igzo tft display made in china

Liquid crystal displays (LCD) began to replace cathode-ray tube-based televisions in the early 2000s. The pixels in these LCDs were, until 2012, driven exclusively by thin-film transistors (TFTs) that use amorphous hydrogenated silicon (a-Si:H) as the semiconducting channel. But as demand grew for ever larger displays, with better viewing and energy performance, a need for improved TFTs emerged. TFTs block light coming from the display, so they need to be small, which lowers their current-driving ability. Additionally, there was a push to move away from LCD technology and into organic light emitting diodes (OLEDs) in order to capitalize on their better performance, which includes direct emission and richer colours, but OLEDs need to be driven by large amounts of current, at levels a-Si:H TFTs cannot accommodate. What was needed was a new technology that could be used to create TFTs with a high charge carrier mobility, which could drive large currents.

Charge carrier mobility tells us how quickly charge carriers (electrons and holes) can move through a semiconductor, and determines the amount of current we can drive through a TFT of a given size. This is limited by the nature of the path that charge carriers take though a material. This path can be thought of in terms of the atomic orbitals and how they interconnect to make up the conduction and valence bands — the energetic levels at which the electrons and holes are free to move around. The sp3 hybridized orbitals in silicon are highly directional, and in the crystalline state the silicon–silicon bonds properly overlap, providing an efficient path to travel through. However, in amorphous silicon, structural disorder leads to disconnects and conduction cannot occur through the orbitals in the same way. Instead, the charge carriers have to hop across the orbitals, which leads to mobilities of at most 1 cm2 V–1 s–1 — about 2–3 orders of magnitude lower than in crystalline silicon.

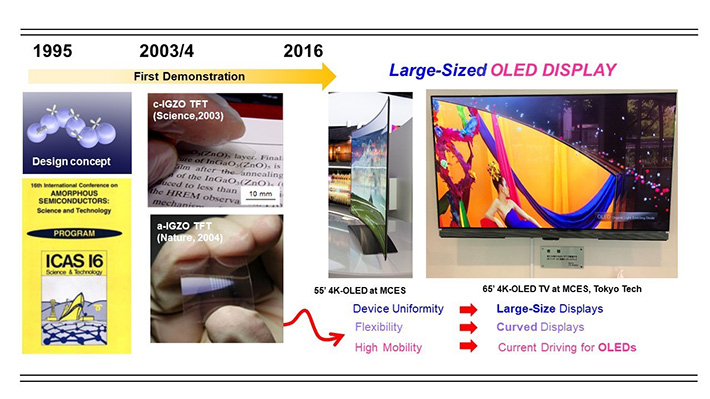

After a few years verifying the validity of the hypothesis, we started research on transparent oxide TFTs. To develop high-mobility TFTs using transparent conductive oxides, the major issue was their high carrier concentrations (the TFTs can’t be turned off). Indium oxide is a typical transparent conductive oxide with a large mobility, but reducing its excessive carrier concentration is difficult due the ease with which oxygen vacancies form. We tested InGaO3(ZnO)m epitaxial films, where m = 4 and 5, as I believed the unique local structure around Ga3+ would help lower the carrier concentration. As expected, the carrier concentration in epitaxial InGaO3(ZnO)4 reduced to a suitable level, and when applied in TFTs showed excellent performance, with a mobility of approximately 80 cm2 V–1 s–1. We then fabricated thin films using amorphous InGaZnO4 (a-IGZO). The electron concentrations in the resulting a-IGZO thin films, which were deposited on glass substrates at room temperature, were below 1016 cm–3 and the TFTs exhibited mobilities of approximately 10 cm2 V–1 s–1 — an order of magnitude larger than that of a-Si:H TFTs. We also found that TFTs fabricated on plastic substrates offered almost identical performance (Fig. 1). At this point we applied for patents and then submitted our paper to Nature, which was published in 2004.

Demonstrations of IGZO TFT-based displays began to emerge in 2007, when Samsung Electronics first reported a-IGZO TFT-based high-definition LCDs. Demonstrations of IGZO TFT-based backplane LCDs in smart phones and tablet computers then appeared around 2012. Arguably the most striking application emerged in 2015, when LG Display demonstrated large-sized OLED televisions. Here the a-IGZO TFT was indispensable because of the need for high mobility and simple formation over large areas.

I believe the success of IGZO transistors is due to a number of factors. First is their high mobility, which is an order of magnitude higher than a-Si:H, and the excellent controllability of their carrier concentration. Second, the production process is almost the same as a-Si:H, except for the deposition of the channel layer (chemical vapour deposition is used for a-Si:H whereas sputtering is used for IGZO), making integration into current manufacturing workflows relatively painless. Third, synthesizing large-sized high-quality sputtering targets is relatively easy, which also makes thin-film deposition on large-sized substrates a relatively simple task. With these attributes, IGZO transistors provide a promising backplane technology to drive the future of flat panel displays.

The thin-film transistor (TFT) became commercially available slightly more than 30 years ago in the form of a switch for the Liquid Crystal Display. It all started with an amorphous silicon (a-Si) TFT. Compared to the traditional crystalline silicon CMOS transistor, the a-Si TFT can be produced on large substrates and at low processing temperatures, below 300 °C, enabling integration on glass substrates and even flexible substrates.

A-Si TFTs are mainly implemented as simple pixel switches due to their low charge carrier mobility (0.5-1 cm²/Vs). An alternative semiconductor on glass substrates is low-temperature polycrystalline silicon (LTPS), outperforming a-Si TFTs by a 100x larger mobility (50-100 cm²/Vs) and often used for high-end displays and imagers. Despite the advantages, fabrication of an LTPS TFT takes more process steps, is limited in substrate size, and requires a larger process temperature. Oxide-based semiconductors as indium-gallium-zinc-oxide (IGZO) fill this gap between a-Si and LTPS nicely, exhibiting low processing temperatures and a decent charge carrier mobility of 10 up to 40 cm²/Vs [1].

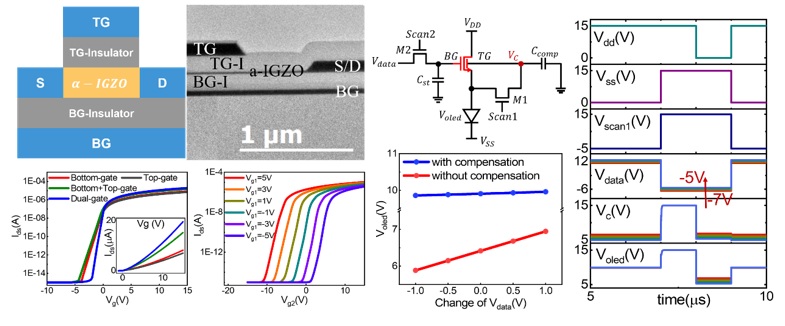

Figure 1: Example cross-section of an IGZO TFT with a dual-gate fabricated on a glass substrate. The top and bottom gates can be connected by vias through the first metal layer (M1). Silicon dioxide (SiO2) is used to insulate the gates from the active IGZO layer, to achieve the field-effect transistor. After fabrication, the glass can be detached from the polyimide layer resulting in a flexible circuit.

With such characteristics, the IGZO TFTs can be used to fabricate relatively complex circuits on flexible substrates. Consequently, IGZO TFTs are evolving beyond displays and entering the fields of wearable devices and the Internet of Things (IoT). Some highlights include an ultra-flexible circuit for recording electrocardiograms [2], radiofrequency identification (RFID) tags and near-field communication (NFC) tags [1]. Even the memory field has noticed IGZO and its extremely low OFF current and recently demonstrated a capacitor-less IGZO-based DRAM cell with a retention time longer than 400 seconds [3]. We can expect the first IGZO products beyond display applications to emerge in the near future.

As with a large majority of products, electrostatic discharge (ESD) protection is an important concern. If we are to see IGZO products enter the fields of IoT or biomedical engineering, they will have to include ESD protection.

Perhaps ESD protection is not a great concern for wireless products, for example, NFC and RFID tags which have no wired input and output ports. Here the sensitive electronic parts will not be exposed to the user as they are electrically insulated. In this case, like for displays [4,5], a good ESD control program might be enough to protect the IGZO components during assembly. The full display will, in any case, include ESD protection circuits at the system level, even perhaps at the peripherals where the electrical connections leave the display, but not necessarily at the IGZO component level. On the other hand, some wearables like the electrocardiogram patch, might not be able to affordsystem-level ESD protection circuits fabricated in a different technology other than IGZO. Since the electrodes have direct contact with the end-user, they may require ESD protection circuits at the device level. The same will be true for displays and imagers if their peripheral circuits are implemented using IGZO – to enable a fully flexible display, for example.

Yes, like any digital or analog circuit, also IGZO TFT circuits are susceptible to ESD. Even though the IGZO TFT technology nominal voltage can be as high as 10 V, degradation and breakdown can be observed already at 20 to 30 V [6]. To avoid damage to performance, the IGZO circuit should never be exposed to voltages higher than 20 V. This means the eventual ESD protection circuits should have a clamping voltage lower than 20V, which is only twice the nominal voltage. These limits depend on the IGZO technology and could change as the technology improves.

There are several challenges when designing IGZO TFT circuits in general, but perhaps the most prominent one is the fact it is a unipolar technology. Unlike the complementary metal-oxide-semiconductor (CMOS) technology integrating two types of transistors, n-type and p-type, the IGZO TFT only provides n-type transistors. Research on p-type oxide-based TFTs to complement the IGZO n-type transistor exists. Unfortunately, the p-type transistors generally have a much lower charge carrier mobility and would make the complementary design less efficient than the unipolar one [1]. Since ESD protection circuits can rarely dictate the technology evolution, ESD protection designs will most likely have to be made with unipolar circuits too.

The second challenge of the IGZO TFT technology for ESD circuit design is that there are usually no diodes available. Even though it is possible to make diodes in the IGZO TFT technology, it also increases the process cost and is not a commodity in this industry. Therefore, the best next choice would be a diode-connected transistor. The technology options to improve the ESD performance of the diode-connected transistor would be to smartly use the back-gate or to optimize the channel material resulting in larger mobility.

Luckily, the negative threshold issue that was observed in the early IGZO TFT technology improved significantly. Therefore, the significant leakage at the zero-volt bias that would be present in IGZO TFT ESD protection circuits can be solved from the technology side.

Figure 3: Drain-to-source current as function of the gate-to-source voltage measured on a dual-gate IGZO transistor shows a positive threshold voltage (top) and leakage currents below the measurement setup noise level (bottom). These data have been measured on a 5 µm by 100 µm TFT with a drain-to-source bias voltage of 50 mV.

Nevertheless, given the limited IGZO TFT conductivity, to achieve a product-worthy ESD protection level, the ESD circuits will have to be in the millimeter or even centimeter size range [5][2]. Given the IGZO TFT technology is optimized for large areas, spending these kinds of areas for ESD protection should not be a showstopper.

Unlike the silicon integrated circuit technology, there is a very limited choice of devices in IGZO, which also limits the possible solutions of ESD protection circuits. Passive devices could help with that. Inductors, capacitors, and resistors could be used as ESD protection or to complement the active devices. A spark gap could be a compact ESD protection option too.

IGZO TFT technology is a good candidate for future wearable and flexible electronic devices. If it is used in a wireless or non-contact way, consumer-side ESD protection should not be a great concern. However, if it will be used as a wearable with electrically exposed pads, it will certainly require ESD protection designs and ESD testing. In this case, the ESD testers might need to be adapted. Take the Human Body Model (HBM) ESD tester, for example. Most HBM ESD testers today target small, packaged devices in millimeter or centimeter sizes. HBM ESD testing of an IGZO TFT product might imply pins to be more than 10 cm apart. That might be challenging indeed, but perhaps some ingenious test fixtures or packaging could overcome this. Bending the flexible wearable device for ESD testing purposes could be an example.

The Transmission Line Pulse (TLP) ESD tester could be an alternative to HBM testing. Since the TLP tester is of a more academic nature than the HBM tester, it could perhaps offer more flexibility in connecting to the large IGZO circuit. Even though the TLP is a 50-Ohm tester while HBM has a typical series resistance of 1500 Ohm, we have observed comparable ESD testing results with both testers [6]. Since there is no universal conversion rule, care needs to be taken when interpreting TLP measurement results as HBM protection values.

TOKYO -- Taiwanese electronics tycoon Terry Gou was so enchanted by Sharp"s cutting-edge display technology that he had no second thoughts about buying the embattled Japanese maker when the opportunity arose.

The display technology that led the chairman of Hon Hai Precision Industry, better known as Foxconn, into signing the $3.5 billion deal to acquire Sharp uses the clunky name IGZO, from indium gallium zinc oxide.

Flexible and fully transparent thin film transistors (TFT) were fabricated via room temperature processes. The fabricated TFT on the PEN exhibited excellent performance, including a saturation mobility (μsat) of 7.9 cm2/V·s, an Ion/Ioff ratio of 4.58 × 106, a subthreshold swing (SS) of 0.248 V/dec, a transparency of 87.8% at 550 nm, as well as relatively good stability under negative bias stress (NBS) and bending stress, which shows great potential in smart, portable flexible display, and wearable device applications.

The field of transparent flexible flat panel displays and wearable sensors with smart, portable, fashion, cool and other advantages have aroused widespread concern in recent years [1,2,3,4,5], as an important component, transparent flexible thin film transistor (TFT) on metal oxides has attracted much attention [3,6,7,8,9,10]. Although the applications of transparent flexible TFTs have broad prospects, some technical problems still restrict the development and application of transparent flexible TFT to a large extent, in which the R & D of the low temperature preparation process of TFT is the most critical. At present, most flexible TFTs are prepared on flexible plastic substrates due to its excellent bendability and reliability, but the flexible plastic substrate is not resistant to high temperature, even for the most heat-resistant flexible polyimide (PI) substrate, the glass transition temperature (Tg) does not exceed 410 °C, also, the translucent nature of yellow leads to its poor application in fully transparent circuits, while the Tg of poly(ethylene 2,6-naphthalenedi-carboxylate) (PEN) and other materials with excellent transparency is only 120 °C [11]. However, the channel layer and electrodes often require thermal annealing process of more than 200 °C to realize the ideal quality and chemical structure of the films, which seriously limits the development of flexible TFT. In addition, most of the current research on flexible TFT focuses on a certain functional layer of TFT, such as electrode, dielectric layer, or semiconductor layer, etc. [12,13,14,15]. However, the process temperature of different functional layers is different, which may easily lead to performance deterioration of some functional layers or the appearance of interface defects, thus reducing the reliability of TFT. Current mainstream solutions are as follows: (i) Developing highly heat-resistant flexible substrate, there are some studies on the transparent flexible PI substrate with high temperature resistance recently [16,17], but the preparation process is difficult and the cost is high, (ii) optimizing the film preparation process to prepare films at low temperatures, especially at room temperature without any thermal annealing process can effectively solve the above problems, it will greatly simplify the process flow and greatly reduce the process cost. However, there are few studies on the preparation of flexible TFT at room temperature now.

In our previous work, we chose metal oxide materials that can be prepared at low temperatures to prepare TFT. Furthermore, high-performance AZO (Al2O3:ZnO = 2:98 wt%) electrode [13] and indium gallium zinc oxide (IGZO)/ultrathin Al2O3 channel layer [18] were prepared at room temperature by using optimized Radio Frequency Magnetron Sputtering (RFMS) and Pulsed Laser Deposition (PLD) technologies that enable the deposited atoms to acquire high kinetic energy, but the fully transparent flexible TFT has not been prepared before. In this paper, on the basis of previous research, we have succeeded in fabricating fully transparent, flexible TFTs at room temperature without any thermal annealing process, and then the electrical performance and bending reliability of TFT were characterized and analyzed, the TFT exhibited excellent electrical properties and transparency, relatively good stability under NBS and bending stress, as well as advantages of low cost, and avirulent environmental protection. It brings the industry one step closer to smart, lightweight, cheap, green flexible displays and wearable applications.

Figure 1a,b show the schematic and picture of the transparent and flexible TFTs, respectively. First of all, a 90-nm-thick AZO (Al2O3:ZnO = 2:98 wt%) gate electrode is deposited on PEN by radio frequency (RF) magnetron sputtering with the optimum condition (Power: 80 W, Pressure: 1 mTorr, Atmosphere: pure Ar). Then 320-nm-thick Al2O3 is fabricated by RF magnetron sputtering, acting as a gate insulator layer. Next, a bi-layer of 8-nm-thick IGZO and 3-nm-thick ultrathin Al2O3 serve as a channel layer. Finally, a 70-nm-thick AZO (Al2O3:ZnO = 2:98 wt%) film as S/D electrode is prepared by PLD at the optimized condition (O2 flow rate: 0 sccm, pulsing energy: 450 mJ, repeating rate: 5 Hz). The films mentioned above are all patterned by shadow masks and deposited at room temperature, the entire preparation process does not require annealing.

The interface structure, cross-sectional morphology, and composition distribution of TFTs were measured by transmission electron microscopy (TEM, JEOL JEM-2100F). The surface band structure was measured by the X-ray photoelectron emission spectroscopy using Thermo VG ESCALAB 250 photoelectron spectrometer. The electrical characterizations of TFTs were measured by the semiconductor parameter analyzer (Agilent, 4155C). The optical properties of TFTs were measured by an ultraviolet-visible spectrophotometer (shimazu uv-2600).

Firstly, we characterize the electrical properties of TFT prepared on a glass substrate and PEN substrate, as shown in Figure 2, there are only slight differences in performance between PEN-TFT and Glass-TFT, which indicates TFTs almost suffer no destruction during transfer and the preparation process to flexible substrates, and the internal stress due to the difference of elasticity between glass and PEN has little effect on TFTs. In addition, this phenomenon indicates that the penetration rate of water/oxygen in the PEN layer is low, which has little impact on the reliability of TFT, there is no need to deposit a buffer layer on the PEN, which is conducive to reducing the technical difficulty and cost.

The PEN-TFT exhibited excellent performance, including a μsat of 7.9 cm2/V·s, an Ion/Ioff ratio of 4.58 × 106, a SS of 0.248 V/dec, and a Vth of 1.04 V. Figure 3 shows the TEM images of PEN-TFT, which exhibit smooth interfaces between two adjacent layers, the good contact between interfaces can reduce the interface defects and ensure the excellent performance of TFT. Furthermore, the EDS mapping results indicate diffusionless phenomenon and the homogeneous distribution of elemental Al, Zn, In, and Ga, these are the basic conditions for the TFT device to achieve good performance.

Figure 4a–d shows the transfer characteristic curves of Glass-TFT and PEN-TFT under positive/negative gate bias stress (positive bias stress (PBS) and NBS) applying VG = +10 V and VG = −10 V for one-hour, respectively. The Von shift under PBS and NBS are compared in Figure 4e. The largest Von shift of the glass-TFT and PEN-TFT under NBS is about −0.9 V, which indicates both Glass-TFT and PEN-TFT possess good NBS stability. However, all TFTs exhibit poor PBS stability with a large positive shift of Von of approximately 5 V. To investigate the reason for the poor PBS stability, the oxygen states of IGZO/Al2O3 film are measured by X-ray photoelectron spectroscopy (XPS). M-O-M, oxygen vacancies (VO) and M-OR peaks centered at ~530, ~531, and ~532 eV are attributed to O2− ions surrounded by metal atoms, the oxide lattice with VO, and adsorbed oxygen, respectively [19,20]. As shown in Figure 4f, the high adsorbed oxygen content (31.91%) of IGZO/Al2O3 film demonstrates channel layer exist numerous adsorbed oxygen, it is well known that adsorbed oxygen can capture electron to form O− or O2−, the chemical reaction is shown in Equation (1), and the accumulation of free electrons under PBS will exacerbate the phenomenon, greater positive gate bias is required to enable the TFT to be on. Correspondingly, the chemical reaction of adsorbed oxygen is not promoted under NBS, so the NBS stability is much better than PBS stability [21].

(a) PBS and (b) NBS results of PEN-TFT, (c) PBS and (d) NBS results of Glass-TFT, (e) the Von shift of these TFTs under PBS (VG = +10 V) and NBS (VG = −10 V), (f) O1s photoelectron spectra (XPS) of IGZO/Al2O3 film.

The PEN-TFT is measured under various bending radius, and the respective parameters are summarized in Table 1. As shown in Figure 5a, the transfer characteristics show a sharp rise in Ioff as the radius decrease and the mobility of TFT decreases, but the SS increases with the increasing bending radius, Wang et al. reported a similar phenomenon in their research [22]. The degradation of TFT is related to the appearance of interfacial cracks and defects under bending stress. With the increase of bending strain, defects and cracks are likely to occur in stress concentration areas in TFT, such as the interface between dielectric layer (GI) and channel, or the interface between gate electrode and dielectric layer, the mechanism that may cause the degradation of TFT is shown in Figure 5b, the pinhole between gate electrode and dielectric layer generated by bending stress could be a charge transport channel, which will increase the IG and lead the Ioff to increase. Moreover, the defects introduced by bending stress between channel and dielectric layer not only degrade Ion, but also increase Ioff, and it will increase the scattering of carriers, resulting in decreased mobility, as shown in Table 1, the density of interface defects (Nt) increases with the increasing bending stress. In addition, cracks will be generated at the interface between the channel and the dielectric layer under large bending stress, which will weaken the control ability of the gate bias on the conductive channel, resulting in a decrease of Ion.

(a) Bending test of the flexible VL-TFT, (b) schematic diagram of TFT performance degradation under bending, (c) transmittance spectra in the wavelength range of 300~800 nm for the flexible TFT on PEN and unpatterned TFT.

Figure 5c shows the average transmittance of the PEN-TFT in the visible range can reach 87.8% at 550 nm. The unpatterned TFT (without any mask process) has all the same layers as PEN-TFT and exhibits a transparency of 58.1% at 550 nm. The improvement of transparency may be due to the decreased coverage of the device on the PEN substrate. Transparent PEN-TFT brings the industry closer to transparent, flexible, and green displays.

A comparison of the device in our work with other reported flexible transparent oxide TFTs is summarized in Table 2. According to Table 2, significant advantages of our device can be seen: (i) The fabrication of TFT does not require annealing, which has great advantages in manufacture of flexible circuit, (ii) the TFT has excellent transparency and good electrical properties, which has potential in flexible display and stealth device applications.

In summary, the flexible transparent TFTs are successfully prepared without any thermal annealing process, the optimized flexible device demonstrates excellent electrical characteristics with a μsat of 7.9 cm2/V·s, an Ion/Ioff ratio of 4.58 × 106, a SS of 0.248 V/dec, good stability under NBS, as well as good flexibility. More significantly, the as-prepared flexible device shows excellent transparency (87.8%). This kind of TFT could bring the industry one step closer to smart, lightweight, cheap, green flexible displays and wearable applications.

1. Bukke R.N., Mude N.N., Saha J.K., Lee S., Jang J. P-22: Flexible La Doped ZnO TFTs and Circuits on Polyimide Substrate for Foldable Display. SID Symp. Dig. Tech. Pap.2021;52:1135–1138. doi: 10.1002/sdtp.14894. [CrossRef]

2. Cao W., Hsu Y., Jiang Z., Liu F., Wu Y., Zhang X. High Performance Top Gate Oxide TFT Technology for Large Area Flexible AMOLED Display. SID Int. Symp. Dig. Tech. Pap.2021;52:21–24. doi: 10.1002/sdtp.14600. [CrossRef]

3. Hu Y., Guo L.Q., Huo C., Dai M., Webster T.J., Ding J. Transparent Nano Thin-Film Transistors for Medical Sensors, OLED and Display Applications. Int. J. Nanomed.2020;15:3597–3603. doi: 10.2147/IJN.S228940. PubMed] [CrossRef]

4. Ko J.B., Lee S.H., Lee T.I., Lee S., Kim J., Kim H., Kim T.S., Park S.H.K. Ultrathin, Flexible, and Transparent Oxide Thin-Film Transistors by Delamination and Transfer Methods for Deformable Displays. Adv. Mater. Technol.2021;6:2100431. doi: 10.1002/admt.202100431. [CrossRef]

9. Park H., Oh D.S., Lee K.J., Jung D.Y., Lee S., Yoo S., Choi S. Flexible and Transparent Thin-Film Transistors Based on Two-Dimensional Materials for Active-Matrix Display. ACS Appl. Mater. Interfaces.2020;12:4749–4754. doi: 10.1021/acsami.9b18945. [PubMed] [CrossRef]

10. Ha T. High-Performance Solution-Processed Zinc–Tin-Oxide Thin-Film Transistors Employing Ferroelectric Copolymers Fabricated at Low Temperature for Transparent Flexible Displays. IEEE Electron Device Lett.2016;37:1586–1589. doi: 10.1109/LED.2016.2623318. [CrossRef]

11. Sarma K.R. Handbook of Visual Display Technology. Springer International Publishing; Cham, Switzerland: 2016. Flexible Displays: Substrate and TFT Technology Options and Processing Strategies; pp. 1389–1429.

13. Zhang H., Li X., Fang Z., Yao R., Zhang X., Deng Y., Lu X., Tao H., Ning H., Peng J. Highly Conductive and Transparent AZO Films Fabricated by PLD as Source/Drain Electrodes for TFTs. Materials.2018;11:2480. doi: 10.3390/ma11122480. PubMed] [CrossRef]

18. Zheng Z., Zeng Y., Yao R., Fang Z., Zhang H., Hu S., Li X., Ning H., Peng J., Xie W., et al. All-sputtered, flexible, bottom-gate IGZO/Al2O3 bi-layer thin film transistors on PEN fabricated by a fully room temperature process. J. Mater. Chem. C.2017;5:7043–7050. doi: 10.1039/C7TC02068F. [CrossRef]

19. Yao J., Xu N., Deng S., Chen J., She J., Shieh H.D., Liu P., Huang Y. Electrical and Photosensitive Characteristics of a-IGZO TFTs Related to Oxygen Vacancy. IEEE Trans. Electron Devices.2011;58:1121–1126.

22. Wang X., Wang M., Jiang W., Zhang D., Wang H., Shan Q. Mechanical Reliability of Flexible a-InGaZnO TFTs under Dynamic Stretch Stress. IEEE Trans. Electron Devices.2018;65:2863–2869. doi: 10.1109/TED.2018.2834228. [CrossRef]

24. Zhang L., Huang C., Li G., Zhou L., Wu W., Xu M., Wang L., Ning H., Yao R., Peng J. A Low-Power High-Stability Flexible Scan Driver Integrated by IZO TFTs. IEEE Trans. Electron Devices.2016;63:1779–1782. doi: 10.1109/TED.2016.2529656. [CrossRef]

a-IGZO-based TFT fabricated via CL-ES process shows the same mask number to that of BCE process (Fig. 1). Compared with a-IGZO-based TFT with BCE structure, a-IGZO-based TFT with CL-ES structure shows two advantages: (1) a-IGZO-based backplane produced using CL-ES process deposits gate insulator, a-IGZO nano-layer, and ES nano-layer sequentially, then forms a ESL nano-mask through dry-etch method. This newly formed ESL nano-mask with 100 nm can prevent the exposure of a-IGZO nano-film to etchant, stripper, or photoresist. Therefore, the contamination at inter-layer interfaces is effectively prevented [25]. (2) At the same time, a-IGZO nano-film is not protected by ES layer but bombarded by CF4 plasma during the ESL nano-mask formation, thus becomes a conductor. This naturally forms the Ohmic contact between S/D electrode of following process and a-IGZO semiconductor. For another part, a simultaneous etching of S/D and a-IGZO nano-layer can be one overlay allowance of ESL-(a-IGZO+S/D metallization) layer, which could decrease the two overlay process error of the a-IGZO-ESL and ES-S/D metallization layer in the conventional ESL process (Fig. 2). The overlay number of the a-IGZO, ES, and S/D layer is reduced, which resulted in the decrease in the size of TFT device that lowered the parasitic capacitance. The outcome planar structure is similar to the BCE structure (Fig. 3a, b).

(Color online) Schematics of simultaneous formation method for TFT channel and S/D electrode in CL-ES process. a The first step that forms gate electrode. b The second step that forms etch-stopper layer. c The third step that forms S/D photo pattern. d The fourth step that forms S/D electrode and active pattern

Figure 3 shows the SEM images of a-IGZO-based TFTs with CL-ES structure (Fig. 3a, c) and BCE structure (Fig. 3b, d). From the top view, it is difficult to identify the differences between CL-ES structure and BCE structure (Fig. 3a, b). From the side view, an ES nano-layer can be found between the a-IGZO nano-layer and the S/D electrode layer in CL-ES structure (Fig. 3c). Meanwhile, a passivation layer can be found on the top of a-IGZO nano-layer in BCE structure (Fig. 3d). In the presented CL-ES process, an a-IGZO nano-layer with a thickness of 30 nm is deposited. Moreover, the damage during wet etching is negligible. For BCE process, a 70-nm a-IGZO nano-layer is deposited, as a-IGZO layer needs compensation for etching loss. The difference between the thicknesses of a-IGZO nano-layers in CL-ES and BCE structures can be observed in the SEM images (Fig. 3c, d).

The I-V characteristics of a-IGZO-based TFT with CL-ES structure and BCE structure are compared (Fig. 4). The saturation electron mobility, threshold voltage, subthreshold voltage swing (SS) value, and more characteristic values are summarized in Table 1. Note that the values summarized in Table 1 are the average number derived from the center and edge of an 8.5 generation glass substrate. The a-IGZO-based TFT with CL-ES structure realizes Vth of − 0.8 V, SS value of 0.18 V/dec, and saturation electron mobility of 8.05 cm2/V s. In the a-IGZO-based TFT with BCE structure, the corresponding results are Vth of + 0.5 V, SS value of 0.77 V/dec, and saturation electron mobility of 6.03 cm2/V s. Compared to the BCE structure, CL-ES structure shows an improved device performances. However, the on-current characteristic of the a-IGZO-based TFT device with CL-ES structure is lower than that with BCE-structured device. This is due to the fact that TFT channel structures are different in CL-ES and BCE structures. Generally, BCE-structured TFT channel length are the distance between S/D metal electrodes, and the measured channel length in this study is 5 um [21]. In CL-ES structure, electrodes are in contact with the a-IGZO nano-film that is stretched at the side of ESL nano-mask. Therefore, the channel length is decided by the distance between the a-IGZOs defined at the etch-stopper’s sides, but not determined by the distance between the electrodes. The channel length of the present CL-ES-structure device is measured to be 10 um.

(Color online) Comparison of I-V characteristic of a-IGZO TFTs with CL-ES and BCE structure on the center (a) and edge (b) of 8.5 generation glass substrate

As shown in Table 1, the measured values of Ion/Ioff ratio (~ 106, see Table 1) are approximately 10 times smaller than the typical value (> 107) of a-IGZO-based TFTs. This is because the measuring equipment used here is for the 8.5 generation mass production. Long cables are necessary for these measurements, as the size of the industrial equipment is large. The long cables resulted in an increased measurement noise. In the following reliability testing, smaller-scale measuring equipment is utilized, and the individual TFT devices is used as specimen for measurement. In this way, the measured Ion/Ioff ratios are all upper 107 (see below).

CL-ES process is carefully designed to prevent a-IGZO channel layer being exposed to etchant, photoresist, or stripper. During the process that produces CL-ES process, gate insulator, a-IGZO nano-layer, and ES nano-layer, each inter-layer interface is in contact with only DI water for cleaning purpose. Hence, the chemical contamination is negligible in insulator layer and a-IGZO nano-layer [25, 26]. However, the BCE process not only exposes channel layer to the chemicals but also involves Cu ion diffusion contamination, as the a-IGZO channel is directly exposed to Cu metal. This is also avoided in device with CL-ES structure. The channel region of the a-IGZO nano-film is well protected by ESL nano-mask. The low chemical contamination in CL-ES process may lead to a low carrier trap density at the interface between a-IGZO nano-layer and insulator layer, resulting in an excellent SS value. This low chemical contamination of a-IGZO-based TFT device via CL-ES process also helps improve the uniformity and reproducibility of a-IGZO TFT, which are highly important in industrial production [27, 28].

Figure 5 shows the measured I-V characteristic of TFTs with CL-ES structure and BCE structure derived from 42 measuring points on an 8.5 generation substrate. a-IGZO-based TFT with CL-ES structure has a Vth range of 0.72 V, while that of BCE-structured device is 2.14 V (Table 1). In other words, the uniformity of device performance is significantly improved by CL-ES structure.

(Color online) a CL-ES structure. b BCE structure’s TFTs I-V transfer characteristic. c 42 measuring points. d the photo of TFT. All measured on an 8.5 generation substrate

Figure 6a, b show the I-V characteristic shift of CL-ES-structured device and BCE-structured device obtained in NBTIS testing, respectively. The NBTIS testing results are summarized in Table 2. Under the stress condition described in the Table 2, the Vth shift of CL-ES-structured device and BCE-structured device are − 0.51 and − 3.88 V, respectively. Additionally, the on-current shift, off-current shift, and SS value variance of the CL-ES-structured device are all lower than those of the BCE-structured device (Table 2); this is because a-IGZO-based device with CL-ES-structure can effectively prevent the contamination of a-IGZO and lower carrier trap density of a-IGZO TFT channel. Especially, when looking at the result from first 1000 s of stress, no SS value change is observed in CL-ES-structured device. This phenomenon is comparable to the 0.16 V/dec increase in SS value of BCE-structured device, as it shows that defect sites, which can form carrier traps on the surface of a-IGZO nano-film constituting CL-ES TFT back channel, are not additionally created by electrical and illumination stress. These results fully prove that CL-ES-structured device is much more stable than BCE-structured device. Figure 6c, d show the I-V curve shift of CL-ES- and BCE-structured TFTs obtained from PBTS testing. The detailed PBTS testing results are summarized in Table 3. Both CL-ES-structured TFT and BCE-structured TFT have decreased in ion current during PBTS evaluation. This is caused by the shift in Vth to the positive direction. During PBTS evaluation, residual ion current ratio [(last ion/initial ion) × 100] of the CL-ES-structured TFT with relatively smaller Vth positive shift (+ 1.94 V) is in the level of 88.2%. When compared to the BCE-structured TFT"s residual ion current ratio of 41.3%, CL-ES-structured TFT is significantly superior. This shows the important capacity difference during designing of gate drive on array (GOA) circuit. Different from NBTIS, SS value of CL-ES-structured TFT does not have significant variation ((∆SS 0.06 V/dec), or rather decreases (∆SS − 0.86) like as BCE-structured TFT. This is perhaps due to the carriers, accumulate in the inner space and interface between gate insulator and a-IGZO nano-film by positive gate bias, filling the carrier trap site at the early stage, causing decrease in carrier trap phenomenon. Moreover, the threshold voltage shift phenomenon occurs by carrier charge trapped near the interface between gate insulator and a-IGZO nano-film. Small threshold voltage shift of CL-ES-structured TFT represents that the interface and the inner space of a-IGZO are remarkably clean. In conclusion, PBTS testing also suggests that CL-ES structure and process lead to a better device reliability.

To overcome the technological and economic obstacles of amorphous indium-gallium-zinc-oxide (a-IGZO)-based display backplane for industrial production, a clean etch-stopper (CL-ES) process is developed to fabricate a-IGZO-based thin film transistor (TFT) with improved uniformity and reproducibility on 8.5th generation glass substrates (2200 mm × 2500 mm). Compared with a-IGZO-based TFT with back-channel-etched (BCE) structure, a newly formed ES nano-layer ( 100 nm) and a simultaneous etching of a-IGZO nano-layer (30 nm) and source-drain electrode layer are firstly introduced to a-IGZO-based TFT device with CL-ES structure to improve the uniformity and stability of device for large-area display. The saturation electron mobility of 8.05 cm2/V s and the V th uniformity of 0.72 V are realized on the a-IGZO-based TFT device with CL-ES structure. In the negative bias temperature illumination stress and positive bias thermal stress reliability testing under a ± 30 V bias for 3600 s, the measured V th shift of CL-ES-structured device significantly decreased to - 0.51 and + 1.94 V, which are much lower than that of BCE-structured device (- 3.88 V, + 5.58 V). The electrical performance of the a-IGZO-based TFT device with CL-ES structure implies that the economic transfer from a silicon-based TFT process to the metal oxide semiconductor-based process for LCD fabrication is highly feasible.

To overcome the technological and economic obstacles of amorphous indium-gallium-zinc-oxide (a-IGZO)-based display backplane for industrial production, a clean etch-stopper (CL-ES) process is developed to fabricate a-IGZO-based thin film transistor (TFT) with improved uniformity and reproducibility on 8.5th generation glass substrates (2200 mm × 2500 mm). Compared with a-IGZO-based TFT with back-channel-etched (BCE) structure, a newly formed ES nano-layer (~ 100 nm) and a simultaneous etching of a-IGZO nano-layer (30 nm) and source-drain electrode layer are firstly introduced to a-IGZO-based TFT device with CL-ES structure to improve the uniformity and stability of device for large-area display. The saturation electron mobility of 8.05 cm 2 /V s and the V th uniformity of 0.72 V are realized on the a-IGZO-based TFT device with CL-ES structure. In the negative bias temperature illumination stress and positive bias thermal stress reliability testing under a ± 30 V bias for 3600 s, the measured V th shift of CL-ES-structured device significantly decreased to - 0.51 and + 1.94 V, which are much lower than that of BCE-structured device (- 3.88 V, + 5.58 V). The electrical performance of the a-IGZO-based TFT device with CL-ES structure implies that the economic transfer from a silicon-based TFT process to the metal oxide semiconductor-based process for LCD fabrication is highly feasible.

IGZO-TFT (Indium Galium Zinc Oxide-Thin Film Transistor) is a promising technology for controlling large display areas and large area sensors because of its very low leakage current in the off state and relatively low cost. IGZO has been used as a switching gate for a large area flat-panel detector. The photon counting capability for X-ray medical imaging has been investigated and expected for low-dose exposure and material determination. Here the design and fabrication of a charge sensitive preamplifier and analog counter using IGZO-TFT processes and its performance are reported for the first time to be used for radiation photon counting applications.

A visible-blind ultraviolet (UV) photodetector was designed based on a three-terminal electronic device of thin-film transistor (TFT) coupled with two-terminal p-n junction optoelectronic device, in hope of combining the beauties of both of the devices together. Upon the uncovered back-channel surface of amorphous indium-gallium-zinc-oxide (IGZO) TFT, we fabricated PEDOT:PSS/SnO x /IGZO heterojunction structure, through which the formation of a p-n junction and directional carrier transfer of photogenerated carriers were experimentally validated. As expected, the photoresponse characteristics of the newly designed photodetector, with a photoresponsivity of 984 A/W at a wavelength of 320 nm, a UV-visible rejection ratio up to 3.5 × 10 7 , and a specific detectivity up to 3.3 × 10 14 Jones, are not only competitive compared to the previous reports but also better than those of the pristine IGZO phototransistor. The hybrid photodetector could be operated in the off-current region with low supply voltages (<0.1 V) and ultralow power dissipation (<10 nW under illumination and ∼0.2 pW in the dark). Moreover, by applying a short positive gate pulse onto the gate, the annoying persistent photoconductivity presented in the wide band gap oxide-based devices could be suppressed conveniently, in hope of improving the response rate. With the terrific photoresponsivity along with the advantages of photodetecting pixel integration, the proposed phototransistor could be potentially used in high-performance visible-blind UV photodetector pixel arrays.

An immunosensor is proposed based on the indium-gallium-zinc-oxide (IGZO) electric-double-layer thin-film transistor (EDL TFT) with a separating extended gate. The IGZO EDL TFT has a field-effect mobility of 24.5 cm2 V-1 s-1 and an operation voltage less than 1.5 V. The sensors exhibit the linear current response to label-free target immune molecule in the concentrations ranging from 1.6 to 368 × 10-15 g/ml with a detection limit of 1.6 × 10-15 g/ml (0.01 fM) under an ultralow operation voltage of 0.5 V. The IGZO TFT component demonstrates a consecutive assay stability and recyclability due to the unique structure with the separating extended gate. With the excellent electrical properties and the potential for plug-in-card-type multifunctional sensing, extended-gate-type IGZO EDL TFTs can be promising candidates for the development of a label-free biosensor for public health applications.

In this study, InGaZnO (IGZO) thin film transistors (TFTs) with a dual active layer (DAL) structure are fabricated by inserting a homogeneous embedded conductive layer (HECL) in an amorphous IGZO (a-IGZO) channel with the aim of enhancing the electrical characteristics of conventional bottom-gate-structure TFTs. A highly conductive HECL (carrier concentration at 1.6 × 1013 cm-2, resistivity at 4.6 × 10-3 Ω∙cm, and Hall mobility at 14.6 cm2/Vs at room temperature) is fabricated using photochemical H-doping by irradiating UV light on an a-IGZO film. The electrical properties of the fabricated DAL TFTs are evaluated by varying the HECL length. The results reveal that carrier mobility increased proportionally with the HECL length. Further, a DAL TFT with a 60-μm-long HECL embedded in an 80-μm-long channel exhibits comprehensive and outstanding improvements in its electrical properties: a saturation mobility of 60.2 cm2/Vs, threshold voltage of 2.7 V, and subthreshold slope of 0.25 V/decade against the initial values of 19.9 cm2/Vs, 4.7 V, and 0.45 V/decade, respectively, for a TFT without HECL. This result confirms that the photochemically H-doped HECL significantly improves the electrical properties of DAL IGZO TFTs. PMID:25435832

In this study, InGaZnO (IGZO) thin film transistors (TFTs) with a dual active layer (DAL) structure are fabricated by inserting a homogeneous embedded conductive layer (HECL) in an amorphous IGZO (a-IGZO) channel with the aim of enhancing the electrical characteristics of conventional bottom-gate-structure TFTs. A highly conductive HECL (carrier concentration at 1.6 × 10(13) cm(-2), resistivity at 4.6 × 10(-3) Ω∙cm, and Hall mobility at 14.6 cm(2)/Vs at room temperature) is fabricated using photochemical H-doping by irradiating UV light on an a-IGZO film. The electrical properties of the fabricated DAL TFTs are evaluated by varying the HECL length. The results reveal that carrier mobility increased proportionally with the HECL length. Further, a DAL TFT with a 60-μm-long HECL embedded in an 80-μm-long channel exhibits comprehensive and outstanding improvements in its electrical properties: a saturation mobility of 60.2 cm(2)/Vs, threshold voltage of 2.7 V, and subthreshold slope of 0.25 V/decade against the initial values of 19.9 cm(2)/Vs, 4.7 V, and 0.45 V/decade, respectively, for a TFT without HECL. This result confirms that the photochemically H-doped HECL significantly improves the electrical properties of DAL IGZO TFTs.

The deposition of the top gate dielectric in thin film transistor (TFT)-based dual-gate ion-sensitive field-effect transistors (DG ISFETs) is critical, and expected not to affect the bottom gate TFT characteristics, while providing a higher pH sensitive surface and efficient capacitive coupling between the gates. Amorphous Ta2O5, in addition to having good sensing properties, possesses a high dielectric constant of ˜25 making it well suited as the top gate dielectric in a DG ISFET by providing higher capacitive coupling (ratio of C top/C bottom) leading to higher amplification. To avoid damage of the a-IGZO channel reported to be caused by plasma exposure, deposition of Ta2O5 by e-beam evaporation followed by annealing was investigated in this work to obtain sensitivity over the Nernst limit. The deteriorated bottom gate TFT characteristics, indicated by an increase in the channel conductance, confirmed that plasma exposure is not the sole contributor to the changes. Oxygen vacancies at the Ta2O5/a-IGZO interface, which emerged during processing, increased the channel conductivity, became filled by optimum annealing in oxygen at 400 °C for 1 h, which was confirmed by an x-ray photoelectron spectroscopy depth profiling analysis. The obtained pH sensitivity of the TFT-based DG ISFET was 402 mV pH-1, which is about 6.8 times the Nernst limit (59 mV pH-1). The concept of capacitive coupling was also demonstrated by simulating an a-IGZO-based DG TFT structure. Here, the exposure of the top gate dielectric to the electrolyte without applying any top gate bias led to changes in the measured threshold voltage of the bottom gate TFT, and this obviated the requirement of a reference electrode needed in conventional ISFETs and other reported DG ISFETs. These devices, with high sensitivities and requiring low volumes (˜2 μl) of analyte solution, could be potential candidates for utilization as chemical sensors and biosensors.

In this study, we investigated how the structure and oxygen flow rate (OFR) during the sputter-deposition affects the photo-responses of amorphous indium-gallium-zinc-oxide (a-IGZO)-based photodetector devices. As the result of comparing three types of device structures with one another, which are a global Schottky diode, local Schottky diode, and thin-film transistor (TFT), the IGZO TFT with the gate pulse technique suppressing the persistent photoconductivity (PPC) is the most promising photodetector in terms of a high photo-sensitivity and uniform sensing characteristic. In order to analyze the IGZO TFT-based photodetectors more quantitatively, the time-evolution of sub-gap density-of-states (DOS) was directly observed under photo-illumination and consecutively during the PPC-compensating period with applying the gate pulse. It shows that the increased ionized oxygen vacancy (VO2+) defects under photo-illumination was fully recovered by the positive gate pulse and even overcompensated by additional electron trapping. Based on experimentally extracted sub-gap DOS, the origin on PPC was successfully decomposed into the hole trapping and the VO ionization. Although the VO ionization is enhanced in lower OFR (O-poor) device, the PPC becomes more severe in high OFR (O-rich) device because the hole trapping dominates the PPC in IGZO TFT under photo-illumination rather than the VO ionization and more abundant holes are trapped into gate insulator and/or interface in O-rich TFTs. Similarly, the electron trapping during the PPC-compensating period with applying the positive gate pulse becomes more prominent in O-rich TFTs. It is attributed to more hole/electron traps in the gate insulator and/or interface, which is associated with oxygen interstitials, or originates from the ion bombardment-related lower quality gate oxide in O-rich devices.

We report two-step annealing, high temperature and sequent low temperature, for amorphous indium-gallium-zinc-oxide (a-IGZO) thin-film transistor (TFT) to improve its stability and device performance. The annealing is carried out at 300 oC in N2 ambient for 1 h (1st step annealing) and then at 250 oC in vacuum for 10 h (2nd step annealing). It is found that the threshold voltage (VTH) changes from 0.4 V to -2.0 V by the 1st step annealing and to +0.6 V by 2nd step annealing. The mobility changes from 18 cm2V-1s-1 to 25 cm2V-1s-1 by 1st step and decreases to 20 cm2V-1s-1 by 2nd step annealing. The VTH shift by positive bias temperature stress (PBTS) is 3.7 V for the as-prepared TFT, and 1.7 V for the 1st step annealed TFT, and 1.3 V for the 2nd step annealed TFT. The XPS (X-ray photoelectron spectroscopy) depth analysis indicates that the reduction in O-H bonds at the top interface (SiO2/a-IGZO) by 2nd step annealing appears, which is related to the positive VTH shift and smaller VTH shift by PBTS.

We report a tunneling contact indium-gallium-zinc oxide (IGZO) thin film transistor (TFT) with a graphene interlayer technique in this paper. A Schottky junction is realized between a metal and IGZO with a graphene interlayer, leading to a quantum tunneling of the TFT transport in saturation regions. This tunneling contact enables a significant reduction in the saturation drain voltage Vdsat compared to that of the thermionic emission TFTs, which is usually equal to the gate voltage minus their threshold voltages. Measured temperature independences of the subthreshold swing confirm a transition from the thermionic emission to quantum tunneling transports depending on the gate bias voltages in the proposed device. The tunneling contact TFTs with the graphene interlayer have implications to reduce the power consumptions of certain applications such as the active matrix OLED display.

Device characteristics changes in an a-IGZO thin film transistor under light illumination and at raised temperature have been investigated. Light exposure causes a large leakage current, which is more obvious with an increase in the illumination energy, power and the temperature. The increase in the leakage current is due to the trap assisted photon excitation process that generates electron-hole pairs and the mechanism is enhanced with the additional thermal energy. The leakage current comes from the source side because holes generated in the process drift to the source side and therefore lower the barrier height. The above mechanism has been further verified with experiments of drain bias induced shifts in the threshold voltage and the subthreshold slope.

An amorphous indium-gallium-zinc-oxide (a-IGZO) thin film transistor (TFT) was fabricated by a self-aligned imprint lithography (SAIL) method with a sacrificial photoresist layer. The SAIL is a top-down method to fabricate a TFT using a three-dimensional multilayer etch mask having all pattern information for the TFT. The sacrificial layer was applied in the SAIL process for the purpose of removing the resin residues that were inevitably left when the etch mask was thinned by plasma etching. This work demonstrated that the a-IGZO TFT could be fabricated by the SAIL process with the sacrificial layer. Specifically, the simple fabrication process utilized in this study can be utilized for the TFT with a plasma-sensitive semiconductor such as the a-IGZO and further extended for the roll-to-roll TFT fabrication.

We present a gas sensitive thin-film transistor (TFT) based on an amorphous Indium-Gallium-Zinc-Oxide (a-IGZO) semiconductor as the sensing layer, which is fabricated on a free-standing flexible polyimide foil. The photo-induced sensor response to NO₂ gas at room temperature and the cross-sensitivity to humidity are investigated. We combine the advantages of a transistor based sensor with flexible electronics technology to demonstrate the first flexible a-IGZO based gas sensitive TFT. Since flexible plastic substrates prohibit the use of high operating temperatures, the charge generation is promoted with the help of UV-light absorption, which ultimately triggers the reversible chemical reaction with the trace gas. Furthermore, the device fabrication process flow can be directly implemented in standard TFT technology, allowing for the parallel integration of the sensor and analog or logical circuits.

We present a gas sensitive thin-film transistor (TFT) based on an amorphous Indium–Gallium–Zinc–Oxide (a-IGZO) semiconductor as the sensing layer, which is fabricated on a free-standing flexible polyimide foil. The photo-induced sensor response to NO2 gas at room temperature and the cross-sensitivity to humidity are investigated. We combine the advantages of a transistor based sensor with flexible electronics technology to demonstrate the first flexible a-IGZO based gas sensitive TFT. Since flexible plastic substrates prohibit the use of high operating temperatures, the charge generation is promoted with the help of UV-light absorption, which ultimately triggers the reversible chemical reaction with the trace gas. Furthermore, the device fabrication process flow can be directly implemented in standard TFT technology, allowing for the parallel integration of the sensor and analog or logical circuits. PMID:29373524

We report a high-performance amorphous Indium-Gallium-Zinc-Oxide (a-IGZO) thin-film transistor (TFT) with new copper-chromium (Cu-Cr) alloy source/drain electrodes. The TFT shows a high mobility of 39.4 cm 2 ·V - 1 ·s - 1 a turn-on voltage of -0.8 V and a low subthreshold swing of 0.47 V/decade. Cu diffusion is suppressed because pre-annealing can protect a-IGZO from damage during the electrode sputtering and reduce the copper diffusion paths by making film denser. Due to the interaction of Cr with a-IGZO, the carrier concentration of a-IGZO, which is responsible for high mobility, rises.

In this work, a high-performance inverter based on amorphous indium-gallium-zinc oxide thin-film transistors (TFTs) has been fabricated, which consists of a driver TFT and a load TFT. The threshold voltage (Vth) of the load TFT can be tuned by applying an area-selective laser annealing. The transfer curve of the load TFT shows a parallel shift into the negative bias direction upon laser annealing. Based on x-ray photoelectron spectroscopy analyses, the negative Vth shift can be attributed to the increase of oxygen vacancy concentration within the device channel upon laser irradiation. Compared to the untreated inverter, the laser annealed inverter shows much improved switching characteristics, including a large output swing range which is close to full swing, as well as an enhanced output voltage gain. Furthermore, the dynamic performance of ring oscillator based on the laser-annealed inverter is improved.

We report a high-performance amorphous Indium-Gallium-Zinc-Oxide (a-IGZO) thin-film transistor (TFT) with new copper-chromium (Cu-Cr) alloy source/drain electrodes. The TFT shows a high mobility of 39.4 cm2·V−1·s−1 a turn-on voltage of −0.8 V and a low subthreshold swing of 0.47 V/decade. Cu diffusion is suppressed because pre-annealing can protect a-IGZO from damage during the electrode sputtering and reduce the copper diffusion paths by making film denser. Due to the interaction of Cr with a-IGZO, the carrier concentration of a-IGZO, which is responsible for high mobility, rises. PMID:28773743

In this study, flexible double-gate thin-film transistor (TFT)-based amorphous indium-galliumzinc- oxide (a-IGZO) was fabricated on a polyimide substrate. Double-gate operation with connected front and back gates was compared with a single-gate operation. As a result, the double-gate a- IGZO TFT exhibited enhanced electrical characteristics as well as improved long-term reliability. Under positive- and negative-bias temperature stress, the threshold voltage shift of the double-gate operation was much smaller than that of the single-gate operation.

Decreasing the active layer thickness has been recently reported as an alternative way to achieve fully depleted oxide thin-film transistors for the realization of low-voltage operations. However, the correlation between the active layer thickness and device resistivity to environmental changes is still unclear, which is important for the optimized design of oxide thin-film transistors. In this work, the ambient gas stability of IGZO thin-film transistors is found to be strongly correlated to the IGZO thickness. The TFT with the thinnest IGZO layer shows the highest intrinsic electron mobility in a vacuum, which is greatly reduced after exposure to O2/air. The device with a thick IGZO layer shows similar electron mobility in O2/air, whereas the mobility variation measured in the vacuum is absent. The thickness dependent ambient gas stability is attributed to a high-mobility region in the IGZO surface vicinity with less sputtering-induced damage, which will become electron depleted in O2/air due to the electron transfer to adsorbed gas molecules. The O2 adsorption and deduced IGZO surface band bending is demonstrated by the ambient-pressure x-ray photoemission spectroscopy results.

In this study, we fabricate the amorphous indium gallium zinc oxide (a-IGZO) thin-film transistors (TFTs) on a stretchable substrate with a buffer stage and investigate the mechanical stability and electrical characteristics when the length of the substrate is stretched by 1.7 times. The buffer stage is responsible for the stiffness modulation of the stretchable substrate. The mobility, the threshold voltage and the on/off ratio of the stretchable a-IGZO TFT are measured to be 18.1 cm2/V·s, 1 V, and 3 × 107, respectively. Our simulation conducted by a three dimensional finite elements method reveals that the stiffness modulation reduces the stress experienced by the substrate in the stretched state by about one-tenth. In addition, the mechanical stability and electrical characteristics of the a-IGZO TFT are maintained even when the substrate is stretched by 1.7 times.

Pulse thermal processing (PTP) has been explored for low thermal budget integration of indium gallium zinc oxide (IGZO) thin film transistors (TFTs). The IGZO TFTs are exposed to a broadband (0.2-1.4 m) arc lamp radiation spectrum with 100 pulses of 1 msec pulse width. The impact of radiant exposure power on the TFT performance was analyzed in terms of the switching characteristics and bias stress reliability characteristics, respectively. The PTP treated IGZO TFTs with power density of 3.95 kW/cm 2 and 0.1 sec total irradiation time showed comparable switching properties, at significantly lower thermal budget, to furnace annealed IGZO TFT.more » The typical field effect mobility FE, threshold voltage VT, and sub-threshold gate swing S.S were calculated to be 7.8 cm 2/ V s, 8.1 V, and 0.22 V/ decade, respectively. The observed performance shows promise for low thermal budget TFT integration on flexible substrates exploiting the large-area, scalable PTP technology.« less

Pulse thermal processing (PTP) has been explored for low thermal budget integration of indium gallium zinc oxide (IGZO) thin film transistors (TFTs). The IGZO TFTs are exposed to a broadband (0.2-1.4 m) arc lamp radiation spectrum with 100 pulses of 1 msec pulse width. The impact of radiant exposure power on the TFT performance was analyzed in terms of the switching characteristics and bias stress reliability characteristics, respectively. The PTP treated IGZO TFTs with power density of 3.95 kW/cm 2 and 0.1 sec total irradiation time showed comparable switching properties, at significantly lower thermal budget, to furnace annealed IGZO TFT.more » The typical field effect mobility FE, threshold voltage VT, and sub-threshold gate swing S.S were calculated to be 7.8 cm 2/ V s, 8.1 V, and 0.22 V/ decade, respectively. The observed performance shows promise for low thermal budget TFT integration on flexible substrates exploiting the large-area, scalable PTP technology.« less

We report solution-processed, amorphous indium-gallium-zinc-oxide-based (a-IGZO-based) thin-film transistors (TFTs). Our proposed solution-processed a-IGZO films, using a simple spin-coating method, were formed through nitrate ligand-based metal complexes, and they were annealed at low temperature (250 °C) to achieve high-quality oxide films and devices. We investigated solution-processed a-IGZO TFTs with various thicknesses, ranging from 4 to 16 nm. The 4 nm-thick TFT films had smooth morphology and high-density, and they exhibited excellent performance, i.e. a high saturation mobility of 7.73 ± 0.44 cm2 V-1 s-1, a sub-threshold swing of 0.27 V dec-1, an on/off ratio of ~108, and a low threshold voltage of 3.10 ± 0.30 V. However, the performance of the TFTs degraded as the film thickness was increased. We further performed positive and negative bias stress tests to examine their electrical stability, and it was noted that the operating behavior of the devices was highly stable. Despite a small number of free charges, the high performance of the ultrathin a-IGZO TFTs was attributed to the small effect of the thickness of the channel, low bulk resistance, the quality of the a-IGZO/SiO2 interface, and high film density.

The recent rise in the market for consumer electronics has fueled extensive research in the field of display. Thin-Film Transistors (TFTs) are used as active matrix switching devices for flat panel displays such as LCD and OLED. The following investigation involves an amorphous metal-oxide semiconductor that has the potential for improved performance over current technology, while maintaining high manufacturability. Indium-Gallium-Zinc-Oxide (IGZO) is a semiconductor material which is at the onset of commercialization. The low-temperature large-area deposition compatibility of IGZO makes it an attractive technology from a manufacturing standpoint, with an electron mobility that is 10 times higher than current amorphous silicon technology. The stability of IGZO TFTs continues to be a challenge due to the presence of defect states and problems associated with interface passivation. The goal of this dissertation is to further the understanding of the role of defect states in IGZO, and investigate materials and processes needed to regulate defects to the level at which

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey