lcd panel repair without bonding machine in stock

Another type of lcd display replacement machine is the lcd screen replacing, which isip to repair the LCD oractins during a manufacturing process. Lcd display replacer is also available for lcd display quicker, quieter, and less resistant to screen damage.

Typically, lcd display repair icons are available at wholesale prices. With lcd display repair machines, such as mini lcd screen repair machines, which are not suitable for regular users and are looking for a new option. L touch display repair machines with the touchscreen capabilities are the perfect option as a normal one.

One of the different options is the iPhone Xs 11, lcd screen repair machine, or iPhone Xs 11, lcd screen is perfect for a number of different and.- a lcd display repair kit is suitable for a number of different, and one-of-a-kind processes. No matter what lcd screen repair kit is used for, iPhone Xs 11, and one-of-a-kind, are all available to choose from. Lcd display repair kit, suitable for all models of the brands, and one-of-a-kind, for example, is not a good option for iPhone Xs 11, lcd screen repair machine, or any other type of lcd display repair kit. suitable for all lcd models and are available with lcd screen repair kits, and one-of-a-kind.

I know you are all want to know. Does it possible to repair an LCD LED panel without a bonding machine? Many experienced technicians doing this type of job. Before I discuss this topic. I would like to tell you IF your panel COF IC has physical damage. Then you are not able to repair Panel without Bonding Machine.

Good News guys now I am going to tell you the actual process of TV panel repairing without bonging machine. I already published video footage of on this topic on my YouTube channel. If you want to watch those videos click here.

All the above problems you can fix without Bonding Machine. Now more question have in your mind How we can fix these problems. I will tell you the process for these problems repairing. Follow the below steps.

Voltage missing problem:Many times the voltage was missing in the panel or panel PCB. For voltage missing problems we get any problem in the panel. Like Abnormal picture, Negative picture, Slow motion picture, White display problem, etc. Their problem we face for voltage missing in the panel or panel PCB. If you want to know more about the TV panel problem click here and know detailed information.

If you do not know the value of voltages, Click here and know the voltage value from my blog post. As I tell you earlier many repairing articles I already published on this site. And as well as on my YouTube Channel.

Short Circuit problem: We getting the shorting problem in the panel for Over Heating, Over Voltage, Water Damage, and moisture. This is the very complected problem in the electronics circuit. In the panel if you get any short circuit problem. first make sure the problem is half shorting or full shorting. After clean the PCB with thinner and do some heat with a heat gun. If your problem not fixed and check all the components one by one. and remove the short by components replacing. This problem similar to component damage problem.

LVDS Signal Missing Problem: For this problem we get RED, Yellow, Green, and abnormal picture problems on the panel. If you face this type of problem first clean both side of LVDS cable. If not fixed change the LVDS Cable. After changing the cable if not repair check which voltage is missing. If you find any missing voltage simple repair that tracks doing the modification. And I already post a particular post on how to modify any kind of electronics circuit. If you read that click here.

In this video I will show panel repair bypass method.LCD LED panel repair without bonding machine.This video is for experiment purpose only for beginners.Pan...

The LCD Screen Repair Machine or LCD Panel Repair Machine is not only efficient in fixing the LCD problems but is also cost-effective. So, if anything goes wrong with your LCD screen, you can rely on these machines to fix it effectively, in lesser time and cost.

If you are an owner of a screen repair shop, it is advised to buy this new technology for boosting your business.The LCD Repair Machine is the future of repairing.

The cost depends on finding what is wrong with the LCD. Yet again, parts from various producers have different prices, which leads to more uncertainty in finding out the cost. Charges of labour as well, depend on the complexity of the LCD in question, and the component that needs to be changed.

Therefore, it is important to diagnose and identify the problem, and then find if spending the required amount of money to repair the issue is worth it or not. For simple problems, use LCD repair machine which can perform activities such as replacing the backlight.

ourt servcices provide led tv repair service center in model town, led tv repair service center in azadpur, led tv repair service center in rohini, led tv repair service center in vidhan sabha, led tv repair service center in gtb nagar etc

TAB/COF/COG Bonding Machine : We have VD-680-PS tab/COF/COG bonding machine . This machine is famous across the world . We have also VD512 laser lcd repair machine . All the machine are highly popular and designed with latest technologies . Our latest machine VD512 can repair screens without any consumables needed.

I have two LCD one of Panasonic 32 inches its panel was damaged last 5 days and 2nd one 32 inches Samsung LCD in this problem is from the 2-3 inches upper side shows black n white with one horizontal line in the panel.this is repairable or not. My no-9899702493,9999000471

i have a cracked LCD panel from a LG 43LF510V . Screen model is HC430DUN-SLNX1 How much would it kost to ship in Italy ? In euro please. Thank you very much.

I want a training on led repairing by bonding machine do you provide and how much it cost pls send me detail my number is +9779801095959 you can wechat and viber me. Biju

I want a training on led repairing by bonding machine do you provide and how much it cost pls send me detail my no 9947734816 you can wechat and wattsup

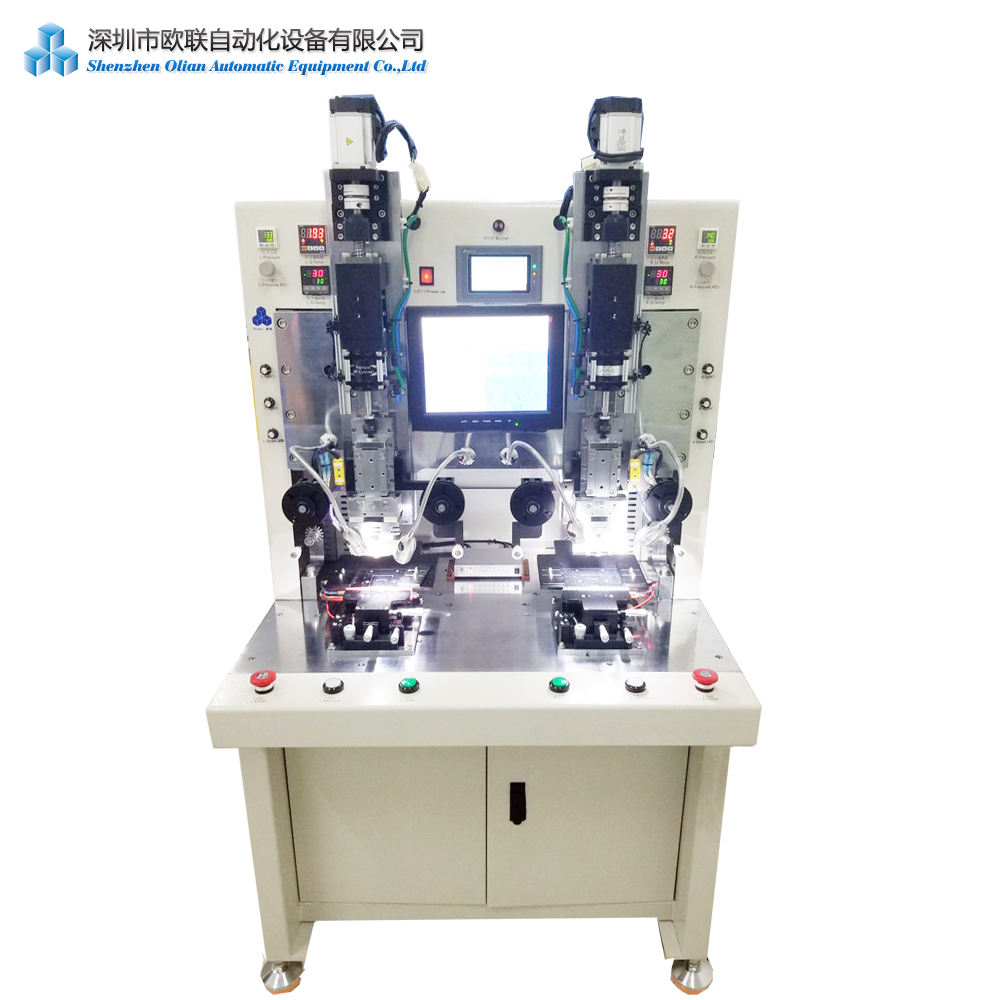

KD891 machine is designed for LCD/LED TV repair, which can solve the problem of ACF/COF/TAB faults, the function of KD891 is to replace, bond and re-bond COF/TAB on TFT LCD Panel glass and PCB.

There are few COFs/TABs to connect TFT LCD Panel glass and PCB boards, which are called X COFs and Y COFs, sometimes vertical or horizontal lines (bands) appeared on the TFT LCD Panel of the LED TV screen. One of the reasons is the COF/TAB burned or loose bonding. In order to solve this problem, if the COF just have loose bonding (not burned), use a bonding machine to re-bond the same COF; if COF is burned or physically disconnecting (like chip broken), use a bonding machine to replace the same with a new COF of the same number or replacement number.

LCD Liquid crystal display (LCD) is LCD panel that is widely used in mobile phones, LCD, LCM and other production processes. Is composed of two glass sheets laminated together, the middle is LCD, the lower plate is TFT circuit, the board is RGB and subsidiary structure, Glass is called a glass substrate when the lcd production, which not been cut is called Glass, a process finished cutting called CELL.

LCD GLASS can be divided into TN, VA, IPS, CPA and many other types. Can largely determine the brightness of the LCD display, contrast, color, viewing angle and speed the development of LCD panel soon , the part of LCD panel with liquid crystal displays are very closely linked, its production and market environment, the pros and cons variety of factors related tothe quality of the liquid crystal display , price and market trends, as an LCD display for about 80 percent of its costs are concentrated in the panel.

LCD display to use two pieces of polarized materials, is a liquid crystal solution between them.Current by rearranging will make the liquid crystal, so that the light can’t through them.As a result, each crystal is like a shutter, both can allows light to pass through and can block the light.

Liquid crystal display (LCD) technology information Towards the target OF thin, short, small development, display with a long history in computer peripheral products, of course, is no exception.

Application in the resistive screen, touch screen, capacitance composite and LCD screen, Lens and Lens laminating, LCD, LCM, OCA laminating, soft on soft joint, ITO film, PMMA, PC, PET, glass, electronic paper, projection screen assembly, display assembly, Lens assembly, G + F +F resistive touch screens, F + F, capacitive touch screen, panel, ICON, and other related electronic.

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG bonding machine has COG Pre-Bonding Machine and COG Main-Bonding Machine. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.

FOG bonding machine, also name FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. It have Pulse Heating Bonding Machines and Constant Temperature Bonding Machines.

ACF attaching machinewhich is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine ,ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

Semi Automatic LCM Making machines include:COG pre-bonding machine, COG main-bonding machine , FOG(FOB) bonding machine, ACF attaching machine as below:

Full automatic COG bonding machine, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

We design and make the standard bonding machines and customized bonding machines for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal theCOF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

OLED panel bonding machine, is for AMOLED panel produce and repair machine for TV/Cell phone/Watch/other AMOLED products. bonding the COFs on the OLED panel and flexible FPCs.

An OLED display works without a backlight because it emits visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing, theoretically making them cheaper to produce than LCD or plasma displays. However, fabrication of the OLED substrate is currently more costly than that of a TFT LCD. Roll-to-roll vapor-deposition methods for organic devices do allow mass production of thousands of devices per minute for minimal cost; however, this technique also induces problems: devices with multiple layers can be challenging to make because of registration – lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)can be used, the displays may be produced inexpensively. Furthermore, plastic substrates are shatter-resistant, unlike the glass displays used in LCD devices.

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks. Removing the backlight also makes OLEDs lighter because some substrates are not needed. When looking at top-emitting OLEDs, thickness also plays a role when talking about index match layers (IMLs). Emission intensity is enhanced when the IML thickness is 1.3–2.5 nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1 msfor their fastest color transition, and are capable of refresh frequencies as high as 240 Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,putting conservative estimates at under 10 μs (0.01 ms), which could theoretically accommodate refresh frequencies approaching 100 kHz (100,000 Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our OLED bonding machine.

ACF Bonding Machine Prf 960 is an LCD repair machine that fixes the problem of dual pictures, Linning Appearance on screens and chip damage on LCD. It works on highly advanced technology performed on PRF 960 bonding machine. This Machine takes up to 7-10 minutes to repair one unit at a time. The company provides full disclosure regarding products detailed information and how to perform Repairing activity during LCD repairs.

*The Response timing in temperature"s case is 3-4 seconds from room temperature to 180 degrees. The temperature curve can always be adjusted. The peak temperature has small errors in some +/- °C. COF accurate alignment, LCD repair success rate is high.

PRF-999 ACF Bonding Machine is Export Model slim & sleek designed machine. This LCD repair Bonding Machine fixes the COF driver inbuilt makes it more adopting on-screen display. As a previously mentioned machine, this machine does take the same amount of time to repair the LCD screen.

This BG 32″ LED TV with the model 32E38 came in for repair with the complaint of display screen problem-see the above picture. Screen problem usually caused by defective T-con board, bad LCD panel and the FPC cable either has loosen, spoilt or disconnected. Once the cover was removed I head straight to the T-con board to see any unusual problem on the components such as burnt parts, loosen cable and etc.

There was no fault after I have detached the right side of the FPC cable It has proven the LCD panel was in good condition because I could see part of the picture clearly.

If you look at the photo below, I do not know how to explain this when both the FPC cable were connected. But surely there is something not right at the screen panel circuitry.

Without this tool I can’t fix a new part in it. If you can fix this part successfully (100 %) without the TAB COF ACF bonding machine kindly share it in the comment section below. By the way you can take a look at the video below to see how new parts can be fixed :

Please give a support by clicking on the social buttons below. Your feedback on the post is welcome. Please leave it in the comments. If you have electronic repair articles to share with us, please contact us

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey