led versus lcd display made in china

The display of LED video wall technology is colorful, energy-saving and environmental friendly, and the visual angle is high. However, we do not know what led technology is and what is good about it. As the leader of LED display screen industry, Shenzhen Kaipu Technology Co., Ltd. has the obligation to popularize what is led and what is led tv.

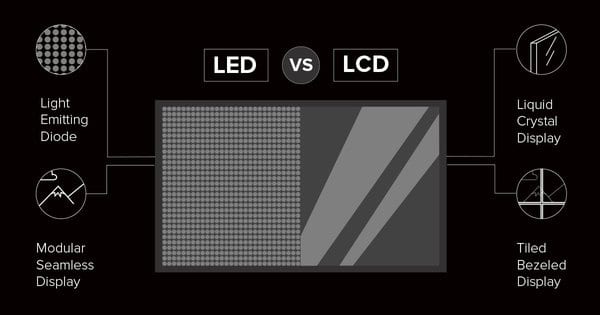

The liquid crystal display we often use is actually an LCD display, which is called liquid crystal display in English. Most of the panels are TFT, TFD, ufb and STN. The working principle of the liquid crystal display is to change the color of the liquid crystal inside the transistor by applying power, and there is a fluorescent lamp CCFL backlight behind the transistor board, which usually consumes a lot of power. The LED screen display we see is usually derived from the LCD display, and generally refers to the liquid crystal display using the LED backlight. The LED technology display is not a real LED display, so Samsung was sued for this matter. Since the LED display on the market only uses LED backlight technology, most of the LED displays on the market have been changed to LED backlight display

Since the display uses LED tubes as the backlight, with the help of LED technology, the display body can be made lighter and thinner; As the LED tube itself is more energy-saving, the energy-saving and environmental protection aspects are certainly better than the normal display; However, there is not as big a gap in imaging as that spread on the Internet, because the essence is the same thing, and it is impossible to have too big differences.

I believe that by now we have basically understood the difference between LCD and LED backlight display. The real LED display does not need backlight, so the process requirements are higher and the price is expensive. At present, it has not been popularized, and the only ones are still limited to commercial use.

Decades ago, China became the world’s factory. So much so that it has even ceased to be so, since the Asian giant has been relocating its production in regions where labor is cheaper, such as Southeast Asia or sub-Saharan Africa. In any case, more and more companies are considering importing certain items from this country: for example, buying LED screens in China. However, before taking this step, it is worth asking if this is the best option.

Now, to acquire an outdoor or indoor LED display in China, you have to be aware of several aspects that some companies do not value, since many are only focused on the product’s cost. Below, we summarize the most delicate ones, and to which special attention should be paid.

Although it is essential for the sales team to have great knowledge of the product and its characteristics, this figure should not replace the technicians specialized in LED screens in any case. For optimal service, it is necessary that both profiles accompany and support the customer in the purchase process, since post-sale services and maintenance will be in the hands of a technical department. All this without overlooking another problem: if the seller disappears, so does the assistance and the guarantee.

In China, the roles within the company are usually not well defined. And even if this differentiation exists, the language barrier can mean that the interaction may all be through a single person. Moreover, communication is frequently channeled through an intermediary or an agent, who will not be the one who specifically deals with the manufacturing process of the LED display.

In addition to the language differences, the cost of intercontinental phone calls also limits and conditions the communication between the customer and the producer with regard to the manufacturing process of the LED display. Thus, something as simple as a mere clarification of a doubt can be considerably delayed over time. In this sense, the time difference with the Asian giant, which can be between 6 and 7 hours in the case of the United Kingdom, is an added difficulty.

Instead, by purchasing a screen from a nearby distributor, such as Visual Led, you will have the peace of mind that the conversation and attention will be constant and fluid.

Assembling and configuring a giant LED billboards or LED panels does not have to be complicated. What’s more: it can be an extremely simple process. This is precisely one of Visual Led’s aims, since our LED screens are self-supporting and have been designed so that they can be assembled and programmed by the client, either alone or with the help of a second person, without needing prior technical knowledge. We also offer online training so that the buyer can generate their own multimedia content with professional results.

However, this changes – for bad – when the documentation that accompanies the newly acquired LED display is non-existent or insufficient, or it presents translation problems. When this occurs, the buyer can feel very alone during the assembly and configuration process of their LED display.

Chinese producers are exempt from the payment of customs fees, taxes and payments, which are paid by the buyer. Hence, although the base price of LED screens may seem competitive, the truth is that the final amount will be different.

If you want to know approximately how much an LED screen adjusted to the features you want it to have costs, you can use our LED display price calculator, with which you will get an approximate budget instantly.

Another problem of buying LED displays in China has to do with the characteristics of the order. Due to import difficulties, Chinese suppliers often require minimum orders of a considerable volume. A cargo container is usually the minimum order.

In some cases, Chinese manufacturers do not have stocks of replacement parts or the sold material, so they can only repair the items supplied. Therefore, the seller has the obligation to send the parts to China for repair. A forced solution that is synonymous with high costs and long waiting periods, something that can have a negative impact on the client’s commercial activity of screens, posters or LED billboards.

So this is our summary of the things that you have to take into account when purchasing an LED screen in China. If you want to expand this information or clarify your doubts, contact Visual Led: our experts will be happy to guide you and advise you.

An LED stands for light-emitting diodes. It is among the latest in technological innovations related to screening display. It makes use of LEDs behind the screen as the source of light. LEDs are brighter and more energy-efficient than an LCD screen that uses a CCFL backlight. They are also a lot smaller that helps in producing thinner screens like never before. Since LEDs are very bright so the display doesn’t get marred even in broad daylight. That is the reason LEDs are extensively used in signboards and advertising boards throughout the world. Let’s take a deeper look at this technology here and get to know it better.

Outdoor LED displays are used for advertising, promotion, and informative purposes. You can install them easily almost anywhere and they will do their job effectively. You can use them 24/7. They consume less electricity, have a long life, low-maintenance and are eco-friendly. They are available in a variety of sizes and you can also make one according to your custom needs. You can make one giant billboard, signboards, advertising banners, LED boards, LED video walls, perimeter LED boards, with the help of LED screens.

The outdoor LED display market is poised to grow at a robust speed. It is estimated to be worth around US$22.4 billion by the year 2024. That’s a CAGR of over 20% from 2016-2024.

Many factors are fueling this growth. For starters, companies prefer to advertise their brands and products through LED displays, smart billboards with wireless connectivity and easily changeable content are a rage nowadays. Similarly, 3D technology is being employed in LED displays for a more immersive and personal viewing experience. Motion sensor technology and interactive displays are also making their mark. The demand for high resolution displays for showcasing anything like advertising in perimeter boards in a stadium, musical concert, traffic updates on roads, live sporting events, exhibitions will contribute to the growth of the LED display sector. The continuous technological advancements in this sector will mean crisper, clearer, and livelier displays in the future. So, just like the display LEDs, the future is very bright for this sector.

Despite all its success and potential growth, the LED display market is not without its share of challenges. Here, we briefly discuss some of the more important ones.

Unstable supply of raw materials: An LED screen is made of several electronic components. It is difficult to produce all of them in the same country. When you have to import from other countries difficulties arise. From ensuring fair quality to optimum quality to coping with fluctuation in forex rates to import tariffs. All these factors combine to make the procurement of raw materials difficult to manage.

Capital: LED manufacturing involves huge capital. It is not always to raise one on your own. If you go to a bank, it will imply interest payments. This will affect your cash flows and profit margins.

Technological innovation: LED manufacturing is technologically intensive. There is a race going on to beat your competitor at the cutting edge of technology. As a manufacturer, it will be a challenge for you to keep up with all the new changes. It might involve the injection of new funds or training the old staff or hiring a new one.

Logistics: Transporting LEDs from one place to another involves a great deal of caution. They have to be securely packed to withstand shocks and jerks. Even a crack can ruin the entire screen, what to talk of a broken one.

Rules of import: As an importer of LEDs you have to comply with the local import laws. This includes getting an import permit, paying import duties, transportation cost, and custom clearing charges. Sometimes a slight change in rules can throw your estimates out of the window.

Low profits: There is stiff competition going on among the LED manufacturers. While this is good news for the consumer the producer may suffer because of low-profit margins. This precludes entry of new players and leads to grouping.

Expensive labor: You require skilled and competent labor to produce LEDs and they come at a price. This is particularly problematic as the margins of profit continue to squeeze.

Ideal location: Everybody wants the best placement of its LED screens for promotional purposes. The best spots are few and far between. This results in a rising price of prime locations and unhealthy competition among the brands to get the best spot.

Rental screens: The rental LED screens face a lot of wear and tear because they change locations and this consequently reduces their life and performance.

The most important use of LED displays is for advertisement purposes. This includes billboards, banners, perimeter boards, boards, signboards, etc. They can be installed at various locations of choice.

It is the same as outdoor advertising with the only difference that their location is not permanent. They can be installed and uninstalled at various locations as per requirement.

Transparent LED display is an innovation of recent times. It lets viewers see things behind the screen as well. This has become possible due to the material, structure, and design of the display screen. It is not 100% transparent, the transparent rate is around 50-95%. The thickness is around 10mm. It is just like a glass.

LEDs have become quite popular for stage productions. People in the back seats can now see the action on stage thanks to these screens. They are usually large and very bright to produce a visible image. They are used in entertainment events and art exhibitions.

Like entertainment events, LEDs have become very popular to broadcast sporting events too. They are installed inside and out of the sporting arenas to bring spectators closer to the game. Their installation has helped rekindle the interest in live sporting events.

Outdoor digital displays are used for a variety of purposes. They can be installed on roads to provide traffic updates, in airports and railway stations to give information about trains and airplanes’ schedule and in sports to display scorecard. The uses are multiple and varied and you can use it for your advantage.

In such kinds of displays, a video is run on a loop on a large screen. Usually, the video is of an educational or informative nature. You can install it at any event to give information to the visitors, on election day telling people how and where to vote or videos that give useful information on health, social issues, etc. to the general public.

What is life without colors? From the time first black and white image surfaced man had been striving to convert it to colors. Once that was accomplished, the race is on to bring colors as close to real-life as possible. LEDs are no exception. They take pride in reproducing colors on screen as close to nature as possible. They look attractive and capture your attention.

In a quest for excellence, the color display went from better to best and the journey is ongoing. HD display is one such example. HD, of course, stands for high definition. HD has a resolution of 1280×720 pixels. Full HD has a resolution of 1920×1080 pixels. It doesn’t stop here and goes further to UHD, OLED, etc. These are especially helpful where you have to showcase products like jewelry, clothes, etc.

Eye-catching: The first and foremost is that the LED advertising screens are attention-grabbing. Their crisp, colorful and sharp images are very appealing. You are instantly drawn towards them.

Eco-friendly: Unlike flex, paper, or clothing banners there aren’t any harmful chemicals used in producing LEDs. You also save a lot of trees because LEDs don’t require organic elements for production.

Energy-efficient: LEDs consume very low voltage and they produce very striking results. This saves electricity. You get a very bright image at a very cost.

Low-maintenance: LED screens are almost maintenance-free and can withstand weather adversaries too. You will see them displaying their imagery in the rain and intense sunlight.

Changing content: You can change the content of an LED advertising screen quite easily. This means you can run multiple campaigns of the same brand simultaneously. This gives variety to the viewer and he doesn’t feel bored with seeing the same campaign again and again.

Flexibility: It is very easy to change the content of the LED screen as well as to change the location of the screen. You can do so either with very little effort. It allows you great freedom to play with it.

P10 and P6 are both LED screen types. The pixel pitch of P10’s display is 10mm and for P6 it is 6mm. They are both very popular when it comes to outdoor advertising. We list down some of the reasons why;

On a single or double poles: This is a simple installation where LED is installed on single or two columns for displays. A single column is used for a small screen size while the double column is used for a larger screen.

Hanging: You can also hang a LED both inside and outside depending on your need. The panel of the LED should be made for hanging purpose and the LED should itself be lightweight. The wind factor must be taken into consideration before installation.

Embedded type: An LED can also be embedded in a wall. You need to be mindful that you won’t be able to perform any maintenance from behind the LED once it is embedded into the wall.

Mounted type: Another option is that you mount the LED on the wall. In this way, you can do maintenance work on the behind of the LED. It is a very common type of LED installation.

For all your LED requirements from China Shenzhen Dreamway Technology Co. Ltd., should be your top choice. We are a reliable indoor and outdoor LED manufacturer from China. We provide you with all the high-tech and latest LED screens and associated paraphernalia to fulfill your needs and stay ahead in the competition. We provide peerless quality with an unmatched price. Our staff is professional and highly trained to take care of your business requirements. We will customize your LED screen at the most competitive price. We will produce your order in the minimum possible type and you won’t hear of delayed shipments from our side.

China is a manufacturing hub and produces anything from a nail to a ship. You can search for LEDs from China through personally visiting China or browsing through b2b Chinese e-commerce sites. There are trade fairs taking place all over the year in China. Some fairs are general while others are industry-specific. You can choose either and pay a visit. Usually, industry-specific fairs are more beneficial as manufacturers prefer to go there.

As for hunting LED factories online, the most popular resource is Alibaba.com. Then there is made-in-china.com. Globalresources.com is also a good option. They are easy to use and reliable e-commerce sites. You will have to register yourself before contacting any supplier/manufacturer. While some suppliers are verified and the websites vouch for their quality, for others you will have to guard yourself against fraud and wrongdoing.

A: Unless you are technically sound and know the electronic component of the LEDs do not attempt any repair on your own. Hire a technician who will find the cause and repair it. You can try to ascertain the cause of the problem and attempt re-booting. Sometimes the problem is resolved by mere re-booting.

A: No, it won’t. Cold, hot, or harsh climate won’t affect the working of the LED lights. They are manufactured keeping in view the hostilities of weather. This adds to their durability and is one of the reasons for their widespread use and popularity.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Everdisplay Optronics (Shanghai) Co.,Ltd.(EDO) is a company dedicated to production of small-to-medium AMOLED display and research of next generation technology. The company currently has generation 4.5 OLED line.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Established in 2013, Eternal Material Technology is committed to the research, development and manufacturing of electronic materials and providing technical services. EMT is leading the industry with its products of OLED and color photoresist materials.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

In the first half of 2019, affected by the overall macroeconomic and investment environment, the overall size of China"s commercial led display market only achieved a small increase. According to relevant data, the market scale of the commercial led display market in China in 2019H1 reached 4.5 billion USD, a year-on-year increase of 3.7%. Compared with the overall market, the growth of the large led screen splicing market is at a high level. The data shows that the sales of the 2019H1 China"s large-screen splicing market (including DLP, LCD, and LED small pitch) have reached 1.05 billion USD, a year-on-year increase. 23.7%. In this three-pronged situation, what is the performance of small pixel pitch

According to the survey, China"s large led screen splicing market can account for 61% of the world, LED display products can account for 57% in the Chinese market, and the global competitiveness of LED companies is also strengthening. In recent years, the competition in the large led screen splicing market has become more and more fierce. At present, the domestic large led screen splicing industry still presents three technologies of LCD, DLP and LED small pixel pitch. It is worth mentioning that LCD is currently at low price competition. DLP is facing internal and external problems, including cost and external pressure. In contrast, the small pixel pitch spacing of LEDs has been continually leaping forward. LEDs have a small gap and grow at a high speed. The development momentum is fierce. There are relatively large threats to LCD and DLP. From the perspective of existing product layout, small pixel pitch led display is more balanced and comprehensive development. The situation has accelerated the popularity of the market.

The small pixel pitch LED display market has formed a pattern of P1.2 leading high-end, P1.5 main performance card and P1.8 leading price market. In particular, further market price wars have made the P1.8-class products almost become the “super-economic large led screen technology” acceptable to the third- and fourth-line markets, and have become a weapon for the continuous increase of the small pixel pitch LED display market. At the same time, COB technology"s small pixel pitch LED product market has further increased brand participation, supply richness and product quality, and market awareness has also been greatly improved. As one of the next-generation small pixel pitch LED technology routes, COB technology brings internal competition and vitality to the small pixel pitch LED display market, which is beneficial to the healthy development of the entire industry and provides sufficient “technical stamina” for the future market.

The essence of the high-end market reflects the technical and service strength of LED display manufacturers, and it also puts more demanding "task" requirements to LED display manufacturers. With the rapid development of big data information, the large led screen splicing products carry not only the function of the display terminal, but also the high-efficiency analysis of massive data information, and then display the analysis results, effectively assisting management decisions. Based on the needs of these markets, in order to facilitate the operation and management of the system, the small pixel pitch led display will be more technology integrated into the future. At the same time, with the continuous advancement of display technology, the high-definition display requirements in the high-end display field will be more The higher the distance, the smaller the spacing will be.

In addition, the development of traditional small pixel pitch LED display has its inherent “progressive” features: that is, most brands in the market are gradually transitioning from outdoor LED display to large pixel pitch LED display technology to smaller pixel pitch products, and then enter P2.5. The "small pixel pitch" and "micro pixel pitch" markets below the pitch, and gradually become more widely used in the field of indoor display. Different from the development of traditional LED display, the field of large-screen splicing is an application-oriented field, not a technical field. This makes the concept of integrated display services more and more emerging. LED display companies to develop product layout based on customer resource advantages, is a good strategy. For example, many security-initiated brands have established product solutions covering all display technology categories, while companies with small-pitch LEDs can also participate in display panels such as LCD and DLP to realize the role of integrated display service providers.

In any industry, the survival of the fittest is the inevitable development. The large-screen splicing market will continue to flourish, and more and more LED small-pitch manufacturers will gradually enter this ranks. Whoever can make rapid progress will be able to live longer in the market. From the perspective of long-term development, in the face of market competition, LED display companies maintain technological innovation, products continue to improve and continue to innovate and develop. The large-screen splicing market is bound to win, and in view of its ever-increasing market threshold, it is obviously not all enterprises. Can be divided. Therefore, the expansion of large-screen splicing will become the touchstone of the market competitiveness of small-pitch LED display enterprises. The gains and losses will directly affect the long-term development of enterprises.

Chinese companies have gained a competitive edge in the large-screen display industry and the exit of South Korean counterparts such as Samsung Electronics and LG Display from the liquid crystal display market will bring opportunities for China"s panel makers despite the challenges posed by the COVID-19 pandemic.

Market research firm Sigmaintell said BOE Technology Group Co Ltd-a leading Chinese supplier of display products and solutions-became the world"s largest shipper of LCD TV panels for the first time in 2019.

The Beijing-based company shipped 53.3 million units of LCD panels in 2019, with production capacity increasing by more than 20 percent on a yearly basis.

The consultancy said the LCD TV panel production area of Chinese manufacturers will account for more than 50 percent of the global total this year, surpassing South Korean competitors who are accelerating the shutdown of large-sized LCD panel production capacity due to competition from Chinese manufacturers.

It estimated the production capacity of large-sized LCD panels will continue to increase in China over the next three years. In addition, global LCD TV panel shipments stood at 283 million pieces last year, a slight decrease of 0.2 percent year-on-year. Meanwhile, the shipment area was 160 million square meters, an increase of 6.3 percent year-on-year.

"Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field," said Li Dongsheng, founder and chairman of Chinese tech giant TCL Technology Group Corp.

Li said South Korean firms will focus on organic LED screens and quantum dot LED displays, while Chinese TV panel makers are catching up at a rapid pace.

The pandemic will accelerate reshuffling in the display industry as supply has surpassed demand in the past few years and competition has become very fierce, he added.

"The outbreak has caused a periodic drop in demand in the global display market and sped up the restructuring of the entire industry. Chinese enterprises are in a favorable position, and I believe that they will further enhance their competitiveness," Li said.

Data consultancy Digitimes Research said it comes as little surprise that Samsung has opted to withdraw from the LCD panel sector as its LCD business was losing money in every quarter of 2019 due to challenges from Chinese competitors.

"China"s semiconductor display industry has made large advances in the past decade, changing the display industry"s global competitive landscape. China has transformed into the world"s largest consumer market and manufacturing base for display terminals, with huge market potential," said BOE Vice-President Zhang Yu.

BOE said its Gen 10.5 TFTLCD production line achieved mass production in Hefei, Anhui province, in March 2018. The plant mainly produces high-definition LCD screens of 65 inches and above. With a total investment of 46 billion yuan ($6.5 billion), the company"s second Gen 10.5 TFT-LCD production line launched operations in Wuhan, Hubei province, in December.

The Gen 11 TFT-LCD and active-matrix OLED production line of Shenzhen China Star Optoelectronics Technology, a subsidiary of TCL, officially entered operations in November 2018, producing 43-inch, 65-inch and 75-inch LCD screens.

Bian said the OLED and QLED will be the next-generation flat-panel display technologies to be in the spotlight. LG Display is currently the world"s only supplier of large-screen OLED TV panels.

OLED is a relatively new technology and part of recent display innovation. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is much thinner and can be made flexible, compared with traditional LCD display panels.

Li Yaqin, general manager of Sigmaintell, said 65-inch TVs will become the mainstream in people"s living rooms in the future, but OLED TVs will not be able to immediately spur customer purchases at this time though the future trend is for higher-tech options.

What is the difference between LCD display and LED display? LED backlight is power saving, high priced, vibrant and saturated. LCD is power consuming and cheaper compared to LED backlight. On the screen, LED backlighting is more vivid and saturated. LED display"s individual element response speed is 1000 times faster than LCD LCD, which can also look good under strong light and adapt to low temperatures of -40 degrees. Here"s a detailed look at LED and LCD displays with me.

LCD is the full name of Liquid Crystal Display, mainly TFT, UFB, TFD, STN and several other types of LCD can not locate the program input point on the dynamic link library.

TFT (Thin Film Transistor) is a thin film transistor, each LCD pixel point is driven by a thin film transistor integrated behind the pixel point, thus allowing high speed, high brightness, high contrast display screen information, is currently one of the best LCD colour display devices, is now the mainstream display device on laptops and desktops. It is one of the best LCD colour display devices available and is now the dominant display device on notebooks and desktops. Compared to STN, TFT has excellent colour saturation, reproduction ability and higher contrast ratio, and can still be seen very clearly under the sun, but the disadvantage is that it consumes more power and is also more costly.

LED is the abbreviation for Light Emitting Diode. LED applications can be divided into two main categories: one is LED displays; the other is LED single tube applications, including backlight LEDs, infrared LEDs and so on. Now in terms of LED display, China"s design and production technology level is basically synchronized with the international. LED display is a display device composed of an arrangement of light-emitting diodes 5000 yuan computer configuration list. It uses low voltage scanning drive, with: less power consumption, long service life, low cost, high brightness, less failure, large viewing angle, visual distance and other characteristics.

Compared to LCD displays, LED displays have more advantages in terms of brightness, power consumption, viewing angle and refresh rate. Using LED technology, a thinner, brighter and clearer display than LCD can be manufactured.

3, LED provides a wide viewing angle of up to 160 °, can display a variety of text, digital, colour images and animation information, can play TV, video, VCD, DVD and other colour video signals.

4, LED display of the individual elements of the response rate is 1000 times faster than LCD LCD, can also be seen in bright light, and adapt to the low temperature of minus 40 degrees.

Simply put, LCD and LED are two different display technologies, LCD is a display made up of liquid crystals, while LED is a display made up of light emitting diodes.

3, If the viewing distance is far and the area is large, please choose LED display, the spacing can be based on the size of the area, choose more than 2mm spacing LED display.

5, Cost, LED display spacing is probably the watershed in the 2mm spacing, 2mm below the LED display unit area is higher than the LCD splicing display. 2mm spacing above the LED display unit is lower than the LCD splicing display.

Apple’s developments in the market are a hot topic in the technology industry, market rumors that next generation iPhones would be using OLED displays ushered in a large wave of investments in the sector in China. OLED, which was a niche market product, became a hot commodity this year because of Apple’s interest in adapting the technology in next-generation iPhones.

Micro-LEDs were also placed onto the technology industry spotlight two years ago following Apple’s acquisition of LuxVue, prior to this development micro-LEDs was under the technology industry radar for years. Could the halo effect from Apple make emerging micro-LED technology a contender to mainstream LCD or rising OLED display technologies?

If Apple is a newbie in micro-LED technology, then Sony is a veteran. The Japanese consumer electronic company studied micro-LED and related technology for years, and launched its first micro-LED TV, Crystal LED Display, at CES 2012.

Four years after the product launch, Sony went mum about micro-LED TV with no new public product releases. Why has Sony’s attitude towards micro-LED technology changed after 2012? The LED technology needed to make micro-LEDs is not an issue, since in theory LEDs can be miniaturized to several micrometers, and the accompanying chip and packaging technology is not an issue either, said Philip Chang, Analyst at LEDinside. Yet, the micro-LED technology in 2012 would require usage of 6.22 million LEDs in a FHD Crystal LED display. Leading to low efficiency, low yield rates, and overtly high costs. Commercialization of the micro-LED TV would be impractical using that technology.

It took another four years before Sony showed results from continuous investments in micro-LEDs, some spurred by Apple. Sony launched its latest addition to the Crystal CLEDIS (Crystal LED Integrated Structure) at Infocomm in June 2016. The latest product features “module splicing”, which greatly lowered the number of LED chips required, and lowered Pixel per Inch from 40 to 15. These changes have made it possible for Sony to realize mass production, and the company announced it would be able to commercialize CLEDIS in 2017.

Sony’s current micro-LED TV design is a “very stupid method,” it requires splicing the LEDs one by one, or by the thousands simultaneously, explained Zhaojun Liu, Assistant Professor at School of Electronics and Information Technology at Sun Yat-Sen University. Transferring the micro-LEDs and manufacturing period will take a long period, hence it is unsuitable for mass production. If companies want to commercialize the product, they need to be able to reach high volume production, high precision, and high transfer rates. Menglong Tu, head of R&D at Ledman Optoelectronics also noted only when the micro-LEDs first pass yield (FPY) reaches 100% can millions and billions of LEDs be freed from dead pixel issues, which takes technology maturation to achieve. It is estimated the technology will not mature next year, hence the possibility of Sony mass producing micro-LED TVs remains low next year.

Apple’s entry in micro-LED not only accelerated Sony’s mass production progress, it also raised Chinese manufacturers interest in the technology. Chinese LED manufacturers are starting to develop micro-LED technology, said Chipone CEO Jingfang Zhang. Last year, Leyard Optoelectronics launched a super small pitch P0.9 mm HD seamless spliced LED wall, which has a pitch less than P1 mm LED displays sold on the market. The main application sector for the LED is still indoor surveillance displays, and unlike Apple and Sony that are both focusing on wearable devices and large TV display market sectors.

Even though China’s LEDs for commercial market reached a reputable size, Chinese manufacturers increased investments in LED equipment sped up national production, but still comprises a small revenue share. Manufacturers are increasingly focused on the commercial LED market, and have not invested as much in advanced micro-LEDs. There have also been few discussions about micro-LEDs in China. So why are Chinese manufacturers uninterested in micro-LEDs?

Apple and Sony’s micro-LEDs are made from a chip perspective, while China’s small-pitch LED displays are also tiny, the LEDs have a major size difference, said Tu. Domestically, no enterprises in China can form vertically integrated supply chain, and each company is specializing in only one segment of the supply chain. Chip manufacturers are focused on making LED chips, LED packaging, and other specialty applications. Most small pitch LEDs are in the application end, and not in upstream supply chain or chips. Mass produced small pitch LEDs in China are P1.2 to 1.5 mm, while the smallest is P0.9.

Apple and Sony’s micro-LEDs are manufactured on CMOS substrate using IC manufacturing technology to make a LED display driver. The LEDs are then aligned and arrayed on the IC using MOCVD to shrink the LED to micro display size of 100 micrometers, which still lags far behind Apple and Sony’s micro-LED volume production.

More importantly the micro-LED trend led by Apple is still in the R&D phase and far from reaching commercialization. Micro-LEDs on the market currently are similar to LCDs 30 years ago, which required a comprehensive supply chain to lower costs and raise production capacity, said Liu. For Chinese manufacturers the outlook of micro-LEDs is uncertain, companies prefer using current technology and patents. As for when micro-LEDs can really enter the market, it will depend on Apple and Sony’s technology breakthroughs and market development.

Micro-LEDs have the advantages of low power consumption, high brightness, ultra-high definition, high color saturation, faster response rate, longer lifetimes and higher efficiency. Compared to LCDs and OLEDs, micro-LEDs have the advantages of higher brightness and color saturation. Indoor LED displays made using micro-LEDs can reach 1,000 to 2,000 nits, while LCD brightness reaches several hundred nits, said Tu. Additionally, micro-LEDs can use RGB or RGBW solutions to achieve wider color gamut performance, or better display effects.

Micro-LEDs can be divided into two mainstream applications, including wearable devices developed by Apple, while the other is super large TV displays represented by Sony. Potential smartwatches and smart band applications for micro-LEDs based on Apple’s current market share, if all Apple Watches used micro-LED screens, it will have larger impact on OLED wearables. If micro-LED entered the smartphone market, and had to reach higher PPI or flexibility, it would present technology challenges. Micro-LEDs would have no competitive edge against LCD and OLEDs, hence it would have minor effect on OLED industry. Wearables also have a very small market share in the OLED industry.

Meanwhile, cost competitiveness is essential in large displays, where micro-LEDs has limited advantages. There are a lot of challenges for micro-LEDs to overcome in large-sized displays, and over the years the technology had no significant advantages compared to LCDs and OLEDs, said IHS Display Search analyst Terry Yu. The extent of impact from micro-LED developments and impact were not as large as previously thought. LCDs low costs, steady yield rates makes it highly competitive, similar to LCDs and PDP. LCD and micro-LEDs market competition in the future will not be limited to technology, but also the entire supply chain and ecosystem.

Micro-LEDs have come under the limelight mainly because of Apple, but it is uncertain whether it can challenge LCD or OLEDs. Technology developments take time, so it is too early to say whether micro-LEDs will replace LCDs or OLEDs, said Professor Zheng Xu, School of Science, Beijing Jiaotong University. Hence, the industry development will still depend on periphery technology developments, for instance if there are no advancements in mask aligner technologies then it will be difficult to raise display image resolution. Micro-LEDs at most can only be described as an emerging challenger of LCD or OLED technologies.

A light-emitting diode (LED) is a semiconductor light source that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons.

This question is important. Outdoor panels are usually seen from further distance, thus resolution will be lower. Outdoor led panels will likely be brighter because they are used in sunlight. Also outdoor panels will be more durable as they need to withstand weather conditions, dust, moisture and dirt. Indoor panels offer superior color, smaller pixels and a more refined picture. For the same pitch, indoor screens are cheaper. For all these reasons, we recommend indoor panels, unless you actually need to use an outdoor screen.

With LED walls, each individual LED is a pixel. The pixel pitch number indicates the distance between LEDs on the wall in millimeters, as well as the minimum viewing distance in meters. The optimal viewing distance is typically 2-3 times the pixel pitch number in meters.

1) Ground Support Installation: This method system is a combination of a base-unit, connection bar and ladder truss that creates a very stable system to support your LED screens in various configurations and offers flexibility in height as well as width.

2) Flown Method (rigging): There are certain requirements that need to be in place in order to fly a screen. Most importantly, there needs to be ample structural support in the ceiling to hold the total weight of the screen. When someone says they want to “Fly” an LED screen, that means the screen will be rigged to either an overhead truss system, a ceiling grid, a crane, or some other support structure from above.

3) Wall Mounted: Some panels can be drilled and mounted into the wall. This is a great option if you’re looking for an aesthetically clean look with easy maintenance features, but it will add cost to the panels.

Most LED Panels are rated for 60,000 to 100,000 hours. You’ll have these panels for a long time and will get a lot of life out of them. In case something malfunctions, you can get in contact with us and we will give you all the information to properly service and maintain your panels.

Your decision to purchase an LED sign is a wise one. You may already know that business signage is a key component of a well thought out marketing strategy, but the details surrounding the hardware are often made to look confusing by other manufacturers.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, digital clocks, calculators, and mobile telephones, including smartphones. LCD screens are also used on consumer electronics products such as DVD players, video game devices and clocks. LCD screens have replaced heavy, bulky cathode-ray tube (CRT) displays in nearly all applications. LCD screens are available in a wider range of screen sizes than CRT and plasma displays, with LCD screens available in sizes ranging from tiny digital watches to very large television receivers. LCDs are slowly being replaced by OLEDs, which can be easily made into different shapes, and have a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile (because OLEDs use a single glass or plastic panel whereas LCDs use two glass panels; the thickness of the panels increases with size but the increase is more noticeable on LCDs) and potentially lower power consumption (as the display is only "on" where needed and there is no backlight). OLEDs, however, are more expensive for a given display size due to the very expensive electroluminescent materials or phosphors that they use. Also due to the use of phosphors, OLEDs suffer from screen burn-in and there is currently no way to recycle OLED displays, whereas LCD panels can be recycled, although the technology required to recycle LCDs is not yet widespread. Attempts to maintain the competitiveness of LCDs are quantum dot displays, marketed as SUHD, QLED or Triluminos, which are displays with blue LED backlighting and a Quantum-dot enhancement film (QDEF) that converts part of the blue light into red and green, offering similar performance to an OLED display at a lower price, but the quantum dot layer that gives these displays their characteristics can not yet be recycled.

Since LCD screens do not use phosphors, they rarely suffer image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs are, however, susceptible to image persistence.battery-powered electronic equipment more efficiently than a CRT can be. By 2008, annual sales of televisions with LCD screens exceeded sales of CRT units worldwide, and the CRT became obsolete for most purposes.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs, along with OLED displays, are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

The origins and the complex history of liquid-crystal displays from the perspective of an insider during the early days were described by Joseph A. Castellano in Liquid Gold: The Story of Liquid Crystal Displays and the Creation of an Industry.IEEE History Center.Peter J. Wild, can be found at the Engineering and Technology History Wiki.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In 1964, George H. Heilmeier, then working at the RCA laboratories on the effect discovered by Williams achieved the switching of colors by field-induced realignment of dichroic dyes in a homeotropically oriented liquid crystal. Practical problems with this new electro-optical effect made Heilmeier continue to work on scattering effects in liquid crystals and finally the achievement of the first operational liquid-crystal display based on what he called the George H. Heilmeier was inducted in the National Inventors Hall of FameIEEE Milestone.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,transparent and flexible, but they cannot emit light without a backlight like OLED and microLED, which are other technologies that can also be made flexible and transparent.

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs behind larger displays. A diffuser (made of PMMA acrylic plastic, also known as a wave or light guide/guiding plateinverter to convert whatever DC voltage the device uses (usually 5 or 12 V) to ≈1000 V needed to light a CCFL.

EL-WLED: The LCD panel is lit by a row of white LEDs placed at one or more edges of the screen. A light diffuser (light guide plate, LGP) is then used to spread the light evenly across the whole display, similarly to edge-lit CCFL LCD backlights. The diffuser is made out of either PMMA plastic or special glass, PMMA is used in most cases because it is rugged, while special glass is used when the thickness of the LCD is of primary concern, because it doesn"t expand as much when heated or exposed to moisture, which allows LCDs to be just 5mm thick. Quantum dots may be placed on top of the diffuser as a quantum dot enhancement film (QDEF, in which case they need a layer to be protected from heat and humi

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey