twisted nematic tn lcd panel factory

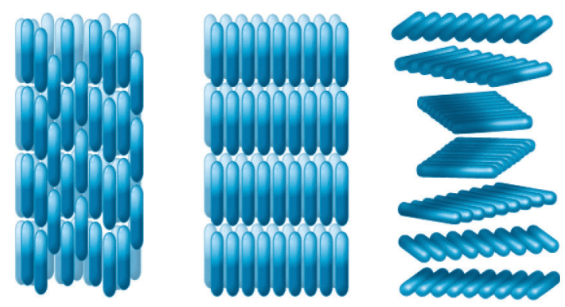

The Nematic liquid crystal state is a unique state not included in the above 3 states. It is a state between the crystalline (solid) and isotropic (liquid) states. Even in the state of liquid crystals, there are several types of liquid crystal states, as below.

The nematic liquid crystal phase is characterized by molecules maintain the general order of tending to point in the same direction. It has one dimensional order. See Fig.1

In smectic phase, molecules show two-dimensional order not present in the nematic. The molecules maintain the general orientationally of nematic, but also tend to align themselves in layers or planes. It is the state between nematic (one-dimensional order) and solid state (three-dimensional order). See Fig.1.

The cholesteric (or chiral nematic) liquid crystal phase is typically the molecules are directionally oriented and stacked in a helical pattern, with each layer rotated at a slight angle to the ones above and below it. See Fig.1.

![]()

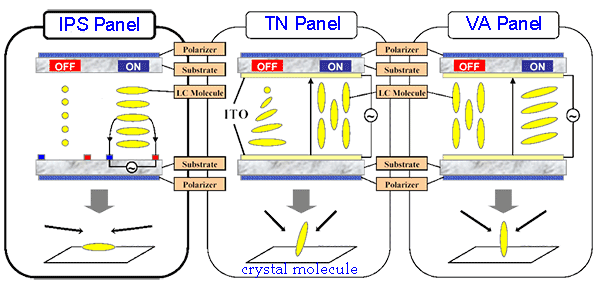

A type of LCD panel technology. In this type of panel, when no electric current is running through the liquid crystal cells, the cells naturally align in a twisted form between two substrate panes of glass which blocks the transmission of light from the backlight. This renders the crystals opaque and results in a black display screen. When an electric current is applied, the liquid crystal cells untwist allowing light to pass through resulting in a white display screen. TN panels have relatively narrow viewing angles especially in the vertical direction and color reproduction is poor; however, they are economical and suitable for a wide-range of general uses, particularly with office tasks (e.g. word processing).

The twisted nematic effect (TN-effect) was a main technology breakthrough that made LCDs practical. Unlike earlier displays, TN-cells did not require a current to flow for operation and used low operating voltages suitable for use with batteries. The introduction of TN-effect displays led to their rapid expansion in the display field, quickly pushing out other common technologies like monolithic LEDs and CRTs for most electronics. By the 1990s, TN-effect LCDs were largely universal in portable electronics, although since then, many applications of LCDs adopted alternatives to the TN-effect such as in-plane switching (IPS) or vertical alignment (VA).

TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display.

The twisted nematic effect is based on the precisely controlled realignment of liquid crystal molecules between different ordered molecular configurations under the action of an applied electric field. This is achieved with little power consumption and at low operating voltages. The underlying phenomenon of alignment of liquid crystal molecules in applied field is called Fréedericksz transition and was discovered by Russian physicist Vsevolod Frederiks in 1927.

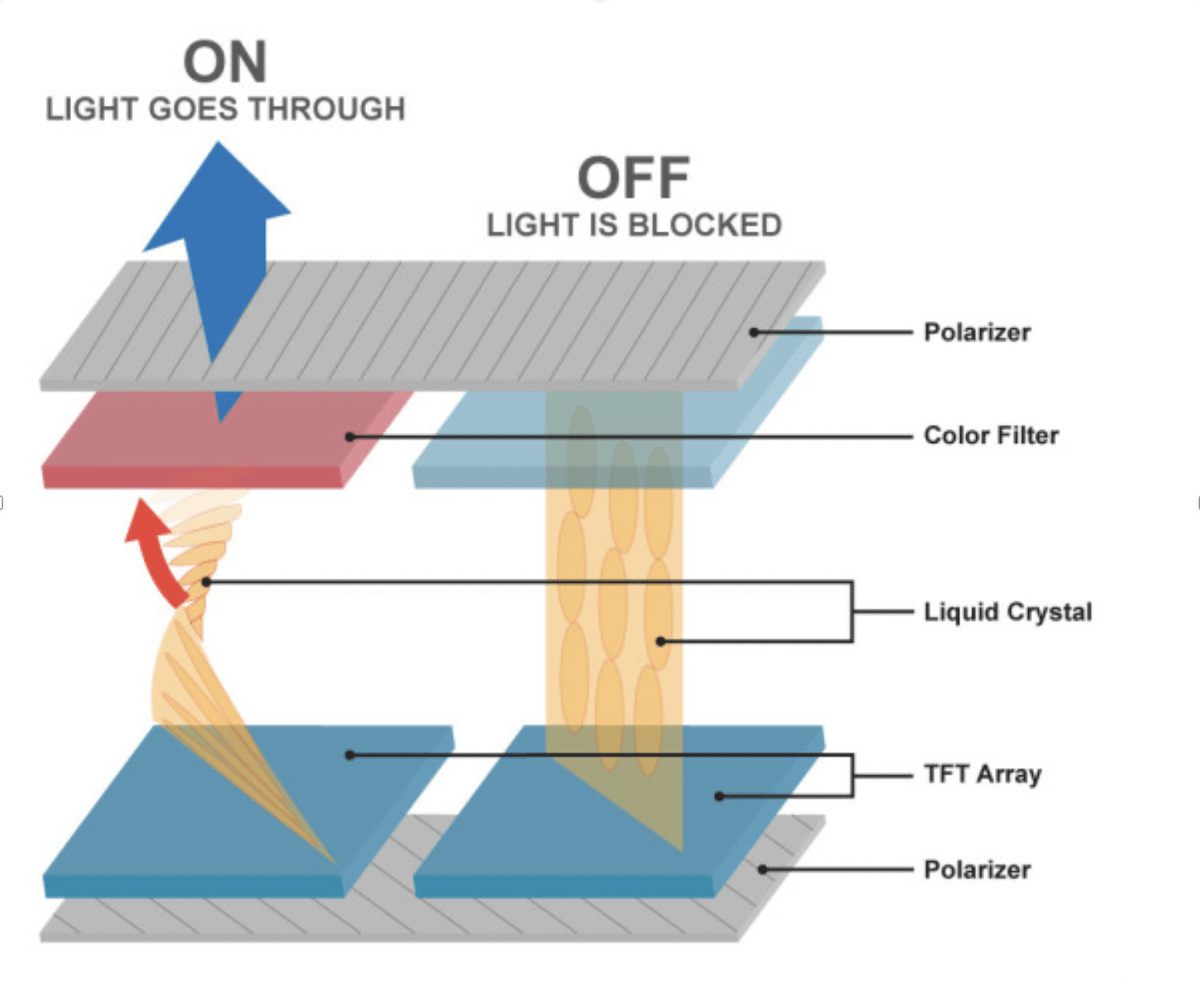

The illustrations to the right show both the OFF and the ON-state of a single picture element (pixel) of a twisted nematic light modulator liquid crystal display operating in the "normally white" mode, i.e., a mode in which light is transmitted when no electrical field is applied to the liquid crystal.

In the OFF state, i.e., when no electrical field is applied, a twisted configuration (aka helical structure or helix) of nematic liquid crystal molecules is formed between two glass plates, G in the figure, which are separated by several spacers and coated with transparent electrodes, E1 and E2. The electrodes themselves are coated with alignment layers (not shown) that precisely twist the liquid crystal by 90° when no external field is present (left diagram). If a light source with the proper polarization (about half) shines on the front of the LCD, the light will pass through the first polarizer, P2 and into the liquid crystal, where it is rotated by the helical structure. The light is then properly polarized to pass through the second polarizer, P1, set at 90° to the first. The light then passes through the back of the cell and the image, I, appears transparent.

To display information with a twisted nematic liquid crystal, the transparent electrodes are structured by photo-lithography to form a matrix or other pattern of electrodes. Only one of the electrodes has to be patterned in this way, the other can remain continuous (common electrode). For low information content numerical and alpha-numerical TN-LCDs, like digital watches or calculators, segmented electrodes are sufficient. If more complex data or graphics information have to be displayed, a matrix arrangement of electrodes is used. Because of this, voltage-controlled addressing of matrix displays, such as in LCD-screens for computer monitors or flat television screens, is more complex than with segmented electrodes. For a matrix of limited resolution or for a slow-changing display on even a large matrix panel, a passive grid of electrodes is sufficient to implement passive matrix-addressing, provided that there are independent electronic drivers for each row and column. A high-resolution matrix LCD with required fast response (e.g. for animated graphics and/or video) necessitates integration of additional non-linear electronic elements into each picture element (pixel) of the display (e.g., thin-film diodes, TFDs, or thin-film transistors, TFTs) in order to allow active matrix-addressing of individual picture elements without crosstalk (unintended activation of non-addressed pixels).

In 1962, Richard Williams, a physical chemist working at RCA Laboratories, started seeking new physical phenomena that might yield a display technology without vacuum tubes. Aware of the long line of research involving nematic liquid crystals, he started experimenting with the compound p-azoxyanisole which has a melting point of 115 °C (239 °F). Williams set up his experiments on a heated microscope stage, placing samples between transparent tin-oxide electrodes on glass plates held at 125 °C (257 °F). He discovered that a very strong electrical field applied across the stack would cause striped patterns to form. These were later termed "Williams domains".

Although successful, the dynamic scattering display required constant current flow through the device, as well as relatively high voltages. This made them unattractive for low-power situations, where many of these sorts of displays were being used. Not being self-lit, LCDs also required external lighting if they were going to be used in low-light situations, which made existing display technologies even more unattractive in overall power terms. A further limitation was the requirement for a mirror, which limited the viewing angles. The RCA team was aware of these limitations, and continued development of a variety of technologies.

Another potential approach was the twisted-nematic approach, which had first been noticed by French physicist Charles-Victor Mauguin in 1911. Mauguin was experimenting with a variety of semi-solid liquid crystals when he noted that he could align the crystals by pulling a piece of paper across them, causing the crystals to become polarized. He later noticed when he sandwiched the crystal between two aligned polarizers, he could twist them in relation to each other, but the light continued to be transmitted. This was not expected. Normally if two polarizers are aligned at right angles, light will not flow through them. Mauguin concluded that the light was being re-polarized by the twisting of the crystal itself.

Wolfgang Helfrich, a physicist who joined RCA in 1967, became interested in Mauguin"s twisted structure and thought it might be used to create an electronic display. However RCA showed little interest because they felt that any effect that used two polarizers would also have a large amount of light absorption, requiring it to be brightly lit. In 1970, Helfrich left RCA and joined the Central Research Laboratories of Hoffmann-LaRoche in Switzerland, where he teamed up with Martin Schadt, a solid-state physicist. Schadt built a sample with electrodes and a twisted version of a liquid-crystal material called PEBAB (p-ethoxybenzylidene-p"-aminobenzonitrile), which Helfrich had reported in prior studies at RCA, as part of their guest-host experiments.

At this time Brown, Boveri & Cie (BBC) was also working with the devices as part of a prior joint medical research agreement with Hoffmann-LaRoche.James Fergason, an expert in liquid crystals at the Westinghouse Research Laboratories. Fergason was working on the TN-effect for displays, having formed ILIXCO to commercialize developments of the research being carried out in conjunction with Sardari Arora and Alfred Saupe at Kent State University"s Liquid Crystal Institute.

When news of the demonstration reached Hoffmann-LaRoche, Helfrich and Schadt immediately pushed for a patent, which was filed on 4 December 1970. Their formal results were published in Applied Physics Letters on 15 February 1971. In order to demonstrate the feasibility of the new effect for displays, Schadt fabricated a 4-digit display panel in 1972.

This work, in turn, led to the discovery of an entirely different class of nematic crystals by Ludwig Pohl, Rudolf Eidenschink and their colleagues at Merck KGaA in Darmstadt, called cyanophenylcyclohexanes. They quickly became the basis of almost all LCDs, and remain a major part of Merck"s business today.

Gerhard H. Buntz (Patent Attorney, European Patent Attorney, Physicist, Basel), "Twisted Nematic Liquid Crystal Displays (TN-LCDs), an invention from Basel with global effects", Information No. 118, October 2005, issued by Internationale Treuhand AG, Basel, Geneva, Zurich. Published in German

TN displays have a 90° or less twist (the rotation of the molecules from one plane of the display to the other). All passive direct drive, active matrix, and most passive low level (x2 to x32) multiplexed LCDs have a 90° twist.

The basic Twisted Nematic (TN) LCD consists of a layer of liquid crystal material supported by two glass plates. The liquid crystal material is a mixture of long, cylindrically shaped molecules with different electrical and optical properties, depending on direction.

The TN technology comes in a single coloration; it is Black characters on a gray background. It is the least expensive, but has the lowest visual quality, primarily in viewing angle.

TN stands for twisted nematic. This is a type of LED (a form of LCD) panel display technology. TN panels are characterized as being the fastest and cheapest among the other main types of display panels, VA (vertical alignment)and IPS (in-plane switching). As such, they work great for gaming monitors and gaming laptops. However, TN panels also offer the worst viewing angles and color when compared to VA and IPS panels.

PerformanceFastest: low response times, highest refresh rates, minimal motion blur; Low input lagLongest response times typically; Higher refresh rates possibleSlower response times than TN, faster response times than VA; Gaming-quality refresh rates are rare

DisplayWorst viewing angles;Worst colorViewing angles typically better than TN, worse than IPS; Good color; Best contrast;Best image depthBest viewing angles; Best color

![]()

Twisted nematic or TN LCD is a type of thin-film transistor liquid crystal display or TFT-LCD that is commonly used in an array of consumer electronic devices such as digital watches and calculators, as well as computer monitors and mobile phones. Note that it is the most common type of LCD technology because of its lowered manufacturing cost than IPS LCD.

1.One advantage of twisted nematic or TN LCD over other display technologies such as IPS LCD, VA display, and OLED is affordability. The technology behind TN LCDs is easier to implement, thus translating to inexpensive manufacturing cost and affordable market price.

2.Energy efficiency is another strength of twisted nematic LCD when compared to IPS LCD and VA display. It can run under low operating voltages and does not require a current flow to operate. Hence, TN LCDs are suitable for low-powered devices.

3.Another notable advantage of twisted nematic LCD is that it has the fastest pixel response rate and highest refresh rate than its counterpart display technologies, particularly IPS LCD and to some extent, OLED display. These characteristics make TNs a favorite in the gaming community.

1.Limited viewing angle is a main disadvantage of twisted nematic LCD. To be specific, when viewed from an angle, images appear darker and color seems less vivid on a TN LCDs. Viewing experience suffers due to this.

2.Another disadvantage of TNs is that it has the poorest color reproduction among the different types of LCD technologies, such as IPS LCD and VA LCD. TNs only have a color depth of 262,144 possible colors.

3.Quality is also an issue. The quality of a particular twisted nematic LCD panel depends on its manufacturer. However, because twisted nematic is generally cheap to manufacture, there are low-end models that severely highlights the disadvantages of TN LCD.

The point when liquid crystals, in response to application of a magnetic field along the axes of their molecules, become parallel; is being refined to a degree that permits the manufacture of projectors, monitors and or video panels that allow 3-D perceptions by human observation. This enhancement is a necessary improvement to enable remote visual communications that replicate personal interactions. Such a technology will present realistic imagery that conveys all the visual cues entailed in interpersonal associations.

The future of human existence may depend on energy reduction strategies that could incorporate remote 3-D video to provide personal interactions without necessitating travel. Such alternatives would need to accommodate normal mobility issues as commonly provided by smartphones and tablet PCs today. Twisted nematic LCD displays currently produced provide scalable solutions for rudimentary dimensional presentations that require headsets for perception of the 3-D effects.

As scientists perfected polymer buffering and magnetic switching characteristics of the controlling electronics, expectations for greater brilliance and wider viewing angels are achieved at significantly lower production cost. These factors have gradually increased the competiveness of LCD products utilizing active matrix technology. Demand for more precise definition in display resolutions drives research in the use of twisted nematics liquid crystals and presents promising prospects for future production of cost effective products with even more realistic presentations.

Most of the advances in monitors and displays are in reference to color and resolution. Conversely, the issues of quality that determine superiority for consumption purposes are viewing angle, image quality, increased brightness, and lower production line costs.

The high cost of building factories to produce competitive thin film transistors liquid crystal displays (TFT-LCD) pushes production of the less costly to produce twisted nematic (TN) into the general display panel market. The product line includes display components for digital televisions, computer monitors, mobile phones, handheld video games, and PDAs and navigation systems. This push also segments the marketplace into quality demanding commercial sells and the less exacting one-off brand name markets.

Screen brightness, as perceptively distinguishable by the human eye, is a result of lessening the scattering of light with respect to the directional movement of the crystal molecules. Improvements to this lessening effect combined with patented faster switching techniques improved image quality by addressing the color gamut with higher luminosity, which corrected color shift errors and deviations.

Over time, several major manufacturers have entered into partnerships and joint ventures that resulted in increasing pixel counts while speeding up switching to yield faster response timing at lower production cost. Developments in alternative technologies for vertical and patterned alignments of pixels lowered distortions in off-perpendicular viewing common in twisted nematic panels. The resulting better viewing angles have since been enhanced with continuously rotating sub-pixels that produce dramatic improvements to viewing angles.

Nine manufacturers produce the world’s supply of TN-LCD display products. Quality is a matter of performance testing of the product as it comes off the assembly lines. Segmented fulfillment is determined by very practical quality factors that sort the destination of the production according to superiority of its performance. The best product goes to commercial channels and the worst is disposed of in the off-brand market. Everything in between is branded by the manufacturers for general consumption.

In this article we will explore the different types of display panel types available on the market. We will cover the most popular and some very niche or near obsolete options to give our fans a good overview.

TN or Twisted Nematic, In-Plane Switching or IPS, and Vertical Alignment or VA. TN is most common on computer monitors although IPS is also very common, while VA is most common on low-end TVs, but is slowly gaining ground in PC monitor spaces.

LCD technology has some real and inherent disadvantages when compared to CRT, Plasma, and OLED, mostly because of the fact that LCDs rely on backlighting (either edge-lit like all computer monitors, or literally backlit on higher end TVs) while CRT, Plasma, OLED produce light on the surface for each and every pixel. This means that those other display types have superior contrast ratios, deeper blacks, more pure whites, far richer and fuller colors. For example, blacks are only true blacks on CRT/Plasma/OLED, not LCD, since the pixel actually has no light on these unlike LCD. LCDs also use sample and hold which leads to a lot more motion blur especially compared to CRT and SED/FED.

TN panels have two large advantages over other types. Cost and response time. It should be noted that even though inferior to IPS and VA for colour critical work, a good, high-end TN monitor with good calibration can still look quite decent for most use cases. It won’t beat decent VA or IPS, but it can still offer a nice visual experience. Good response times and low motion blur can make a TN look great in action.

This is the panel type used in many slightly older HDTVs. Overall it is a very nice and increasingly popular LCD panel type although the potential has yet to be fully realized in computer monitors.

- Inconsistent response times. Most VA displays have at least a few very slow transitions. Black to dark grey or just black to grey are the most common culprits, even if other transitions are good or even fast. As a result, VAs offer better minimum response times than IPS, but worse average and maximum response times than IPS. It should be noted that some higher end panels seem to have this issue mostly figured out though.

- “Black crush” which causes a loss in black detail (e.g., grey detail lost in black content). Compared to TN’s dark grey blacks and IPS’s white blacks, this isn’t a cause for concern save for color critical work, but it is a real con.

IPS is the most used panel type for photo editing, because of all LCD panels it has the best color accuracy. It is becoming more and more common and may eventually overtake TN panels.

- The best potential color accuracy of all LCD panels. Especially for professional panels, but even normal IPS monitors still have far better color accuracy than typical TN monitors though.

IPS is a very good LCD panel type and it has many advantages, but it is not the end all be all of monitors. Still, we believe that it and VA are overall tied in their pros and cons. But remember, the specific panel and product (and price!) always matter more than the technology it is based off!

The image above is based on slightly older monitors, but it shows the difference in blacks in a similar scene.IPS (far left), TN (middle), and VA (right).

CRT monitors have gone out of fashion and very few are still in any sort of production. Any CRT monitors one finds are likely to be used or old stock. We mostly expect only really hardcore competitive gamers to use such monitors thanks to their response time advantage, but the truth is that modern ultra-high end LCDs with blur reduction can offer a good alternative here.

This tech was prominent in HDTVs for a while, before LCD became the big thing. We are covering it in case you find an old plasma TV and are wondering if it would be a good fit. It has excellent contrast ration, good blacks and no backlight. Viewing angles are also very good and there is almost no motion blur.

Like CRT and plasma, the light source is on the screen surface itself, hence the much better image. An OLED powers each and every subpixel. OLED may have the potential to be the best panel type for everything, but there are still some longevity concerns on many models and its higher cost is still an issue.

- They use sample and hold just like LCD technology, so motion blur still exists. However, there is already a blur reduction technique for it, used by Oculus Rift (black frame insertion).

- While colour accuracy is good, it is hard to make it excellent. Lots of calibration is needed on the manufacturer’s side and probably on the user’s side too. It will easily surpass all other panels, except a perfectly calibrated CRT.

The point when liquid crystals, in response to application of a magnetic field along the axes of their molecules, become parallel; is being refined to a degree that permits the manufacture of projectors, monitors and or video panels that allow 3-D perceptions by human observation. This enhancement is a necessary improvement to enable remote visual communications that replicate personal interactions. Such a technology will present realistic imagery that conveys all the visual cues entailed in interpersonal associations.

The future of human existence may depend on energy reduction strategies that could incorporate remote 3-D video to provide personal interactions without necessitating travel. Such alternatives would need to accommodate normal mobility issues as commonly provided by smartphones and tablet PCs today. Twisted nematic LCD displays currently produced provide scalable solutions for rudimentary dimensional presentations that require headsets for perception of the 3-D effects.

As scientists perfected polymer buffering and magnetic switching characteristics of the controlling electronics, expectations for greater brilliance and wider viewing angels are achieved at significantly lower production cost. These factors have gradually increased the competiveness of LCD products utilizing active matrix technology. Demand for more precise definition in display resolutions drives research in the use of twisted nematics liquid crystals and presents promising prospects for future production of cost effective products with even more realistic presentations.

Most of the advances in monitors and displays are in reference to color and resolution. Conversely, the issues of quality that determine superiority for consumption purposes are viewing angle, image quality, increased brightness, and lower production line costs.

The high cost of building factories to produce competitive thin film transistors liquid crystal displays (TFT-LCD) pushes production of the less costly to produce twisted nematic (TN) into the general display panel market. The product line includes display components for digital televisions, computer monitors, mobile phones, handheld video games, and PDAs and navigation systems. This push also segments the marketplace into quality demanding commercial sells and the less exacting one-off brand name markets.

Screen brightness, as perceptively distinguishable by the human eye, is a result of lessening the scattering of light with respect to the directional movement of the crystal molecules. Improvements to this lessening effect combined with patented faster switching techniques improved image quality by addressing the color gamut with higher luminosity, which corrected color shift errors and deviations.

Over time, several major manufacturers have entered into partnerships and joint ventures that resulted in increasing pixel counts while speeding up switching to yield faster response timing at lower production cost. Developments in alternative technologies for vertical and patterned alignments of pixels lowered distortions in off-perpendicular viewing common in twisted nematic panels. The resulting better viewing angles have since been enhanced with continuously rotating sub-pixels that produce dramatic improvements to viewing angles.

Nine manufacturers produce the world’s supply of TN-LCD display products. Quality is a matter of performance testing of the product as it comes off the assembly lines. Segmented fulfillment is determined by very practical quality factors that sort the destination of the production according to superiority of its performance. The best product goes to commercial channels and the worst is disposed of in the off-brand market. Everything in between is branded by the manufacturers for general consumption.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

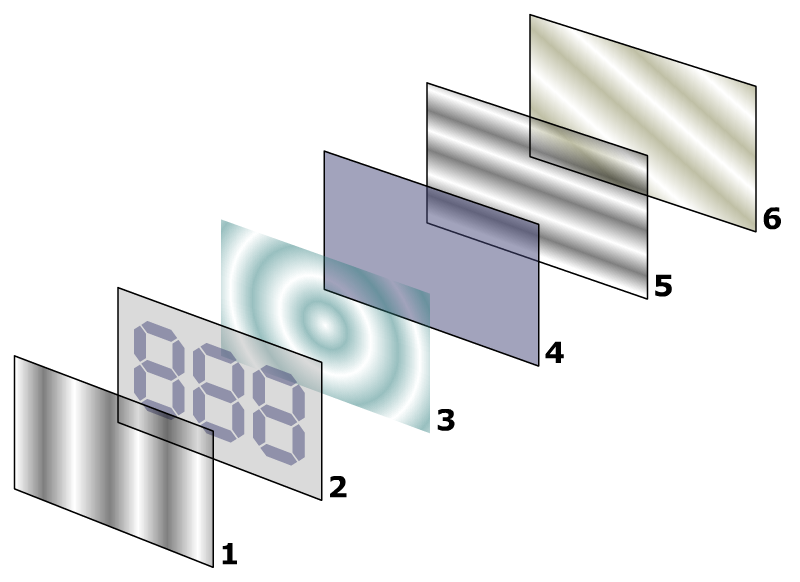

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

Nematic refers to one of the common phases of liquid crystals (LC). In this phase, rod-like molecules tend to self-align more or less parallel to each other.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

New Vision Display (NVD) has decades of experience designing and manufacturing custom display and touch panel assemblies for some of the world’s largest original equipment manufacturers (OEMs) in the automotive, medical, industrial, and consumer markets.

You may be surprised to know that not all LCD panels are created equal. That’s because there’s more than one type of LCD screen. While their differences are subtle, the type of panel technology significantly impacts its image quality and display performance.

In this post, we’ll compare the three types of LCD panel technologies – IPS vs. TN vs. VA – and the pros and cons of each. Knowing the differences is critical to help you find the best type that fits your needs.

The main difference between them is how they arrange and move the liquid crystal display (LCD) molecules in their panels. This, in turn, has a profound effect on image quality, refresh rate, and other performance factors.

A twisted nematic or TN monitor is the oldest and most common type of LCD still used today. It uses a nematic liquid crystal, meaning it has its molecules arranged in parallel, but not on a level plane. These can twist or untwist themselves when a voltage runs through them, hence the name. This twisting effect either allows or blocks light from passing through, turning screen pixels “on” or “off.”

In-panel switching (IPS) panels work similarly to TN monitors, except that the liquid crystal molecules are parallel to the glass panel of the screen. Instead of twisting like in TN monitors, these molecules rotate when a voltage is applied.

Vertical alignment (VA) displays arrange their LCD molecules vertically, perpendicular to the glass panel. When voltage is present, they tilt themselves instead of twisting or rotating.

Being the oldest LCD technology still in use today, TN monitors undoubtedly have their share of benefits, otherwise they wouldn’t have this much longevity! Comparing TN vs. IPS and VA, TN panels are the cheapest and fastest to manufacture. As a result, they are better for the more budget-conscious user. They’re also the most versatile LCD type and have no real-world limits on size, shape, resolution, and refresh rate.

You’ll be hard-pressed to find a TN monitor in a reasonable price range that can display 24-bit (8 bits per channel) color at a wide color gamut, and contrast is limited. The second problem with TN monitors is that because the molecules are not oriented uniformly across the plane, it suffers from a narrow viewing angle. That is, anyone looking at the screen off-axis, such as from a 45-degree angle, will most likely find the image completely un-viewable.

Comparing IPS vs. TN, the former is a drastic improvement over the latter. IPS panels resolve some of the limitations and problems of TN monitors, specifically color accuracy and issues with viewing angles. However, IPS panels suffer from a phenomenon called “IPS glow,” where you can see the display’s backlight clearly if you view it from the side.

Another significant limitation of IPS panels, particularly for gamers, is that they have the lowest refresh rates of any LCD type. And while the color fidelity is fantastic with IPS vs. VA, the latter has superior contrast ratios over the IPS panels.

The biggest strength of VA panels lies in their excellent contrast ratio. Keep in mind that irrespective of the LCD technology used, a backlight is required; this is typically LED. The LCD’s ability to block this light will determine how well it can reproduce blacks, and it’s in this detail where VA excels. That is, blacks are dark and rich in a VA panel vs. IPS. They also lie somewhere in the middle regarding overall image quality, color reproduction, viewing angle, and refresh rate. Overall, VA is a good compromise between TN and IPS.

A drawback of VA vs. IPS and TN is it exhibits an relatively high response time. As such, VA displays are more prone to motion blur and ghosting if you’re viewing fast-moving visuals on a screen, such as when you’re playing a racing game.

It’s worth noting that there is no universal “right” choice for choosing a type of LCD panel. Which one you pick depends on your budget, your intended use, and your expected outcome.

A TN monitor is best if you’re looking for a low-cost, readily available display for tasks that don’t rely on contrast and color accuracy, such as sending emails or typing a document or spreadsheet. They are also the best choice for competitive gamers who want the best refresh rates and response times to give them an edge in online multiplayer games, despite a technically lower image quality.

With their superior color reproduction, IPS panels are best for graphic designers, film editors, photographers, and other visual design professionals. For them, image quality including contrast and color accuracy are more important than refresh rates. IPS panels are also fantastic for casual gamers who want the best visuals and don’t mind the compromise in refresh rate or response time.

Whichever LCD type you choose, make sure you get the right cable, a Premium High Speed HDMI® Cable, or an Ultra High Speed HDMI® Cable to ensure delivery of all the HDMI 2.1 features. Doing this ensures that you’ll get the best experience on your screen.

The Acer V176Lb monitor is loaded with latest features and has a stylish form factor. Engineered to deliver a powerful display performance and an ergonomic design, it offers a comfortable computing experience for home and office environments. The V176L b 17" Essential LED Backlit LCD Monitor from Acer features Acer eColor technology, 1280 x 1024 maximum resoulution, a 100,000,000:1 contrast ratio, and 250 cd/m² brightness for striking visuals. Acer ComfyView innovations reduce glare to deliver comfortable viewing. This sturdy monitor also has a VGA port, so it is compatible with many different types of computers. In addition, it utilizes eco-friendly features to save power.

The Nematic phase is one of the two major phases of liquid crystals, the other being Smetic phase. The Nematic phase is closer to a liquid substance than to a solid substance.

The introduction of TN LCD technology in the 1970s was a breakthrough in display technology to help the commercialization of LCDs in electronic devices.

TN display technology uses nematic liquid crystal placed in the midst of glass substrates dusted with ITO (indium-tin-oxide). The ITO is in turn coated with layers that rub in a direction.

Polarized light manipulation is the underlying principle in TN display technology. As light enters the TN cell, there is a twist in the polarization state with the liquid crystal director.

TN liquid display crystal technology is easy to implement. This means inexpensive manufacturing requirements for industries and an affordable end product for consumers. This has made the use of TN LCD to serve as a good replacement for CRT and LED technologies. It is also a cheaper alternative to newer technologies like AMOLED and IPS.

TN technology does not need any current requirement to function. It operates with low voltages. For this, it can be operated with batteries and other low power sources.

The response time of a pixel is the time lapse required for a pixel to change from a state to another. The unit of measurement is milliseconds. The smaller, the better. The refresh rate, in contrast, is the frequency at which the image of a display is refreshed. It is measured in Hertz. The superior refresh rate and pixel response time give the Twisted Nematic LCD technology the capability to display faster images in a short period of time.

The viewing angle of TN LCD technology is low. A user has to look up from a 90-degree range for a maximum visual experience and good performance. In a lower angle range view, colors tend to be duller while images will be darker.

Unlike LCD’s IPS and VA panels, using TN panels produces poor color reproduction. This negative aspect of TN LCD may have resulted from the restricted viewing angle. The bad color reproduction also translates to inaccuracy in color production from the TN panels. This makes TN LCD not suitable for image-oriented works such as a graphic design, video editing, and photo editing.

Twisted Nematic LCD panels vary in quality from different producers. When a low-quality product is adopted, the other disadvantages will be more pronounced in the output of the implementation such as the color implementation and the viewing angle. Cheaper and poor quality TN panels can also bring out another demerit of susceptibility of dead pixels.

Its affordability and the change it brings into display technology are however being outshined by the incoming of superior display technologies such as IPS LCD, OLED and other latest development in display technology of today.

The two most common and widely used technologies used in the manufacturing of liquid crystal displays are twisted nematic (TN) and in-plane switching (IPS). These are the two most preferred technologies used in the displays of PC monitors, especially gaming monitors. Most of the liquid crystal displays use either twisted nematic (TN) or super twisted nematic (STN) electro-optical effects. The first TN displays were first appeared in the 1970s and quickly became a breakthrough in display technology that led to the commercialization of liquid crystal displays in electronic devices. The two best things about TN panels are super fast response times and less manufacturing cost. But the technology has its downsides too; for one, it has poor viewing angle and second, the color reproduction is very poor. As a result, IPS display technology was developed to overcome the limitations of TN display panels with better color reproduction and superb viewing angles.

Twisted nematic (TN) panels were the first widely produced liquid crystal display screen technology which went on to become the cheapest and the fastest among the other display technologies. TN panels were the first mass produced flat-screen monitors and were simple, directly addressed segment displays as still used. Soon after the production of TN displays in 1971, the commercialization of low information content LCDs for watches and calculators began. However, passive matrix addressing of TN cells failed to meet the requirements for viewing angle and contrast ratio in laptop displays. This led to the development of super twisted nematic (STN) displays which offered substantial improvements in contrast ratio and viewing angle over the passive matrix TN displays. But it did not lead to a general solution of the problem.

In-Plane Switching (IPS) is one of the widely used screen technology for liquid crystal displays that offer an improved, alternative solution to the earlier TN panel’s limited viewing angle, contrast ratio and color reproduction. The IPS display technology was first introduced by Hitachi in 1996 and demonstrated excellent viewing angle capabilities due to the horizontal movement of liquid crystal molecules with respect to the substrate plane. It soon became the leader in the field of LCD industry. IPS displays use liquid crystals aligned in parallel to produce rich colors and improve picture uniformity. In 1998, Fujitsu introduced the multi-domain vertical alignment (MVA) based on the VA technology, which improved the viewing angle performance substantially.

–Both IPS and TN are popular screen technologies for liquid crystal displays used in PC monitors, especially gaming monitors. TN is probably the most common type of display panel used for liquid crystal displays on PC monitors. TN panels work on the underlying principle of polarized light and use vertical alignment of the molecules, termed homeotropic. The liquid crystal director is perpendicular to the glass surface instead of parallel to it. IPS panels, on the other hand, are a different technology wherein LC molecules are aligned in one planar direction in the off state and are still parallel to the glass substrate.

– Due to the horizontal movement of liquid crystal molecules with respect to the substrate plane, IPS panels demonstrate excellent viewing angle capabilities. IPS displays have much wider viewing angles and the colors do not shift even if you’re not directly facing the screen. TN panels, on the other hand, offer very poor viewing angle and colors may look a little washed out if you are not directly sitting in front of the screen. The IPS displays definitely look better at varying angles and the poor viewing angles of TN displays is the only reason you would not want a TN panel on your monitor.

– IPS displays use liquid crystals aligned in parallel to produce rich colors and improve picture uniformity. IPS offers superior display quality with better color reproduction, especially the black color reproduction which eliminates the washed-out effect as you would normally experience in TN panels. When it comes to display quality, the TN panels definitely lack in contrast and viewing angle performance, but offer high brightness and fast response times while using less power than its IPS counterpart. Color gamut is yet another area where IPS displays have an upper hand. However, unlike IPS displays, TN panels are relatively cheaper.

In IPS displays, the liquid crystal molecules are oriented in a planar manner on the substrate, wherein in TN panels, the liquid crystal molecules are perpendicular in orientation with respect to the glass substrate plane. Due to this horizontal movement of LC molecules, IPS displays offer much wider viewing angles with excellent color reproduction, which results in significantly improved picture uniformity. Though, they relatively cost more than their TN counterparts, the colors are much better if you’re looking straight on. TN panels, however, offer faster response times and refresh rates than IPS displays, and are cheaper. TN panels can also handle high refresh rates of up to 240 Hz, which makes them ideal for multiplayer gaming, particularly eSports.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey