rotary encoder lcd display quotation

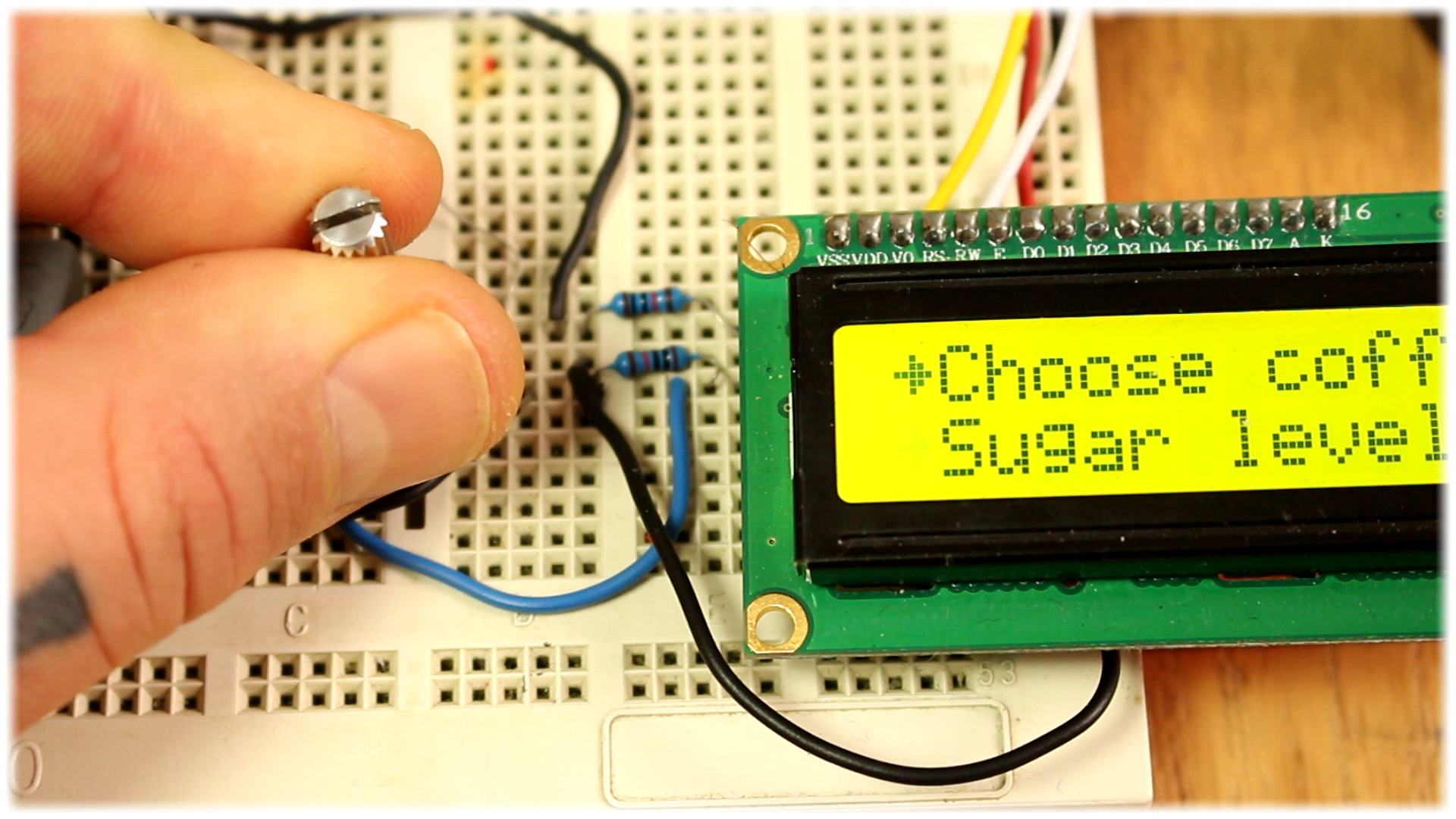

I am currently trying to get my rotary encoder and lcd to work together. For now the aim is to have the LCD display the rotary count as i turn the rotary and when i push the button switch on LED on 13 for 1 second, and return the counter to 0.

In our last tutorial, we examined how to create a menu for your Arduino project on a Nokia 5110 LCD, with push buttons to navigate through it. In today’s tutorial, we will build a modified version of it which will make use a rotary encoder (in place of the push buttons) for menu navigation.

A menu is one of the easiest ways through which users can interact with devices with diverse features. From Smartphones to PCs and even TVs, it is used in almost every electronic device with a screen and navigating through it is done usually by pressing certain buttons to move up/down, right/left and make selections. However, in some recent smart devices, either for aesthetics or for an improved form factor, a knob-like approach is employed for navigation. For today’s tutorial, we will explain how to create a menu with the same Knob style control, using a rotary encoder.

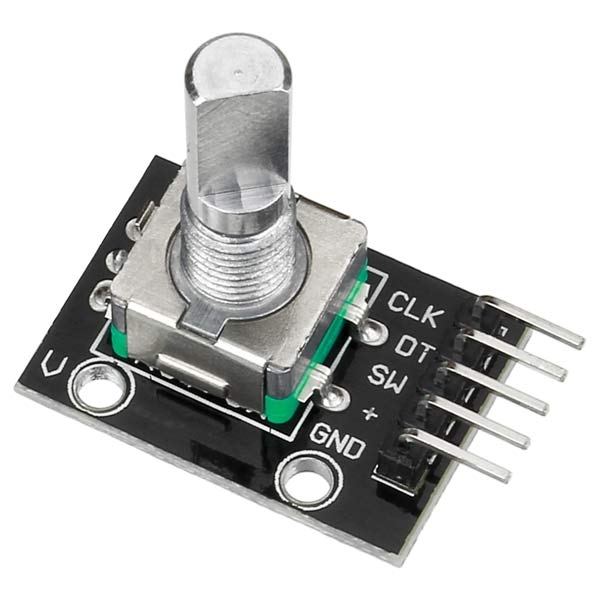

Rotary Encoders are used in several systems where precision and feedback in terms of rotational motion or angular position are required. By turning the shaft to the right or left, we either get an increase or decrease in value (depending on the configuration). One of the major advantages of rotary encoders is the fact that their rotation is limitless. If the maximum position, (which is 20 for the particular rotary encoder used in this tutorial) is reached, the device starts the position counting all over again while the value attached to the position continues to increase/decrease with every turn of the knob in the same direction. Another good feature which will be handy for this tutorial is that they come with buttons attached, so it can be clicked by pressing the knob and is recognized by the Arduino just as any other button or switch.

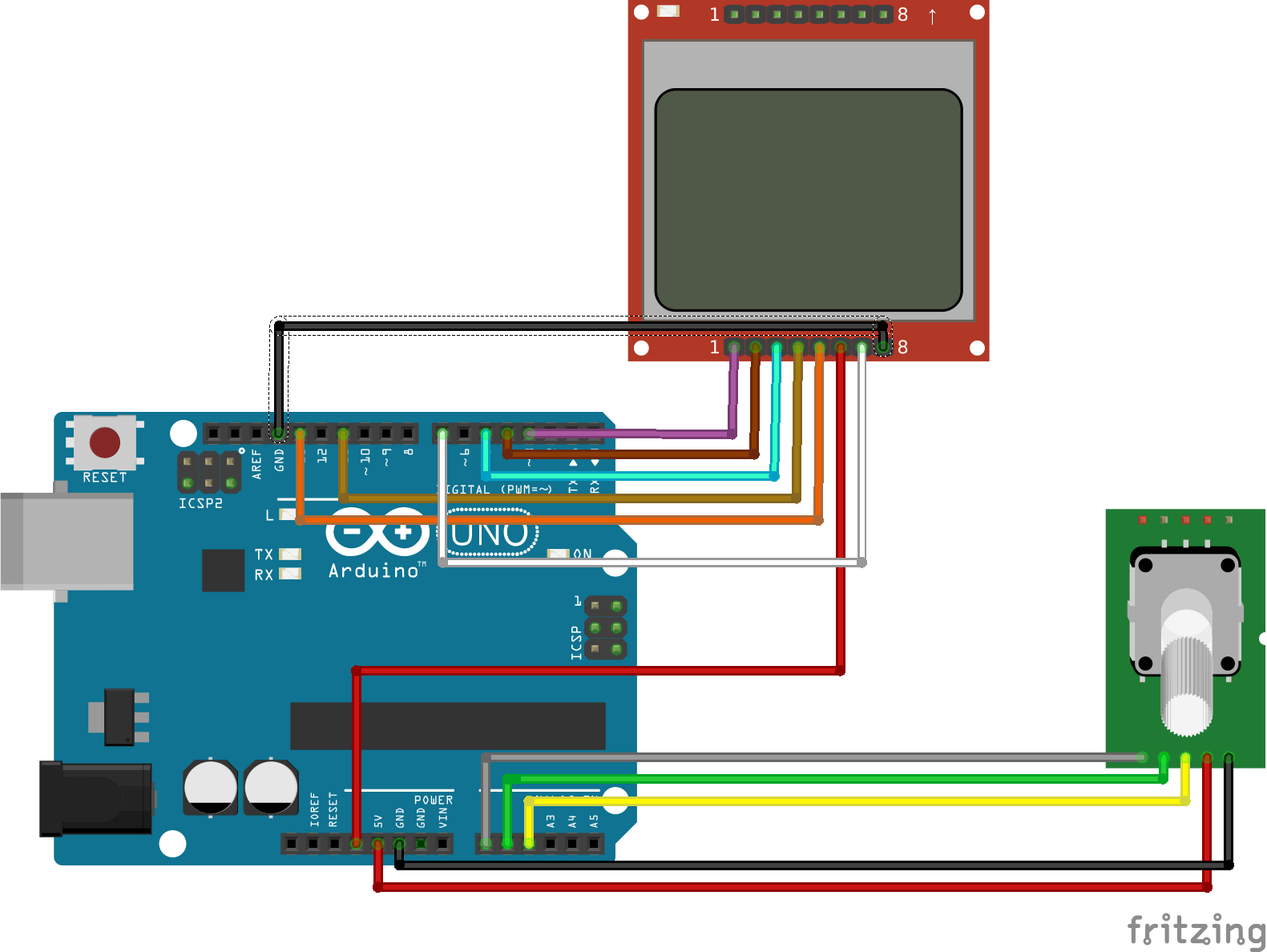

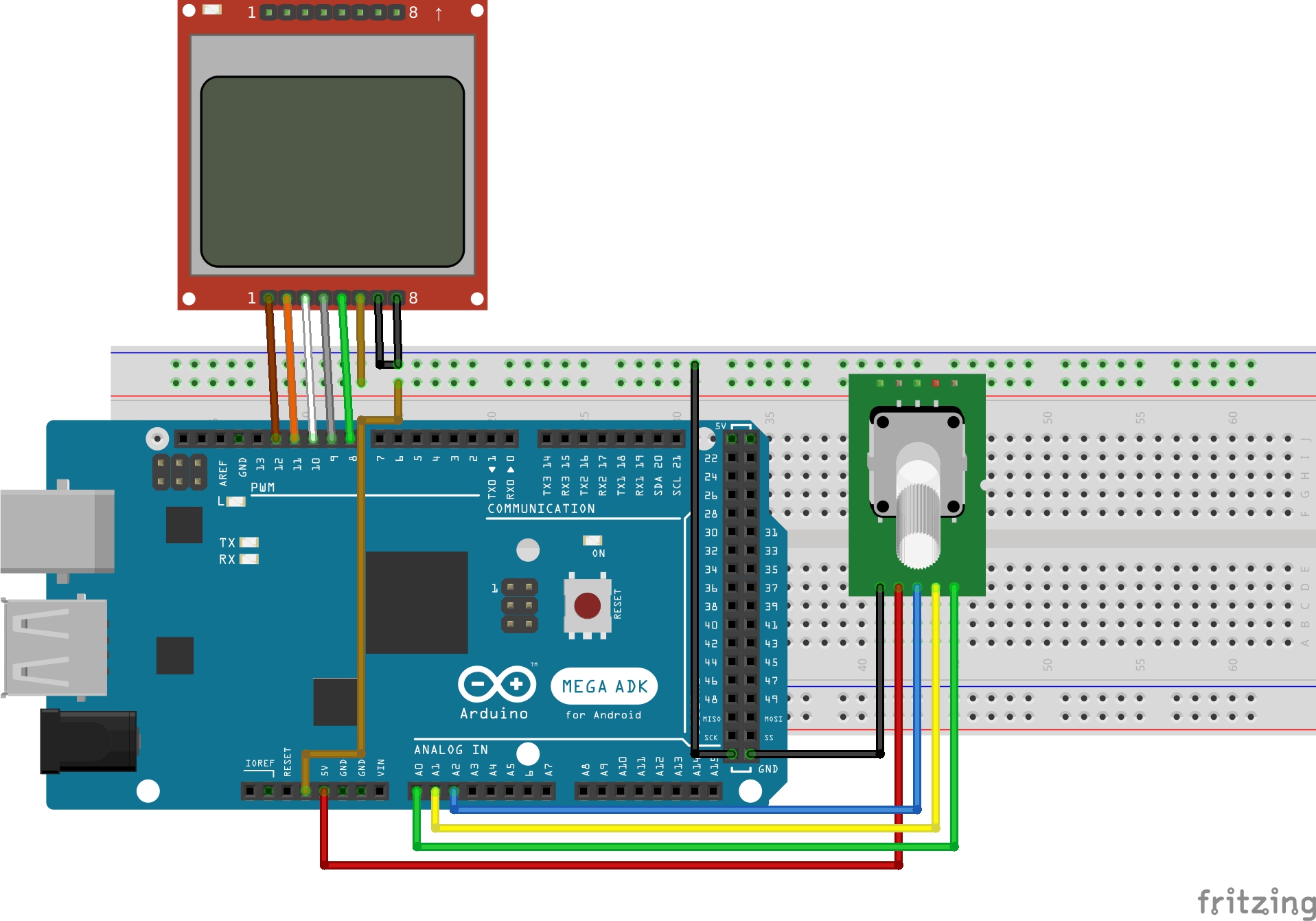

The schematics for today’s project is almost similar to the one of the last tutorial. We will take out the three push-buttons and add a rotary encoder. Connect the components as shown in the schematics below.

To simplify/reduce the amount of work we need to do, we will use four libraries. Two of the libraries; the Adafruit GFX library and the Nokia 5110 LCD library, will be used to interact with the display while the other two; the Encoder Library and the TimerOne library, will reduce the amount of code we write to interact with the rotary encoder. Each of the libraries can be downloaded via the links attached to them or installed via the Arduino Library Manager.

Next, we write the void setup() function. We start by declaring the pin to which the LCD’s backlight is connected (D7) as output and then proceed to create an encoder object before initializing the display and the rotary encoder, setting it to start at zero. We also create an interrupt routine which will be used to detect button press within any of the menu pages.

Up next is the void loop() function. This function is the most complex part of the whole code. The function basically creates the menu and uses the variables created initially to keep track of the previous, current and next state so when the rotary encoder is turned, it knows the right menu to display. The menu selection part of the code is also handled by a routine within the void loop() function.

Next, Data from the encoder is fed into a series of if-else statements which checks if the encoder was clicked or turned in a particular direction and which of the screens is currently being displayed to determine what action is to be done next. For instance, the first if statement checks if the menu is currently on page 1 and if the encoder is turned to the right (indicates up). If this is the case, it then checks the position of the menu cursor and adjusts it accordingly.

Verify your connections, by comparing with the schematics above, to ascertain that everything is as it should be. With that done, connect your board to the computer and upload the sketch to it. You should see the screen come on with the menu displayed. Try to turn the knob in different directions to navigate the menu and use the click feature of the knob to select an option.

A rotary encoder is an electro-mechanical device that converts angular position or the rotation of a shaft into analog or digital values. They are mainly of two types, absolute and incremental rotary encoders. The output of the absolute encoders indicates the current position of the shaft, making it more of an angle transducer. The output of incremental encoders provides information about the motion of the shaft, this can then be further processed to give information such as speed, distance and position among others.

By turning the shaft to the right or left, we either get an increase or decrease in value. One of the major advantage of rotary encoders is the fact that rotation is limitless. If the maximum position, (which is 20 for the particular rotary encoder used in this tutorial) is reached, the device starts the position counting all over again while the value attached to the position continues to increase/decrease with every turn of the knob in the same direction. This means we could still keep increasing the value associated with turning the rotary encoder so far we keep rotating in the same direction.

Rotary encoders are used in many applications that require precision and limitless rotation, like industrial controls, Robotics, computers and micro-controller based applications like the one we are working on today.

Another good thing about this rotary encoder is the fact that it comes with a button attached so you can click by pressing the nob as shown in the image below and the click/press will be recognized by the Arduino like a button input press, just as it will if it were any other button.

The rotary encoder used in this tutorial is available on ebay for $1 – $2. This rotary encoder has 20 positions and it can be clicked as earlier described. It has 5 pins and it is connected to the Arduino as shown in the schematics below.

from the last tutorial, we went through the connection for the LCD but just in case you missed it, connect the LCD also as shown in the schematics above.

The display has two sides to which the headers pins can be connected. You can pick one of the sides and solder header pins so that the display can fit firmly on the breadboard. This display works best when on 3.3 volts, so its probably best to power it with 3.3v.

The code for this project is heavily dependent on the Timerone and the encoder libraries which can be downloaded from the links attached to them. Install these libraries in your arduino IDE and launch the IDE to start coding. You can learn how to install Arduino Libraries from several other tutorials on this website.

After including the Libraries the next thing we did was perform necessary setups to use the LCD like declaring the pins to which it is connected and setting up the fonts to be used.

The first thing we did under the setup function was to handle the initialization of the LCD, then setting up the font we in which we would like the text to be displayed.

We then display an introductory message “Rotary encoder” with the added center parameter indicating we want it printed at the center of the screen. We print “demo” immediately after it then the lcd.update method is called to display the rotary encoder followed by demo on the screen.

After the setup function, we move to the loop function. The first few lines of code within the loop function handles the creation of variables that will be used later in the code, the include encoder value which increases when the encoder is turned continuously in the same direction and the encoder position which goes from 0 to 20, but since our encoder has no rotational limit, it starts again from zero.

With the rotary part handled, the next part of the code handles the click event. The click event is in four forms; pressed, Held, Released, click and double click. Each of this action was programmed to display its status at the bottom of the screen.

Roendi(Rotary Encoder with DIsplay) has a STM32L433 MCU, 1.28" TFT round display and a Alps Alpine 15Pulses/ 30Detent encoder. It can be programed by using ST-LINK/V2 or Arduino IDE, and is open source & open hardware. This rotary encoder is suitable for integration into projects as a unique user interface, or can be used as standalone development board. All pins that not used by the encoder are broken out to the peripheral of the board.

Rotary encoders are used in the myriad of common devices we see every day. From printers and photographic lenses to CNC machines and robotics, rotary encoders are closer to us than we think. The most popular example of the use of a rotary encoder in everyday life is the volume control knob of a car radio.

A rotary encoder is a type of position sensor that converts the angular position (rotation) of a knob into an output signal that is used to determine which direction the knob is being turned.

There are two types of rotary encoders – absolute and incremental. The absolute encoder reports the exact position of the knob in degrees while the incremental encoder reports how many increments the shaft has moved.

Potentiometers are used in situations where you need to know the exact position of the knob. Whereas, rotary encoders are used in situations where you need to know the change in position rather than the exact position.

Let’s connect the rotary encoder to the Arduino. The connections are quite simple. Start by connecting the +V pin on the module to 5V on the Arduino and the GND pin to Ground.

In the setup section, we first configure the connections to the rotary encoder as inputs, then we enable the input pullup resistor on the SW pin. We also setup the serial monitor.

When a change occurs, the function updateEncoder() (known as the Interrupt Service Routine or just ISR) is called automatically. The code within this function is executed and then the program returns back to what it was doing before.

Here is the sketch to precisely control the servo motor with the rotary encoder. Each time the knob is rotated one detent (click) the position of the servo arm will change by one degree.

It could an be adapted to other displays using micropython"s framebuffer or even to a very basic like a one-line display like a liquid crystal display.

Doing 100 clicks can be tedious if we do not really need that degree of precision so there is an option for the encoder value to be multiplied by Increment when it is displayed.

You can provide the text as a simple string but you can also provide a function that returns a string. This would allow you, for instance, to display the current time.

These functions are provided as a form of hardware abstraction in case you want to use different libraries from SSD1306_i2c and rotary-irq library (which I think is probably unlikely)

setencoder sets the rotary encoder so that value ranges between the maximum and minimum value inclusive. It increments on clockwise clicks and decrements on anti-clockwise clicks. It wraps over to minimum after click maximum and vice versa. This is the standard behaviour of the library rotary_irq.

This cancels the global task above. This way we can make and stop tasks without worrying about global declarations. For instance if we have a rolling rainbow display on neopixels this should be run as a task, otherwise it will block the menu. We can make the task by passing our function or more precisely our co-routine to make_task(). If we want to run a different pattern we would stop the current pattern by calling stop().

This is a 2x16 character RGB LCD with Keypad plate for Raspberry Pi. DF Robot have made improvements in the wiring connection based on the previous LCD display..

84861000Machines and apparutus of a kind used solely or principally for the manufacture of semi conductor boules or wafers,semi conductor devices,electronic integrated circuits or flat panel displays; machines and apparutus specified in note 9(c) to this chapter ; parts and accessories - machines and apparutus for the manufacture of boules or wafers

In this tutorial we will learn how rotary encoder works and how to use it with Arduino. You can watch the following video or read the written tutorial below.

A rotary encoder is a type of position sensor which is used for determining the angular position of a rotating shaft. It generates an electrical signal, either analog or digital, according to the rotational movement.

There are many different types of rotary encoders which are classified by either Output Signal or Sensing Technology. The particular rotary encoder that we will use in this tutorial is an incremental rotary encoder and it’s the simplest position sensor to measure rotation.

Let’s take a closer look at the encoder and see its working principle. Here’s how the square wave pulses are generated: The encoder has a disk with evenly spaced contact zones that are connected to the common pin C and two other separate contact pins A and B, as illustrated below.

We can notice that the two output signals are displaced at 90 degrees out of phase from each other. If the encoder is rotating clockwise the output A will be ahead of output B.

So if we count the steps each time the signal changes, from High to Low or from Low to High, we can notice at that time the two output signals have opposite values. Vice versa, if the encoder is rotating counter clockwise, the output signals have equal values. So considering this, we can easily program our controller to read the encoder position and the rotation direction.

Description of the code: So first we need to define the pins to which our encoder is connected and define some variables needed for the program. In the setup section we need to define the two pins as inputs, start the serial communication for printing the results on the serial monitor, as well as read the initial value of the output A and put the value into the variable aLastState.

Then in the loop section we read the output A again but now we put the value into the aState variable. So if we rotate the encoder and a pulse is generated, these two values will differ and the first “if” statement will become true. Right after that using the second “if” statement we determine the rotation direction. If the output B state differ from the output A state the counter will be increased by one, else it will be decreased. At the end, after printing the results on the serial monitor, we need to update the aLastState variable with aState variable.

That’s all we need for this example. If upload the code, start the Serial Monitor and start rotating the encoder we will start getting the values in the serial monitor. The particular module that I have makes 30 counts each full cycle.

I needed a rotary encoder — I pulled a cheap one out of one of those “49 boards for Arduino” kits you see around. Not the finest encoder in the land, I’m sure, but it should do the job. Unfortunately, Mbed OS doesn’t have a driver for an encoder and the first few third-party libraries I found either worked via polling or wouldn’t compile with the latest Mbed. Of course, reading an encoder isn’t a mysterious process. How hard can it be to write the code yourself? How hard, indeed. I thought I’d share my code and the process of how I got there.

There are many ways you can read a rotary encoder. Some are probably better than my method. Also, these cheap mechanical encoders are terrible. If you were trying to do precision work, you should probably be looking at a different technology like an optical encoder. I mention this because it is nearly impossible to read one of these flawlessly.

So my goal was simple: I wanted something interrupt driven. Most of what I found required you to periodically call some function or set up a timer interrupt. Then they built a state machine to track the encoder. That’s fine, but it means you eat up a lot of processor just to check in on the encoder even if it isn’t moving. The STM32 CPU can easily interrupt with a pin changes, so that’s what I wanted.

In theory, reading an encoder is a piece of cake. There are two outputs, we’ll call them A and B. When you turn the knob, these outputs send out pulses. The mechanical arrangement inside is such that when the knob is turning in one direction, pulses from A are 90 degrees ahead of the pulses from B. If you turn the other way, the phase is reversed.

People usually think of the pulses as going positive, but most real encoders will have a contact to ground and a pull up resistor, so actually, the outputs are often high when nothing is happening and the pulses are really low pulses. You can see that in the diagram when no one is turning the knob, there is a long stretch of high signal.

Note there is nothing magic about A, B, or the clockwise and counterclockwise labels. All it really means is “one way” and “the other way.” If you don’t like how the encoder is moving you can just swap A and B or swap it in software. I just picked those directions arbitrarily. Usually, channel A is supposed to “lead” in the clockwise direction, but it also depends on the edge you measure and how you connect everything. In software, you generally add one to a count for one direction and subtract for the other direction to get an idea of where you are over time.

But on the sampling edge of A, B is rock solid. The lower trace on the scope looks like a straight line because all the B transitions are off the screen at that scale. That’s the secret to easily debouncing an encoder. When A is changing, B is stable and vice versa. Since it is a gray code, that makes sense, but it is the insight that makes a simple decoder possible.

There is a problem, though. The whole scheme relies on the idea that B will be different on a true rising edge for A compared to a falling edge. There is one case where B doesn’t change but we still want to accept the A edge. That’s when you change directions. If you monitored B, that would be easy to solve, but that’s more code and two more interrupts. Instead, I decided that for a person twisting a knob, if you wildly twist in different directions very quickly, you won’t even notice that one or two clicks of the encoder went the wrong way. What you will notice is if you make a fine adjustment and then twist the other way deliberately.

Getting the encoder right was a little harder than I thought it would be, but mostly because I didn’t want to process more interrupts. It would be simple enough to modify the code to watch the B pin relative to the A pin and have a true understanding of the correct state of B. If you try that modification, here’s another idea: by measuring the time between interrupts, you could also get an idea of how fast the encoder is turning, which might be useful for some applications.

If you want a refresher on gray code and some of where it is useful, we’ve talked about it before. If all this sounds oddly familiar, I used an encoder on an old version of Mbed in 2017. In that case, I used a canned library that periodically polled the inputs on a timer interrupt. But like I say, there’s always more than one way to make stuff like this happen.

Designed specifically for measuring water level in a stilling well, the Shaft Encoder (H-3342) sturdy design incorporates the use of a float and pulley to produce accurate data within minutes of installation. With the use of magnetic sensors, the WaterLOG Shaft Encoder features minimize static sensitivity for enhanced performance.

You"ll enjoy the easy-to-read, ultra-low power, built-in LDC display allowing you to view the last measured value at any time. And this series is compatible with most data loggers, to allow easy installation.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey