lcd screen construction made in china

China"s first 8.5-generation TFT-LCD production line was launched in Bengbu, East China"s Anhui province, on June 18, 2019, representing a breakthrough in the production of high-definition LCD screen, Science and Technology Daily reported.

TFT-LCD, or Thin Film Transistor Liquid Crystal Display, is key strategic material of the electronic information display industry. The Gen 8.5 TFT-LCD production line, launched by the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group, will produce high-definition LCD screens of 55 inches, the report said.

According to the Liquid Crystal Branch of the China Optics and Optoelectronics Manufactures Association, the demand for TFT-LCD in the Chinese mainland was about 260 million square meters in 2018, including 233 million square meters" Gen 8.5 TFT-LCD. However, the annual supply of domestically made TFT-LCD is less than 40 million square meters, with all of them Gen 6 or below, which cannot meet the demand in scale and quantity.

The association predicted that China"s market demand for Gen 8.5 TFT-LCD or above will exceed 300 million square meters by 2020, accounting for 49.6 percent of the total global demand.

The production and control precision of Gen 8.5 TFT-LCD is comparable to that of the semiconductor industry, representing a higher level of large-scale manufacturing of modern glass industry.

The institute in Bengbu, with 60 years of expertise in glass, has finally made a breakthrough in the production of Gen 8.5 TFT-LCD, and will provide key raw material guarantee for China"s LCD panel industry after it goes into mass production in September, the report said.

BEIJING (Reuters) - A joint venture between Hon Hai Precision Industry Co, known as Foxconn, and Sharp Corpplans to build a 61 billion yuan ($8.8 billion) factory in China to produce liquid-crystal displays (LCDs).

Sakai Display Products Corp’s plant will be a so-called Gen-10.5 facility specializing in large-screen LCDs and will be operational by 2019, the company said at a signing event with local officials in Guangzhou on Friday. It said the plant will have capacity equating to 92 billion yuan a year.

Global LCD output was hit this year by the closure of a Samsungfactory that accounted for 3 percent of the market, as well as factory stoppages in Taiwan after an earthquake in March.

China’s largest LCD panel maker, BOE Technology Group, began construction on its own Gen-10.5 plant in Hefei in December last year, with production scheduled to begin in 2018.

In May Shenzhen China Optoelectronics Technology Co, asubsidiary of TCL Corp, announced that it would begin construction on a 50 billion yuan LCD plant in Shenzhen.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Toshiba is a famous multinational company with a history of 130 years. It covers a wide range of businesses, including social infrastructure construction, home appliances, digital products, and electronic components. It covers almost every aspect of production and life. Toshiba has the largest research and development institution in Japan. Through unremitting innovation and development, Toshiba has been at the forefront of science and technology in the world.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Introduction: Global LCD industry shift and automotive intelligence together to promote the rapid development of China’s LCD panel industry, which will bring a continuous increase in demand for backlight modules, China’s backlight module industry has greater potential for development.

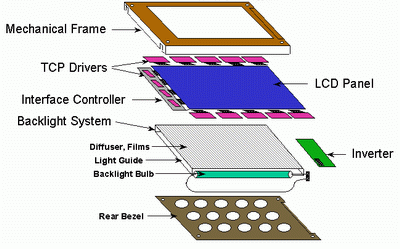

LCD panel backlight module consists of a backlight light source, light guide, optical film, and a plastic frame, which is an important component of LCD display panel. As the backlight module has technology-intensive and labor-intensive attributes, with abundant high-skilled labor advantage China is attracting the global LCD panel industry to the domestic rapid transfer.

From LCD application to the present, the global LCD panel industry capacity transfer has gone through three periods, 2000 Japan dominated the global LCD industry; 2000 – 2010, Japan’s production capacity to South Korea and Taiwan; 2010 to the present, Japanese manufacturers gradually withdraw from the LCD panel industry, production capacity began to transfer to mainland China, so far, mainland China LCD production capacity has occupied the global half of the world.

In recent years, South Korea’s Samsung and LG display will shift their business focus to OLED, and will gradually shut down their LCD production lines and withdraw from the LCD panel industry; at the time of South Korean manufacturers’ withdrawal, domestic enterprises are stepping up new construction to expand LCD production capacity.

BOE, Huaxing photoelectric, Huike, CEC in 2020 – 2021, a total of eight 7 generation LCD production lines completed and put into operation, and domestic panel manufacturers have further expansion plans, the next few years domestic LCD production capacity will continue to increase.

LCD panel manufacturers tend to choose the nearby supporting module suppliers for the safety of the key component supply chain and cost reduction considerations. LCD panel production capacity transfer to China will bring opportunities to domestic backlight module manufacturers and drive the development of the domestic backlight module industry.

The future of the car will pay more attention to the human driving experience, to the intelligent development, which will bring the increasing demand for car display. On the one hand, the number of car displays gradually increased, for example, the instrument panel, rearview mirror, central control platform more to display the way, the passenger and rear position with entertainment display. On the other hand, the car display is constantly to a large screen, multi-screen development, especially in high-end models, the large display has become standard, for example, Tesla Model S screen size of 17 inches, Mercedes-Benz A-class car configuration of two 10.5-inch display.

According to the terminal application size, backlight module can be divided into large, medium, and small size, of which small size backlight module is mainly used in smartphones, wearable devices, and other terminals, the medium size used in notebook computers, tablet PCs, car screens and other terminals, the large size is mainly used in LCD TV.

From the industry development trend, smartphone display is transitioning to OLED, LCD TV market is gradually saturated, the future of large size and small size backlight module market potential is relatively small; and the future of the car display market potential is huge, by the backlight module manufacturers are unanimously optimistic, are currently accelerating the layout ( see Table 2 ). Focusing on the traditional medium-sized backlight module field, Hanbo Hi-Tech and Weishi Electronics have significant advantages in core technology patents, downstream customer resources, process experience accumulation, production costs, etc., and have more development advantages in the future.

The current global LCD display panel industry is rapidly moving to China, which brings development opportunities to China’s backlight module industry. In addition, automotive intelligence will also bring a continuous increase in demand for medium-sized car displays, the first to enter the field of medium-sized backlight module manufacturers with its customer resources, core technology, scale efficiency, and other advantages will be more beneficial.

BOE Technology Group Co., Ltd., or Jingdongfang (Chinese: 京东方科技集团股份有限公司), is a Chinese electronic components producer founded in April 1993. Its core businesses are interface devices, smart IoT systems and smart medicine and engineering integration.LCD, OLEDs and flexible displays.

In April 1993, Beijing Oriental Electronics Group Co., Ltd was founded by Wang Dongsheng. In 1997, it listed B shares on the Shenzhen Stock Exchange. In 2001, Beijing Oriental Electronics was renamed BOE Technology Group Co., Ltd. BOE acquired SK Hynix"s STN-LCD and OLED businesses for US$22.5 million.flat-panel display businesses for US$380 million.

In 2019, BOE formed a joint venture with Rohinni for MicroLED and mini LED backlighting manufacturing.Hisense announced its U9E TVs featuring dual LCD panels which Hisense said exceeds OLED TVs in brightness, color gamut and color accuracy. Its panels are produced by BOE.Huawei Mate X scheduled for release in Q4 2019 reportly has a foldable OLED from BOE.Samsung Displays.flat-panel display producer.Huawei to research cameras under OLEDs.LG Display and Tianma as OLED supplier for LG Electronics smartphones in 2020.Apple beginning in 2021 for the iPhone.

They filed a Swiss patent for the idea on Dec. 4, 1970. Though it attracted scant attention at the time, the milestone now stands as the birthdate of the liquid crystal display (LCD) – the technological platform which has transformed consumer electronics and presented a brilliant new way to view the world.

Early LCD developers took a few years to figure out that specialty glass, not plastic, was the best stable substrate for the delicate LCD circuitry and the color backplane component. Once they did, they turned increasingly to Corning to supply them with extraordinarily stable, flat, fusion-formed glass, able to preserve the critical properties of the liquid crystal and withstand high processing temperatures.

And LCDs rapidly transformed from “passive matrix” models, mostly used in pocket calculators and digital watches, to “active matrix” LCDs in which each sub-pixel was controlled with an isolated thin-film transistor. AMLCDs enabled wide viewing angles; brilliant, fast-moving images; and high-resolution images that had never been possible before.

Corning Incorporated was a critical player in this development, and eventually became the world’s leading supplier of LCD glass substrates. And Corning® EAGLE XG® Glass, the world’s first LCD substrate with no arsenic or other heavy metals, went on to exceed sales of 25 billion square feet, making it one of the most successful products in Corning’s history.

![]()

Foxconn Technology Group on Friday said it will build an LCD screen fabrication facility in Mount Pleasant, a move that was put into question after reports earlier this week of the company reconsidering its plans.

The company said the decision came after “productive discussions between the White House and the company, and after a personal conversation between President Donald J. Trump and Chairman Terry Gou.” That Gen 6 plant will fabricate smaller, high-resolution LCD screens than the company had originally planned to make in its Mount Pleasant plant.

Reports from Reuters and Japanese news publication Nikkei Asian Review had called into question whether Foxconn would be fabricating any LCD screens in Wisconsin at all. The company earlier this week committed to building packaging plants, assembly facilities and research centers over the next 18 months in Mount Pleasant. But it fell short of committing to the Gen 6 fabrication plant to make TFT, or “thin-film-transistor” screens.

That fabrication plant could break ground over the next 18 months, according to a Friday statement from Racine County, the village of Mount Pleasant and the Racine County Economic Development Corp. The company in April is expected to hold open houses regarding its upcoming construction plans.

Foxconn first announced last year it was backing off from plans for a Gen 10.5 facility in Wisconsin to make very large LCD screens. Instead, the Gen 6 plant will produce small to mid-sized displays that would be used in televisions and by automakers.

"Over the last year at least, the capacity for the large LCD screen manufacturing in China has grown exponentially, and the cost has been cut in half," Sheehy said.

The actual fabrication of screens in Wisconsin is significant. The company is building Gen 10.5 plants in China, but such operations don’t exist in the United States. Fabricating the screens, versus assembling products around the finished LCD displays, was expected to attract a new supply chain of manufacturers to Foxconn’s plant.

Racine County Executive Jonathan Delagrave said the advanced manufacturing piece is important because it brings jobs paying $25 an hour and more. He said Foxconn has kept a direct line of communication with Racine County, and never communicated that screen fabrication was out of the picture.

When it comes to precision and exact measuring in home improvement projects, the Neiko family of digital calipers are an excellent digital solution for your measuring needs due to its accurate and easy-to-read displays. Ranging from 6”, 8”, to 12” options, it is an essential tool to cover everything you need for your job at the worksite or automotive garage. Each tool comes with an extra-large LCD digital display for clear readouts and the stainless-steel build of these calipers ensures longevity and lasting service life over all your projects. Factory calibrated to professional standards, trust in Neiko for all your caliper-based application needs with an exact internal and outside measurement accurate to .001 of an inch with a display that can be zeroed at any point on the slide. The machine grooved thumb-roll mechanism and positioning lock are provided for sure adjustment. The premium steel shaft with depth-measurement probe, precision ground jaws, on-off switch with auto-off and inclusion of two long-life batteries (one spare) with each caliper makes each unit the choice measuring tool whether in standard SAE or metric MM or fractional display.

Manufacturing is the process of making the components that go into the iPhone. While Apple designs and sells the iPhone, it doesn"t manufacture its components. Instead, Apple uses manufacturers from around the world to deliver individual parts. The manufacturers specialize in particular items—camera specialists manufacture the lens and camera assembly, screen specialists build the display, and so on.

Glass screen:Corning, based in the U.S., with locations in Australia, Belgium, Brazil, China, Denmark, France, Germany, Hong Kong, India, Israel, Italy, Japan, South Korea, Malaysia, Mexico, Philippines, Poland, Russia, Singapore, South Africa, Spain, Taiwan, The Netherlands, Turkey, the U.K., and the United Arab Emirates

Touch-screen controller: Broadcom, based in the U.S. with locations in Israel, Greece, the U.K., the Netherlands, Belgium, France, India, China, Taiwan, Singapore, and South Korea

Foxconn, which received controversial state and local incentives for the project, initially planned to manufacture advanced large screen displays for TVs and other consumer and professional products at the facility, which is under construction. It later said it would build smaller LCD screens instead.

Now, those plans may be scaled back or even shelved, Louis Woo, special assistant to Foxconn Chief Executive Terry Gou, told Reuters. He said the company was still evaluating options for Wisconsin, but cited the steep cost of making advanced TV screens in the United States, where labor expenses are comparatively high.

When it comes to manufacturing advanced screens for TVs, he added: "If a certain size of display has more supply, whether from China or Japan or Taiwan, we have to change, too."

Rather than a focus on LCD manufacturing, Foxconn wants to create a "technology hub" in Wisconsin that would largely consist of research facilities along with packaging and assembly operations, Woo said. It would also produce specialized tech products for industrial, healthcare, and professional applications, he added.

Rather than manufacturing LCD panels in the United States, Woo said it would be more profitable to make them in greater China and Japan, ship them to Mexico for final assembly, and import the finished product to the United States.

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved January 02, 2023, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed January 02, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: January 02, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited January 02, 2023)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey