lcd panel just flashes through patterns free sample

Given the ubiquity of smartphones, it is unfortunate that the flicker on their displays (especially OLED displays) is still an issue for many people. But wait! Why do they flicker? Well, let’s remember that smartphone display hardware is based on either LCD (liquid crystal display) or OLED (organic light-emitting diode) technology. LCDs don’t emit their own light; rather, they are back-illuminated by a strip of LEDs whose light intensity is quite powerful so as to compensate for the brightness drop due to the low transmission rate of the LCD panel (caused mainly by the RGB color filter). By contrast, in an OLED display, every pixel is itself an OLED that produces its own light.

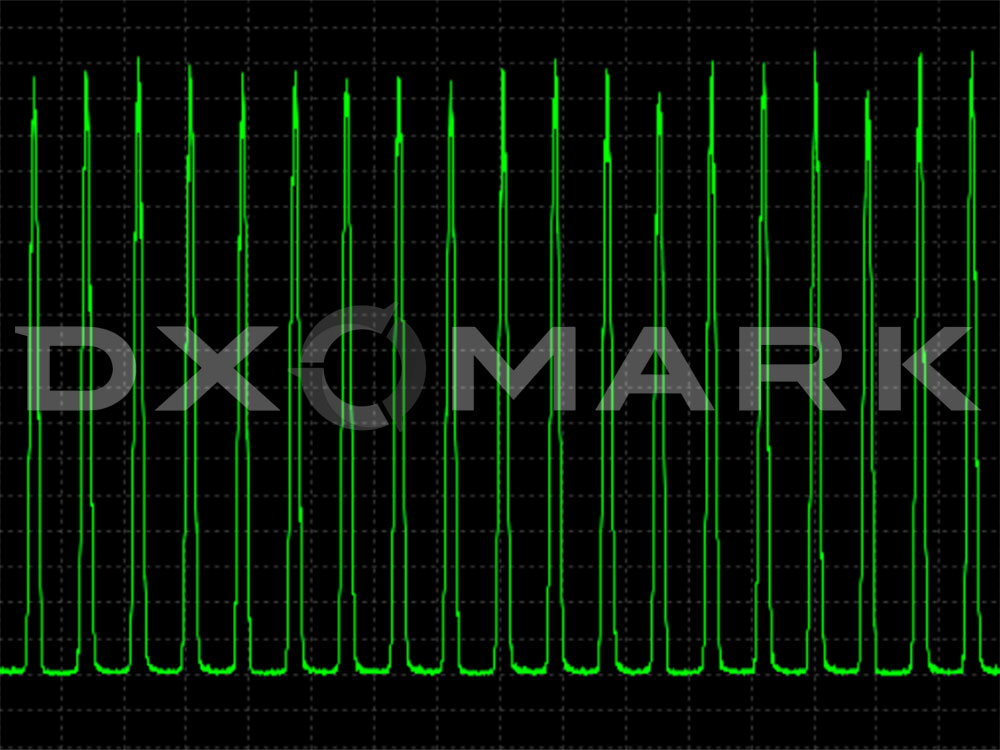

Since both LCDs and OLED smartphone displays are composed of light-emitting diodes, let’s describe how these diodes are driven. Because of a diode’s intrinsic physical properties, it cannot be dimmed by changing the intensity of the current (mA) without impacting the color of the light. So how do phone manufacturers dim displays? They make use of a technique called pulse-width modulation (PWM), which means that they turn the diodes off and on at varying rates. Because we normally should not be able to see this switching between off and on (in other words, the flicker!), our brains are fooled into perceiving the screen as simply dimmer overall (a phenomenon known as the “brain averaging effect”). How dim depends on how long the diodes are off versus how long they are on: the longer they’re off, the dimmer the screen will appear.

So both LCDs and OLED displays power their light sources differently, but both technologies are subject to flicker effect; however, it is usually more noticeable on OLED displays than on LCDs. For one thing, OLED displays and LCDs show PWM at different frequency ranges — the PWM of OLED displays range from ~50 to ~500 Hz, whereas the PWM of LCDs starts at around 1000 Hz or higher. Second, as the human eye may experience flicker sensitivity up to about 250 Hz (at least for most people), it should come as no surprise that OLED displays are more likely to cause eyestrain than LCDs.

A significant disadvantage to using PWM technology can be that when a display adjusts to its minimum brightness in very dim or completely dark ambient light conditions, the duty cycle is very short and the interval when the diode is off is proportionately much longer (for example, minimum brightness may translate to a 10% duty cycle, meaning that the diode is off for 90% of the period). At lower PWM frequencies, flicker can become much more noticeable, which helps explain why reading text or watching videos in bed at night is more likely to cause headaches and eyestrain than when viewing screens in brighter conditions.

The first spike in our flicker graph appears at a phone’s listed refresh rate, but it is the highest spike — that is, the one that comes closest to or surpasses 0 dB — that is of interest to us in terms of flicker, as it indicates the PWM frequency; in this case, 241 Hz for the Samsung (S20), 362 Hz for the Huawei, 481 Hz for the OnePlus, and 240 Hz for the other Samsung (Note20). (Just in passing, you can nearly always ignore values below -40 (dB) on the graph, as they correspond to testing noise.)

Finally, it’s also important to remember that some people are more sensitive to noticing flicker than others; in fact, even people who may not consciously perceive flicker may nonetheless be sensitive to it, winding up with headaches or eyestrain after overdoing their screen time. Such people could choose an OLED smartphone with an anti-flicker feature, or one with an LCD. As you can see in the table below, the last entry shows the data for the Xiaomi Mi 10T Pro; since it uses LCD technology, its PWM frequency is so high that it in essence eliminates the flicker issue.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

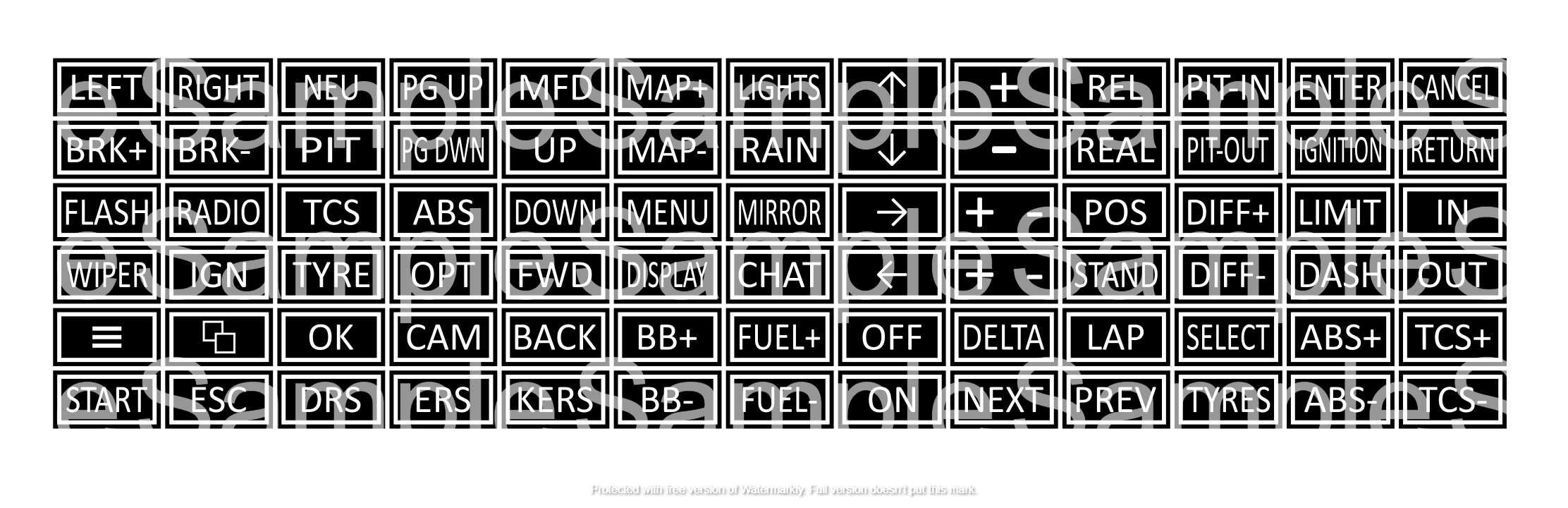

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

That annoying dead pixel on your TFT, OLED, or LCD screen might just be stuck and easy to fix. We"ll show you how to do it. You can still return your monitor if this doesn"t work; nothing we recommend here will void your warranty.

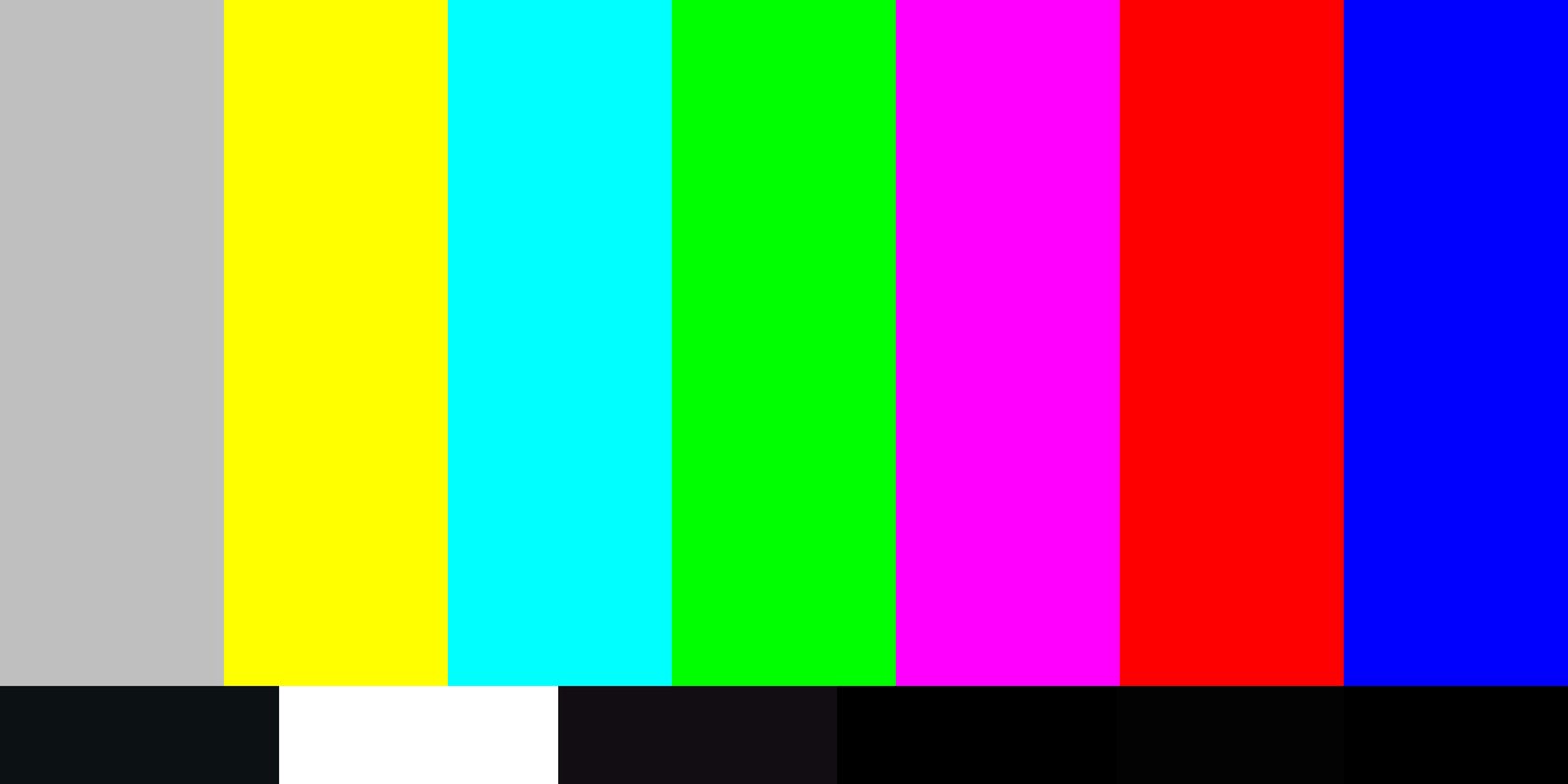

Yes, you should test any new monitor for bad pixels. You can simply run your screen through a palette of basic colors, as well as black and white in full-screen mode using a tool like EIZO Monitor Test.

Below you see the first test pattern. Each screen has an explainer in the bottom right detailing what you should look for. Next, you"ll see a menu that lets you go from one test to the next on the left. Move through the black and white screens and all the solid colors (green, blue, and red) and check our screen. To exit, press the ESC key or the exit symbol in the top right.

Move the mouse to the top of the test window, and a menu will appear. There is an info window that you can turn off with a button in the top right corner of the menu. Then click on the Homogenuity test point and move through the three colors as well as black and white.

In a dead pixel, all sub-pixels are permanently off, which will make the pixel appear black. The cause could be a broken transistor. In rare cases, however, even a black pixel may just be stuck.

Let it run through all colors in Auto mode to spot whether you have any weird pixels on your screen. If you do, start the fix, which will rapidly flash your entire screen with black, white, and basic color pixels.

This works because, in a stuck pixel, the liquid in one or more of its sub-pixels has not spread equally. When your screen"s backlight turns on, different amounts of liquid pass through the pixel to create different colors. When you apply pressure, you"re forcing the liquid out, and when you release the pressure, chances are the liquid will push in, spreading around evenly as it should.

When all attempts to revive your bad pixel fail, the next best thing you can do is to make peace with it. One ugly pixel won"t break your screen, and eventually, you"ll forget about it. If the defect affects more than a single pixel, however, or just bothers you a lot, you can always replace your monitor.

Bright or dark sub-pixels can occur during the production of the LCD Monitor panel but does not affect the LCD Monitor functionality. The customer may notice the bright or dark spots if the film of the liquid crystal does not perform as expected while customers uses the LCD monitor. However, this is not considered a defect unless the number of bright and dark subpixels exceeds the maximum allowable threshold (...)

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

There are many different types of TVs, from CRT TVs to LCDs to plasma screens, and the causes of color problems are numerous and diverse. In general, muddy, oversaturated, or strange shades of color result from a simple misuse of the TV’s built-in color settings.

Your TV could also be in service mode. In this mode, the TV circulates through a red, green, blue, white, and partially white full-screen display to check for inactive pixels.

Adjust the contrast so that white and black are distinguished, and adjust the brightness so that black is darker than gray. Increase the sharpness completely, then decrease it until the halo around the lines and letters disappears.

Flatscreen liquid crystal displays recalibrate the molecular structure of crystals to create color displays. LCD monitors rely on a single-pixel to provide the entire image.

Another flat-panel television, the plasma display, creates color images through small cells of charged ionizing gas. Like LCD TVs, plasma TV colors can be affected if the TV is not set to the proper resolution.

Such damage can be caused by magnets near the screen, for example from unshielded speakers, and can either be permanent or reversible. In any case, you need to use a professional repair service to inspect the set. It may be more economical to just buy a new set.

If using an antenna for your TV, broadcast signals reflected by nearby tall buildings may cause ‘ghosting’ in the picture. Simply try readjusting the antenna direction and location.

Photosensitive epilepsy is when seizures are triggered by flashing lights or contrasting light and dark patterns. Photosensitive epilepsy is not common but it may be diagnosed when you have an EEG test. Flashing or patterned effects can make people with or without epilepsy feel disorientated, uncomfortable or unwell. This does not necessarily mean they have photosensitive epilepsy.

Around 1 in 100 people has epilepsy and of these people, around 3% have photosensitive epilepsy. This is when seizures are triggered by certain rates of flashing lights or contrasting light and dark patterns. Photosensitive epilepsy is more common in children and young people (up to 5%) and is less commonly diagnosed after the age of 20.

This is when you have a seizure straightaway, caused by being exposed to flashing lights or patterns. An electroencephalogram EEG can help with diagnosis, and may include testing for photosensitive epilepsy. This involves looking at a light which will flash at different speeds. If this causes any changes in brain activity, the technician can stop the flashing light before a seizure develops.

Between 3-30 hertz (flashes per second) are the common rates to trigger seizures but this varies from person to person. While some people are sensitive at frequencies up to 60 hertz, sensitivity under 3 hertz is not common.

Some people are sensitive to geometric patterns with contrasts of light and dark such as stripes or bars. Patterns are more likely to be a trigger if they are changing direction or flashing, rather than if they are still or moving slowly in one direction.

For about 3% of people with epilepsy, exposure to flashing lights at certain intensities or to certain visual patterns can trigger seizures. This condition is known as photosensitive epilepsy.

Many people are not aware they are sensitive to flickering lights or to certain kinds of patterns until they have a seizure. They may never go on to develop epilepsy with spontaneous seizures. They could only have seizures triggered by certain photic (light) conditions.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The function digitalWrite() is used to apply either HIGH or LOW voltage to a pin. HIGH will apply 5 volts to the pin you designate and LOW will apply 0 volts. If you apply 5 volts to a pin that is connected through an LED to ground, then the LED will light up.

There is a voltage difference between the pin and ground, thus current is able to flow through the LED. If you apply 0 volts to the same pin the LED will not light up because no current is being “pushed” through the circuit – the voltage at ground and at the pin are both zero.

Once digitalWrite() function has been executed, the LED will get bright – we just applied 5 volts, so hey, that makes sense. The next thing we do is delay the Arduino sketch to enjoy the bright glow of our LED. To do this, we use the delay() function.

Once again, the LED will light up, delay a second and then go dark for one second. And repeat – now you have a blinking LED – pretty cool for just a couple lines of code!

In LCD screens, the LCD itself does not flicker, it preserves its opacity unchanged until updated for the next frame. However, in order to prevent accumulated damage LCDs quickly alternate the voltage between positive and negative for each pixel, which is called "polarity inversion". Ideally, this wouldn"t be noticeable because every pixel has the same brightness whether a positive or a negative voltage is applied. In practice, there is a small difference, which means that every pixel flickers at about 30 Hz.

More of a concern is the LCD backlight. Earlier LCDs used fluorescent lamps which flickered at 100–120 Hz; newer fluorescently backlit LCDs use an electronic ballast that flickers at 25–60 kHz which is far outside the human perceptible range, and LED backlights have no inherent need to flicker at all. On top of any inherent backlight flicker, most fluorescent and LED backlight designs use digital PWM for some or all of their dimming range by switching on and off at rates from several kHz to as little as 180 Hz,

Flicker is used intentionally by developers on low-end systems to create the illusion of more objects or colors/shades than are actually possible on the system, or as a speedy way of simulating transparency. While typically thought of as a mark of older systems like 16-bit game consoles, such flicker techniques continue to be used on new systems, as in the temporal dithering used to fake true color on most LCD monitors.

Video hardware outside the monitor can also cause flicker through many different timing and resolution-related artifacts such as screen tearing, z-fighting and aliasing.

‡ Medicare coverage is available for FreeStyle Libre 14 day systems for cell phone use if FreeStyle LibreLink is used in conjunction with the FreeStyle Libre 14 day readers. Patients must meet Medicare eligibility coverage criteria LCD L33822 (July 2021). Local Coverage Article: Glucose Monitor Policy Article (A52464), July 2021.

§§§ or ♢ Eligible patients will receive one (1) FreeStyle Libre 2 sensor for users with a compatible mobile phone operating system at $0 copay. The expiration date of the voucher is 60 days from the issue date. This program is available for patients with Type 1 and Type 2 diabetes; it is not available for patients with gestational diabetes. Only patients ages 18 and older are eligible to sign up and receive an offer for the FreeStyle Libre 2 sensor and patients ages 4-17 are eligible to receive an offer for the FreeStyle Libre 2 sensor through their parent or guardian. This offer is void where prohibited by law. Abbott may modify or rescind this offer at any time without notice. The discounts are not available to beneficiaries of Medicare, Medicaid or other federal or state healthcare programs or residents of Massachusetts, Puerto Rico and other US territories. The free FreeStyle Libre 2 sensor is provided as a sample and is limited to one NDC per eligible person. The FreeStyle Libre 2 sensor cannot be re-sold, traded nor submitted to any third-party payer for reimbursement and is not provided as any inducement for future purchases. The free sample card is not health insurance.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey