attaching lcd panel to ramps board for sale

This Smart Controller contains a SD-Card reader, an rotary encoder and a 128x64 LCD display. You can easy connect it to your Ramps board using the "smart adapter" included. After connecting this panel to your Ramps you don"t need your pc any more, the Smart Controller supplies power for your SD card. Further more, all actions like calibration, axes movements can be done by just using the rotary encoder on the Smart Controller. Print your 3D designs without PC, just with a g-code design stored on the SD card.

Compares to the 2004 Smart LCD Controller With Adapter, this 128x64 screen can display much more information, which would help for you run the 3D printer without a computer.

LED background light control circuit, a small function of intelligent controller, With pin short time to decide on all LED turn or steering 30 seconds

You can turn on the light time to do long or short form of the adjustment TRIMM R4100K from 10 seconds to 2 minutes If you use a print job at night and parts department, which means that the new modifications LCD backlight would be suitable for you

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

PO Box, APO/FPO, Afghanistan, Alaska/Hawaii, Algeria, American Samoa, Angola, Armenia, Azerbaijan Republic, Bahrain, Bangladesh, Benin, Bermuda, Bhutan, Botswana, Burkina Faso, Burundi, Cambodia, Cameroon, Cape Verde Islands, Central African Republic, Chad, China, Comoros, Congo, Democratic Republic of the, Congo, Republic of the, Cook Islands, Côte d"Ivoire (Ivory Coast), Djibouti, Equatorial Guinea, Eritrea, Ethiopia, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Gabon Republic, Gambia, Georgia, Ghana, Guam, Guernsey, Guinea, Guinea-Bissau, Guyana, Hong Kong, Iraq, Jersey, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Lebanon, Lesotho, Liberia, Libya, Macau, Madagascar, Malawi, Maldives, Mali, Marshall Islands, Mauritania, Mauritius, Mayotte, Micronesia, Mongolia, Morocco, Mozambique, Namibia, Nauru, Nepal, New Caledonia, Niger, Niue, Oman, Pakistan, Palau, Papua New Guinea, Qatar, Reunion, Russian Federation, Rwanda, Saint Helena, Saint Pierre and Miquelon, Saudi Arabia, Senegal, Seychelles, Sierra Leone, Solomon Islands, Somalia, Sri Lanka, Suriname, Swaziland, Tajikistan, Tanzania, Togo, Tonga, Tunisia, Turkmenistan, Tuvalu, US Protectorates, Uganda, Ukraine, United Arab Emirates, Uzbekistan, Vanuatu, Vietnam, Wallis and Futuna, Western Sahara, Western Samoa, Yemen, Zambia, Zimbabwe

After connecting this panel to your Ramps you don"t need your pc any more, the Smart Controller supplies power for your SD card. Further more all actions like calibration, axes movements can be done by just using the rotary encoder on the Smart Controller. Print your 3D designs without PC, just with a g-code design stored on the SD card.

The connector nearest the wider end of the L-shaped "smart adaptor" is #2; the other is #1. Looking at the bottom face of the display card, with the ribbon cables going away from you (so the encoder, buzzer, and reset switch are to your right), the left socket is #1, and the right socket is #2.

On the back of the panel in the top right corner is a tiny trimpot labelled "Contr". This is a fragile part, so be very gentle when turning it. The ideal tool is a plastic "TV alignment tool".

About: Avid 3D printer builder, currently completing my 3rd printer design. If you like what you see and maybe even implement what provide, consider supporting subscribing to my youtube channel https://www.youtube.co…

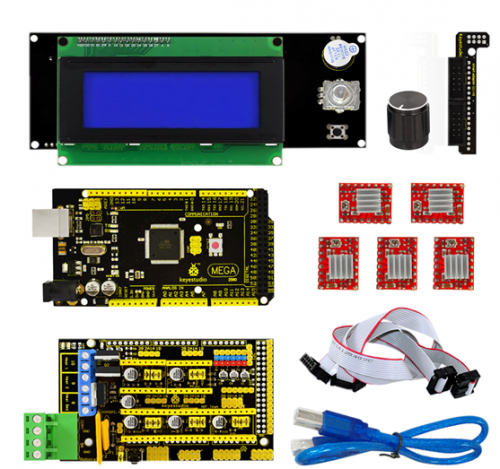

In this instructable I will walk through all the components and steps required to setup a 3D Printer using the most commonly used RAMPS 1.4 controller board.

Please note that although most components on the 3D printer run 12Volts and less. You do need to connect your power brick to 110 Volts. BE CAREFULL, YOU ARE DEALING WITH LIVE POWER.

There are many other boards on the market and I"ve personally had good luck with the KFB2.0 board with acts almost identical to the RAMPS 1.4 but uses slightly different connectors.

The Type of extruder you purchase is up to you. You can choose from Direct Extrusion (motor on the Extruder) or a Bowden type of extrusion (motor feeds filamant through a tube to Hot-end) but it won"t make a difference in hooking them up.

it was pointed out, some of the pictures show wires directly screwed into components. It best to use fork connectors and ferrules for better connectivity:

The Shield should fit right on top of the Arduino board. The USB port on the Arduino should be on the same side as the Green power connector on the Shield. Make sure that all the pins from the bottom of the shield line up with the connectors on the Arduino. Push both boards snuggly together (this may sting a little)

Before adding the Stepper Drivers you need to decide what type of micro stepping is needed by the 3D Printer. I"m not going explain what exactly it means (there is plenty of articles on that). in general, when you buy a 1.8 deg. step angle (200 steps/revolution), the micro stepping becomes a multiplier. What"s important is that for the RAMPS 1.4 most precise stepping is 1/16th micro stepping (16 x 200 = 3200 steps/rotation).

In order to instruct the hardware to use 1/16th micro stepping, jumpers are added between the banks in which the stepper drivers will fit. For 1/16th stepping you need to add three jumpers under each driver. Make sure they are on straight, it"s easy to plunge one of these past the actual pin.

VERY IMPORTANT!! Note how the drivers A4988 Stepper drivers above have a little potentiometer on top (this little phillips screw). When inserting your stepper Driver MAKE SURE THE POTENTIOMETER POINTS AWAY FROM THE BOARDS POWER END (GREEN CONNECTOR).

If you are still unsure: Find a labeled pin on one or more corners of the stepper driver board (DIR, GND, ENABLE, VMOT) and match it up to the RAMPS pinouts.

I hate to say this but, sometimes you"ll find that the bays for these stepper drivers are too close, or the edges of your stepper driver are a bit too wide. In the image above you can see a gap between the top two drivers, whereas the bottom ones barely fit. It might make for a very tight fit and in cases where it doesn"t fit, you may have to file some of the edges from the stepper driver.

It"s a bit hard to see on the smart Adapter I have here, but but you can kind of make out that the left connector (10 pins) says EXP2 and the right connector says EXP1. These correspond with the EXP1 and EXP2 connectors on the LCD board

power comes in on two tracks into the Ramps 1.4 shield. One track is 12V 5A which powers the board and motors, the second track is 12V 11A which powers the heated elements like the extruder and heated bed.

Connect the wires as seen in the images. Be careful, as you can see, the 110V live wire is exposed. Unplug your power source prior to lifting the lid accessing the screws.

Also, note that when you plug in the RAMPS 1.4 with a USB cable to your computer the LCD will come one and you can program the Arduino that way. There is no power to run any motors or heating elements though. For that, you do need the external power source.

Stepper motors come in many varieties and with different power specifications. The printer built in the previous instructable uses Nema 17 0.4Amp Stepper motors. These aren"t the strongest steppers but they do just fine. My CoreXY printer that can handle more speed/torque runs 2.0Amp stepper motors.

Generally the Nema 17 Stepper motors and associated cables are configured correctly, so when you plug them in, they"ll run at first try. If your stepper motor is making funky jumps or just shakes, it generally means the wires from the motor don"t line up with the 2B 2A 1A 1B pins on the board.

If that happens you"ll need to closely look at the data sheet that generally is shown when you purchase the steppers (or it will say something like Black(A+), Green(A-), Red(B+), Blue(B-)). Granted when the wires don"t line up it can be a bit of a puzzle trying to figure out the proper combination.

If you"re building a Prusa/RepRap type printer, you"ll employ 2 stepper motors for the Z-Axis. The RAMPS 1.4 shield has accounted for this and offers two rows of connection pins for the Z-Axis.

Nowadays you can buy really fancy stepper drivers that feel resistance. Along with Marlin software changes you can do without end stops. In most printers though, you"ll need end stops to make sure your X/Y and Z axis don"t run off the rail (or worse; tear something of your printer apart).

The RAMPS 1.4 comes with 6 end stop connections (X Min, X Max, Y Min, Y Max, Z Min, Z Max). Rarely do you use all six. What you"re really interested in is either the Max or Min. If you know one, you can limit movement based on it"s location (0) via the software (if I can detect Min and know my bed is only 200mm wide then I can tell the software to not move beyond min+200)

The most common types of end stops are mechanical swithes, optical switches and proximity sensors. Proximity Sensors tend to only be used for the Z-Axis in conjunction with Auto Bed Leveling. I won"t cover inductive sensor wiring here but if you"re interested, I did write something on the wiring in this article Proximity-Sensor-Detection LJ12A3-4-Z-BX vs LJ12A3-4-Z/BY wiring

If you are using the most commonly used end stops "Makerbot Designed Mechanical Endstop Kit", it comes with little circuit board and wiring. It will light up an LED when triggered.

There are 3 wires coming from the end stop: RED/BLACK/GREEN IMPORTANT: make sure the wires correspond with the image above. If you turn around the connector on the RAMPS board and accidentally put the RED wire on the Signal (as opposed to +) YOU WILL SMELL SMOKE real fast.

If you forego the fancy Makerbot Switch (don"t do it for the price, it"s generally more about the size of the sensor) and instead go with a micro switch it"s my experience wiring is a bit easier. You really only need two wires. solder the wire to the two outside pins of the Micro switch and connect them to the -(minus) and s (signal) pin on the ramps.

You can test the micro switches and their behavior by opening an application like Pronterface or Octo Print and sending the g-code m119. It will show the state of all end stops. As seen in the video below.

The Extruder (the hot-end that spits out the plastic) generally has 6 wires associated and possibly more if you you use auto bed leveling and an additional Hot-end Cooling fan (Unlike the Heat sink fan, it cools the last layer of deposited plastic).

The normal wiring setup generally means we hook the heat sink cooling fan to the 12V fan connector on the RAMPS 1.4. These fan pins can be found between the fuses and the X Stepper Driver (see image above). On the image the left pin is + so make sure the red wire from the fan connects to that one. Oh, and for some reason all wires on 3D printers seem to come at 1 meter but the cooling fan wires generally never do. Be prepared to extend them.

The RAMPS Board has 3 Thermistor hookups (2 extruders, 1 heated bed). The Thermistor wire for the extruder (The white skinny wires) go on T0. Polarity does not matter.

Most heated bed you buy will come with wires and thermistor but are often not yet connected. The most common heated bed is the one seen in the image (the MK 2B by Joseph Prusa, or most likely some clone of it).

At the bottom of the bed you"ll generally see either two or three metal connectors to which to solder the power. If your printer is 12V follow the instructions and solder one wire to both 2 and 3 and the second wire to 1. Don"t bother with the LED connection, There really is no point to those.

The glass bead head of the thermistor goes right into the tiny hole at the center of the bed (this so it will close up to the material on top (like a glass plate).

There you have it. All the wiring that was done for the Laminated 3D printer. These instructions are pretty much the same of any other RAMPS 1.4 installation. There are additional options such as Hotend Cooling fan and Auto Bed Leveling (both of which can be done with the standard RAMPS 1.4) but I"ll save those for another instructable.

The only jumpers you really care about are the jumpers that will be under the stepper drivers. if you fill the three rows under each stepper driver you will use, it will set the micro stepping to the highest (1/16th on the A4988). each jumper oriented shield to shield (see ramps image below). Microstepping options in other image

Do you change the default value of the potentiometer in the stepper driver or do you let it be? I have a 2.6 V 1.2 A NEMA 17 Stepper motor but I am not sure what the current and voltage value on the stepper driver should be to get the best result.

You may have to end up tweaking it when running. I have mine at about 0.6v (If I remember correctly. You can change the pot meter when running the motor and kind of go by sound. If you want to do it right: https://youtu.be/OpaUwWouyE00

I searched more and figured out that there is not a universal standard for colors and letters. I used a multimeter to find out which wire is for what coil inside the motor.

Hi, I’m trying to use this setup for a robotics project, how would I include sensors to trigger motors on the 2560 if the ramps has used all the pins? Do I run a master/slave setup

How do you wire up a 3-wire endstop (makerbot) as a runout sensor? I know you have to use one of the servo ports but I don"t know which one and what wire goes where.

Can I use a MKS base board, v1.6 and control the printing action using Octoprint which will loaded on rasperby pi, instead of using the RAMPS kit ? and i was wondering how can i callibrate or it ? or if you have a guide to use step up the printer using MKS-BASE ?

I"m not familiar with the MKS 1.6 but when I started out with my KFB 2.0 board it"s closed "pin output" pal was the "MKS gen L". Wiring the KFB2.0 3D Printer Controller : 11 Steps (with Pictures) - Instructables Check it out and I think you"ll find the layout and setup very similar.

As for calibration; that will be independent of board and all configuration in the Marlin Software. Check out my other instructable starting at step 10: 3D Printer Cantilever 2.0 C3Dt/c : 14 Steps (with Pictures) - Instructables There"s also videos associated that walk you through some of the steps.

Hi, i have a question. My arduino mega works fine but when i fit the Ramps 1.4 board to it and plug it into my computer the leds on the mega board do not come on nor does my computer acknowledge it either aubily or on device manager. If i take the ramps board off the mega is recognised. Am i right in assuming the ramps board is faulty?

that hasn"t happened to me so I can"t be certain. Certainly doesn"t sound right. Here"s a link with what sounds like an issue similar to yours (with some things to try) https://www.reddit.com/r/3Dprinting/comments/39mzvb/help_ramps_board_makes_arduino_stop_working/0

The power source in this printer actually uses (ring connectors) and the power unit is covered but, you are correct. This was the very first printer I built (over 5 years ago) when forks and ferrules were barely on the radar. All my subsequent printer designs here use forks and ferrules.

I"ve installed Marlin on my Arduino board, no issue. Installed the jumpers and drivers to the Ramps 1.4 board, plugged the Ramps into the Arduino, added the LCD adapter board and connected the LCD screen. Plug it into the computer with the USB cable and voila, she fires up great, ready to go. Unplug the USB and connect the Ramps board to my 12VDC power supply + to +, - to -, and *nothing*. My VOM is showing 12.1 volts at the connectors on the Ramps board, but no LED"s on the boards light up and the display screen doesn"t work. Unhook the power supply, reconnect the Ramps to the computer with the USB cable and it comes back to life. What gives? I"ve triple-checked every connection and it all matches documentation in this instructable. Am I right in thinking I got a bad Ramps board?More CommentsPost Comment

After connecting this panel to your Ramps you don’t need your pc any more, the Smart Controller supplies power for your SD card. Further more all actions like calibration, axes movements can be done by just using the rotary encoder on the Smart Controller. Print your 3D designs without PC, just with a g-code design store on the SD card.

Keyestudio Mega 2560 R3 is a microcontroller board based on the ATMEGA2560. It has 54 digital input/output pins (of which 15 can be used as PWM outputs), 16 analog inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, 2 ICSP headers, and a reset button.

It contains a SD-Card reader, a rotary encoder and a 20 Character x 4 Line LCD display. You can easy connect it to your Ramps board using the "smart adapter" included. After connecting this panel to your Ramps you don"t need your pc any more, the Smart Controller supplies power for your SD card.

It is a Mega Pololu Shield, or RAMPS for short, designed to fit the entire electronics needed for a RepRap in one small package for low cost. RAMPS interfaces an Arduino Mega with the powerful Arduino MEGA platform and has plenty room for expansion.

The modular design includes plug in stepper drivers and extruder control electronics on an Arduino MEGA shield for easy service, part replacement, upgrade-ability and expansion. Additionally, a number of Arduino expansion boards can be added to the system as long as the main RAMPS board is kept to the top of the stack.

This product is a carrier board or breakout board for Allegro"s A4988 DMOS Microstepping Driver with Translator and Overcurrent Protection by Pololu; we therefore recommend careful reading of the A4988 datasheet before using this product. This stepper motor driver lets you control one bipolar stepper motor at up to 2A output current per coil.

In the kit, we have applied the A4988 drive module to drive stepper motor. When using, you can turn the potentiometer on the drive module to adjust the drive current.

When you connect Arduino Uno to your computer at the first time, right click “Computer” —>“Properties”—> “Device manager”, you can see “Unknown devices”.

G. After driver is installed, go to “Device manager” again. right click “Computer” —> “Properties”—> “Device manager”, you can see 2560 device as below figure shown, also the correct Com port.

A. You must close Arduino IDE firstly, and then place three libraries LiquidCrystal, SPI and U8glib from Marlin_Marlin_v1→ArduinoAddons→Arduino_1.x.x→libraries into Arduino/libraries.

B. Enter Marlin_Marlin_RAMPS_2004_Ver1 this folder, double click Marlin_Marlin_RAMPS_2004_Ver1 into this file, finally click “Tools” to set “Board”and “Port”.

E. After slicing, go to Preview→G-Code Editor, copy G-Code to SD card, and then insert the card into the main board. It is time to kick off the print! The LCD screen goes to: Print from SD→Desired File. Or you can connect your 3D printer to computer using a USB cable to start the print.

F. Click “Connect”and then click “Start Print” to begin the print. After some time, your printer gets ready and the buzzer rings, then you should press the button on LCD to start.

G. We just introduce a simple method about printing. You can design your own structure and outlook of your 3D printer, and also set your own configuration to meet your need.

After assembling your printer, the printer need to be leveled, so you can make some setup in Preview and Manual Control, and surf the internet for further information.

H. We have a G-Code to test the main board. Power it on, open limit switch and stepper motor, drive three motors; put a Fnbduino.gco file to Preview, click Start Print, if the motors rotate, X/Y/Z value in Manual Control changes, the main board works as shown below:

As with our Iduino Mega 2560, the Iduino MEGA R3 is also a microcontroller board based on the ATmega2560. It has 54 digital input/output pins (of which 14 can be used as PWM outputs), 16 analog inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, an external power jack, an ICSP header, and a reset button, enabling the board to be plug-and-play.

It contains a SD-Card reader, an rotary encoder and a 20 Character x 4 Line LCD display. You can easy connect it to your Ramps board using the "smart adapter" included. After connecting this panel to your Ramps you don"t need your pc any more, the Smart Controller supplies power for your SD card.

It is a Mega Pololu Shield, or RAMPS for short,designed to fit the entire electronics needed for a RepRap in one small package for low cost. RAMPS interfaces an Arduino Mega with the powerful Arduino MEGA platform and has plenty room for expansion. The modular design includes plug in stepper drivers and extruder control electronics on an Arduino MEGA shield for easy service, part replacement, upgrade-ability and expansion. Additionally, a number of Arduino expansion boards can be added to the system as long as the main RAMPS board is kept to the top of the stack.

This product is a carrier board or breakout board for Allegro"s A4988 DMOS Microstepping Driver with Translator and Overcurrent Protection by Pololu; we therefore recommend careful reading of the A4988 datasheet before using this product. This stepper motor driver lets you control one bipolar stepper motor at up to 2 A output current per coil.

128x64 Graphic LCD Smart Controller Display for RAMPS 1.4 3D Printer contains an SD-Card reader, a rotary encoder, and a 128x64 LCD display. You can easily connect it to your Ramps board using the "smart adapter". After connecting this panel to your Ramps you don"t need your pc anymore, the Smart Controller supplies power for your SD card. Furthermore, all actions like calibration, axes movements can be done by just using the rotary encoder on the Smart Controller. Print your 3D designs without PC, just with a g-code design stored on the SD card.

Compares to the 2004 Smart LCD Controller With Adapter, this 128x64 screen can display much more information, which would help for you run the 3D printer without a computer.

Features:Popular RepRap 3D Printer LCD Controller and SD Card Reader Included adapter for RAMPS 1.4 board Fully supported by Marlin firmware With Smart LCD Controller you can print 3D designs without USB connection to your computer.

LED background light control circuit, a small function of intelligent controller, With pin short time to decide on all LED turn or steering 30 seconds

You can turn on the light time to do long or short form of the adjustment TRIM R4100K from 10 seconds to 2 minutes If you use a print job at night and parts department, which means that the new modifications LCD back light would be suitable for you.

This 20×4 LCD board is used with the RAMPS 1.4 3D printer controller. You simply connect the LCD to the RAMPS board. This control unit has a built in SD card reader, rotary encoder as well as a 20×4 LCD display.

If you want a board with a lot less of setting up and assembly, MKS gen 1.4 is very compact. I have been using it for upwards of a year now on a cheap acrylic geeetech prusa i3, and I have never had a problem with it. The drivers are already installed in the actual board and it is very easy to use. I find the RAMPS and Ad. Mg. very difficult to use, and the MKS boards just look cooler.

I"m assembling a 3D printer with the RAMPS 1.4 board and Arduino Mega. I have assembled the structure and the electronics (set drivers, placed the jumpers, connected stepper motors...) and have uploaded Marlin firmware (configuring: thermistor, endstops...) on the Arduino Mega.

I"ve tried to connect, via USB, to the computer and using the Repetier software I have commanded the printer which did do some movement. The printer worked perfectly. After a few tests, however, I"ve noticed that the Arduino was restarting several times and at one point I saw a component on the Arduino board burning. Searching the internet I saw that the burned component was the voltage regulator.

I heard also about unplugging the screen because it consumes a lot of current, that passes through the voltage regulator, thereby heating it up. I then proceeded to buy another Arduino Mega. I also checked the voltage of my 12V 360W power supply and it is correct. I always powered the Arduino with USB and RAMPS 1.4 was connected to the power supply from the two terminals.

When the new Arduino arrived, I connected the whole (without connecting the screen) and tried. The printer worked very well until it started giving the same problem as the first Arduino board. Someone can tell me if I have done something wrong, or is it the RAMPS board that does not work properly?

I read that the endstops can cause this problem. I have these endstops: 1 PZ di Alta Qualità Finecorsa Meccanico Per rampe Reprap 1.4 stampante 3D Con imballaggio indipendente kit fai da te and I connected the black wire to GND, red wire to 5V and the green wire to SIGNAL.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey