data image lcd panel brands

Data Image is a manufacturer of LCD modules, established in 1997. Currently, we have manufacturing strongholds in Taiwan and China. With constant, proactive development in the expertise of LCD Modules, we provide diversified products and services for customers that include mono/ color LCD modules.

In 2009, we further invested in the application and integration of touch panels with LCDs, providing coordinated processing solutions to customers from design to manufacturing of capacitive touch panels. We provide in-house optical bonding technology and total solutions for touch display requirements.

Our products are sold primarily to manufacturers and distributors in a diverse and growing range of industries, including Industrial HMI, Marine MFT, Automotive, VoIP phone, Payment terminal, MFP, etc. To make our competence qualified, DATA IMAGE has certifications of TS16949 (for automotive application), ISO13485 (for medical devices), ISO 9001, ISO 14001, and QC080000.

LED video wall solution with advanced video wall processing, off-board electronics, front serviceable cabinets and outstanding image quality available in 0.9mm pixel pitch

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

LED video wall solution with advanced video wall processing, off-board electronics, front serviceable cabinets and outstanding image quality available in 0.9mm pixel pitch

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

There has been a significant shift in the global display industry lately. Apart from new display technologies, the display world is now dominated by players in Asian countries such as China, Korea, and Japan. And rightly so, the world’s best famous LCD module manufacturers come from all these countries.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a Cortex A8 1GHz Standard 256MB. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

In this post, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the reputable LCD module manufacturers in the world.

Samsung is the world’s largest semiconductor and consumer electronics manufacturer by revenue. The electronics giant is well-known for its smartphones and home appliances, but the company also manufactures LCD, LED, and OLED panels.

Probably the most in-demand and popular display panel product for Samsung is their OLED technology. Most of its current smartphones use their trademark Super AMOLED displays. The technology allowed Samsung’s smartphones to be ultra-thin, with better image brightness, and less energy consumption.

Samsung now produces panels for smart TVs. With their ever-evolving technological expertise and high-quality products, the company shows no signs of slowing down as one of the world’s best famous LCD module manufacturers.

Stone provides a professional product line that includes intelligent TFT-LCD modules for civil, advanced, and industrial use. Furthermore, Stone also creates embedded-type industrial PCs. The company’s products are all highly-reliable and stable even when used with humidity, vibration, and high temperatures.

Stone Technologies caters to a wide range of clients and industries, being among the world’s best famous LCD module manufacturers. The company’s products are used in the following industries:

Originally, LG Display was a joint venture of mother company LG Electronics and the Dutch company Phillips. They dedicated the company to creating active-matrix LCD panels. Another joint venture called LG. Phillips Displays was created to manufacture deflection yokes and cathode ray tubes.

LG Display has risen above the rest because of its world-class module products. Because of this, the company caters to a massive range of famous clients including Hewlett Packard, Apple, Sony, Dell, Acer, and Lenovo. LG Display also creates LCD modules and similar display panels for the company’s television product range.

Innolux Corporation is another famous LCD module manufacturer. This company was established in 2003 and is currently based in Zhunan, Miaoli County, Taiwan.

The company is a well-known manufacturer of display panels in Taiwan. Innolux supplies TFT-LCD and LED panels, open cells, and touch modules for the following products:

What makes Innolux stand out from other LCD module manufacturers is the company’s commitment to its humanistic qualities. Innolux believes that they are in the business to contribute to the well-being and prosperity of their customers. This is then achieved by creating world-class products that satisfy its clients.

Sharp is a Japanese company founded in 1912. It is now based in Sakai, Osaka Prefecture. The company produces various kinds of electronic products including mobile phones, LCD panels, calculators, PV solar cells, and consumer electronics. Sharp has produced TFT-LCD products as early as the 1980s.

For the regular public consumers, Sharp produces a variety of smart TVs and LCD TVs marketed under the Aquos brand. The company’s television line-up boasts of impressively high-quality technology. The TVs are equipped with technologies that support 4K and 8K UHD display, allowing for a great high-resolution viewing experience.

BOE Display is among the leading display manufacturers in the world. The company started in 1993 and is currently based in Beijing, China. Apart from display panels, BOE also manufactures smart systems using IoT technology.

The company proudly utilizes high-end technologies to create world-class display solutions. For instance, AU’s production lines can manufacture a variety of display applications in a full panel size range. The manufacturing lines also support:

Sustainability is among the ultimate goals of AU Optronics. The company takes steps to integrate green solutions into their products for more sustainable development. This commitment to sustainability, among other strong qualities, makes AU Optronics one of the best LCD manufacturers in the world.

Most of these products use TFT-LCD panels alongside other technologies to create ultra-high-definition images. Also, modern Toshiba display products incorporate IoT and artificial intelligence for a smarter product experience.

Kyocera is a Japanese LCD manufacturer. The company started in 1959 as a fine technical ceramics manufacturer but gradually added consumer electronics products to its offerings.

The Japanese company acquired Optrex Corporation in 2012. The acquisition paved the way for creating an R&D center and more production, sales, and marketing bases. Hence, Kyocera’s global LCD business boomed even more.

The company also operates factories, R&D centers, and marketing facilities in Asia, the Middle East, Europe, Africa, North and South America, and Oceania continents. Kyocera has a vast worldwide reach that makes it one of the world’s best famous LCD module manufacturers.

To wrap all this up, we listed 10 of the world’s best famous LCD module manufacturers. These are all highly-respected companies that built their reputations and climbed up the ladder of LCD module manufacturing. Their quality products, dedication to their craft, and excellent customer service truly make them among the world’s best display solutions providers.

Since 1993 we offer LCDs and LCD system solutions. We are always up to date with the latest technology and are looking for the best products for our customers. Our TFT display range includes high-quality displays:

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

These different technological approaches to display technology have big impact in some features including contrast, brightness, viewing angles, lifespan, black levels, image burn-in, and price.

Contrast refers to the difference between the lightest and darkest parts of an image. High contrast will produce sharper images and more easily readable text. It’s a crucial quality for high fidelity graphics and images or to make sure that a message on a display is very visible.

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

Have you ever looked at a screen from an angle and noticed that the images became washed out or shadowy? The further away you get from the “front and center” view, the worse the image appears to be. This is an example of viewing angles in action – the wider the viewing angle, the better the images on screen will appear as you view them from different vantage points.

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

There are 3 responsive data-driven creative formats in Display & Video 360: Panorama, Cuecard, and Blank Slate. These new formats are ideal for promoting brand awareness. To get started, choose a format, add your brand assets, then customize for your audiences and goals.

Because data-driven creatives can have hundreds of variants, there are different preview options for these formats. In the list of creatives, there"s no Preview option

See demos and learn more about the features and assets for each format below. All assets are optional, so if you don"t have the right image for an asset, you can leave it out.

As a Systems Integrator & Managed Services Provider, Visual Image display boasts years of expertise in Consumer Engagement Technology Solutions ranging from LED Video Walls to Interactive Experiences (including kiosks, mobile & beyond), Sensor Technologies, DOOH & Electronic Shelf Labels. Our cloud-based platform allows our clients to collect data, while also seeing the results of their investment & health of the technology estate in real-time.

First, let us start with dividing internal and external interfaces in LCD modules. Internal interface of display means it used inside the device. Those are usually the embedded interfaces that are not visible, and we do not have access to them as the users of the device. External interfaces, on the other hand, are connected to the device using a cable. Once we have defined internal and external interfaces, both of these categories come as universal or image transfer interfaces.

Let’s try to get the interfaces right. For internal interfaces, interfaces embedded into the device, we have universal interfaces and image transfer interfaces. Universal display interface can send other data, not only an image. Being universal, they are not perfect for image transfer, because in most of the displays used nowadays, the image transfer is one of the most demanding. The bit rate, the data transfer needed for the image transfer is rather high. Higher that many universal interfaces can offer. If we need to send an image every once in a while, then we don’t need very high bandwidth. If we do not need live video stream, then we can use some of the internal universal interfaces such as SPI, I2C or even slow interfaces as RS232 or UART.

The first universal interface will be SPI (Serial Peripheral Interface). This interface is serial, used for communication between a host, in SPI called a Master, and devices called Slaves. One host can communicate with many slaves. To select the Slave, we use the Chip select or SS line and then we use two data lines, Master output or Master input. And of course we have to define the clock, to synchronize the data, because this is a clock synchronized interface.

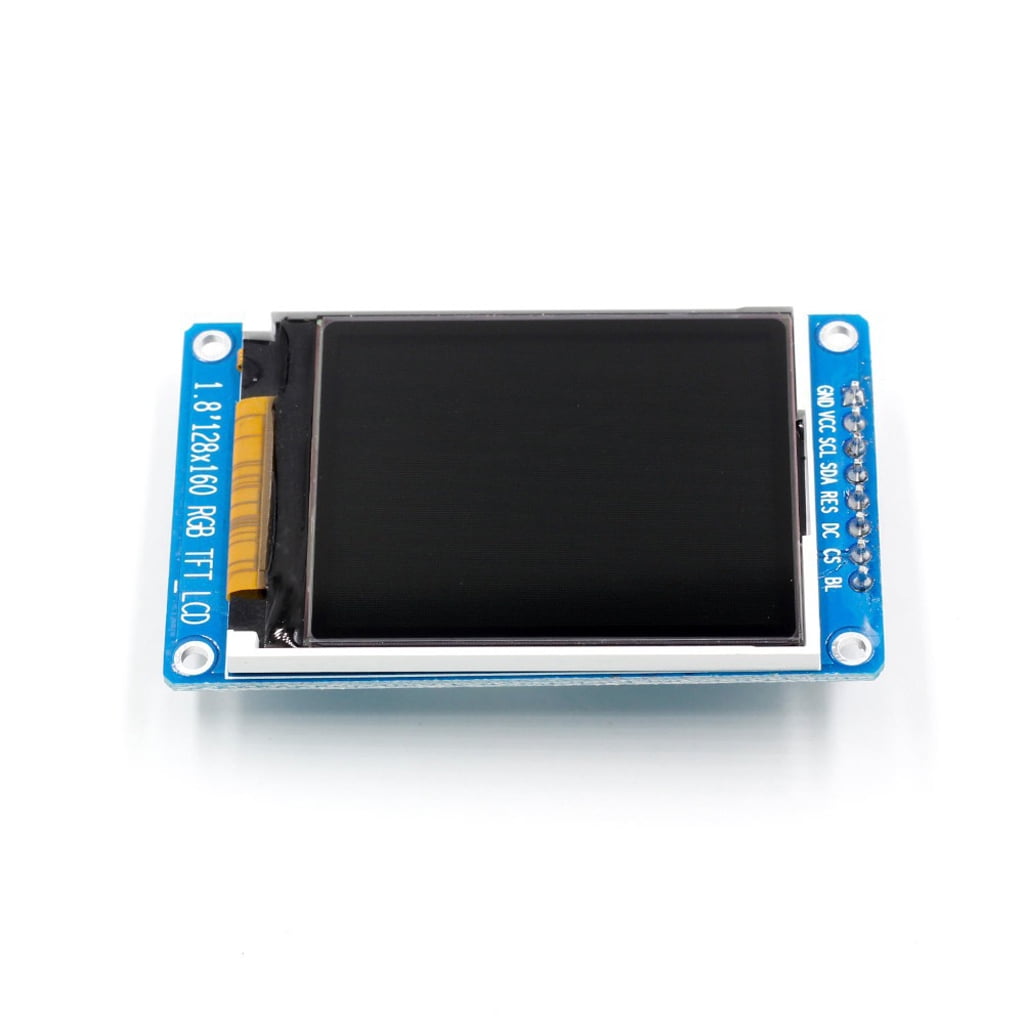

It can be fast but is not fast enough for live video. The baud rate can be 1 MBd, but it can also be 10 MBd or even 50 MBd on the SPI or QSPI. QSPI is a Quad SPI, a kind of modification of SPI that is faster. But still this interface is very universal, we can use it to connect memory or some input and outputs internally in our device. In the display universe the SPI is used for simple displays, for small size displays, where we can transfer the image relatively fast, because the resolution is low. The maximum size for SPI display interface would be 3.5 inch, 320 by 240 pixel TFT displays. If we have higher resolution, image transfer will be too slow to use SPI even with a high-speed SPI.

Next, we have the I2C interface. This kind of interface is usually slower than SPI. It uses only two lines, so one is a clock for synchronization, and the other one is the data line. This data line is bidirectional. It means that if in SPI we have two data lines, one outgoing and one incoming, then in an I2C interface we have only one data line.

If, for example, the Master is sending some data, the only thing Slaves can do is to receive it. And then we need to wait a little bit for the Master to finish. We can then respond as Slave to Master. In I2C Slave selection works a little bit different than in SPI, where we had a Chip Select line (CS line) or SS line to select from. In I2C we first need to send the logical address to the interface that is being written by Slaves. In general, this procedure is slow and universal interface used also to connect the simple memory and some other I2S that we have around our microcontroller on the PCB. It is very useful, but usually not used for image transfer. This interface is very popular in the display world for touchscreens. Most of the embedded touch screens that we use have I2C interface because the touchscreen does not generate many data. We only have coordinates of the finger or few fingers at most, that need to be sent back to the microcontroller, to the device processor. The slow baud rate is good enough for the touchscreen, but not enough for the image.

The UART is basically the same as RS232, but it is a fully internal interface. It is pretty slow. We have a TX line and a RX line – a Transmit Line and a Receive Line. We do not have a clock here, we only have a clock to synchronize the device internally, but the clock signal is not sent out. So, we need to synchronize the data that is coming through the lines and to do that we need to set the same baud rate on both sides of the communication line. That means that before we use UART we need to agree first what speed we will use.

That is not a case for SPI or I2C, because we have a clock there that gives the speed to every device. Then each device works according to the clock. In UART we do not have a clock. It is rather not used for image transfer. The UART, or SPI, or I2C can be used for low resolution displays. For high resolution displays we need an Intelligent Display, a display that will generate the image internally and through these slow universal interfaces we only send commands, or we send the image once, the image is being stored into the internal memory of the intelligent display, that we will use later sending the commands. You can find Riverdi’s intelligent display line on our website: https://riverdi.com/product-category/intelligent-displays/.

These Riverdi products are very advanced Intelligent Displays, made with Bridgetek controllers. The controllers use SPI and QSPI for communication. That means your software, your system, your microcontroller can be simple. You can use SPI interface to drive them, and you can still have high resolution image, even as high as 1280 by 800 pixels in 10.1-inch LCD displays. So, please remember that if you want to use a slow universal interface and have a high-resolution image, you need to use an Intelligent Display.

There are also the internal image transfer interfaces. The image transfer interface allows continuous high speed image transfer. Internal transfer is high enough to refresh the display many times per second. This is called the refresh rate of a display. When you go to a display, monitor, or TV set specification, you will see refresh rate or maximum refresh rate parameter. If it’s 60 Hertz, that means the display image is refreshed 60 times per second. More advanced displays would have higher values, like 100 Hertz. The refresh rate means we need to send full image 60 times or 100 times in each second. To visualize this amount of data, we need to multiply refresh rate by the resolution of the screen. For example, for a 7-inch Riverdi LVDS display with resolution 1024 by 600 it is roughly 600 thousand pixels.

The most common internal image transfer interface in industrial LCD displays nowadays is LVDS – Low Voltage Differential Signal. A crucial feature of this interface is that it is differential. It means that the signal is immune to interference and we can use a twisted pair of wires to transfer the data. We can send data fast and it will not be corrupt by any noise, interference. This kind of data corruption is quite common in other interfaces.Key Takeaway: In LVDS display interface the differential signal allows you to send the signal at a very high speed and keep it safe from noise.

The next, older image transfer interface is called RGB. Name comes from the colors sent parallelly to the display: red, green and blue. LVDS is a serial interface and the RGB is a parallel interface. The main difference is that RGB is not differential, so it is easier to disturb signal with noise and you configure the speed of this interface too high. Parallel interface means that we send every bit in a separate line. In theory this interface could be fast, but because it is not differential, the transfer speed is limited. Moreover, the RGB display interface will work with rather small screen sizes – usually up to 7-inch or 10-inch.

12 inch screen size is the total maximum for a LCD display with RGB interface, but the resolution will be lower, like 800 by 600. For this display size it is very low resolution. This is the reason why the 7-inch is size above which the LCD displays are being switched from RGB to LVDS interface. Among Riverdi products (if you go to the Riverdi website and to the IPS display tab), there are displays without the controller, and the small displays like 3.5-inch, 4.3-inch and 5-inch are equipped with RGB interface. But when you go to the 7-inch LCD displays tab on Riverdi website, you will find RGB, LVDS and MIPI displays. But when you go to the 10-inch or bigger displays, you will only find the LVDS displays because our 10-inch LCD displays are high resolution 1280 by 800, and it is impossible to build it with the RGB interface.Key Takeaway: RGB is low speed and not immune to noise. Use it for the smaller size displays or with lower resolution.

MIPI – Mobile Industry Processor Interface – is an internally embedded image transfer interface, getting popular these days. This kind of interface is used in mobile applications, tablets or mobile phones, but it is entering as an option in industrial applications. In Riverdi we offer 7-inch MIPI displays, but please be careful with other MIPI displays on the market. Many come from mobile phones or tablet market. Also, the TFT glass availability may not be stable as the mobile market changes really fast, every six months or every year. When you buy a 7-inch Riverdi MIPI interface display you are safe, because it is an industrial display.

Next interface is the Vx1. It is similar to LVDS and MIPI, so it’s low voltage differential signal. Vx1 is a very high-speed interface, usually used in large high-resolution screens, like 55-inch 4K TVs or even larger ones. If you buy this kind of a TV set right now, probably the embedded interface inside will be the Vx1.Key takeaway: Vx1 is a super-fast interface used for high bandwidth image transfer, with high refresh rate and high-resolution displays, used in 4K screens and above.

The last internal image transfer interface is Embedded DisplayPort (eDP). We call it the new LVDS, because many new industrial displays are equipped with the eDP. If you go through industrial manufacturers of TFT LCD displays, you will notice increasing number of models available with the eDP. eDP is also a native interface in new Intel or AMD based processors.Key Takeaway: With the embedded DisplayPort as a native display interface you can cut down costs, because you do not need anything extra to connect a display to the processor.

Now, with the processors on the market, we need displays with embedded DisplayPort. Many laptops or monitors already use embedded DisplayPort as an internal interface instead of LVDS. LVDS still is the most popular industrial LCD display interface. All the internal image transfer interfaces like MIPI, Vx1 and eDP are variations of LVDS, where the protocols and the signals are a little bit different. For example, for eDP we can have lower noise and reduced power consumption. All of them have advantages over regular LVDS, but they are all LVDS type.

Now, let’s take a closer look at external interfaces. Those are the ones that we usually have direct access to. It can be TV or monitor connected to your computer with the HDMI . It can be a DVI usually used for monitors. Or VGA which is an outdated image interface for monitors. The DisplayPort that is a HDMI successor. Finally, an universal USB-C, the most common interface nowadays used to connect devices.

Let us start with USB-C, the most universal interface . It is one of the best interfaces that we have ever designed, because it is really fast and also very universal. It not only transfers data, not only it is fast enough to transfer image, but it can also transmit a lot of power.

USB-C transmits up to 100 watt of power, because you can increase voltage and current. In a regular USB it is usually 5 volt and 0.5 or 1.0 amp, so only a couple watts. In USB-C you increase the voltage up to 20 volt and with the 5 amp current, so in total it’s even 100 watt of power. This interface is made not only for data, but for real power transfer. Through USB-C you can charge your phone and your laptop. If you buy a new laptop right now, you may even not get a regular power connector, but only an USB-C. The USB-C is a very smart interface. If you connect the devices, they can negotiate with each other which one has more power. For example, if we connect a charger to a laptop, the charger has more power and will charge the laptop, but if you connect the laptop with the same interface to your mobile phone, then they will discuss the power levels, and of course the laptop will be charging the phone. You can already find monitors on the market that have USB-C instead of HDMI. Those monitors can be powered from your computer and need only one USB cable, both for image transfer and power. For sure the future belongs to USB-C implementations.Key Takeaway: USB-C is a really smart, universal and fast interface for displays. It comes with power transmission option.

Let’s move on to image transfer interfaces. The most common one is HDMI – High-Definition Multimedia Interface. M stands for Multimedia, because it transfers image with sound. If you connect your computer to your TV set with HDMI, you will need one cable for both the video and the audio. There are variations of HDMI connectors:standard HDMI,

The connector is little bit different in each, but the pinout and everything else stays the same.Key Takeaway: HDMI is an extremely popular and easy to use interface. It can send both multimedia A/V data.

The next one is DVI – Digital Visual Interface. The first DVI was not a multimedia interface, because it did not have audio data transfer. Nowadays, there are some variations that can transfer audio, but it is non-standard. We can assume DVI is rather for image transfer. It is a digital interface, similar in signals to HDMI. The latest variation is DVI-I, where I stands for integrated interface. It can have a digital and analog part for VGA compatibility. In the picture above there is a DVI-D, digital only, where we do not have the pins for analog VGA interface. Analog VGA is sometimes available in your desktop computer, but not in laptops anymore.Key Takeaway: DVI is digital visual interface with multiple variations and updates, similar in signal to HDMI

The last external interface that we can find in our devices nowadays is a DisplayPort. DisplayPort is similar to HDMI or DVI. It can also transfer image and sound. It is even faster than the HDMI. Usually, the DisplayPort is used for high resolution displays, for new monitors and TVs with 4K or 8K resolution where it is really hard, or nearly impossible, to achieve such resolution using HDMI interface.Key Takeaway: DisplayPort is super-fast image and sound transmitting interface, used in highest resolution displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey