saw technology touch screen monitors factory

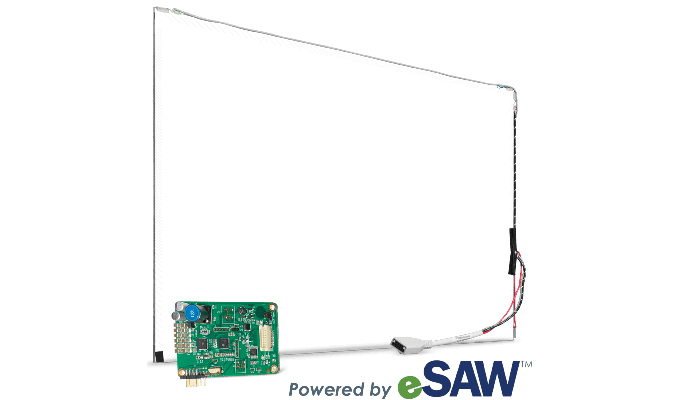

IntelliTouch Surface Acoustic Wave (SAW) is a cost-effective alternative to projected capacitive (PCAP) touch technology that offers better optical clarity with significantly smaller border width and an edge designed for your bezeled applications. Three axes of touch information are used to precisely discern two simultaneous touch locations anywhere on the screen. IntelliTouch solutions offer a simple bill of material, a less complex manufacturing and touchscreen integration process, and less capital investment than PCAP technologies. When combined with Elo"s 3200-series controller, powered by eSAW™ technology, IntelliTouch offers an extreme touch performance of 4Xs the sensitivity of traditional SAW touchscreens.

SAW touchscreen technology delivers superior image clarity, resolution, light transmission, and reliability because it utilizes clear glass that continues to work even if scratched. There are no coatings, plastic films or moving parts to wear out or be damaged. The active area of the touchscreen is resistant to chemicals such as acetone, toluene, methyl ethyl ketone, isopropyl alcohol, methyl alcohol, ethyl acetate, ammonia-based glass cleaners, gasoline, kerosene, and vinegar.

Customization capabilities include logos, clear icons, border buttons, and other enhancements can be added during the design cycle. IntelliTouch can scale across a wide range of screen sizes, without performance degradation. With SecureTouch®, the strength of the touchscreen can be increased by increasing the thickness of the glass up to 12mm.

Elo’s new state of the art facility in Suzhou, China occupies a quarter of a million square feet and includes 155,000 square feet of manufacturing space with adjacent offices and warehouses. It is home to Elo’s industry leading touchscreen solutions including AccuTouch 5-wire resistive, IntelliTouch surface acoustic wave and TouchPro projected capacitive touchscreens.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

With evolving technology, surface acoustic wave (SAW) touch screens have emerged as an excellent choice for touch panels. It is one of the advanced touch screen solutions available in the market. SAW touch screens are integrated with applications utilized in ATMs, amusement parks, public information kiosks, computer-based training and other high traffic indoor environments.

When compared to capacitive and resistive touch screens, SAW technology appears to be superior in several ways. It offers great optical clarity, and higher transmission of light. The all-glass construction with no coatings to wear out contributes to the longer life of this touch screen. This touch panel is highly sensitive and respond quickly. It has a unique ability to be activated by different touch inputs. It can recognize the location swiftly upon touch.

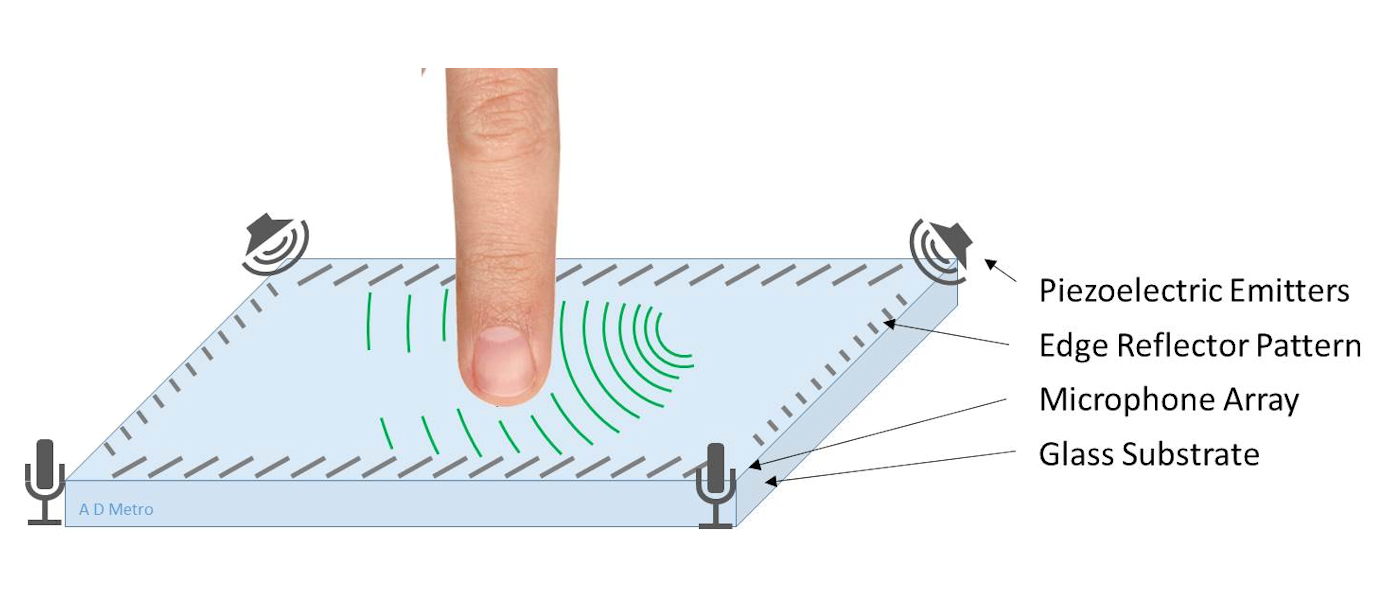

SAW touchscreens rely upon ultrasonic sound waves and make use of them for touch detection. The surface acoustic wave touch screen consists of one glass sheet with two transmitting transducers, two receivers, and sound wave reflectors placed along the edges of the glass. The transmitting transducers generate ultrasonic waves that travel over the panel surface.

When a finger or stylus makes contact with the touch surface, a portion of the wave is absorbed. This change in the ultrasonic waves registers the position of the touch event and sends this information to the controller for processing. The touchpoint is detected with a drop in the amplitude of the sound wave in corelation with the timing on when the sound was expected to be heard by the microphones.

However, with SAW touch screens, you must keep in mind that touch detection in this technology can be affected by a large amount of dirt, dust, water droplets etc. therefore, it is not recommended for rugged or outdoor applications.

SAW touch screens offer attractive, simple to implement, and cost-effective solutions. It would be an ideal pick for image clarity and sensor durability. And for a more reliable solution in SAW technology, it would be a good choice go with A D Metro who provides a complete line of Surface Acoustic Wave (SAW) touch screens kits, bundled with a controller and USB or RS232 interface.

With the latest in display technology, the 42″ Comark Fire & Life Safety 42″ 16:9 Touchscreen Display brings data to life like never before. This bright (700-nit) screen features surface acoustic wave touchscreen technology, for better image clarity, screen resolution, lighter pressure response, and longer life than other touch screens. It’s also available as a standard display if you just need a large, UL864 certified display. All Comark displays can be further customized to meet specific industry or technical needs.

A touch screen display can be found nearly everywhere. You interact with a touchscreen monitor constantly; they have become very commonplace in our daily lives. Cell phones, ATM’s,kiosks, ticket vending machines,manufacturing plantsand more all use touchscreen monitors. Touch displays enable the user to interact with a computer, control system or device without the use of a keyboard or mouse.

TRU-Vu Monitors offers a wide range of industrial touch screen display monitors, including Sunlight Readable touch screens, panel mount touch monitors and Medical touch screens with P-Cap touch. We also offer Resistive touch, Capacitive touch, SAW touch, and IR industrial touch panels, with USB and RS-232 interfaces. New models are HID Compliant, eliminating the need to load drivers. We provide the best heavy duty LCD touch screen panels for industrial use; all are TAA-Compliant. Which one Is right for you?

The most important decision in choosing the best touch screen display for your application will be the type of touch technology screens to use. There are five major types of touch screens, each with its own advantages and disadvantages. Some have multi touch capability. All are TAA-Compliant touch screens. The 5 major types of touch screen technology are:

Touch screens will obviously require cleaning and disinfecting due to the high number of contact and touch points. Special care must be taken not to damage the touch screen display face, especially for 5-wire resistive touchscreen monitors. Their surface can easily be permanently damaged by corrosive cleaning agents (bleach, ammonia, etc.) or abrasive materials (dirty cloths, steel wool). Please see ourmonitor cleaning guidelines, andmonitor COVID-disinfecting guidelinesfor more specific details. These guidelines will help ensure you keep your touch screens clean, and safely disinfected from germs or viruses.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

Our industrial display touch screen monitors can help your factory personnel and workshops handle complex industrial tasks on intuitive factory grade touch screens. Our wide range of rugged LCD displays with multi-touch and various touch technologies such as resisitive, SAW, optical imaging, projected capacitive and infrared are tough and suitable for virtually any industrial applications. We can help you choose the best touch screen technology and solution that fits best with your needs, and close the gap between your vision and implementation of the digital factory.

Viewsonic"s Touch Screen Solutions helped us simplify the hassle of operating complex machinery in our factory. It really helped us improve our factory line operations and reduced labor input.”

Take a look at the figure. Surface acoustic wave touch screen consists of one glass sheet with transmitting transducers, receiving transducers, and reflectors. Transmitting transducers generate ultrasonic waves that travel over the panel surface. The ultrasonic waves are reflected by the reflectors and received by the receiving transducers.

SAWs are sent out from the transmitting transducers, and traveling along the edge of panel. The reflectors located on the edge of the panel change directions of the SAWs at the angle of 90 degrees, thus the SAWs travel over the panel. Once the SAWs reached the other side of the panel, their directions get changed again by the reflectors located on the other side, and travel toward the receiving transducers. Once the SAWs are received by the receiving transducers, they will be converted into electric signals.

I see. If it is touched by a finger, the SAWs will be absorbed by it and do not reach to the receiving transducer. Then, the sensor detects where the SAWs were absorbed?

Good guess! As shown in the figure, there are routes on which the SAWs travel from the transmitting transducers to the receiving transducers. Each route has its own distance. If one of the routes is touched by a finger, the pulse will be absorbed, and the SAW on the route will not be received by the receiving transducers. Thus, the sensor will recognize which route was touched, and locate the touched point.

SAW touch screen is notable for its durability. It has long life, and its glass surface is strong against scratch. Even though the panel surface gets scratched, its sensing function will not be affected.

SAW is usually employed for large size applications such as kiosk, arcade game, automated cash dispenser, medical equipment, office automation, factory automation, financial field, and so on.

A Surface Acoustic Wave (SAW) touch screen works slightly differently than other touch technologies. The SAW touch screens use special transducers that are mounted on the edge of the panel. These so-called transducers create an invisible grid of ultrasonic waves across the surface, which are collected by receivers. This is where the name surface acoustic wave comes from.

When a user touches the screen, some waves are absorbed. The receivers localize the touch and send this information to the controllers of the touch screen. SAW touch screens work with a finger, without or with glove, or special soft pen. They can only register one touch at a time.

Each sound wave spreads across the screen by bouncing off reflector arrays along the edges of the display, and is detected by two receivers for each axis.

When the user touches the glass surface of the display, some of the energy of the acoustic wave is absorbed by the water content of the user’s finger.

The controller measures the time at which the received amplitude dips to determine the X and Y coordinates of the touch location. In addition to the X and Y coordinates, SAW technology can also provide Z axis (depth) information.

Science fiction has always served as a window into a potential future, namely in the way of technology. But what was once regulated to episodes of Star Trek is quickly becoming the stuff of reality. Many fixtures of these kinds of shows and books have begun to inspire real-life counterparts, including - but not limited to - touchscreen technology.

One only has to look at how far cell phones have come since their inception. Physical keyboards, like those from BlackBerry, gave people about as much of a solution as is possible for those who found themselves doing more on the devices as they became more advanced. Where tactile options came up short, touchscreens graciously stepped up to bat, providing a much fuller experience. This kind of functionality then spread to tablets, which are considered by many to be rivals of laptops and even standard PCs.

While there are still some things that are best done on a desktop computer, that does not change the fact that many users find themselves longing for the same abilities on their PCs afforded by many of their mobile devices. This is what helped breed the touchscreen monitor market, which has many viable options for people seeking the best of both worlds. With stronger computing power and a finer ability to control actions occurring in the screen, users can get more work done in new and exciting ways.

Traditionally, computer mice are what have allowed us to "touch" in a virtual context, but touchscreen monitors are changing all that. It might be said that the reason that mice were used in the first place was because the technology had not evolved to a responsive enough level to enable that natural solution. Now that people have the touchscreen technology, they want it everywhere.

If one thing is for certain, it is that the burgeoning adoption of touchscreen technology is no fad. Proliferation has already come too far to turn back now, and computer manufacturers are taking notice. Everyone is trying to get a piece of the action, including ELO Touch Solutions, Laiputuo Electronics, Planar, HP, 3M, Touch Systems, ViewSonic, Dell and ACER as well. Getting into the touchscreen monitor game is a no-brainer for the companies involved in this generation of computing. With so many different applications made for touchscreen monitors, options exist for all sorts of interested parties.

Touchscreen monitors are becoming the new standard in both private and enterprise settings. Here are some of the ways they can be leveraged effectively for business: touchscreen monitors for workstations, touchscreen monitors for hospitals, and touchscreen monitors for POS systems.

Newegg offers a large selection of touchscreen monitors which vary according to the type from 5-wire Resistive touchscreen monitors, and Accu Touch touchscreen monitors, to Capacitive touchscreen monitors, and more. Newegg’s wide selections will definitely meet your needs.

The Elo Touch Solutions 1515L touch monitor is designed, developed and built to provide a cost-effective touch solution for system integrators and VARs. It packs Elo quality and reliability into a integrated, affordable touchmonitor with a footprint smaller than a standard 15" display. This cost and space-saving touch monitor is "designed for touch"- the technology is built into the 1515L from the ground up and not added as an afterthought by altering the original monitor. It includes a stable base, with controls that are placed on the side rather than the front and are locked-out for public use. The 1515L can function as a desktop or wall-mounted unit and includes a VESA mounting option. The optional 3-track magnetic stripe reader (MSR), is easily installed by the user, providing an elegant, integrated solution. The display is factory sealed against dirt and dust, and the unit offers a choice of touchscreen technologies: the anti-glare clarity and superior performance of IntelliTouch surface acoustic wave, time- tested AccuTouch five-wire resistive, and IntelliTouch Pro projected capacitive (PCAP) for a multi-touch experience and zero-bezel, seamless design.

The Elo 1515L 15" LCD desktop touch monitor provides an affordable product in a convenient, space- saving design that both first-time and experienced users can deploy more easily, reliably, and more cost- effectively than ever before.

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey