s3 lcd panel free sample

ESP chips can generate various kinds of timings that needed by common LCDs on the market, like SPI LCD, I80 LCD (a.k.a Intel 8080 parallel LCD), RGB/SRGB LCD, I2C LCD, etc. The esp_lcd component is officially to support those LCDs with a group of universal APIs across chips.

In esp_lcd, an LCD panel is represented by esp_lcd_panel_handle_t, which plays the role of an abstract frame buffer, regardless of the frame memory is allocated inside ESP chip or in external LCD controller. Based on the location of the frame buffer and the hardware connection interface, the LCD panel drivers are mainly grouped into the following categories:

Controller based LCD driver involves multiple steps to get a panel handle, like bus allocation, IO device registration and controller driver install. The frame buffer is located in the controller’s internal GRAM (Graphical RAM). ESP-IDF provides only a limited number of LCD controller drivers out of the box (e.g. ST7789, SSD1306), More Controller Based LCD Drivers are maintained in the Espressif Component Registry

RGB Interfaced LCD - is based on a group of specific synchronous signals indicating where to start and stop a frame. The frame buffer is allocated on the ESP side. The driver install steps are much simplified because we don’t need to install any IO interface driver in this case.

LCD Panel IO Operations - provides a set of APIs to operate the LCD panel, like turning on/off the display, setting the orientation, etc. These operations are common for either controller-based LCD panel driver or RGB LCD panel driver.

esp_lcd_panel_io_spi_config_t::dc_gpio_num: Sets the gpio number for the DC signal line (some LCD calls this RS line). The LCD driver will use this GPIO to switch between sending command and sending data.

esp_lcd_panel_io_spi_config_t::cs_gpio_num: Sets the gpio number for the CS signal line. The LCD driver will use this GPIO to select the LCD chip. If the SPI bus only has one device attached (i.e. this LCD), you can set the gpio number to -1 to occupy the bus exclusively.

esp_lcd_panel_io_spi_config_t::pclk_hz sets the frequency of the pixel clock, in Hz. The value should not exceed the range recommended in the LCD spec.

esp_lcd_panel_io_spi_config_t::spi_mode sets the SPI mode. The LCD driver will use this mode to communicate with the LCD. For the meaning of the SPI mode, please refer to the SPI Master API doc.

esp_lcd_panel_io_spi_config_t::lcd_cmd_bits and esp_lcd_panel_io_spi_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

esp_lcd_panel_io_spi_config_t::trans_queue_depth sets the depth of the SPI transaction queue. A bigger value means more transactions can be queued up, but it also consumes more memory.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the SPI IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

esp_lcd_panel_io_i2c_config_t::dev_addr sets the I2C device address of the LCD controller chip. The LCD driver will use this address to communicate with the LCD controller chip.

esp_lcd_panel_io_i2c_config_t::lcd_cmd_bits and esp_lcd_panel_io_i2c_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the I2C IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

esp_lcd_i80_bus_config_t::data_gpio_nums is the array of the GPIO number of the data bus. The number of GPIOs should be equal to the esp_lcd_i80_bus_config_t::bus_width value.

esp_lcd_panel_io_i80_config_t::pclk_hz sets the pixel clock frequency in Hz. Higher pixel clock frequency will result in higher refresh rate, but may cause flickering if the DMA bandwidth is not sufficient or the LCD controller chip does not support high pixel clock frequency.

esp_lcd_panel_io_i80_config_t::lcd_cmd_bits and esp_lcd_panel_io_i80_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

esp_lcd_panel_io_i80_config_t::trans_queue_depth sets the maximum number of transactions that can be queued in the LCD IO device. A bigger value means more transactions can be queued up, but it also consumes more memory.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the I80 IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

esp_lcd_panel_dev_config_t::reset_gpio_num sets the GPIO number of the reset pin. If the LCD controller chip does not have a reset pin, you can set this value to -1.

More LCD panel drivers and touch drivers are available in IDF Component Registry. The list of available and planned drivers with links is in this table.

esp_lcd_rgb_panel_config_t::clk_src selects the clock source for the RGB LCD controller. The available clock sources are listed in lcd_clock_source_t.

esp_lcd_rgb_panel_config_t::bits_per_pixel set the number of bits per pixel. This is different from esp_lcd_rgb_panel_config_t::data_width. By default, if you set this field to 0, the driver will automatically adjust the bpp to the esp_lcd_rgb_panel_config_t::data_width. But in some cases, these two value must be different. For example, a Serial RGB interface LCD only needs 8 data lines, but the color width can reach to RGB888, i.e. the esp_lcd_rgb_panel_config_t::bits_per_pixel should be set to 24.

esp_lcd_rgb_panel_config_t::sram_trans_align and esp_lcd_rgb_panel_config_t::psram_trans_align set the alignment of the allocated frame buffer. Internally, the DMA transfer ability will adjust against these alignment values. A higher alignment value can lead to a bigger DMA burst size. Please note, the alignment value must be a power of 2.

esp_lcd_rgb_panel_config_t::bounce_buffer_size_px set the size of bounce buffer. This is only necessary for a so-called “bounce buffer” mode. Please refer to Bounce Buffer with Single PSRAM Frame Buffer for more information.

esp_lcd_rgb_panel_config_t::timings sets the LCD panel specific timing parameters. All required parameters are listed in the esp_lcd_rgb_timing_t, including the LCD resolution and blanking porches. Please fill them according to the datasheet of your LCD.

esp_lcd_rgb_panel_config_t::fb_in_psram sets whether to allocate the frame buffer from PSRAM or not. Please refer to Single Frame Buffer in PSRAM for more information.

esp_lcd_rgb_panel_config_t::num_fbs sets the number of frame buffers allocated by the driver. For backward compatibility, 0 means to allocate one frame buffer. Please use esp_lcd_rgb_panel_config_t::no_fb if you don’t want to allocate any frame buffer.

Most of the time, the RGB LCD driver should maintain at least one screen sized frame buffer. According to the number and location of the frame buffer, the driver provides several different buffer modes.

This is the default and simplest and you don’t have to specify flags or bounce buffer options. A frame buffer is allocated from the internal memory. The frame data is read out by DMA to the LCD verbatim. It needs no CPU intervention to function, but it has the downside that it uses up a fair bit of the limited amount of internal memory.

If you have PSRAM and want to store the frame buffer there rather than in the limited internal memory, the LCD peripheral will use EDMA to fetch frame data directly from the PSRAM, bypassing the internal cache. You can enable this feature by setting the esp_lcd_rgb_panel_config_t::fb_in_psram to true. The downside of this is that when both the CPU as well as EDMA need access to the PSRAM, the bandwidth will be shared between them, that is, EDMA gets half and the CPUs get the other half. If there’re other peripherals using EDMA as well, with a high enough pixel clock this can lead to starvation of the LCD peripheral, leading to display corruption. However, if the pixel clock is low enough for this not to be an issue, this is a solution that uses almost no CPU intervention.

The PSRAM shares the same SPI bus with the main Flash (the one stores your firmware binary). At one time, there only be one consumer of the SPI bus. When you also use the main flash to serve your file system (e.g. SPIFFS), the bandwidth of the underlying SPI bus will also be shared, leading to display corruption. You can use esp_lcd_rgb_panel_set_pclk() to update the pixel clock frequency to a lower value.

To avoid tearing effect, using two screen sized frame buffers is the easiest approach. In this mode, the frame buffer can only be allocated from PSRAM, because of the limited internal memory. The frame buffer that the CPU write to and the frame buffer that the EDMA read from are guaranteed to be different and independent. The EDMA will only switch between the two frame buffers when the previous write operation is finished and the current frame has been sent to the LCD. The downside of this mode is that, you have to maintain the synchronization between the two frame buffers.

This mode allocates two so-called bounce buffers from the internal memory, and a main frame buffer that is still in PSRAM. This mode is selected by setting the esp_lcd_rgb_panel_config_t::fb_in_psram flag and additionally specifying a non-zero esp_lcd_rgb_panel_config_t::bounce_buffer_size_px value. The bounce buffers only need to be large enough to hold a few lines of display data, which is significantly less than the main frame buffer. The LCD peripheral will use DMA to read data from one of the bounce buffers, and meanwhile an interrupt routine will use the CPU DCache to copy data from the main PSRAM frame buffer into the other bounce buffer. Once the LCD peripheral has finished reading the bounce buffer, the two buffers change place and the CPU can fill the others. The advantage of this mode is that, you can achieve higher pixel clock frequency. As the bounce buffers are larger than the FIFOs in the EDMA path, this method is also more robust against short bandwidth spikes. The downside is a major increase in CPU use and the LCD CAN’T work if we disable the cache of the external memory, via e.g. OTA or NVS write to the main flash.

Note that this mode also allows for a esp_lcd_rgb_panel_config_t::bb_invalidate_cache flag to be set. Enabling this frees up the cache lines after they’re used to read out the frame buffer data from PSRAM, but it may lead to slight corruption if the other core writes data to the frame buffer at the exact time the cache lines are freed up. (Technically, a write to the frame buffer can be ignored if it falls between the cache writeback and the cache invalidate calls.)

This mode is similar to the Bounce Buffer with Single PSRAM Frame Buffer, but there is no PSRAM frame buffer initialized by the LCD driver. Instead, the user supplies a callback function that is responsible for filling the bounce buffers. As this driver does not care where the written pixels come from, this allows for the callback doing e.g. on-the-fly conversion from a smaller, 8-bit-per-pixel PSRAM frame buffer to an 16-bit LCD, or even procedurally-generated frame-buffer-less graphics. This option is selected by setting the esp_lcd_rgb_panel_config_t::no_fb flag and supplying a esp_lcd_rgb_panel_config_t::bounce_buffer_size_px value. And then register the esp_lcd_rgb_panel_event_callbacks_t::on_bounce_empty callback by calling esp_lcd_rgb_panel_register_event_callbacks().

It should never happen in a well-designed embedded application, but it can in theory be possible that the DMA cannot deliver data as fast as the LCD consumes it. In the ESP32-S3 hardware, this leads to the LCD simply outputting dummy bytes while DMA waits for data. If we were to run DMA in a stream fashion, this would mean a de-sync between the LCD address the DMA reads the data for and the LCD address the LCD peripheral thinks it outputs data for, leading to a permanently shifted image.

In order to stop this from happening, you can either enable the CONFIG_LCD_RGB_RESTART_IN_VSYNC option, so the driver can restart the DMA in the VBlank interrupt automatically or call esp_lcd_rgb_panel_restart() to restart the DMA manually. Note esp_lcd_rgb_panel_restart() doesn’t restart the DMA immediately, the DMA will still be restarted in the next VSYNC event.

esp_lcd_panel_draw_bitmap() is the most significant function, that will do the magic to draw the user provided color buffer to the LCD screen, where the draw window is also configurable.

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

This function can be useful when the LCD controller is out of sync with the DMA because of insufficient bandwidth. To save the screen from a permanent shift, you can call this function to restart the LCD DMA.

If CONFIG_LCD_RGB_RESTART_IN_VSYNC is enabled, you don’t need to call this function manually, because the restart job will be done automatically in the VSYNC event handler.

If this flag is enabled, the host only refresh the frame buffer when esp_lcd_panel_draw_bitmap is called. This is useful when the LCD screen has a GRAM and can refresh the LCD by itself.

Amazon S3 storage usage is calculated in binary gigabytes (GB), where 1 GB is 230bytes. This unit of measurement is also known as a gibibyte (GiB), defined by the International Electrotechnical Commission (IEC). Similarly, 1 TB is 240 bytes, i.e. 1024 GBs.

* S3 Intelligent-Tiering can store objects smaller than 128 KB, but auto-tiering has a minimum eligible object size of 128 KB. These smaller objects will not be monitored and will always be charged at the Frequent Access tier rates, with no monitoring and automation charge. For each object archived to the Archive Access tier or Deep Archive Access tier in S3 Intelligent-Tiering, Amazon S3 uses 8 KB of storage for the name of the object and other metadata (billed at S3 Standard storage rates) and 32 KB of storage for index and related metadata (billed at S3 Glacier Flexible Retrieval and S3 Glacier Deep Archive storage rates).

** S3 Standard-IA and S3 One Zone-IA storage have a minimum billable object size of 128 KB. Smaller objects may be stored but will be charged for 128 KB of storage at the appropriate storage class rate. S3 Standard-IA, and S3 One Zone-IA storage are charged for a minimum storage duration of 30 days, and objects deleted before 30 days incur a pro-rated charge equal to the storage charge for the remaining days. Objects that are deleted, overwritten, or transitioned to a different storage class before 30 days will incur the normal storage usage charge plus a pro-rated charge for the remainder of the 30-day minimum. This includes objects that are deleted as a result of file operations performed byFile Gateway. Objects stored for 30 days or longer will not incur a 30-day minimum charge.

*** The S3 Glacier Flexible Retrieval and S3 Glacier Deep Archive storage classes require an additional 32 KB of data per object for S3 Glacier’s index and metadata charged at the appropriate storage class rate. Amazon S3 requires 8 KB per object to store and maintain the user-defined name and metadata for objects archived to S3 Glacier Flexible Retrieval and S3 Glacier Deep Archive. This allows you to get a real-time list of all of your S3 objects using the S3 LIST API or the S3 Inventory report. S3 Glacier Instant Retrieval has a minimum billable object size of 128 KB. Smaller objects may be stored but will be charged for 128 KB of storage at the appropriate storage class rate. Objects that are archived to S3 Glacier Instant Retrieval and S3 Glacier Flexible Retrieval are charged for a minimum storage duration of 90 days, and S3 Glacier Deep Archive has a minimum storage duration of 180 days. Objects deleted prior to the minimum storage duration incur a pro-rated charge equal to the storage charge for the remaining days. Objects that are deleted, overwritten, or transitioned to a different storage class before the minimum storage duration will incur the normal storage usage charge plus a pro-rated storage charge for the remainder of the minimum storage duration. Objects stored longer than the minimum storage duration will not incur a minimum storage charge. For each object that is stored in S3 Glacier Flexible Retrieval or S3 Glacier Deep Archive, Amazon S3 adds 40 KB of chargeable overhead for metadata, with 8 KB charged at S3 Standard rates and 32 KB charged at S3 Glacier Flexible Retrieval or S3 Deep Archive rates. For customers using the S3 Glacier direct API, pricing for API can be found on the S3 Glacier API pricing page.

s3 display oem provide the touch interface in smartphones, which are vital for them to function. Alibaba.com stocks a stunning range of high-tech s3 display oem with vibrant color depictions. Truly crystal-clear displays of s3 display oem are available covering various brands and models such as the Samsung Galaxy Edge 2, OnePlus 7T, Samsung Galaxy C5, and many more.

s3 display oem are the most commonly used displays, as they produce great image quality while consuming low power. Rather than emitting light directly, they use back lights or reflectors to produce images, which allows for easy readability even under direct sunlight. s3 display oem are energy-efficient, and are comparatively safer to dispose of, than CRTs. s3 display oem are much more efficient when it comes to usage in battery-powered electronic equipment, due to their minimal power consumption.

Some other advantages of s3 display oem over the CRT counterparts are - sharper images, little to no heat emission, unaffected by magnetic fields, narrow frame borders, and extreme compactness, which make them very thin and light. Some types of s3 display oem are transmissive, reflective, and transflective displays. Transmissive displays provide better image quality in the presence of low or medium-light, while reflective displays work best in the presence of bright light. The third type of s3 display oem, transflective, combine the best features of both the other types and provide a well-balanced display.

Whether as an individual purchaser, supplier or wholesaler, browse for an extensive spectrum of s3 display oem at Alibaba.com if you don"t want to stretch a dollar yet find the best fit.

If you are moving your filestore to S3 in the context of upgrading Artifactory, or a first time installation, we recommend that you first do a standard installation of Artifactory using the default settings, or a standard upgrade using your current settings.

The default S3 chain templates rely on an eventual upload mechanism, whereby an upload from a client is considered successful when the full binary has been uploaded to Artifactory. From Artifactory 7.9.0, thedirect upload mechanism serves as an alternative mechanism whereby an upload is not considered successful until it reaches S3. There are advantages to both which we cover below.

If you are uploading on a system where the S3 upload speed is slow (for example, when Artifactory is hosted on-prem), you may want to use the Eventual Upload mechanism. The Eventual Upload mechanism also allows you to upload when S3 is down or experiencing network issues.Client uploads an artifact to Artifactory.

Using the Amazon S3 Official SDK template requires a shared mount for cluster. This is because an arbitrary node will handle the object store interaction, while all of the nodes will be able to add files to the shared mounteventualdirectory.

Only official AWS endpoints, such ass3.amazonaws.com,*.amazonaws.com, and*.amazonaws.com.cnare supported in all JFrog subscriptions. Additional endpoints are supported in the JFrog Enterprise/ Enterprise+ subscriptions."

If set to true, S3 encrypts artifacts on the server based on the default KMS key. You can also set it with the encryption key ID or alias instead of true.

The following snippets show the basic template configuration and examples that use the S3 binary provider to support several configurations (CEPH, CleverSafe and more).

The S3 direct (or eventual-less) template allows directly uploading to S3, bypassing the eventual upload mechanism. For more information, see Direct (Eventual-less) versus Eventual Upload Mechanism.

This example sets S3 with your credentials, use pre-signing for object manipulations and sets the pre-signed URL for 10 minutes (600 seconds). The default settings for maxConnections, connectionTimeout, and cache-fs maxCacheSize configuration are also shown in this example.

When using the cluster-s3-storage-v3 template , data is temporarily stored on the file system of each node using the Eventual-Cluster Binary Provider , and is then passed on to your S3 object storage for persistent storage.

Because you must configure the s3 provider with parameters specific to your account (but can leave all other parameters with the recommended values), if you choose to use the cluster-s3-storage-v3 template, your binarystore.xml configuration file should look like the example below.

Amazon S3 supports two authentication methods.Basic credentials - If you use the basic credentials, you will need to enter the identity and credential parameters

You can implement sharding with multiple S3 buckets. The s3-sharding template is available with Artifactory to configure sharding with S3. A sub-binary provider, state-aware-s3, template is used with the s3-sharding template to implelement sharding across multiple S3 buckets.

Sharding rules such as redundancy and write/read mechanisms are applicable on the new data added to the filestore post the changes to the filestore configuration. For existing data in the filestore, you must copy the data to other new S3 shards.

This binary provider is not independent and will always be used with S3 sharding. The provider is aware if its underlying S3 bucket is functioning or not. It can also recover from errors (the parent provider is responsible for recovery) with the addition of thecheckPeriodfield.

Enables/disables the write operations for the binary provider. If set to false, the state-aware-s3 provider will continue to serve read requests, so Artifactory can continue to read binaries from that provider. In addition, the garbage collection can continue to clean the deleted binaries from the provider. (Only applicable under a sharding provider.)

With this setting, as soon as Artifactory starts up, it will automatically move your complete filestore over to your S3 provider. Artifactory validates each file uploaded to S3 and removes the file from the NFS if the transfer is successful.

The process of moving your filestore to your S3 provider will delete your current filestore. We strongly recommend you do a complete system backup before doing this migration.

Copy the$JFROG_HOME/artifactory/var/data/artifactory/filestoredirectory to your S3 object storage to the bucket name and path specified when you configured Artifactory to use S3.

03 For the get-findings command output returned at the previous step, review each security finding by analyzing its properties: "type" - the type of the security finding, e.g. "Policy:IAMUser/S3BucketEncryptionDisabled". For example, if default encryption was enabled for an S3 bucket when you enabled Macie for your AWS account, and default encryption is later disabled for the bucket, then Amazon Macie generates a "Policy:IAMUser/S3BucketEncryptionDisabled" finding for the bucket.

"description" - a detailed description of the finding, e.g. "Encryption is disabled for the Amazon S3 bucket. The data in the bucket isn"t encrypted using server-side encryption."

"resourcesAffected.s3Bucket.defaultServerSideEncryption" - the S3 Server-Side Encryption algorithm used to encrypt data stored within the specified (affected) bucket. If encryption is disabled for the specified bucket, the "defaultServerSideEncryption.encryptionType" property value is set to "NONE".

04 Based on the information reviewed at the previous step you can analyze the security finding and make a plan to implement the recommended fix. In this case, the remediation consists of enabling S3 Server-Side Encryption (S3 SSE) for the Amazon S3 bucket specified within the Amazon Macie finding details. To enable and configure Server-Side Encryption for the affected Amazon S3 bucket, follow the steps outlined in the S3 Server-Side Encryption conformity rule.

Amazon Web Services (AWS) allows one to use their cloud-based object storage service, Amazon Simple Storage Service, (Amazon S3), to store among other items, images. They are stored in an S3 bucket.

In this article, I"d like to explore one of several ways to display images stored in an S3 bucket on a web page from Node.js. and in such a way that we do not have to store the image to the file system.

However, when the S3 bucket is Private, things become a bit more complicated. With this situation there are two main options. One is to establish a signed URL to your S3 bucket. The other is to access images as a stream.

I will assume you already have a private S3 bucket called companyimages with an image in it. Use the resources mentioned above to help build an S3 if needed.

When the user browses to our web site, the default route (/) will be accessed. In here, app.get(‘/"), is where we will do the majority of our work. First we will establish our AWS credentials. I do not recommend hard coding your IAM credentials like we will be doing. Then we will create an instance of S3.

The const data will contain a data stream. We will need to convert this to a Base64 string and prepend the MIME type. The encoding will be done in a function, encode(). The encode() function below will be invoked once we get the data from S3.

We have successfully pulled an image from an AWS S3 bucket and displayed it without having to use the file system to store the image. Why bypass the file system? If you happen to be running this on an AWS EC2, you do not have access to the file system or rather should not be using it.

Log in to the AWS console on your browser and click on the Services tab at the top of the webpage. Click on “S3” under the Storage tab or type the name into the search bar to access the S3 dashboard.

Click on the blue button at the bottom of the page that says Next: Permissions. Select the box that says Attach existing policies directly and find "AmazonS3FullAccess policy" from the list.

In this project, a user will go to the Flask web application and be prompted to upload a file to the Amazon S3 bucket. After clicking the button to upload, a copy of the media file will be inserted into an uploads folder in the project directory as well as the newly created S3 bucket.

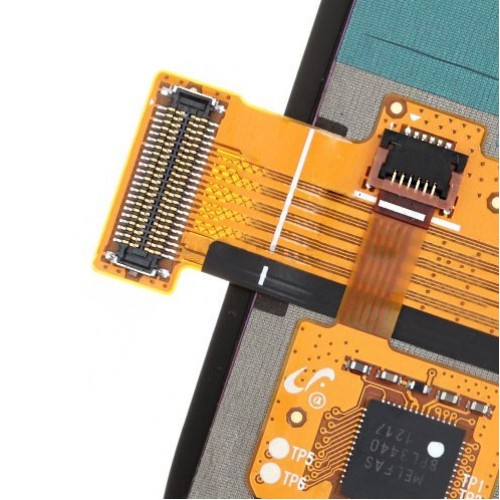

Awesome! Glad to see that you’re trying to use these displays. In my work I discarded the original circuit board and just used the display touch panel and added different electronics.

If you want to just reuse the touch panel display, first you will need to figure out the pin outs for the display connector. I guess the pin outs are probably the same as the one in my two units but take a close picture of the connector and you can make an educated guess if it’s the same. Also if you find the part number of the display panel you can look for that part number on the “panelook” website.

Next you will need to wire your display to a controller that can drive the RGB signals. I’m using the ESP32-S3 in this project. The ESP-IDF has a sample program that you can try out. But there will be a lot of wires to connect! Also you will need some way to drive the backlight. My first prototype was a mess and wires kept coming loose when I moved something but at least I proved that my display worked and that I had the right pin outs.

Also you can verify the touch panel works much easier since it only has a few pins. I unsoldered the FPC connector off of the original PCB and soldered on wires that I could connect to an Arduino or CircuitPython board.

After I proved the pin outs worked, I designed a PCB with a backlight driver and all the display connections between the ESP32-S3 development board and the display. That made it much more compact and portable and less likely to come apart during testing.

The Samsung Galaxy S3 arrives packing a very generous 4.8in HD Super AMOLED display – which might possibly push the boundaries of comfortable one-handed use for some of the smaller-handed gadgeteers out there. Still, it could be the sweet spot for many, falling nicely between the HTC One X’s and Galaxy Nexus’ 4.7in screens and the Samsung Galaxy Note’s monolithic 5.3in display.

The Galaxy S3’s screen packs a 1280×720 resolution into its 4.8in frame, giving you 306ppi to play with – that’s just shy of the iPhone 4S’ and HTC One X’s 326ppi and 312ppi respectively. Given the size of the screen however, it’s fair to say that Samsung has pulled off something rather special here.

The Samsung Galaxy S3’s screen utilises HD Super AMOLED technology (as seen in the Samsung Galaxy Note) – which should result in vivid, detailed colours and deep, rich blacks. We’re slightly disappointed in the lack of a HD Super AMOLED Plus screen (which is found on the Galaxy S2) – but you can’t have everything we suppose.

Finished off with an even slimmer bezel than the one found on the Galaxy SII, the Samsung Galaxy S3’s display is set to be one of the best available on any current smartphone and will undoubtedly have iPhone users (with their 3.5in screens) green with tech-envy.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey