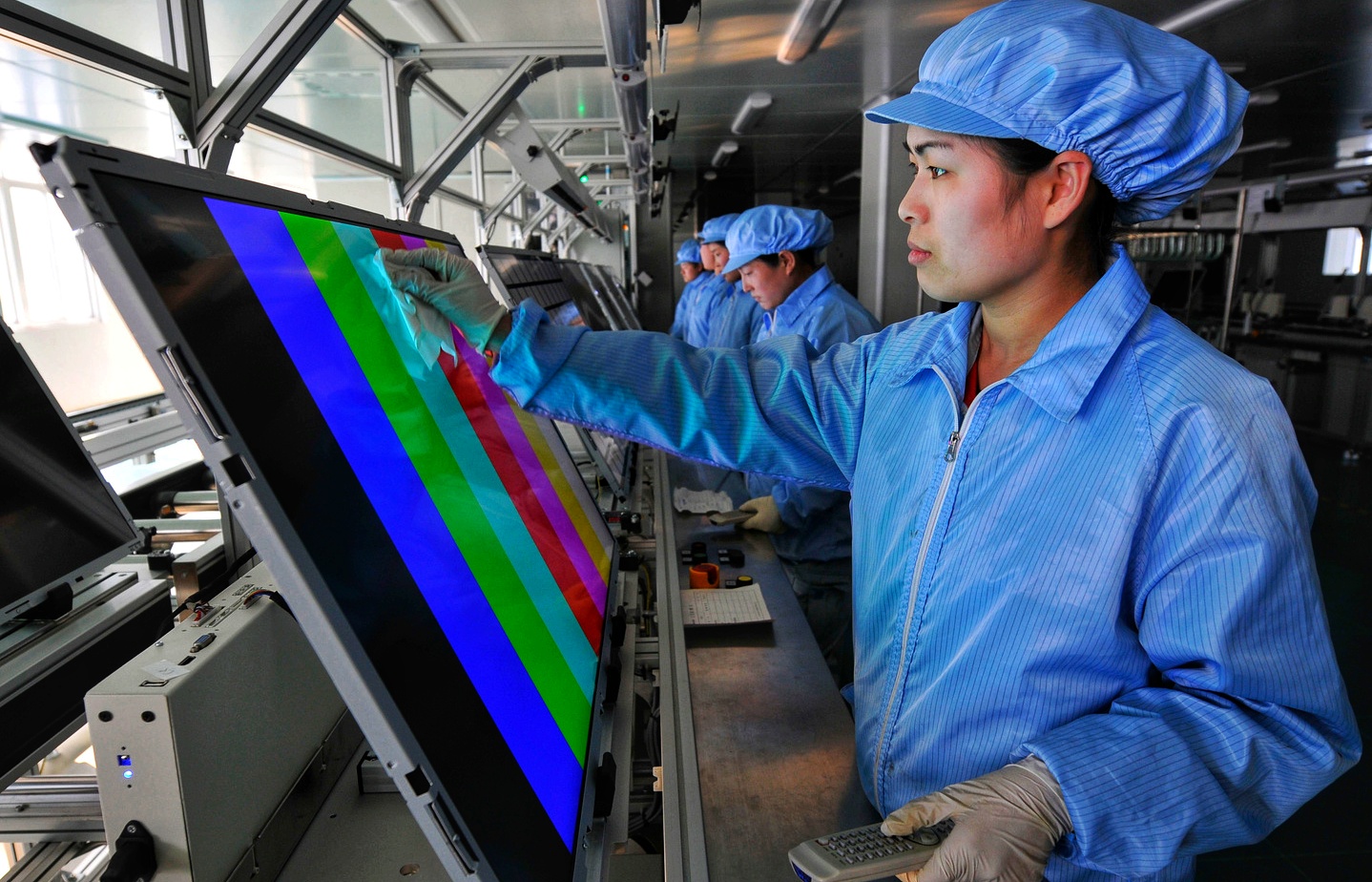

auo lcd panel manufacturer factory

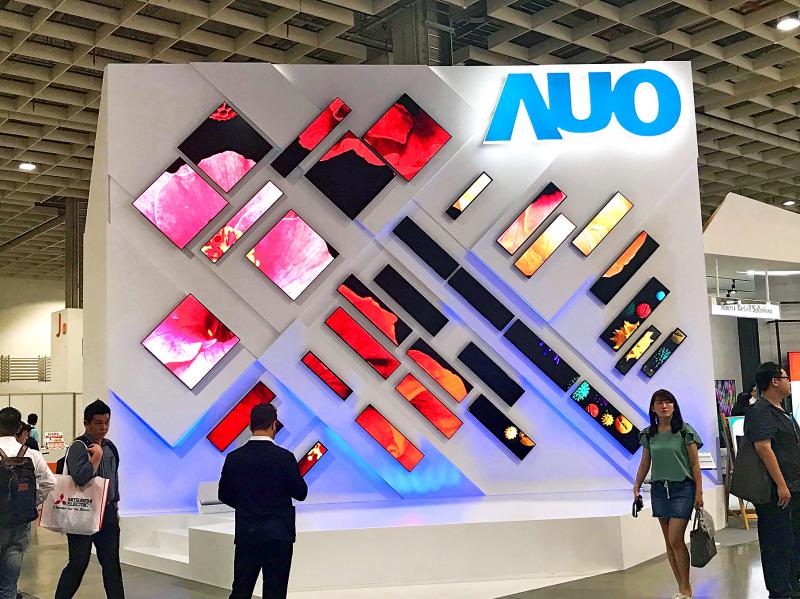

Founded in 1996, AUO is an enthusiastic, technology-driven company delivering products and solution services that advance the frontier of innovation. Consolidating the strength of the Group, AUO’s operation covers five major business areas including display, system solution, industrial intelligence, healthcare, and energy. The company is based in Taiwan and operates across Asia, the US and Europe, with a global team of 38,000 people. AUO’s consolidated net revenues in 2021 were NT$370.69 billion.

AUO specializes in the R&D and manufacturing of display panel, and develops high-valued and differentiated product applications. Leading the industry with abundant R&D personnel and innovative technologies, AUO is committed to providing diverse vertical solutions through integrating core display technologies with AIoT. By integrating software, hardware, cloud, and service platforms, AUO provides one-stop services that fulfill the diverse demands of vertical markets including retail, education, enterprise, medical, healthcare, mobility, manufacturing, and energy. Through cooperation, complementation, and co-creation, AUO constructs the smart AIoT eco-system with our strategic partners, achieving our vision of realizing an innovative living future.

AUO takes corporate sustainability as its core corporate philosophy, and dedicates actions to corporate governance, environmental sustainability, the popularization of science education, cultural preservation, and caring for social welfare. AUO has been listed in Dow Jones Sustainability World Index since 2010 and in Bloomberg Gender-Equality Index since 2018. In 2022, AUO became an official member of RE100, the first enterprise in the global display manufacturing industry to commit to using 100 percent renewable energy by 2050. Through our endless devotion to smart manufacturing and sustainable production, AUO was selected for the Global Lighthouse Network by the World Economic Forum and awarded the Manufacturing Leadership Award by the Manufacturing Leadership Council of The National Association of Manufacturers.

AUO understands the needs and critical points that make or break the manufacturing sector. Having manufactured over 240 million panels ranging over 1,000 models per year, we have accumulated our expertise through comprehensive and extensive process optimization of our productions. This knowledge enables us to help other businesses step forward to upgrade manufacturing processes and approaches.

AUO understands the needs and critical points that make or break the manufacturing sector. Having manufactured over 240 million panels ranging over 1,000 models per year, we have accumulated our expertise through comprehensive and extensive process optimization of our productions. This knowledge enables us to help other businesses step forward to upgrade manufacturing processes and approaches.

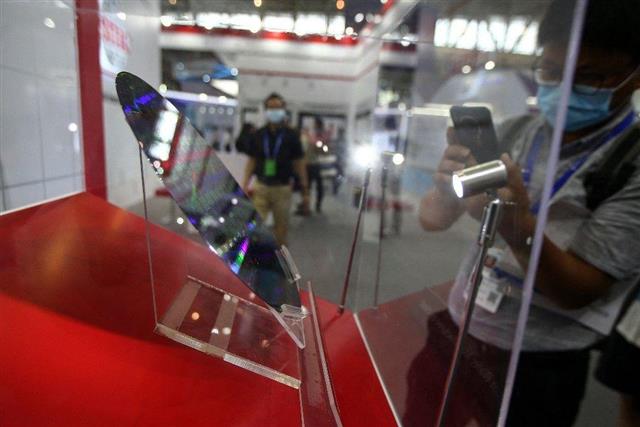

December 2020 AUO 9.4-inch high resolution flexible micro LED display technology honored with 2020 Innovative Product Award from Hsinchu Science Park

AU Optronics (AUO) is a leading global manufacturer of TFT-LCD committed to providing green solutions to its worldwide customers in a manner that is sustainable and friendly to the environment. Besides being named to Dow Jones Sustainability World Index, AUO is also the world"s first TFT-LCD manufacturer to have received a LEED Platinum Certification. In addition to its strengths in product and technological innovation, AUO stresses its commitment to going green and to utilizing manufacturing excellence to develop its solar business.

Leveraging the company"s innovation ability, AUO makes efforts in providing high reliability and premium quality solar solutions. Furthermore, AUO possesses a complete solar value chain that focuses on high efficiency at each stage, including polysilicon, ingot, wafer, cell, module and system production. AUO"s solar solutions fulfill the requirements in residential, commercial, and utility segments.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

LCD panel makers AUO Corp (友達) and Innolux Corp (群創光電) would likely reduce factory utilization this quarter amid an industry downturn, market researcher TrendForce Corp (集邦科技) said yesterday.

AUO’s factory utilization rate is likely to drop to about 50 percent from the prior quarter, while Innolux’s could be 6.7 percentage points lower this quarter, TrendForce said.

The industry has been hit by flagging demand for TV and PC panels, which has driven prices down, TrendForce analyst Jeanette Chen (陳巧慧) said in a report.

AUO booked NT$8 billion (US$267.43 million) in depreciation and amortization costs in the first quarter, well below its cash flow of NT$90.13 billion as of March 31, a company statement showed.

AUO in April said that its customers were experiencing an inventory correction cycle, with price-sensitive and lower-end products severely affected by global inflation.

Global LCD panel makers are likely to reduce factory utilization for large panels to about 70 percent this quarter, down by at least 7.3 percentage points from the second quarter, the researcher said.

As TV and PC vendors continue to adjust their inventories, flat panel makers are being forced to reduce production to avoid losing money, as panel prices are stuck in a downward spiral, it said.

Over the past two years, TV and PC vendors have overstocked panels and other components over concerns that border controls and port congestion amid the COVID-19 pandemic would disrupt supply flows, it said.

However, as the stay-at-home economy wanes, inventory problems at every level of the LCD supply chain have reached a critical point, with goods ordered arriving at warehouses and ports, it added.

TrendForce expects the world’s major flat panel makers to keep utilization rates low at large factories producing notebook computer and TV panels next quarter as they aim to minimize inventory risks next year.

AU Optronics (AUO) is a leading global manufacturer of TFT-LCD committed to providing green solutions to its worldwide customers in a manner that is sustainable and friendly to the environment. Besides being named to Dow Jones Sustainability World Index, AUO is also the world"s first TFT-LCD manufacturer to have received a LEED Platinum Certification. In addition to its strengths in product and technological innovation, AUO stresses its commitment to going green and to utilizing manufacturing excellence to develop its solar business.

Leveraging the company"s innovation ability, AUO makes efforts in providing high reliability and premium quality solar solutions. Furthermore, AUO possesses a complete solar value chain that focuses on high efficiency at each stage, including polysilicon, ingot, wafer, cell, module and system production. AUO"s solar solutions fulfill the requirements in residential, commercial, and utility segments.

LCD prices are on a relentless downward trend. Lower prices are key to stimulating more demand and further growing the total market in terms of units as well as shifting demand to larger panel sizes. In order to maintain margins as prices fall, LCD producers constantly strive to lower costs. This trend is being exacerbated by the current weak economic environment and significant oversupply, causing prices to fall near cost levels, ever intensifying the focus on cost reduction.

Accounting for 15%-25% of total module costs, backlight unit and inverters are the single most expensive components of an LCD. For this reason, it is not surprising that the backlight assembly is an important focal point of cost reduction. In the backlit unit (BLU), CCFL lamps are the most expensive components, accounting for 30%-40% of the bill of materials — and in the case of LED-based BLUs, the lamps are substantially more expensive.

Increasing LCD panel transmissivity has now become an industrywide goal — not for the purpose of increasing on screen brightness, but rather to maintain brightness and reduce backlight lamps, inverters, and optical films in order to lower panel costs. Another benefit of improved transmissivity is power reduction. Not only is lower power consumption “green,” but in conventional LCDs the large majority of illumination generated by the backlight lamps is lost from polarizer absorption, shading by the TFT array aperture ratio, color filter, etc. so that only about 5% of the light emitted makes it to the front of the screen.

Even small improvements in transmissivity can lead to large gains in BLU lamp reduction. For example, a typical 400-nit panel with 5% transmissivity has 8000-nits luminance at the backlight. If transmissivity is increased from 5% to 10%, the same amount of front of panel luminance can be achieved with a 4000-nit backlight. In other words, the number of backlight lamps and inverters can be reduced by 50%.

There are a variety of technologies in production or in development by different panel manufacturers that target transmissivity improvements. Some of the most important include:

Adoption of low resistance gate and data lines provides multiple benefits that include reduced RC delay that improves performance and can potentially eliminate requirements for dual scan driving. In addition, due to lower resistivity, the width of the bus line can be reduced, which increases aperture ratio without sacrificing performance. Since copper has a very low resistance, it is the material of choice. Already LG Display is mass-producing the majority of its larger panels using Cu, and over the next five years Cu and Cu-alloy application is expected to grow substantially.

In PSA, a polymer alignment layer is formed over a conventionally coated polyimide by mixing a UV curable monomer into the LC. The monomer is then activated by UV radiation while applying an AC voltage. The monomer reacts with the polymer layer to form a surface that fixes the pre-tilt angle of the LC. Because it eliminates a protrusion from the color filter side of the display, aperture ratio is increased and panel brightness can be improved by more than 20%; contrast ratio and LC switching speed are also improved. At the same time, costs are reduced because the protrusion mask step can be eliminated from the color filter process.

PSA technology was originally developed by Fujitsu, and now AUO is bringing it to mass production, showing stunning examples of its technology (called “AMVA-III”) at this year’s FPD International. PSA offers multiple benefits, with minimum trade-offs. Several panel makers are expected to start mass production of PSA for both small/medium and large size LCDs over the next year.

In the color filter process, panel manufacturers are reducing the width of the black matrix (BM). Similar to reducing the width of gate and data lines, a thinner BM translates to a wider aperture ratio.

COA is another CF related manufacturing technology that moves RGB pixels from the common electrode glass to the array glass. There are multiple variations of this technology, but all increase transmissivity by widening the aperture ratio as well as improve contrast. However, moving color pixels to the array creates multiple process challenges, specifically yield loss. For this reason, COA is not yet widely adopted. TMDisplay and Samsung are currently the two main producers of COA based LCDs.

Lowering LCD costs are essential to maintain margins, and in the current environment, just to stay in business. Panel makers are applying a holistic strategy to cost reduction, which includes implementing new manufacturing technologies. Of these, improving panel transmission in order to lower backlight costs has emerged as a key trend. What technologies will be adopted will vary by panel maker, but those that both reduce cost and at the same time improve performance with minimal trade-offs will see the highest adoption rates. Particularly, LCDs adopting low-resistance bus lines, thinner BM, and PSA are already available in stores, and expect more in the near future.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey