lcd screen coating repair free sample

This article was co-authored by Linh Le and by wikiHow staff writer, Nicole Levine, MFA. Linh Le is a Certified Mobile Repair Specialist and the Owner of SC Mobile Repairs in San Clemente, California. With more than 12 years of experience, he specializes in smartphone, tablet, and smartwatch hardware repair. Linh has an iTech Mobile Device Repair Certification and an iOS Certification. He holds a Bachelor’s degree from The Franciscan University of Steubenville.

Note: If your MacBook Pro has any damage which impairs the service, that issue will need to be repaired first. In some cases, there may be a cost associated with the repair.

Purchasing an LCD monitor can be a difficult task at the best of times. Knowledgeable buyers have to consider many aspects of their future screen, not just basing a decision on price and marketing hype. Of course decisions are ultimately driven by a buyers budget, but one must always consider the things which will make the screen suitable to their uses, which are where technologies, features, connections and design come into play. Panel technology is not always discussed by manufacturers but is one of the most important aspects to consider when buying a new screen as it will tell you a lot about the real-life performance you can expect from the display, and ensure you are buying a screen suitable for your requirements. Fortunately we are here to help and you can read our in depth panel technologies article to help you in your quest.

One thing which many buyers will be unaware of is that all LCD displays are supplied with a protective filter layer on the front of the panel itself. This coating is used to protect the panel from damage, filter and diffuse the light output and in many cases reduce glare from other light sources in your workspace. What is also tricky to understand is that different panels can have different types of coating, varying considerably by panel technology and manufacturers. This article is designed to help highlight some of those differences so that readers can make an informed decision about their next monitor purchase.

The most common type of protective coating is ‘Anti-Glare’ (AG). This is often described as a matte coating as it is non-reflective to the user since it diffuses rather than reflects ambient light. It provides a method for manufacturers to avoid glare on the viewing surface from other light sources and has been used in the LCD monitor market for many years since the first TFT displays started to emerge.

This matte coating is included as an outer polarizing later which has been coarsened by mechanical or chemical processes. This achieves a surface coating which is not smooth and so can diffuse ambient light rather than reflect it. What is particularly important to understand is that this AG coating can be applied to panels with varying thicknesses, which has an impact on the anti-glare properties, but also on the underlying image of the screen. Where the coating is particularly thick and aggressive, the image from the screen can deteriorate as the light being emitted is also affected. This can have some impact on contrast and colour vibrancy and the perceived image can sometimes look dull as a result. Sharpness degradation can also occur in some extreme cases where AG coating is too thick. Users may also sometimes see the graininess of the coating, particularly when viewing white or light backgrounds. This can be particularly distracting for office work and images can look grainy or dirty if the coating is too aggressive. I would point out that not everyone would even notice this at all, and many users are perfectly happy with their screens even where aggressive AG is used. It’s just something to be wary of in case you have found problems with image quality in the past or are susceptible to it.

In other cases, AG coating is applied but it is light and far less obtrusive. The polarizer is less rough and has a lower haze value. Sometimes users refer to it as “semi-gloss” to distinguish the difference between these and the heavy AG coatings. This provides anti-glare properties but does not result in the grainy appearance of images. It is not a fully glossy solution though.

AG coating has long been the choice for nearly all professional-grade displays as well, helping to avoid issues with reflections and external light sources which are vital for colour critical work. In addition it should be noted that AG coating is less susceptible to dust, grease and dirt marks which can become an issue on reflective glossy coating alternatives.

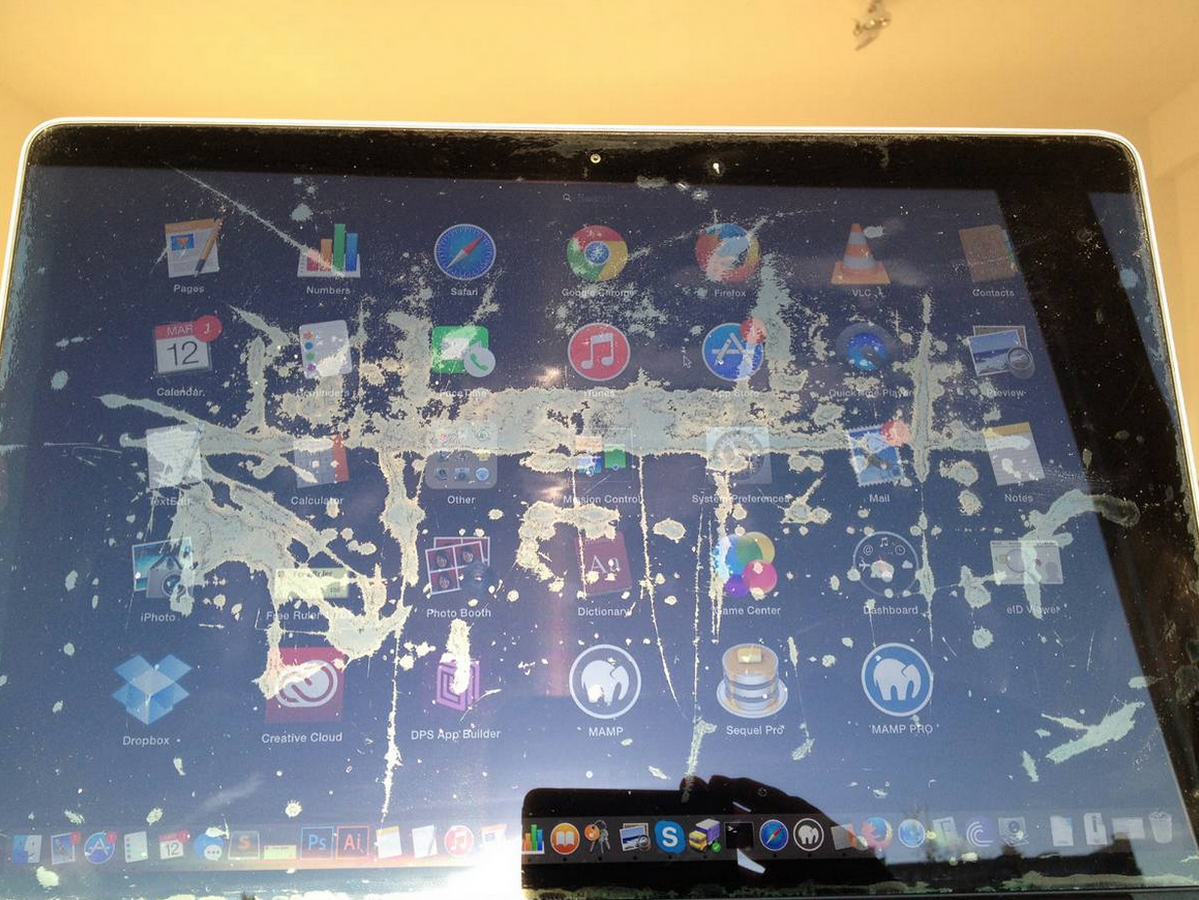

Some users have even taken matters into their own hands and removed the AG coating from their screens to produce a glossy surface. This will of course void your warranty and should be done with caution and entirely at the users risk. We mention it here as the above images are a good demonstration of the aggressive coating applied to the screen in some cases. You can see from the top picture the film being peeled off to leave a glossy reflective surface underneath. The second image is of course exaggerated quite a lot but you can see how the image is affected when the photograph is taken with the AG coating in front, on the right hand side. Of course this is far less obvious when the coating is in contact with the surface of the screen but it’s a fairly good demonstration of the coating being used in some cases (note, these were taken from an LG.Display IPS panel on the Dell U2312HM).

It is important to realise that different manufacturers tend to use different levels of AG coating, often linked to the panel technology they are developing. See our following sections for more information about specific panel manufacturers and technologies.

As an alternative some manufacturers choose to supply their screens with a glossy screen surface. This gives somewhat of a “wow factor” when you first see the screen and has often been used by manufacturers like Apple for their screens and tablets. The glossy panel coating is sometimes combined with a glass protective layer to give a hard exterior surface to the display and to emphasise that overall glossy appearance.

Glossy coatings provide very clear, clean and crisp images, free from any form of graininess or dirtiness you might see from AG alternatives. Images can look and feel nicer in some cases, often helping colours and blacks “pop” in practice. However, they aren’t without their own problems as the glossy coating can cause a lot of unwanted reflections in certain conditions. You have to be very careful of your ambient lighting conditions and the position of lamps and windows near your screen. Finger prints, dust and dirt can also become an issue and are more noticeable on shiny, reflective, glossy surfaces. In some instances chemical coatings are applied to help try and reduce some of the ambient light reflections but in reality they still remain reflective in practice and very different to AG coatings. Glossy screens aren’t for everyone at all, and it would be advisable to try and see one in person in a shop before making a purchase if you can.

Where glass coatings are applied as an additional protective layer buyers should also be aware that there is sometimes the risk of trapped dust or particles behind the glass which can become an annoyance over time. Some screens are completely free from this, but it’s just something to be aware of (e.g. dust issues were found on some Hazro’s HZ27WA/C/D screens where glass layers were used). Glass layers are also often provided on touch-screen displays for that added level of protection.

Glossy screen coatings have been offered over the years in several forms including older models featuring Sony X-Black, Acer CrystalBrite and NEC OptiClear technologies. Apple have used glossy coatings on their Cinema Displays for many years and in fact a lot of the modern glossy offerings are based on IPS panels. More recently other manufacturers like Hazro (HZ27WA/C/D) and DGM (IPS-2701WPH) have produced screens based on the 27” glossy IPS panels available. Samsung have also released their first glossy PLS panel in the Samsung S27B970D.

As we’ve already mentioned, the type of coating applied to a panel is very dependent on the manufacturer and the technology being used. Trends have emerged over the years and here is a summary of the typical coating usage from different panel solutions:

LG.Display IPS – These panels are often criticised for their aggressive AG coating. Where AG is used it is normally very aggressive and some people find the images are too grainy or dirty looking. As an example the Dell UltraSharp series (U2410, U2412M, U2711, U3011) are all using aggressive AG coating on their IPS panels. Some IPS panels are provided with a glossy screen coating as an alternative which avoids issues with grainy coating, but can result in distracting reflections.

AU Optronics AMVA – Modern versions of these panels are provided with a light AG coating which is sometimes referred to as semi-gloss. It is not overly grainy or obtrusive.

Samsung PLS – early versions of the panels were provided with a light AG coating, similar to that of AMVA panels although not quite as low haze. It was not overly grainy or distracting. More recently PLS panels have also been supplied with a glass glossy coating. The technology is in its infancy and so it is hard to establish a future trend.

TN Film panels – these are nearly always provided with AG coating although some glossy models have been produced from time to time. Coating tends to vary but is normally considered to be ‘medium’ in terms of its aggressiveness. Not as aggressive as the IPS panels, but not “semi-gloss” like AMVA offerings.

Above is a comparison of macro images taken of varying panel types. This was designed to capture the structure of the panel at a pixel level but can also be used to demonstrate the coating type being used and the resulting image clarity. You will see that the aggressive AG coating of the IPS panels leads to a blurry and grainy image, but the glossy equivalent leaves a clear and crisp view of the underlying pixels. TN Film is a medium AG coating and while not as aggressive as the IPS AG coating, it can lead to noticeable graininess in some cases. AMVA has a light AG coating and as you can see does not deteriorate the image quality too much.

This hopefully gives you a summary of the common types of coating used on the main panel technologies in the market. Of course there are always variations and so we will try to discuss the coatings in our reviews so you have an idea.

As a final thought I would like to reiterate the point that not everyone is bothered by the screen coating being used on their displays. This article is not designed to scare or concern people, just provide a reference point and information to help buyers make an informed decision. AG coating has been the main choice for many years now and continues to be popular with some manufacturers. While some people might be put off by the grainy coating, others may not even notice it. Glossy solutions also have their pros and cons and so it’s important to try and see screens in person if you can if you worry you may be affected by any of the characteristics described here.

Have you ever noticed a weird stain on your MacBook or MacBook Pro screen that just won’t go away? Did you try to wipe it off, only for it to get bigger? You may be experiencing staingate.

In 2015, Apple announced a repair program for several MacBook models affected by issues with its anti-reflective coating. Users who have found that they are affected by these issues can get Apple to replace the anti-reflective coating for free.

Staingate, or delamination, is when the anti-reflective coating on screens wears off, causing a stain-like appearance. It is a known issue in MacBook models and tends to happen after several months of regular use. A common aggravator of staingate is the pressure exerted on the screen by the keys and trackpad when a MacBook is closed. Additionally, staingate can also occur due to the recurred use of cleaning agents and microfiber cloths.

Once the reflective surface begins to peel, it is only a matter of time before it affects the rest of your screen. Not only does this look concerning, but it can also affect your webcam and color clarity. For professionals that need these a perfect screen, it is well worth the effort to fix any staingate issues that arise.

If you are not sure if your Mac has problems with its reflective coating, you can contact Apple for a proper diagnosis. Apple will also be able to tell you if your device is included in its recall program or not.

In addition, your MacBook purchase date must be within four years for it to be eligible for free repair. It must also have no history of tampering from a non-authorized service provider.

Depending on your MacBook model, out-of-pocket repairs for the anti-reflective coating can run anywhere from $500 to $800. While unauthorized repair centers will be able to do this at a lower price, Apple insists on replacing the whole screen to avoid any potential issues.

On the next screen, you can select your registered MacBook or manually type in the serial number. Afterward, set your location so Apple can recommend the nearest authorized Apple repair centers. From there, you can choose your preferred repair date and time.

MacBook users who have previously paid for a reflective coating replacement at an authorized Apple repair center may also be eligible for a refund. However, this is decided on a case-to-case basis, and you will need to consult with a Genius bar representative if you might qualify.

Aside from the aesthetic issue, most delamination in MacBook screens won’t cause any real problems for daily use. If staingate doesn’t bother you so much, be sure to weigh out the risks before you decide to do a DIY screen repair.

On the Mohs Hardness scale of materials, glass has a hardness level between 5.5 to 7. On the other hand, baking soda or Sodium Bicarbonate is 2.5. As a result, it should be impossible for baking soda to scratch the display, though it is abrasive enough to remove the rest of the coating on your MacBook screen.

For this method, mix baking soda with water until it creates a paste. Then, apply the solution to your screen in a circular motion with a light touch. Next, wipe off the solution using a cloth dampened with water. Lastly, use a toothpick or dry toothbrush to scrape out any remaining baking soda from the sides of the screen.

As an alternative to baking soda, you may also use all-purpose wet wipes. Although, the effectiveness of wet wipes depends on the brand and composition. Use wet wipes in a circular motion on your screen. Then, wipe off any remaining wet spots with a microfiber cloth.

While there are other recommendations online, be careful which ones you follow, as brands may not have the same formulation across countries. Additionally, anything that wasn"t explicitly designed for the purpose of cleaning your screen is not without risk.

When it comes to removing staingate, don’t feel the need to remove everything in one go. You can remove parts of the screen stains intermittently to lessen the possibility of damage.

Avoid using cleaning agents that are corrosive to your screens, such as mouthwash or toothpaste. If you are determined to use these, use only a small amount because they can degrade the quality of your screen. If you want to be careful, test a small area of your screen before using the product on the whole screen.

Whether it is water or a screen cleaning agent, never pour bulk liquid into your screen. All you need to use is a damp cloth. Be very careful of having liquids seep into the sides of your screen and wipe off any that get too close.

Unfortunately, even for Apple-certified repairs, staingate has a history of recurring within a few years. However, you can make some changes to avoid it happening again.

For example, avoid touching the screen unless necessary. You can use your laptop hinge to open your MacBook. You should also leave your device slightly open when not in use to avoid pressure on the lid. In addition, don’t overclean your screen. Avoid strong screen display cleaning agents and use a light touch when possible.

After successfully removing your reflective coating, it is best to invest in a screen protector film to take its place. Not only will this protect your eyes from glare, but it should protect the screen itself from being damaged further.

-immediately after purchase, I placed a genuine Sony LCD screen protector on my A7RII in the mistaken belief that it would protect the screen and coating.

-the protector reacted with the factory-installed plastic protector on the LCD screen. This may or may not have had an anti-glare coating (quite likely), but the fact remains that it is a removable factory protector, as stated. It"s in my hand right now and I can confirm that it"s a sorry-looking curled up bit of plastic with some obvious signs of degradation. here"s a picture of it still on the camera:

-The usability of the LCD screen has improved dramatically as a result of this repair, including in bright sunlight. Others experience may vary, but my point was that there is a film on the screen, and, if damaged, it can be removed and replaced.

“I bought a MacBook Air M1 6 months ago and the screen cracked for no apparent reason. I left my computer on the top of my desk during the night and the next day I opened it the screen had 2 small cracks on the right which damaged the functioning of the screen. I contacted an authorized Apple center which told me Apple warranty would not cover it as it is a contact point crack; as if I have left something the size of a rice berry between the screen and the keyboard. It is absurd as I have nothing like it on my desk and the computer was properly closed as usual and didn’t move the whole night.”

“We bought a M1 Macbook Air 4 months ago. Last weekend my wife was watching a movie on Netflix and adjusted the screen at the edge to change the viewing angle. The screen blacked out except for an area on the left which had bright lines in a irregular pattern. I have taken the MBA to the local Apple store and they advise me that my wife caused the pressure crack and it is not covered under warranty. Cost to repair is $725 Australian dollars. This leaves a very sour taste. The screen should not break when the screen angle is changed.”

“My 17yr old daughter was at her desk, working on her MacBook Pro (M1 display) and shut it to take a break. When she went back to work, on opening the device she noticed that the bottom of the display was covered by flickering black and white lines and that there were also perpendicular coloured lines on the left hand side of the screen.”

The MPC 1000 XLCD Large ( 240 x 128 ) LCD screen doubles the screen size of the MPC1000. The XLCD screen utilizes the mounting points of the original factory LCD. This new screen comes mounted in the plastic holder surround and easily drops in the place of the old one. With a simple install of the included operating system update, you upgrade to a much larger LCD screen.

The LCD screen is available in two colors (White and Blue), which can also be inverted using a function in the JJ OS128 operating system included for free. The operating system allows this larger LCD screen to utilize the full capabilities of the MPC1000 with a larger overall LCD screen footprint.

- LCD Screen with complete snap in housing, and plug and play design wire harness foreasy install and uninstall.Please Note: The housings are B Stock and have a small line on the top of them. If you have any questions about this please email us at sales@mpcstuff.com Its small but slightlynoticeable. It does not hinder usage of the LCD screen.

The LCD screen is very easily installed as you can see from our instructional video linked below. Typical install takes about 10-15 minutes and only requires a Phillips screwdriver and flat head screwdriver. (Please note: MPCstuff is not responsible for any issues that may arise when you are installing screen).

To learn more about the operating system, click here. There are several operational videos below. If you are interested in a more full-featured version of the OS, the paid version of the JJ OS made specifically for this LCD screen is available from JJ OS click here.

PLEASE NOTE: Akai is a registered trademark of Akai Pro. These LCD screens are not made or endorsed by Akai Pro. The OS is made by JJ OS. They are aftermarket products and should be installed at your own risk.

Thank you, it worked like a charm. It took me some 20 minutes in total, I’d say 10 minutes to remove the coating alone. There where two spots which were hydro repellent initially, but that was because of the coating. After some time they finally came off. The result is amazing, I almost forgot how bright the screen was. Thank you very much, spot on!

Hi Deanne! It is not clear whether Apple has done any change to the anti-reflective coating of their Macbook lineup. While researching this topic, I noticed a couple of instances of people having this issue even on a never laptops (2018, 2019). If the problem arises in a greater measure again, Apple will likely just add the newer models to the repair program. Hope that helps, Jakub.

Thank you for this!! My screen was looking so bad. There were scratches and blotches everywhere from the coating wearing away. I think it must have taken me about 20 minutes as well. Mine was really bad so it took about 4 different wipe downs but my laptop looks brand new now!!! I am so beyond happy. Apple wouldn’t help me with it and wanted to charge me to replace the glass costing me an arm and a leg.. pfffff. Thank you so much OP!

Same here my screen was looking very bad i didn’t used to have interest but must say just four days ago after I tried it’s amazing laptop looks almost new now

Thank you so very much Jakub! As the title says, this is the best and easiest way to remove the anti-reflective coating from my MacBook Pro (Retina, 13-inch, Late 2013)!

Jakub you are the man! I got some rain drops on my screen when I was outside during a zoom meeting and the screen was streaked and looked BAD and I had no idea why! I rubbed it hard with a lens cloth and it got worse! It looked like a coating on the screen was coming off – and it turns out that’s exactly what was happening. I am an educator and multimedia specialist – so my screen and its sharpness and color is critical. It is PERFECT now – THANK YOU SO MUCH!!

Hi Erik, thank you for the tip, I’m glad you found a good alternative that works for you! If I can get my hands on the W5 Multi-purpose cleaning wipes I’ll give it a try, since my wife’s MacBook screen is getting pretty bad as well.

Hi. I’ve tried W5 cleaning wipes from LIDL as well and I was shocked how easy it is going down. Thanks for a tip. W5 works perfectly. 10min est. time. No issues, screen as new. THANK YOU ALL guys!

Thanks so much Jakub! I didnt have staining that was too bad, but it was where it was that was annoying. I could basically see an outline of the trackpad where the anti-glare had come off. I’m a qualified apple service tech but I didnt know about the baking soda. It absolutely works a treat and I’m actually not too bothered about how reflective the clean screen is. Only difficult bits were the edges of the screen, especially near the keyboard. No scratches whatsoever – you sold me when you talked about the Moh’s scale, it gave me the confidence that you knew what you were talking about.

Hi Kola, thank you for the nice comment! Honestly, after some time, I really do not notice the higher reflectivity of the screen, so I’m quite positive after a while, you will barely notice it if at all! I’m glad I could help!

I have a Macbook air 2011 that accidentally got residue from a Method cleaner used to clean the rest of the machine. The screen looked terrible where the keys and trackpad smudge the AR coating. I used your baking soda method and was able to get about 90% of the coating removed, however, since then nothing I do seems to budge the remaining 10% which is very visible. I’ve tried, Lysol wipes, Isopropyl alcohol, glass cleaner, method cleanser (originally caused the problem), cook top cleaner, auto polish, glasses cleaner, screen cleaner, and Mr Clean Magic Eraser. I am super frustrated because the original suggestion of baking soda seemed like a good solution, but not able to do the complete job. Any ideas why some of it is so stubborn and anything else I can try??

Hi Andy! If you notice the Macbook Air 2011 is not on the list of reported devices with possible AR issues, which indicates Apple used different type of screen, and thus I would not recommand to use the method described in this article. As far as I know, older models such as Macbook Air didn’t have a glasss screen protecting the LCD panel which sits behind it, like the newer Macbook Pro’s have. Unfortunately in your case I’cant give you any further advice, since I’ve tested my method on device with a glass screen. The good news is that the older displays for devices such yours are much cheaper to purchase.

I just finished removing my anti reflective coating. I used hand wet wipes to remove the coating and after I used some floor anti bacterial solution and let it soften the residue that remained after removing the coating. Polished with micro fiber cloth and it is shinny. Looks good.

The bad stuff. Viewing angle is poor from side to side. The display has a green-ish tint for darker colours and the colours seem a bit faded (i was kind of expecting this). However, I recommend changing the colour profile from the default Colour LCD to Generic RGB Profile. Why? Because it darkens the image a bit and adds a touch of colour, feels more like it used to be.

Hi Roajah, thanks for the comment. I’m glad you find your way to deal with this issue. Personally, I haven’t noticed any change to the colors of the display after removing the AR coating using the baking soda method. The only downside is the higher reflectivity. Anyways thanks for the tip about changing the color profile of the display, maybe someone will have a similar issue as you had.

*EDIT: This is a great technique for removing the AR coating, BUT it has altered the colour profile of my screen. the dark tones now have a green hue to them, which isn’t ideal if you’re in any form of visual arts job. Luckily, this laptop is only my secondary back-up computer which I use for emergencies and data mining, so it doesn’t really bother me. But be warned that this can happen

Hi Jon, could you tell us what model of Macbook Pro you have? And what method of removing the anti-reflective coating did you use so that others know what to avoid? Thanks! Jakub

Thank you so much for sharing this method Jakub! I thought the only way to resolve my terrible screen was to replace it. You shared your experience and saved me $800! My screen looks perfect now. Thank you Jakub!!

It worked! Took me 20 minutes too. I found that a cloth took longer than just using my fingers with the paste. I used the cloth to polish it afterwards. I had to use a little more pressure than I would have liked but, it came off and the screen still works! Thanks for the tip!

holy hell 3 minutes of baking soda and just a little baby wipe and i got a new screen … AR poor in the sun AR poor without but holy mother after removing the AR i got a new computer thanks so much. I never leave comments on these forums. but this got me so damned hyped up thank you so much

Thank you very much! worked perfectly on my MacBook Pro (15-inch, Mid 2015). Although I ignored his advice about “don’t perform the procedure if it’s just for aesthetic reasons”. My slight TOC reached very high limits looking every day at my stained screen.

Brilliant! Thank you. My screen has been bothering me SO MUCH for over a year. It took a bit of elbow grease but so worth it. There is still a tiny tiny strip (about 2mm wide) where I struggled to get into the edges. I will tackle that later with a q-tip and alcohol. Unless someone has a better suggestion! I feel like I have a new laptop

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey