can you repair tv lcd screen made in china

Broken screen replacement service is provided from thousands of repairs stores and phone parts wholesalers worldwide, iPhone of which are mostly engaged in. So how to purchase reliable LCD screens among so many quality grades from China suppliers? Let me firstly elaborate on the quality grades of the iPhone LCD digitizer assembly that most repair stores and traders used to replace the broken ones.

According to the investigation, 90% of the Chinese iPhone LCD screen suppliers are found selling third-party manufactured screens and seldom sell genuine original LCD screens. Therefore, if your phone screen is broken, there would be a high chance for your screen to be replaced with a non-original one. Why? Maybe the cost and quality are relatively competitive, so why not?

As known, Foxconn is authorized to assemble iPhone, so there are some original iPhone LCD screens leaked from the assemble factory. And there are brought out from the factory for replacement. However the price is definitely high and still, some people care more about the quality of the screen than how much they cost, so for this group of customers, the Original Quality of LCD digitizer assemblies are preferred.

For some LCD digitizers, the LCDs are still working while the front glasses are broken, which can be recycled. Some factories recycled these broken screens by removing the broken front glass and attach a new one, then the LCD digitizer assembly would be new again, which is what called refurbished. Brand new original LCD screens are limited, and the refurbished ones can replenish the shortage of the new original LCD digitizer assemblies, for their quality would be more stable than the third-party manufactured.

Some Chinese factories purchase the original single LCD display, not compete LCD screen from the original factory, and then attach high copy front glass, backlight, etc, materials into a complete LCD screen, which quality is not stable and the display color is slightly different from the ones with high copy backlight. Well, their price would be cheaper and loved by many repair shops and wholesalers.

Under the shortage of original LCD screens, many Chinese factories begin to produce the high copy LCD screen. The stock and supply are getting less and less since about 2015, which leads the price goes higher and higher. Therefore the Chinese manufacturer starts to produce LCD screens with high copy raw materials. With competitive prices and good quality that meet most iPhone users’ needs, they are also popular among many wholesalers and repair shops.

With the premium quality of LCD and OLED screens tested strictly, we’ve helped many clients enlarge their markets worldwide. If you wholesale the LCD digitizer assembly or retail them in your repair shop, more information and sample are supported for your reference, please do not hesitate to contact us or leave your comment to discuss more.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Unfortunately, in most cases, you cannot fix a broken TV screen. TV manufacturers do not sell screen replacements, and there is no secondary market for used screens. That’s because the screen is the most expensive part of the TV, by far. Replacing it would cost more than buying a new TV!

In many cases, your local electronics or TV repair shop won’t even consider working on your broken TV screen. They know that it’s just not worth their time.

If you bought your TV recently, chances are incredibly high that it came from China. Specifically, the BOE Technology factory in Hefei, the capital of China’s Anhui Province.

The BOE factory, where most US TV screens are made today, is almost a mile long and cost about 7 BILLION dollars to build! Sony, Samsung, LG, Vizio, etc. all buy their TV screens from BOE.

“Liquid Crystal display screens are made by putting two thin sheets of glass together. On one of the sheets transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through. That’s how you can get electrical signals to the middle of a screen.

Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts. This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen. Each step has to be precisely aligned to the previous one within a few microns. Remember, the average human hair is 40 microns in diameter.”

This is the number one reason your TV screen is so costly – they are incredibly challenging to build, and as a result there are only a few companies in the world that make them.

I’ve also heard that only 1 out of every 3 TV screens pass testing at the END of the manufacturing process. That means 2 out of every 3 screens made are worthless!

The screens are made in China and then have to be shipped across the world to be sold in the US. The cost to ship them is high, and a lot of damage can happen during the journey.

So the complexity, and shipping both contribute to the high cost of TV screens. It’s why no one sells the screen separately, it just doesn’t make financial sense.

If your TV screen has an imperfection, discoloration, lines, streaks, spots, etc., then there is a good chance that your warranty will cover it (if it’s within the allotted time period). Most TV warranties are in place for the first year, and they cover these types of manufacturer defects.

And the even better news here is thatthe majority of issues you’re likely to encounter with your TV will happen within the first year (when you’re covered by the manufacturer).

You can always try selling it. Your broken TV isn’t worth much, but to the right person, it’s worth something. Someone who knows what they are doing will take your TV apart, and sell off each individual piece.

Technically, you could do this yourself, but it’s time consuming and you risk damaging the parts. I wouldn’t bother. Instead, try listing the whole TV for sale. Getting something for a broken TV it is better than nothing.

If it turns out no one is willing to buy it, you can try listing it on those same marketplaces for free!Tons of people usually respond when they can get something for no cost, even if it’s broken.

Find a local electronics recycler. There are a lot of these out there. You can look up the closest one to you using Earth911’s website. Type in “TV” and then your Zip Code to find the nearest option to you. Once you find the closest location, you just have to drop off your TV.

Local electronics stores typically recycle products that they sell. A great example of this is Best Buy. They have a nationwide recycling program. But keep in mind, they will charge you a small fee!

Your town likely collects e-waste. Check out your town/cities trash website and see what their policies are for electronic waste. Some towns have special pick up days, others have drop off locations. I would just call your city’s public works department and ask for a place to recycle or dispose of old electronics.

Buy a TV screen protector. You can buy a screen that covers your TV and protects it against damage, and many are waterproof! These provide great added protection from possible bumps and contact with liquids from pets and children.

Mount your TV on the wall.This way your television is up off the ground, and out of reach. It won’t stop your kids from throwing a toy at it, but at least they can’t bump into it, or accidentally knock something, or someone into it.

Don’t allow video games. This might sound harsh (especially for the kids), but I’ve heard too many stories of Nintendo Wii controllers being accidentally thrown at the TV. If you don’t hook up a video game console to your TV, this can’t happen.

Most TV repair shops won’t even bother trying to fix a broken screen. In the end, between a screen replacement and the repair costs, you’d spend the same amount for a brand new TV!

If your TV is cracked or damage because of something you did, your warranty is unlikely to cover it. In that case, consider selling your broken TV or disposing of it.

The wiring connections to the screen would have to match between the old display and the new. By that I mean that the wires coming from the system board would have to perform the same functions when connected to the same points on the new display. For this you would have to know the internal wiring details of both the old and the new display panels. It would also have to have the same type of cable connector as well.

One way that might possibly work is to open the phone and see if there is a part number printed on the back of the LCD panel itself. Using just the number try searching online to see if you get results.

Most LCD panels be it for TV, Monitors , Phones etc., are made by specialist LCD panel manufacturers who make to order for the device manufacturer. Also don"t be surprised that even if you find the manufacturer that you will not be able to purchase it directly from them.

You could also search places like Ebay etc where your particular model phone may be offered for sale as faulty good for parts where it appears that the LCD screen is undamaged and possibly still working but cannot verify as the phone doesn"t work at all. You could always contact the seller and ask was it working before the phone failed, was the phone dropped etc., and hope for honest answers. Then it depends on how much you are prepared to gamble, money wise, hoping that the LCD is at least OK, so that you can swap it over.

If you have two identical phones, one with a faulty screen and the other with a working screen but not working otherwise then you could swap the good into the faulty but to re-purpose it between different brands or even different models you would have to know its" input wiring connections so that it would be suitable to use somewhere else.

As you can see from the schematic (scroll down a bit) in the link below the example shows the LCD having 16 input leads. There is no standard as to what function goes onto what input as the LCD manufacturer would make to order from the device manufacturer to suit whatever particular requirements.

The best that I can suggest is that you offer it for sale (or for free) as faulty -good for parts, LCD works on places such as Ebay, Gumtree, etc. to minimize the amount going to landfill. You might be surprised at the response as usually the major problem with devices is a broken screen which is hard to source, especially on the lesser known brands. So if it is re -usable by someone else you have minimized, as best you can, the amount going to landfill (the other phone is repaired instead of replaced, again with less landfill and your phone has less parts being sent to landfill by the new owner - basically one completely faulty phone being sent instead of two partially faulty), and also perhaps you have recouped a little cash towards the purchase of a new phone.

They filed a Swiss patent for the idea on Dec. 4, 1970. Though it attracted scant attention at the time, the milestone now stands as the birthdate of the liquid crystal display (LCD) – the technological platform which has transformed consumer electronics and presented a brilliant new way to view the world.

Early LCD developers took a few years to figure out that specialty glass, not plastic, was the best stable substrate for the delicate LCD circuitry and the color backplane component. Once they did, they turned increasingly to Corning to supply them with extraordinarily stable, flat, fusion-formed glass, able to preserve the critical properties of the liquid crystal and withstand high processing temperatures.

And LCDs rapidly transformed from “passive matrix” models, mostly used in pocket calculators and digital watches, to “active matrix” LCDs in which each sub-pixel was controlled with an isolated thin-film transistor. AMLCDs enabled wide viewing angles; brilliant, fast-moving images; and high-resolution images that had never been possible before.

Corning Incorporated was a critical player in this development, and eventually became the world’s leading supplier of LCD glass substrates. And Corning® EAGLE XG® Glass, the world’s first LCD substrate with no arsenic or other heavy metals, went on to exceed sales of 25 billion square feet, making it one of the most successful products in Corning’s history.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

Stripping: High concentration of alkali solution (NaOH solution) is used as a stripping solution to peel off the remaining photoresist on the glass so that ITO glass can form ITO graphics exactly consistent with the photolithography mask.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Television is a very intimate object in our daily lives. It not just entertains and informs us about the happenings around us, but it also helps unite families at several houses as we binge on our favourite movies and TV shows together. And despite it being the age of hand-held gadgets, there are still enough people around who prefer television to mobile. No doubt, it feels terrifying when your beloved TV gets a cracked screen.

Though a cracked TV screen is not something that happens so often. But when it happens, not any random mechanic should be assigned the task of repairing it. Instead, only the experts who know the job in and out should be called upon.

Besides, here’re some important things and suggestions, directly from our experts, you must go through before moving ahead on cracked tv screen repair

Firstly, the question is how TV screens can get cracked. Well, there are umpteen reasons to cause this. In most cases, it is accidentally damaged. Your child kicking or hitting at a ball that, unfortunately, lands up at the heart of the TV! Or, the television, placed precariously at the edge of a table, tips over and develops a crack! And at times, you may drop it while either moving or installing it. So it’s advisable to place your TV out of kids’ reach, and you had better not allow kids to play balls in that room. Also, its installation and movement (from one place to another) should be immaculately done, preferably with the help of trained professionals.

Now, the next question is what if your TV screen does get cracked? Is it the end of the story (as some internet articles seem to claim) or you can still get it repaired successfully?

Access the Damage: When a TV screen cracks, there could be several levels of severity and you could be dealing with anything from a completely dead screen to small lines in the picture, and no-picture, no-sound to poor picture quality.

Unless you’re skilled at electronics, you should not try to fix the problem at home, especially if it’s a flat-screen CRT. Most often than not, you end up touching it wrong and are likely to get a serious jolt.

Check Your TV Warranty: A feasible thing to do here is, bring out the papers and check if the TV is still within the warranty period. If yes, then all you need to do is to take the TV to the authorized service centre (Please, make sure to contact the guys only at an authorised service centre to get genuine services). Most probably, you will earn a free repair or a paid repair or a replacement (depends on the reason behind the damage and the sub-clauses in the warranty contract from your TV manufacturer/supplier).

Get A Professional, Authorized Repair:Taking your TV to a professional, authorized service center is your best choice to get your TV screen back to life. If you spot any such issue in your Synix TV screen, walk down to your nearest Carlcare service center immediately. Our trained TV technicians will check it thoroughly and give proper detail of the damage, as well as providing a cost-effective repairing. We are skilled in fixing cracked TV screen of various brands. In case your TV is not a recent purchase and the warranty period has lapsed, we ensure you the best repair at the best prices, combined with authentic and professional advice from our experts.

TV experts at Carlcare can determine the extent of the damage to give it a fix that’s needed. A minor crack may not be difficult to repair and may not be all that expensive. A slightly deeper crack or multiple cracks may be irreparable or may require replacement. In either case, you can rest assured that we will never misguide you but assist you with the best of our intentions.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

Alibaba.com offers 8,127 tv screen replacement products. such as advertising publish, exhibition hall, and shopping mall. You can also choose from video wall, digital poster, and touch screen. As well as from ntsc(60hz), pal(50hz), and 120hz. And whether tv screen replacement is hotel tv, bathroom tv, or portable tv.

In 1991, a business unit called Samsung Display was formed to produce the panels used in products made by its parent company, Samsung Electronics. Afterward, it was a leading supplier of LCD panels not just for Samsung Electronics but for other companies in the industry as well.

The business received a stay of execution when the pandemic led to a global surge in demand for consumer electronics, but that demand is now declining, and projections aren"t good for LCD panel revenue.

Add to that the fact that emerging technologies like QD-OLED are the future for TV and monitors, and the case for keeping Samsung Display"s LCD business going becomes a hard one to make.

Samsung Display will now focus heavily on OLED and quantum dot. Most of the employees working in the LCD business will move to quantum dot, the publication claims.

Even if there isn"t a statement about a change in direction, the writing has been on the wall for Samsung"s LCD business. Unless something radical changes, it"s more a question of when than if at this point.

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

One of my relatives had this exact symptom happening all of a sudden. This problem on low-end TVs often occurs within the first couple years. As the repair costs for that kind of TV is pretty low, considering repairing it yourself might be a good idea!

The first step into repair is to find the root cause of the issue. As backlight failure is a very common issue, this is the first thing to test. To do so, the easiest way is to power on your screen, put a flashlight very close to it and check if you can see the image through. The image would be very dark, like turning the brightness of the screen very very low.

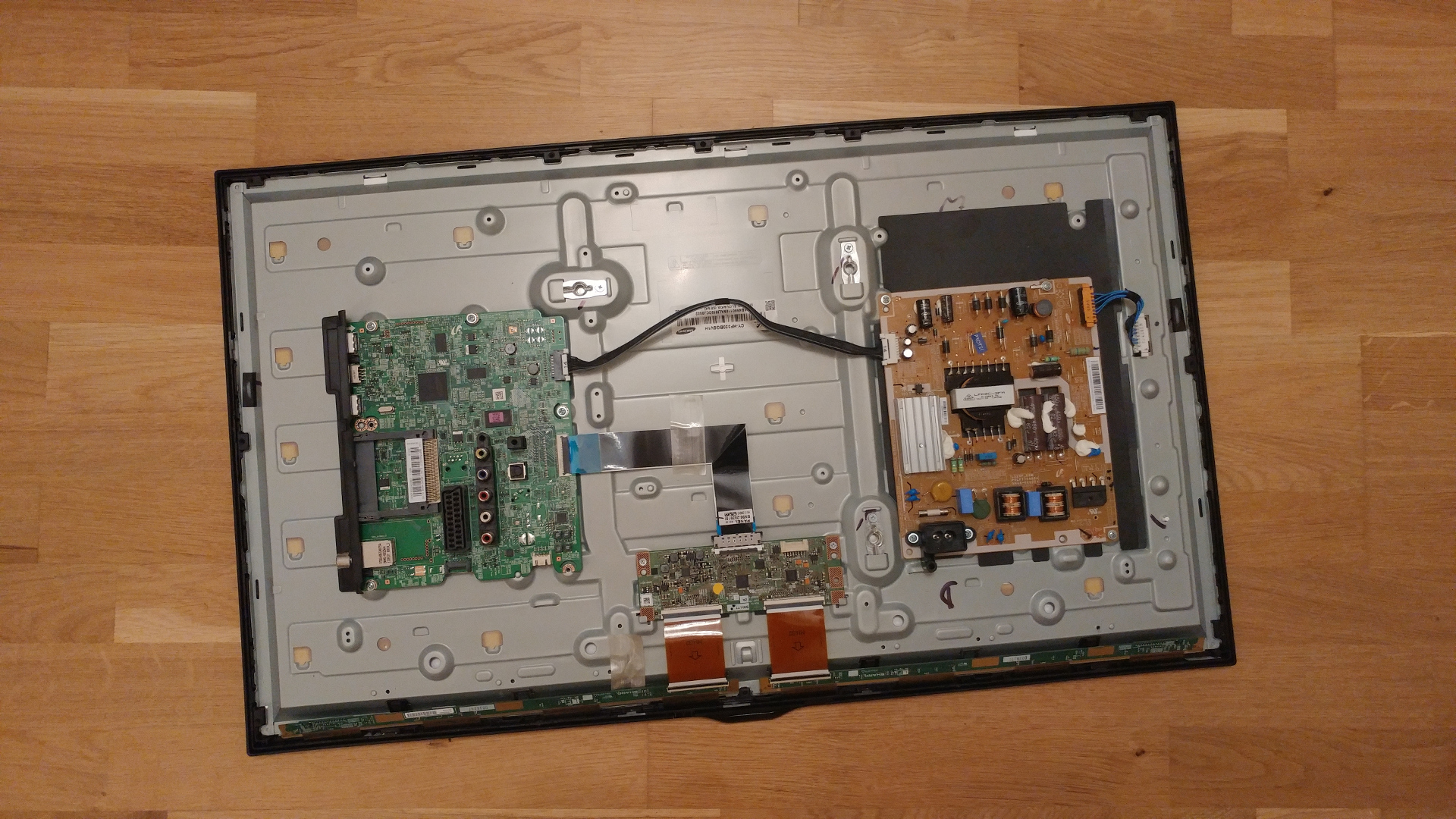

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

As we can see, the backlight system is made of 5 LED strips. First thing to do is look for burnt LEDs. Most LED backlight systems have strips set in series, meaning that if one of the them fails, all the system goes dark…

Using a multimeter, we can confirm that the strips are indeed set in series, so now we have to test each strip individually. Professionals use LED testers such as this one (about 40$ on amazon) but as I didn’t had one at the time, I decided to make one, McGyver style!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey