lcd panel test equipment manufacturer

Aside from Cold Cathode Fluorescent Lamp (CCFL), low voltage, long life, mercury-free LED Back Light Units are a new trend in today’s LCD technology. When in the cell process of an LCM testing solution, various defects can be inspected by shorting-bar signals and repaired with lasers. Based on the panel sizes and backlight features (CCFL or LED BLU) in the LCM process, the tests of LCM voltage, current and power can be used to analyze an images lit pixel, dead pixel, color and resolution with both software and hardware using a video signal source plus programmable power supply administered by a user-friendly PC interface. This solution not only incorporates an automatic conveyor production line, but also utilizes integrated network management for data collection and analysis.

Try using lcd screen testing machine found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd screen testing machine to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd screen testing machine are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd screen testing machine at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd screen testing machine on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

The QuickTest™ II+ performs rapid statistical Qualification and QC testing on cell phone displays, hand-held displays, and other small format LCD and OLED displays. QuickTest™ II+ is a successor to our QuickTest™ system which is installed at LCD manufacturing facilities world-wide.

In the past, Qualification and QC testing of cell phone displays often involved a dark room laboratory with optical instruments mounted on home-made fixtures. The testing was labor intensive and took too long to acquire significant statistical data. This resulted in very long test times for qualification testing and limited QC verification. With its integrated instruments, display drive, and powerful software, QuickTest II+ makes rapid qualification testing and QC testing possible!

Today, semiconductor and LCD panel manufacturing equipment is essential for the production of all kinds of electric and electronic appliances, including PCs, cell phones and flat-panel televisions. Advances in this equipment promote enhancements to PC performance and cell phone functions, and enrich people"s lives by reducing the cost of flat panel TV sets. THK"s products can meet this kind of high-technology need for fine movement control.

Compact ball screws and Caged Ball LM Guides exhibiting very smooth movement are used in highly efficient production systems used for LCD panels for car navigation systems and mobile tools.

In order to test the electrical characteristics of LCD panel substrates, the measuring instrument must be capable of positioning the substrates accurately over a wide area. LM Guides and ball screws, machined to a high level of accuracy, can provide this tracking control and contribute to efficient manufacturing even as the size of the substrates increases.

In addition to the robotic touch testing, the test system is also able to carry out a variety of different tests, so to verify all the product characteristics within a single test stage:

Optical inspection. Pattern matching test, dead pixel recognition, backlight brightness and color test can be performed to ensure the display is defect-free, with an accuracy able to verify the goodness of every pixel also on the newest microLED technologies.

Electrical test. The test system can house all the resources to contact and test electrical and electronic parts of the device, recognizing defective parts and detecting process defects (such as open pins and short circuits)

Acoustic test. Correct sound emission from the device (e.g. when a buzzer is present) can be verified via dedicated, robotic units. Extreme accuracy can be guaranteed by anechoic chambers.

Scott Testing Machines, once the industry leader in a wide variety of tensile testing categories and still widely used in many industries, designed their equipment in the pre-digital era.

With the rapid advances in computer hardware and software over the past twenty years a whole new breed of electronic testers has emerged, with digital LCD panels, software and load cells capable of far greater accuracy. Mechanical testers have largely disappeared from the tensile testing landscape.

Time to scrap your old Scott Testing Machine and move on? Not so fast. Many Scott test machines can easily be converted to a digital weighing system, allowing companies to stretch their quality budgets in many ways while achieving a wide range of benefits.

Improved Accuracy. A digital conversion replaces the old analog dial face and pointer with an LCD Panel with bright, easy to read numbers at operator level and a state of the art electronic load cell.

Reduced Operating Expenses. Perhaps the biggest benefit to a Scott conversion is the capital investment required. Most Scott DH, J, L, Q and X series mechanical testers can be converted for $1400-$1800. By comparison, a new entry level electronic tester with similar capacity ranges and basic controls starts around $10,000.

But the benefits don’t stop after the purchase. A digital conversion eliminates all the moving mechanical parts of the weigh head. Bearings no longer need to be changed every year, pawls don’t need replacing, cracked pointers and dial faces no longer need repair, etc. Most of the common repair items performed for these testers are eliminated.

Lastly, the cost of training new and existing employees is also greatly minimized versus the steep learning curve required converting to a new electronic machine. The Scott Testing Machine after conversion is used the exact same way it was before. The only difference is the LCD Display. In fact, there are less steps required of the operator with a converted machine. This can be a huge benefit to companies that use testers on the production floor where employees may have little or no quality training control training, companies that have a large number of employees or where established QC technicians have been using the machine “the same way” for many years.

Scott Testing Machines were built to last. Heavy metal frames and gear boxes that have been in service for decades provide a solid foundation for materials properties testing. Adding the latest digital technology to this platform ensures your Scott equipment will continue to be in use for decades to come.

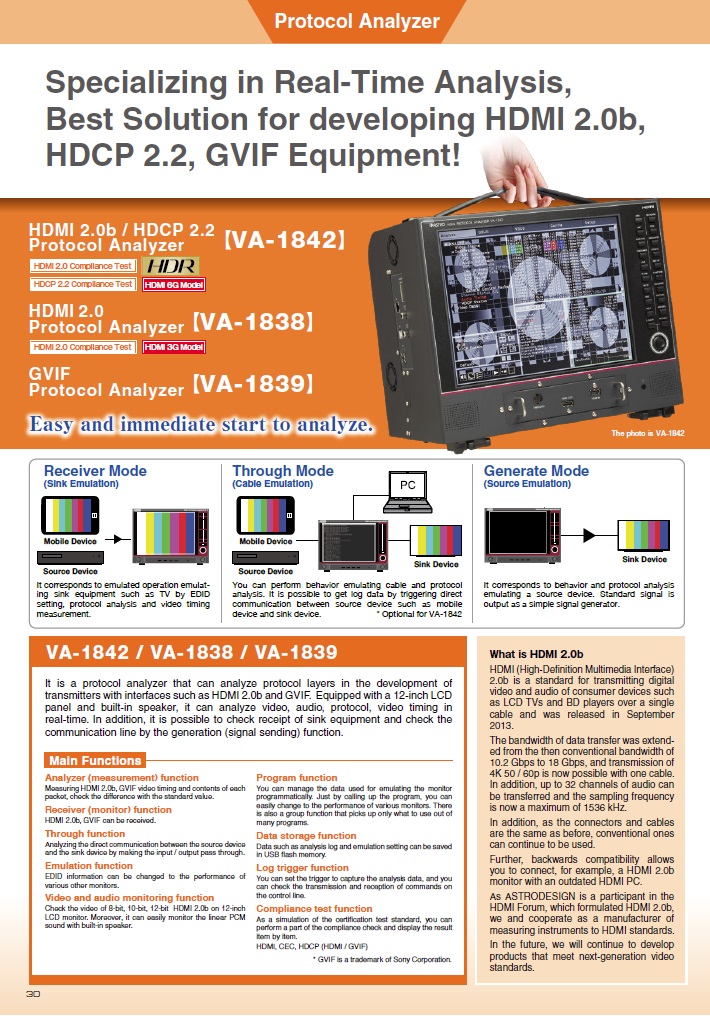

Along with the development of technology, the display device has also become a flat panel from the cathode ray tube, and the items required for the evaluation of the display have changed significantly. In recent years, the connection interface between devices has changed from analog to digital and various interfaces corresponding to the purpose have appeared, so new functions are constantly being demanded for evaluation and inspection as well. HDMI, which is widely used for connecting home video equipment. We have focused on this HDMI from the earliest and are the only HDMI protocol testing equipment manufacturer in Japan. In addition to home appliance video equipment, display devices, semiconductors, etc., the market is expected to expand also in relation to automobile and medical equipment in the near future.

Yes, the Panel and Inverter are on MFR"s production schedule for at least 8 years. National Test Equipment will carry spare parts for immediate shipment when necessary.

Abachy.com is a specialized platform that includes Business Directory, News, Jobs and Marketplace sections dedicated to semiconductor, photonics, nanotechnology, electronics, solar energy, flat panel display, LED and superconductor topics. Here you can find the semiconductor manufacturing industry suppliers, news, post your jobs.

Voltage requirements are increasing, especially for the EV market. Even devices that might be considered relatively low voltage, such as display drivers, are now pushing past established baselines. Learn how testing SiC and GaN devices is evolving in the market and which gaps remain.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey