, the long-standing featured technology has always been miniLED - which consists of increasing the number of lighting zones in the backlight while still using an LCD panel. There are whispers going around that smartphones and smartwatches will be looking at incorporating microLED technology in their devices soon, with it being radically different from LCD/LED displays as it sports similar image characteristics to that of OLEDs.

As previously stated, OLED/AMOLED screens have the advantage of a varied contrast level, resulting from individual brightness control for the pixels. Another result of this is the more realistic reproduction of black, as well as low power consumption when the screen shows off dark images - which has also helped to popularize dark modes on smartphones.

In the case of LCD displays, the main advantage lies in the low manufacturing cost, with dozens of players in the market offering competitive pricing and a high production volume. Some brands have taken advantage of this feature to prioritize certain features - such as a higher refresh rate - instead of adopting an OLED panel, such as the Xiaomi Mi 10T.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, digital clocks, calculators, and mobile telephones, including smartphones. LCD screens are also used on consumer electronics products such as DVD players, video game devices and clocks. LCD screens have replaced heavy, bulky cathode-ray tube (CRT) displays in nearly all applications. LCD screens are available in a wider range of screen sizes than CRT and plasma displays, with LCD screens available in sizes ranging from tiny digital watches to very large television receivers. LCDs are slowly being replaced by OLEDs, which can be easily made into different shapes, and have a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile (because OLEDs use a single glass or plastic panel whereas LCDs use two glass panels; the thickness of the panels increases with size but the increase is more noticeable on LCDs) and potentially lower power consumption (as the display is only "on" where needed and there is no backlight). OLEDs, however, are more expensive for a given display size due to the very expensive electroluminescent materials or phosphors that they use. Also due to the use of phosphors, OLEDs suffer from screen burn-in and there is currently no way to recycle OLED displays, whereas LCD panels can be recycled, although the technology required to recycle LCDs is not yet widespread. Attempts to maintain the competitiveness of LCDs are quantum dot displays, marketed as SUHD, QLED or Triluminos, which are displays with blue LED backlighting and a Quantum-dot enhancement film (QDEF) that converts part of the blue light into red and green, offering similar performance to an OLED display at a lower price, but the quantum dot layer that gives these displays their characteristics can not yet be recycled.

Since LCD screens do not use phosphors, they rarely suffer image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs are, however, susceptible to image persistence.battery-powered electronic equipment more efficiently than a CRT can be. By 2008, annual sales of televisions with LCD screens exceeded sales of CRT units worldwide, and the CRT became obsolete for most purposes.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs, along with OLED displays, are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

The MOSFET (metal-oxide-semiconductor field-effect transistor) was invented by Mohamed M. Atalla and Dawon Kahng at Bell Labs in 1959, and presented in 1960.Paul K. Weimer at RCA developed the thin-film transistor (TFT) in 1962.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,transparent and flexible, but they cannot emit light without a backlight like OLED and microLED, which are other technologies that can also be made flexible and transparent.

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs behind larger displays. A diffuser (made of PMMA acrylic plastic, also known as a wave or light guide/guiding plateinverter to convert whatever DC voltage the device uses (usually 5 or 12 V) to ≈1000 V needed to light a CCFL.

EL-WLED: The LCD panel is lit by a row of white LEDs placed at one or more edges of the screen. A light diffuser (light guide plate, LGP) is then used to spread the light evenly across the whole display, similarly to edge-lit CCFL LCD backlights. The diffuser is made out of either PMMA plastic or special glass, PMMA is used in most cases because it is rugged, while special glass is used when the thickness of the LCD is of primary concern, because it doesn"t expand as much when heated or exposed to moisture, which allows LCDs to be just 5mm thick. Quantum dots may be placed on top of the diffuser as a quantum dot enhancement film (QDEF, in which case they need a layer to be protected from heat and humidity) or on the color filter of the LCD, replacing the resists that are normally used.

WLED array: The LCD panel is lit by a full array of white LEDs placed behind a diffuser behind the panel. LCDs that use this implementation will usually have the ability to dim or completely turn off the LEDs in the dark areas of the image being displayed, effectively increasing the contrast ratio of the display. The precision with which this can be done will depend on the number of dimming zones of the display. The more dimming zones, the more precise the dimming, with less obvious blooming artifacts which are visible as dark grey patches surrounded by the unlit areas of the LCD. As of 2012, this design gets most of its use from upscale, larger-screen LCD televisions.

RGB-LED array: Similar to the WLED array, except the panel is lit by a full array of RGB LEDs. While displays lit with white LEDs usually have a poorer color gamut than CCFL lit displays, panels lit with RGB LEDs have very wide color gamuts. This implementation is most popular on professional graphics editing LCDs. As of 2012, LCDs in this category usually cost more than $1000. As of 2016 the cost of this category has drastically reduced and such LCD televisions obtained same price levels as the former 28" (71 cm) CRT based categories.

Monochrome LEDs: such as red, green, yellow or blue LEDs are used in the small passive monochrome LCDs typically used in clocks, watches and small appliances.

Today, most LCD screens are being designed with an LED backlight instead of the traditional CCFL backlight, while that backlight is dynamically controlled with the video information (dynamic backlight control). The combination with the dynamic backlight control, invented by Philips researchers Douglas Stanton, Martinus Stroomer and Adrianus de Vaan, simultaneously increases the dynamic range of the display system (also marketed as HDR, high dynamic range television or FLAD, full-area local area dimming).

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure (prism sheet) to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

Due to the LCD layer that generates the desired high resolution images at flashing video speeds using very low power electronics in combination with LED based backlight technologies, LCD technology has become the dominant display technology for products such as televisions, desktop monitors, notebooks, tablets, smartphones and mobile phones. Although competing OLED technology is pushed to the market, such OLED displays do not feature the HDR capabilities like LCDs in combination with 2D LED backlight technologies have, reason why the annual market of such LCD-based products is still growing faster (in volume) than OLED-based products while the efficiency of LCDs (and products like portable computers, mobile phones and televisions) may even be further improved by preventing the light to be absorbed in the colour filters of the LCD.

A pink elastomeric connector mating an LCD panel to circuit board traces, shown next to a centimeter-scale ruler. The conductive and insulating layers in the black stripe are very small.

A standard television receiver screen, a modern LCD panel, has over six million pixels, and they are all individually powered by a wire network embedded in the screen. The fine wires, or pathways, form a grid with vertical wires across the whole screen on one side of the screen and horizontal wires across the whole screen on the other side of the screen. To this grid each pixel has a positive connection on one side and a negative connection on the other side. So the total amount of wires needed for a 1080p display is 3 x 1920 going vertically and 1080 going horizontally for a total of 6840 wires horizontally and vertically. That"s three for red, green and blue and 1920 columns of pixels for each color for a total of 5760 wires going vertically and 1080 rows of wires going horizontally. For a panel that is 28.8 inches (73 centimeters) wide, that means a wire density of 200 wires per inch along the horizontal edge.

The LCD panel is powered by LCD drivers that are carefully matched up with the edge of the LCD panel at the factory level. The drivers may be installed using several methods, the most common of which are COG (Chip-On-Glass) and TAB (Tape-automated bonding) These same principles apply also for smartphone screens that are much smaller than TV screens.anisotropic conductive film or, for lower densities, elastomeric connectors.

Monochrome and later color passive-matrix LCDs were standard in most early laptops (although a few used plasma displaysGame Boyactive-matrix became standard on all laptops. The commercially unsuccessful Macintosh Portable (released in 1989) was one of the first to use an active-matrix display (though still monochrome). Passive-matrix LCDs are still used in the 2010s for applications less demanding than laptop computers and TVs, such as inexpensive calculators. In particular, these are used on portable devices where less information content needs to be displayed, lowest power consumption (no backlight) and low cost are desired or readability in direct sunlight is needed.

STN LCDs have to be continuously refreshed by alternating pulsed voltages of one polarity during one frame and pulses of opposite polarity during the next frame. Individual pixels are addressed by the corresponding row and column circuits. This type of display is called response times and poor contrast are typical of passive-matrix addressed LCDs with too many pixels and driven according to the "Alt & Pleshko" drive scheme. Welzen and de Vaan also invented a non RMS drive scheme enabling to drive STN displays with video rates and enabling to show smooth moving video images on an STN display.

Bistable LCDs do not require continuous refreshing. Rewriting is only required for picture information changes. In 1984 HA van Sprang and AJSM de Vaan invented an STN type display that could be operated in a bistable mode, enabling extremely high resolution images up to 4000 lines or more using only low voltages.

High-resolution color displays, such as modern LCD computer monitors and televisions, use an active-matrix structure. A matrix of thin-film transistors (TFTs) is added to the electrodes in contact with the LC layer. Each pixel has its own dedicated transistor, allowing each column line to access one pixel. When a row line is selected, all of the column lines are connected to a row of pixels and voltages corresponding to the picture information are driven onto all of the column lines. The row line is then deactivated and the next row line is selected. All of the row lines are selected in sequence during a refresh operation. Active-matrix addressed displays look brighter and sharper than passive-matrix addressed displays of the same size, and generally have quicker response times, producing much better images. Sharp produces bistable reflective LCDs with a 1-bit SRAM cell per pixel that only requires small amounts of power to maintain an image.

Segment LCDs can also have color by using Field Sequential Color (FSC LCD). This kind of displays have a high speed passive segment LCD panel with an RGB backlight. The backlight quickly changes color, making it appear white to the naked eye. The LCD panel is synchronized with the backlight. For example, to make a segment appear red, the segment is only turned ON when the backlight is red, and to make a segment appear magenta, the segment is turned ON when the backlight is blue, and it continues to be ON while the backlight becomes red, and it turns OFF when the backlight becomes green. To make a segment appear black, the segment is always turned ON. An FSC LCD divides a color image into 3 images (one Red, one Green and one Blue) and it displays them in order. Due to persistence of vision, the 3 monochromatic images appear as one color image. An FSC LCD needs an LCD panel with a refresh rate of 180 Hz, and the response time is reduced to just 5 milliseconds when compared with normal STN LCD panels which have a response time of 16 milliseconds.

Samsung introduced UFB (Ultra Fine & Bright) displays back in 2002, utilized the super-birefringent effect. It has the luminance, color gamut, and most of the contrast of a TFT-LCD, but only consumes as much power as an STN display, according to Samsung. It was being used in a variety of Samsung cellular-telephone models produced until late 2006, when Samsung stopped producing UFB displays. UFB displays were also used in certain models of LG mobile phones.

In-plane switching is an LCD technology that aligns the liquid crystals in a plane parallel to the glass substrates. In this method, the electrical field is applied through opposite electrodes on the same glass substrate, so that the liquid crystals can be reoriented (switched) essentially in the same plane, although fringe fields inhibit a homogeneous reorientation. This requires two transistors for each pixel instead of the single transistor needed for a standard thin-film transistor (TFT) display. The IPS technology is used in everything from televisions, computer monitors, and even wearable devices, especially almost all LCD smartphone panels are IPS/FFS mode. IPS displays belong to the LCD panel family screen types. The other two types are VA and TN. Before LG Enhanced IPS was introduced in 2001 by Hitachi as 17" monitor in Market, the additional transistors resulted in blocking more transmission area, thus requiring a brighter backlight and consuming more power, making this type of display less desirable for notebook computers. Panasonic Himeji G8.5 was using an enhanced version of IPS, also LGD in Korea, then currently the world biggest LCD panel manufacture BOE in China is also IPS/FFS mode TV panel.

Most of the new M+ technology was employed on 4K TV sets which led to a controversy after tests showed that the addition of a white sub pixel replacing the traditional RGB structure would reduce the resolution by around 25%. This means that a 4K TV cannot display the full UHD TV standard. The media and internet users later called this "RGBW" TVs because of the white sub pixel. Although LG Display has developed this technology for use in notebook display, outdoor and smartphones, it became more popular in the TV market because the announced 4K UHD resolution but still being incapable of achieving true UHD resolution defined by the CTA as 3840x2160 active pixels with 8-bit color. This negatively impacts the rendering of text, making it a bit fuzzier, which is especially noticeable when a TV is used as a PC monitor.

In 2011, LG claimed the smartphone LG Optimus Black (IPS LCD (LCD NOVA)) has the brightness up to 700 nits, while the competitor has only IPS LCD with 518 nits and double an active-matrix OLED (AMOLED) display with 305 nits. LG also claimed the NOVA display to be 50 percent more efficient than regular LCDs and to consume only 50 percent of the power of AMOLED displays when producing white on screen.

This pixel-layout is found in S-IPS LCDs. A chevron shape is used to widen the viewing cone (range of viewing directions with good contrast and low color shift).

Vertical-alignment displays are a form of LCDs in which the liquid crystals naturally align vertically to the glass substrates. When no voltage is applied, the liquid crystals remain perpendicular to the substrate, creating a black display between crossed polarizers. When voltage is applied, the liquid crystals shift to a tilted position, allowing light to pass through and create a gray-scale display depending on the amount of tilt generated by the electric field. It has a deeper-black background, a higher contrast ratio, a wider viewing angle, and better image quality at extreme temperatures than traditional twisted-nematic displays.

Blue phase mode LCDs have been shown as engineering samples early in 2008, but they are not in mass-production. The physics of blue phase mode LCDs suggest that very short switching times (≈1 ms) can be achieved, so time sequential color control can possibly be realized and expensive color filters would be obsolete.

Some LCD panels have defective transistors, causing permanently lit or unlit pixels which are commonly referred to as stuck pixels or dead pixels respectively. Unlike integrated circuits (ICs), LCD panels with a few defective transistors are usually still usable. Manufacturers" policies for the acceptable number of defective pixels vary greatly. At one point, Samsung held a zero-tolerance policy for LCD monitors sold in Korea.ISO 13406-2 standard.

Dead pixel policies are often hotly debated between manufacturers and customers. To regulate the acceptability of defects and to protect the end user, ISO released the ISO 13406-2 standard,ISO 9241, specifically ISO-9241-302, 303, 305, 307:2008 pixel defects. However, not every LCD manufacturer conforms to the ISO standard and the ISO standard is quite often interpreted in different ways. LCD panels are more likely to have defects than most ICs due to their larger size. For example, a 300 mm SVGA LCD has 8 defects and a 150 mm wafer has only 3 defects. However, 134 of the 137 dies on the wafer will be acceptable, whereas rejection of the whole LCD panel would be a 0% yield. In recent years, quality control has been improved. An SVGA LCD panel with 4 defective pixels is usually considered defective and customers can request an exchange for a new one.

Some manufacturers, notably in South Korea where some of the largest LCD panel

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey