lcd screen display problem supplier

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

Typically, the default blame starts with the supplier. However, it could be an issue with your assembly process, the design integration between the product and the display, or even a problem with a non-display component that fails (that affects the display).

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

The likelihood of damage, or the display being non-functional from the supplier’s end, is fairly low, as it is standard to test 300%, or three times throughout the process. Additionally, the final packaging itself is subject to drop testing during the initial development phase prior to mass production to ensure a damage-free trip despite your carrier’s best efforts to drop the packaging. That means the defect is likely latent or occurred during installation into the end-product.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

Chances are you selected an LCD display supplier to work with your CM and now feel locked into the relationship. You’ve already gone through the qualification process, investing time and money. Not to mention approving the PO in good faith, believing the CM would be getting the right cost, on-time delivery, and high-quality components from your LCD supplier.

A CM had a quality issue with an LCD module. The CM felt comfortable notifying the LCD supplier of the problem. A comprehensive QA check at the supplier’s factory did not reveal any quality issues. The LCD supplier, taking accountability for their role in the end product, scheduled a visit to the CM’s factory. Working collaboratively with the CM, they discovered missing steps in the CM’s process that were compromising the quality of the displays. Quick and intelligent action meant the impact was negligible. The OEM, while informed, was not involved or burdened throughout this process.

Given the LCD supplier’s role and responsibilities, they should keep the OEM informed on aspects that pose a significant impact on products or customer perception:

Lead time: Contrary to the lines you may be fed, lead-time problems are not just part of doing business. Sure, uncertainty and circumstances happen, but an experienced LCD supplier will have safety nets in place to address this, like safety stock of the longest lead time component, multiple delivery options, and pull with their factory to increase or speed production.

Quality: Shoddy displays? Field failures? Dimensional tolerances not being met? These types of quality issues are a sure sign it’s time to start a new LCD supplier search.

Performance: Are the displays you’re receiving simply not performing as expected or designed? There may be excessive component variability or process variability. Either way, it’s time to look for a supplier that will meet your performance expectations.

For specialty components like LCD displays, it’s typical that you dictate to your CM the supplier they need to use. And if you are observing any issues with lead time, quality, performance, cost, or obsolescence, you should look for an alternate supplier.

Find an LCD display supplier that has experience dealing with a contract manufacturer. There are some items that are dealt directly with the CM, such as schedules, payments, and RMAs. But the supplier needs to know when to get the OEM involved, which is any time there may be a significant impact to your products or customer perception.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

Point defect is a kind of defect that some point on your screen don’t display correctly. There are mainly three situations: the point keeps displaying black or whitewhen the screen is working or the point can only display a single color.

Usually, assembly of cell and IC is under heat and should be positioned accurately. Problems with IC connection will be checked out very soon, followed by the adjustment on machine parameter.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

To avoid this problem, we have to pay attention to the gap distance parameter in sealing process. By the way, newton’s rings has became a method to exam the glass sealing process in reverse .

The black matrix on CF glass or a additional shield bar is used to avoid this problem. So if this problem occurs, we have to check the CF deposition process.

You may notice there are some screens have uneven display, which means some white area appears in dark picture or vice versa. We call this ‘mura’, a word originated from Japanese.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Surprisingly cost issue is the least common. The pain of changing LCD suppliers is high, such that all the problems mentioned above end up costing more than a regular cost delta between competitive suppliers.

An LCD’s cost is an obvious challenge as it’s usually the most expensive component. The challenge is that cost is also difficult to quantify and properly understand. Determining the right price to pay depends on three main factors.

The ideal option in most cases is a custom or semi-custom display designed for its application. This is often the most cost-effective solution, despite what many think.

System-level manufacturability is another cost challenge where display integration improvements can reduce product complexity, improve manufacturing time, and reduce system-level manufacturing defects. For the most seamless LCD integration, additional components such as buttons, LEDs, PCB boards, and connectors are more efficiently integrated on display than a separately assembled component. Clearly, in this case, the LCD cost will go up, but when done right, the system-level cost is reduced to result in a net gain.

Lastly, you need to know system-level costs. You are trading market share and profitability for display savings, and the net result may be decreased profit if you are giving up customer valued performance or functions. The opposite also holds; adding performance that is not necessary (these are attributes that the customer does not value) adds additional product costs.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Throughout your daily activities, you continually interface with a touch screen. They can be found in various places, including mobile phones, tablets, ATMs, kiosks, ticket machines, and manufacturing facilities.

Touchscreens are a popular type of LCD module used nowadays and can be seen in various devices. The principal buyers and suppliers are companies that manufacture point-of-sale terminals, ATMs, PCs, laptops, and other electronic gadgets. Touchscreens with capacitive technology do not respond unless they sense the energy coming from the human body. They rely on the electrical properties of the human body, whereas resistive uses pressure to trigger a response. As a result, the resistive touchscreen only reacts to light pressure from fingers or a stylus.

Choosing the suitable touch screen LCD display module for your project or business requires more information than simply being aware of the various varieties available. Additionally, you must be mindful of all the issues each technology encounters and be equipped to deal with them.

At the component level, liquid crystal display (LCD) modules are used to replace less efficient displays such as cathode ray tubes (CRTs). These modules need to be integrated into a more prominent instrument or system because they don’t come with panels. The category of non-emissive technologies, or displays that do not produce their own light but regulate the transmission or reflection of an external light source, includes liquid crystal displays (LCD’s).

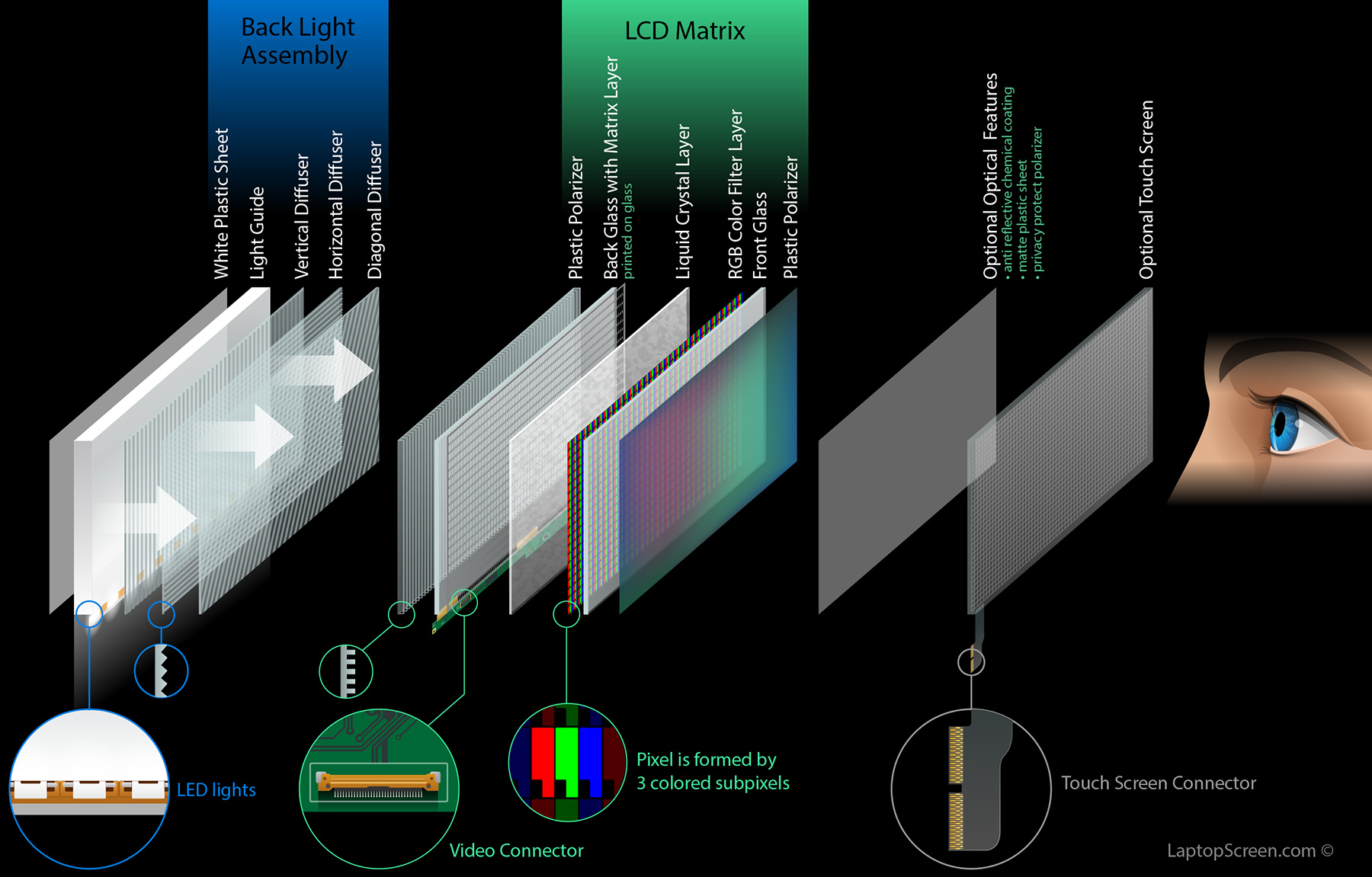

In a liquid crystal display, a liquid crystal solution is sandwiched between two sheets of polarizing material. The crystals in the liquid align so that light cannot travel through them when an electric current is passed across it. Each crystal functions as a shutter, letting light through or obstructing it. When an electric field is applied over the liquid crystal material in an LCD, the optical path of the light is altered.

Touchscreen technology must be appropriately calibrated to detect where the screen is being touched in order to match the command to a screen’s response. Inaccurate calibration prevents the screen from displaying the correct response. A touch could sometimes not even be registered on the screen. For users, this defeats the purpose of the device. This problem can be resolved by calibrating the screen properly.

Touchscreens are prone to scratching or damage since they are often manipulated by fingers or other devices exposed to foreign substances. Oil and dirt can be transferred to the screen when handled or used with a stylus and cause problems with operation. If there is damage to the screen, it won’t be able to react appropriately. It’s possible that some screen components won’t function at all. You can prevent this by utilizing screen protectors and maintaining a clean smartphone. The proper cleaning tips for keeping your LCD modules free from dirt are mentioned in our blog, A Guide in cleaning and keeping TFT LCD Display Screens in the top shape.

Despite your best efforts, touch displays can experience problems due to their delicate nature. The system may become unresponsive due to input registration errors or issues with the device itself. In other situations, the screen may register input that hasn’t been given when the calibration starts to waver. The reaction time slows and becomes unpredictable. All of these things can happen as the device ages. Recalibrating and rebooting the system might occasionally be helpful, but the device might stop working altogether if the hardware malfunctions.

When a touch screen malfunctions, it is unresponsive to finger or stylus taps. Several factors, like a screen protector, dust, or inaccurate calibration, may be to blame for this. Resetting the device or wiping the touch screen can frequently restore functionality.

The problems with touchscreen technology stated above are frequent, even with routine maintenance. You may better prepare for these problems and respond to them when they arise by understanding their underlying causes.

By tackling the problems with the best possible solutions, Microtips USA, a business with more than 30 years of market experience, has significantly upgraded the technology of touchscreen LCD modules, making it a fantastic display for use.

Unlike older cathode ray tube (CRT) displays that scan an electron beam over a phosphor screen to create light, LCD displays are composed of a fixed grid of tricolor pixels that change transparency based on a range of voltage levels provided by the monitor"s controller. Without a voltage the pixel is opaque and blocks the screen"s backlight from transferring through it, and when a full voltage is applied then the pixel allows full transmittance of the backlight. When this is done over the entire pixel grid in patterns, then you see those patterns on the screen.

At a very basic level, the way pixels work is a voltage change alters the pixel to allow more or less light through. When there is no voltage, no light is let through (darker), and when the voltage is at its maximum level then 100 percent of the light is allowed to pass through (brighter). By supplying intermediate voltages the computer adjusts the pixel"s transmittance levels for its three color components, to display various combined colors and intensities.

This pixel-based setup for LCD monitors provides many advantages over CRT displays, but does have potential drawbacks arising from the fact that the image is dependent on millions of independent electrical components as opposed to a single scanning beam, so if faults occur in these components then the display output can be affected. The resulting problems include stuck or dead pixels, as well as a residual image effect.

One of the more common problems with LCD displays is the potential for stuck or broken pixels, where the pixel either does not receive a voltage and remains black, or does not respond to voltage changes and stays at a set luminance level. Sometimes this can happen for individual pixels, suggesting a problem with the pixel itself, or it can happen to groups of pixels, suggesting the possibility of problems with the display"s controller or a defect in a portion of the pixel grid.

When stuck or broken pixels occur, there are a couple of things you can try in order to fix the problem. One is to apply a small amount of pressure to the pixel when turning the display on or off, which can sometimes help stimulate the electronics to work properly. Unfortunately, Apple"s glass-covered glossy displays prevent this from working on modern Mac systems.

The alternative to using pressure is to exercise the pixel"s electronics by using a program that displays quick-changing patterns on the screen and thereby rapidly switches the pixels on and off. Three such programs that will work on the Mac are the following:

LCD monitors can also be affected by another problem called "transient persistence" that is reminiscent of CRT burn-in. Classic burn-in would happen because the phosphor coating on the screen would get depleted by the persistent bombardment of electrons from the CRT, resulting in the inability of those sections of the display to convert the electron beam to visible light. This meant that if you kept a specific pattern showing on the screen then over time it could become a permanent residual image on the display that would show even when the display was turned off. This was a reason why screensavers were developed--to keep the wear on the screen"s phosphor coating as even as possible.

The physical burn-in of displays is no longer an issue now that LCD displays have taken over, but while transient image persistence is not a physical burn of the device, it is an alteration of the pixel response to voltage changes (usually temporary) that prevents pixels from getting as bright as others on the screen.

Similar to CRT burn-in, LCD image persistence generally happens after you have displayed a pattern of intense colors on screen; however, unlike CRT burn-in, LCD persistence can sometimes set in after only a few hours of displaying the image, as opposed to the weeks or even months that it can take for burn to set in on a CRT monitor. Additionally, unlike CRT burn-in, image persistence can often be reversed.

What happens with LCD monitors is the affected pixels have lost their ability to respond to the full range of voltages that the display gives them, resulting in a limited range of colors that can be output. This can happen if the pixel is acting like a capacitor and is retaining a residual charge, or if it is not able to reach the level of luminance that is desired when given a specific voltage. Either way, the pixel is not able to reach its full range of possible intensities.

Unlike stuck or dead pixels that may benefit from having the monitor turned on and off rapidly to produce rapid voltage changes, image persistence will benefit from a lengthy stretching of the pixel"s range. Therefore, instead of using tools like JScreenFix to run random patterns over the affected screen area, you might instead place a pure white window (such as an empty TextEdit window, or what you get using the "White" option in the LCD Repair tool listed above) over the affected area for a few hours or even a few days if necessary. Doing this will force those pixels to be fully on, and over time their intensities may increase to be the same as the surrounding pixels.

Likewise, try turning off the pixels fully by shutting down the display for a long period of time or placing a pure black texture over the affected area (see the LCD Repair tool listed above for this option as well). This will turn the pixels completely off and allow residual voltage in them to drain slowly over time.

So far we have discussed pixel-based problems with LCD displays, but the system"s backlight can also suffer some common problems that include the backlight randomly blinking off, not turning on, or only illuminating part of the screen.

When the display fully cuts out and does not show any light, one possibility could be that your computer is not properly communicating with the display, or the display"s controllers or power supply are not working properly. If this occurs, try connecting the display to another system. But if power LEDs and other indicator lights turn off when the backlight goes out, then it may be your display"s power supply is failing.

If only the backlight is malfunctioning, then the LCD panel itself should still be working just fine and should be rendering the text and images of your computer"s output. To test for this, use a bright flashlight and shine it on your screen at an angle in an area where you expect images and text to be (such as the Dock or menu bar). On Apple"s laptop systems, you can shine the flashlight through the Apple logo on the back to illuminate the screen on the front and better detect text and images that way.

If shining an alternative light source on the display causes graphical content to show up, then either the backlight or some component involved in controlling it (such as the power inverter for it) have failed and will likely need to be replaced, especially if you cannot rectify the problem by restarting the system, resetting PRAM and SMC, or otherwise toggling different hardware and software settings on your system.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

XIANHENG TECH established in 2013, began operation by instituting time-honored ideals, continues to reinforce the principles of being a leading display manufacturer to industry. XIANHENG Tech consistently strives to uphold exceptionally high standards concerning technology and product development while remaining deeply attentive to quality, on-time delivery and remaining highly price competitive.

As a reliable LCD display and touch screen supplier in the display market, we provide customers with standard and customized LCD display and touch total solutions. Our LCD displays ranges from vehicle LCD display, industrial LCD display and bar type LCD display, all the touch screen LCD display are made from high-quality materials and LCD modules. When you need the independent TFT LCD display or integrated with touch and cover integration, or custom highlighted backlights, different types of interfaces, our team can develop the right solution for your project.

:max_bytes(150000):strip_icc()/Emerson-McDonalds_CNN_Burn-In-5692ad0d3df78cafda81df58-5c619daec9e77c0001d92fc1.jpg)

To find the app that causes issues, uninstall recently downloaded apps one by one. After you remove the app that causes the problem, you can reinstall the other apps you removed.

Slowly drag your finger to the bottom right corner without lifting. Try to move your finger slowly enough that you can count to 10 before reaching the opposite corner of the screen.

You dropped your iPhone for the third time this week. Now you have to decide if you’re going to get your broken screen replaced at a local Apple repair service provider or if you’re going to start scrolling online to find the best options for a new or refurbished iPhone.

Let’s say you decide to have the screen on your old phone fixed up by a tech-savvy friend of yours so you can sell or exchange the old, beat-up iPhone 6 for a good deal on a new iPhone 13. Now you’re wondering, “Can Apple tell if I replaced my screen?”

Screen replacements come in a variety of different kinds, like LCD or OLED. Other types of smartphone screens include TFT and IPS. You may have heard of AMOLED or even Super AMOLED displays. Most of these touch screens are made by third-party manufacturers. All of these screens can function on an iPhone — and they’re cheaper than an original. So what’s the problem?

Apple says that all its screens are designed and tested for ‘Apple quality and performance standards.’ This is done before iPhones and iPads hit the shelves for the first time to ensure all Apple products have their proprietary technology like multi-touch, true tone, night shift, and haptic touch functioning properly.

While you may not understand all the jargon, this basically means that iPhone screens are immaculate in functionality — and we’re not even talking about the Pro versions here. There are many reasons why having an original iPhone screen is important, both as a buyer and as a seller. An original screen can go a long way in terms of performance, specifications, aesthetics, and exchange offers if you’re eventually looking to upgrade.

Getting your iPhone screen replaced by an authorized Apple service provider can be an expensive affair — but cheaper, aftermarket screens that aren’t from Apple often come with several issues.

To answer the question above: yes. Apple can tell if you’ve replaced your screen. As a matter of fact, you can check for yourself. In this guide, we’ll look at how you can check for genuine Apple iPhone screens, issues with non-genuine screens, and the difference between the two.

Genuine iPhones will use OEM parts. This means they’re the original equipment manufacturer for all their hardware. Every original Apple product goes through a rigorous quality check process to ensure every part, from the display to the speakers, is compliant with their standards.

Most non-OEM parts come from third-party manufacturers who use cheaper materials to make their screens. The costs are lower upfront, but, you get what you pay for. It"s likely that you"ll have to keep replacing your screen at iPhone repair shops because third-party screens perform poorly and lack longevity.

If the display is non-genuine, pre-used in another iPhone, or not functioning as it should, you’ll see “Unknown Part ! ” appear just below the serial number, next to Display.

Another quick way to check whether your iPhone screen is genuine is by shining a flashlight on it. You just want to shine the light directly on the iPhone’s screen.

Focus on the reflection of the light on the display. Fake screens tend to have grid lines on them, which will show up under a flashlight. These could be running across the screen horizontally, vertically, or both. The most common causes for this include software incompatibilities, hardware failure, or screen damage.

The last few iPhones to be released all have a maximum brightness level of around 1200 units. This means that iPhone screens get very bright and usually have best-in-class color accuracy.

You can use this to check if your iPhone’s screen is genuine. Simply bump the brightness slider up to maximum brightness, and open a solid black picture. You can head over to this website for a completely black screen.

Once you’re on this screen, zoom in and look at the display. If you have a genuine Retina OLED screen, it will look pitch black — as if you haven’t turned on your iPhone.

However, if the screen replacement process was non-genuine, you might have an LCD screen that isn’t from Apple. You can tell if you have a non-genuine screen if you notice color mismatch, specks, or marks of white or grey. Anything other than solid, fullscreen pitch black is not an original iPhone display.

Having a non-genuine screen on your phone can cause several issues. Not only this, but the chances of selling or exchanging your phone for maximum value will substantially decrease.

One of the most common issues with a non-genuine touch screen is multi-touch. Non-genuine screens will not be as prompt or accurate as genuine iPhone screens. Some of the signs of a non-genuine screen are:Missed screen touches or touches not registering in the intended area.

Another common issue with non-genuine iPhone screens is that there could be LCD display panels that aren’t from Apple. Original iPhone screens usually have Retina or Super Retina displays made from an OLED panel that is incredibly bright and color accurate.

If you notice the following issues with your screen’s display, you might have a non-genuine iPhone screen:iPhone"s true tone feature does not work properly (this is when your screen uses different sensors to adapt the screen"s color to the light sources around it).

Apart from the more common issues related to multi-touch and display brightness, you may experience the following issues with your iPhone if you have a faulty screen:Your iPhone does not turn on.

With some non-genuine iPhone screens, digitizers tend to malfunction, creating dead areas in the screen (usually the bottom) where your touch commands have no effect. A digitizer is a layer of glass that converts analog movements like your touch commands and gestures to digital signals that your iPhone can understand and interpret. The digitizer rests over the device"s LCD or OLED display.

While original iPhone screens may be slightly more expensive, they’re the screens that were initially manufactured specifically for Apple iPhones. You can slap a third-party screen on an iPhone, and it will work, but the performance will be nowhere near as seamless. Non-genuine LCD panels will have lower brightness levels and weaker contrast. The colors won’t pop and the screen will feel coarse to the touch.

As mentioned in the previous section, non-genuine screens have tons of issues when it comes to multi-touch, true tone, night shift, and other features that Apple meant to be enjoyed exclusively on an iPhone.

A non-genuine screen’s touch will be inaccurate, the iPhone won’t respond as well, the screen won’t be as smooth to the touch, the brightness will flicker on its own, the battery might deplete quicker, and you may experience a lag in day-to-day usage. With a genuine Apple-approved iPhone screen, you are far less likely to experience these issues.

A genuine iPhone screen is just as important on the day you buy it as it is when you decide to sell it. If you’re looking to sell your phone or hand it in to exchange for a new iPhone, the value of an iPhone with a genuine screen will always be far higher than an iPhone with a non-genuine screen.

Non-genuine screens will show up in your device’s parts and services history, and you’ll end up selling your iPhone for way less than it could have. There’s a good chance that you will pay for a screen a third time after your first non-genuine replacement fails to work properly. It’s best to get a genuine iPhone screen replaced with another genuine iPhone screen.

It’s likely you’ll have a more durable screen, better performances, and fewer problems in the long run until you decide to sell your phone for the best price available.

It’s clear that while a genuine iPhone screen may be more expensive than third-party replacement counterparts, the pros far outweigh the cons. Not only will you enjoy using your phone more, but you also won’t have to break the bank when you want to upgrade.

Speaking of upgrades, if you’re looking to buy or sell a used iPhone, we highly recommend a complete device certification report from Phonecheck. This report will help uncover any issues and give you an in-depth record of your iPhone. Avoid costly hidden problems by purchasing a history report on phonecheck.com for about the cost of a cup of coffee.

Troubleshooting CRTs versus LCDs begins with similar steps, but diverges due to the differing natures of the two display types. The first troubleshooting steps are similar for either display type: power down the system and display and then power them back up; make sure the power cable is connected and that the outlet has power; verify that the signal cable is connected firmly to both video adapter and display and that there are no bent pins; verify that the video adapter is configured properly for the display; try the problem display on a known-good system, or try a known-good display on the problem system; and so on. Once you"ve tried the "obvious" troubleshooting steps, if the problem persists, the next step you take depends on the type of display. The following sections cover basic troubleshooting for CRTs and LCDs.

CRTs seldom fail outright without obvious signs, such as a loud snap or a strong odor of burning electrical components. Most CRT problems are really problems with the power, video adapter, cable, or hardware/software settings. To eliminate the CRT as a possible cause, connect the suspect CRT to a known-good system, or connect a known-good display to the suspect system. It is worth noting, that older CRTs eventually wear out, and starts dimming. Common signs of a weak CRT are a dim picture, dysfunctional brightness and/or color controls, image smearing at high brightness, and in color CRTs, a tint towards a single color (Red Green Blue)

If the CRT is the problem, it is often not worth repairing. If the CRT is out of warranty, parts and labor may cost more than buying a new CRT, which also gives you better specs and a warranty. About the only CRTs we"d even consider repairing out-of-warranty are high-end 21" or larger models, and even there the economics are dubious.

Check the obvious things first. Verify that the CRT is plugged in (and that the receptacle has power), the video cable is connected to the video card, the computer and CRT are turned on, and the brightness and contrast settings are set to the middle of their range. If none of these steps solves the problem, your CRT, video card, or video cable may be bad. Check the suspect CRT on a known-good system or a known-good CRT on the problem system.

CRTs contain multiple filaments, which can be broken, or gas may have leaked into the vacuum inside the CRT. CRTs damaged this way are unrepairable without specialist equipment. With the display open. check if all three filaments are glowing bright orange. Excessive redness or purple arcing signifies gas has leaked in. There may also be an internal short inside the CRT, which is also unfixable without specialist equipment.

If you have ACPI or APM power management enabled, it may be causing the problem. Some systems simply refuse to wake up once power management puts them to sleep. We have seen such systems survive a hardware reset without restoring power to the CRT. To verify this problem, turn off power to the system and CRT and then turn them back on. If the CRT then displays an image, check the power management settings in your BIOS and operating system and disable them if necessary.

The horizontal and/or vertical deflection system has failed. The CRT tube itself is fine, but the circuitry driving the tube has failed. Replace the display.

This is a hardware problem with one of the electron guns. Replace the CRT. This problem may also manifest as a strong color cast during normal operation that is not correctable using the normal color balance controls.

There are two likely causes. First, you may be driving the CRT beyond its design limits. Some CRTs display a usable image at resolutions and/or refresh rates higher than they are designed to use, but under such abuse the expected life of the CRT is shortened dramatically, perhaps to minutes. To correct this problem, change video settings to values that are within the CRT"s design specifications. Second, the power receptacle may be supplying voltage lower than the CRT requires. To correct this problem, connect the CRT to a different circuit or to a UPS or power conditioner that supplies standard voltage regardless of input voltage.

This is usually a minor hardware problem. The most likely cause is that the signal cable is not connected tightly to the CRT and/or video card, causing some pins to make contact intermittently or not at all. Verify that no pins are loose, bent, or missing on the cable or the connectors on the CRT and video card, and then tighten the cable at both ends, If that doesn"t fix the problem, open the computer, remove the video card, and reseat it fully.

The video card settings are likely outside the range supported by the CRT, particularly if you have just installed the CRT or have just changed video settings. To verify this, restart the system in Safe Mode (press F8 during boot to display the Windows boot menu and choose Safe Mode). If the system displays a VGA image properly, change your display settings to something supported by the CRT.

Most modern CRTs can display signals at many different scan frequencies, but this doesn"t mean that the CRT will necessarily automatically display different signals full-screen and properly aligned. Use the CRT controls to adjust the size and alignment of the image.

Depending on the CRT, video card, and video settings, this may be normal behavior, adjustable using the CRT controls. If the distortion is beyond the ability of the controls to correct, the problem may be with the video card, the CRT, or the driver. First try changing video settings. If the problem persists at several settings, move that CRT to a different system (or use a different video card) to determine whether the problem is caused by the CRT or video card. Repair or replace the faulty component.

This is usually caused by RF interference from another electrical or electronic device, particularly one that contains a motor. Make sure such devices are at least three feet from the CRT. Note that such interference can sometimes penetrate typical residential and office walls, so if the CRT is close to a wall, check the other side. Such image problems can also be caused by interference carried by the power line or by voltage variations in the AC power supply. To eliminate interference, plug the CRT into a surge protector. Better still, plug it into a UPS or power conditioner that supplies clean power at a constant voltage.

This problem may also be caused by using a video cable that is too long or of poor quality or by using a poor-quality KVM switch (keyboard/video/mouse switch). Manual KVM switches are particularly problematic.

The CRT may need to be degaussed. A CRT that sits in one position for months or years can be affected even by the earth"s very weak magnetic field, causing distortion and other display problems. Exposing a CRT to a strong magnetic field, such as unshielded speakers, can cause more extreme image problems. Many modern CRTs degauss themselves automatically each time you cycle the power, but some have a manual degauss button that you must remember to use. If your CRT has a manual degauss button, use it every month or two. The degaussing circuitry in some CRTs has limited power. We have seen CRTs that were accidentally exposed to strong magnetic fields, resulting in a badly distorted image. Built-in degaussing did little or nothing. In that case, you can sometimes fix the problem by using a separate degaussing coil, available at RadioShack and similar stores for a few dollars. We have, however, seen CRTs that were so badly "magnet burned" that even a standalone degaussing coil could not completely eliminate the problem. The moral is to keep magnets away from your CRT, including those in speakers that are not video-shielded.

An incorrect yoke may have been attached to the CRT. Unless you have a lot of spare time on your hands, this is usually not worth fixing. Replace the display.

If your LCD displays no image at all and you are certain that it is receiving power and video signal, first adjust the brightness and contrast settings to higher values. If that doesn"t work, turn off the system and LCD, disconnect the LCD signal cable from the computer, and turn on the LCD by itself. It should display some sort of initialization screen, if only perhaps a "No video signal" message. If nothing lights up and no message is displayed, contact technical support for your LCD manufacturer. If your LCD supports multiple inputs, you may need to press a button to cycle through the inputs and set it to the correct one.

Unlike CRTs, where increasing the refresh rate always reduces flicker, LCDs have an optimal refresh rate that may be lower than the highest refresh rate supported. For example, a 17" LCD operating in analog mode may support 60 Hz and 75 Hz refresh. Although it sounds counterintuitive to anyone whose experience has been with CRTs, reducing the refresh rate from 75 Hz to 60 Hz may improve image stability. Check the manual to determine the optimum refresh rate for your LCD, and set your video adapter to use that rate.

First, try setting the optimal refresh rate as described above. If that doesn"t solve the problem and you are using an analog interface, there are several possible causes, most of which are due to poor synchronization between the video adapter clock and the display clock, or to phase problems. If your LCD has an auto-adjust, auto-setup, or auto-synchronize option, try using that first. If not, try adjusting the phase and/or clock settings manually until you have a usable image. If you are using an extension or longer than standard video cable, try connecting the standard video cable that was supplied with the display. Long analog video cables exacerbate sync problems. Also, if you are using a KVM switch, particularly a manual model, try instead connecting the LCD directly to the video adapter. Many LCDs are difficult or impossible to synchronize if you use a KVM switch. If you are unable to achieve proper synchronization, try connecting the LCD to a different computer. If you are unable to achieve synchronization on the second computer, the LCD may be defective. Finally, note that some models of video adapter simply don"t function well with some models of LCD.

If the screen is displaying a full, stable image, but that image is of poor quality, first verify that the display is not connected through a KVM switch or using an extension cable. If so, connect the display directly to the video adapter using the standard cable. If that is already the case, adjust the brightness, contrast, and focus controls. If you are unable to get a proper image using these controls, the problem is most likely a clock or phase mismatch, which you can cure by taking the steps described in the preceding item.

The best way to adjust clock and phase is to use auto-adjust first. Check the utility and driver CD that came with the monitor. It may have a wizard or at least the appropriate background screens to use while adjusting phase and clock settings. If not, go to the Windows Start menu and select Shutdown. When the screen goes gray and the Windows Shutdown dialog appears, leave that dialog onscreen, but ignore it. Use the gray screen to adjust clock and phase manually. Any problems with clock and phase and any changes you make to the clock and phase settings are clearly evident on the gray screen.

Always adjust clock first. Clock is usually not a problem if you have used the auto-adjust feature of your monitor, but if you do have clock problems they will be evident as large vertical bars on your screen. Tweak the clock setting until those bars disappear. Then adjust phase. Phase problems are evident as thin black lines running horizontally across the screen. Adjust phase until the lines disappear or are minimized.

Not all analog video cards synchronize perfectly with flat panels. The gray Shutdown screen exaggerates the problem, so don"t worry if very tiny movements are visible after you"ve adjusted clock and phase as well as possible. After you"ve set the clock and phase controls for the best image possible on the gray screen, cancel Shutdown and the image should be optimized.

Your video card is supplying a video signal at a bandwidth that is above or below the ability of your LCD to display. Reset your video parameters to be within the range supported by the LCD. If necessary, temporarily connect a different display or start Windows in Safe Mode and choose standard VGA in order to change video settings.

This occurs when you run an LCD at other than its native resolution. For example, if you have a 19" LCD with native 1280x1024 resolution but have your display adapter set to 1024x768, your LCD attempts to display those 1024x768 pixels at full screen size, which physically corresponds to 1280x1024 pixels. The pixel extrapolation needed to fill the screen with the smaller image results in artifacts such as blocky or poorly rendered text, jaggy lines, and so on. Either set your video adapter to display the native resolution of the LCD, or set your LCD to display the lower-resolution image without stretching the display (a feature sometimes referred to as display expansion), so that pixels are displayed 1:1, which results in the lower resolution using less than the entire screen.

This is a characteristic of LCDs, particularly older and inexpensive models, caused by defective pixels. Manufacturers set a threshold number below which they consider a display acceptable. That number varies with the manufacturer, the model, and the size of the display, but is typically in the range of 5 to 10 pixels. (Better LCDs nowadays usually have zero dead pixels.) Nothing can be done to fix defective pixels. Manufacturers will not replace LCDs under warranty unless the number of defective pixels exceeds the threshold number.

Some people claim that leaving the unit powered off for a day or two will "erase" a persistent after-image. Others suggest leaving a neutral gray screen (like the one used for phase adjustment) up on the screen to "equalize" the display. I dunno. FWIW, I"ve seen this problem on older Samsung panels but never on the Sony or NEC/LaCie panels I use.

Again, this is a characteristic of LCDs, particularly older and inexpensive models. The after-image occurs when the display has had the same image in one place for a long time. The after-image may persist even after you turn the display off.

Transistor-based pixels in an LCD respond more slowly than the phosphors in a CRT. The least-expensive LCDs exhibit this problem even with slow image movement, as when you drag a window. Better LCDs handle moderately fast image movement without ghosting, but exhibit the problem on fast-motion video. The best LCDs handle even fast-motion video and 3D gaming very well. The only solution to this problem is to upgrade to an LCD with faster response time.

Use the brightness control to increase image brightness. If you have set brightness to maximum and the image is still too dim, contact the display manufacturer. The CCRTs used to backlight the screen have a finite lifetime

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey