tft lcd led unterschied made in china

The display of LED video wall technology is colorful, energy-saving and environmental friendly, and the visual angle is high. However, we do not know what led technology is and what is good about it. As the leader of LED display screen industry, Shenzhen Kaipu Technology Co., Ltd. has the obligation to popularize what is led and what is led tv.

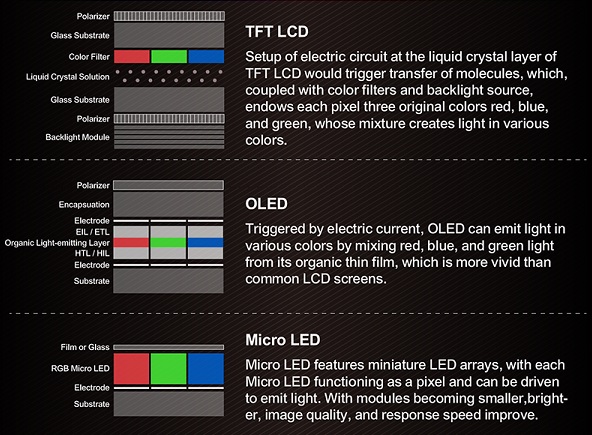

The liquid crystal display we often use is actually an LCD display, which is called liquid crystal display in English. Most of the panels are TFT, TFD, ufb and STN. The working principle of the liquid crystal display is to change the color of the liquid crystal inside the transistor by applying power, and there is a fluorescent lamp CCFL backlight behind the transistor board, which usually consumes a lot of power. The LED screen display we see is usually derived from the LCD display, and generally refers to the liquid crystal display using the LED backlight. The LED technology display is not a real LED display, so Samsung was sued for this matter. Since the LED display on the market only uses LED backlight technology, most of the LED displays on the market have been changed to LED backlight display

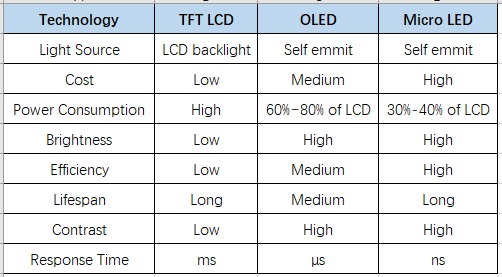

Since the display uses LED tubes as the backlight, with the help of LED technology, the display body can be made lighter and thinner; As the LED tube itself is more energy-saving, the energy-saving and environmental protection aspects are certainly better than the normal display; However, there is not as big a gap in imaging as that spread on the Internet, because the essence is the same thing, and it is impossible to have too big differences.

I believe that by now we have basically understood the difference between LCD and LED backlight display. The real LED display does not need backlight, so the process requirements are higher and the price is expensive. At present, it has not been popularized, and the only ones are still limited to commercial use.

LED (Light Diode Emitting) , although it can also be used as a display, but usually used for large screen display, such as outside the building of large billboards and so on.

TFT is a kind of material of liquid crystal screen, Thin film Transistor, a thin film transistor liquid crystal screen, in addition to TFT, UFB and STN materials, etc., but like mobile phone, notebook computer, PDA, digital cameras and other commonly used is TFT, some older mobile phone screen may be used STN screen.

LED (Light Emitting Diode) a light emitting diode, a solid state semiconductor device that converts electricity directly into light. The heart of LED is a semiconductor wafer, one end of which is attached to a bracket, one end is negative, and the other is connected to the positive electrode of the power to encapsulate the entire wafer with epoxy resin. Semiconductor wafers consist of two parts, one is P type semiconductor, in which the hole dominates, and the other end is N type semiconductor, which is mainly electronic here. But when the two semiconductors are connected, they form a "P-N" junction". When the current passes through the wire acting on the chip, the electrons are pushed into the P region. In the P region, electrons combine with the hole and then emit energy in the form of photons, which is the principle of LED luminescence. The wavelength of light, that is, the color of light, is determined by the material that forms the P-N junction.

50 years ago, people had already understood the basic knowledge that semiconductor materials can produce light. The first commercial diode was produced in 1960. LED is English light emitting diode (light emitting diode) abbreviation, its basic structure is an electroluminescentsemiconductor materials, placed on a wire rack, then sealed with epoxy resin around the solid package, so can protect the internal batteries, so the seismic performance of LED good.

The core part of the LED is a wafer consisting of type P semiconductors and type N semiconductors. There is a transition layer between the P type semiconductor and the N type semiconductor, called the P-N junction. In some PN junctions of semiconductor materials, the injected minority carriers combine with the majority carriers to release excess energy in the form of light, thereby converting the electric energy directly into light energy. When the PN junction applies reverse voltage, the minority carrier is difficult to inject, so it does not emit light. The diode, produced by injection electroluminescent principle, is called light-emitting diode, commonly known as LED. When it in a positive state of the work (which ends with forward voltage), the current flows from the LED anode cathode, semiconductor crystals on the issue from the ultraviolet to infrared light of different colors light and the strength of the current.

Initially, LED was used as an indicator light source for instruments and meters. Later, various light colored LED were widely used in traffic light and large area display screen, which produced very good economic and social benefits. Take 12 inch red traffic lights, for example, in the United States originally using long life, low light 140 watt incandescent lamp as a light source, which produces 2000 lumens of white light. After the red filter, the light loss is 90%, leaving only 200 lumens of red light. In the newly designed lights, Lumileds employs 18 red LED light sources, including electricity

Road loss, including a total power consumption of 14 watts, can produce the same light effect. Automobile signal light is also an important field of LED light source applications.

For general lighting, people need white light sources more. In 1998, white light LED was successfully developed. The LED is fabricated by encapsulating GaN chips with yttrium aluminum garnet (YAG). GaN chips emit blue light (lambda p=465nm, Wd=30nm), sintered at high temperature, and Ce3+ containing YAG phosphors emit yellow light after excitation by this blue light, with a peak value of 550nm. Blue chip installed in the LED based wanxingreflection in the cavity covered with a resin mixed with thin films of YAG, about 200-500nm. The blue light emitted by the LED substrate is absorbed by the phosphor, and the other part of the blue light is mixed with the yellow light emitted by the phosphor, so that the white light can be obtained. Now, for InGaN/YAG white LED, by changing the chemical composition of YAG phosphor and adjusting the thickness of phosphor layer, the white light of color temperature 3500-10000K can be obtained. The method of obtaining white light through blue light LED has the advantages of simple structure, low cost and high technical maturity, so the utility model has the most application.

In the 60s of last century, scientific and technological workers developed LED LED using the principle of semiconductor pn junction light emitting. The LED was then made of GaASP, whose emitting color was red. After nearly 30 years of development, now we are very familiar with the LED, has been able to issue red, orange, yellow, green, blue and other colors. However, the white light LED required for illumination has only developed in recent years. Here we introduce the white light LED for illumination.

1, the relationship between the spectrum of visible light and LED white light. As far as we can see, the wavelength range of light spectrum is 380nm ~ 760nm, which is the seven chromatic light that can be perceived by human eyes - red, orange, yellow, green, cyan, blue and purple, but each of the seven colors is a monochromatic light. For example, the peak wavelength of red light produced by LED is 565nm. In the visible light spectrum is not white light, because white is not monochromatic light, but light composite by a variety of monochromatic light synthesis, as the sun light is composed of seven kinds of monochromatic and white light, white light color TV is composed of three primary colors of red, green and blue synthesis. Thus, to make LED emit white light, its spectral characteristics should include the entire visible spectral range. But to manufacture this kind of LED, it is impossible under the present process condition. According to the research of visible light, the human eye can see white, mixed with at least two light, two light emitting wavelength (blue light and yellow light emitting wavelength) or three (blue light + + red light green light) model. Blue light is needed for all two modes of white light, so the uptake of blue light has become the key technology for manufacturing white light, the Blu ray technology pursued by major LED manufacturers". The international master "Blu ray" only a handful of manufacturers, such as Japan, Japan"s Nichia chemical synthesis, TOYOTA CREE of America, Germany"s OSRAM, so white LED application, especially the high brightness white LED spread in China there is a process.

2, white LED process structure and white light source. For general lighting, the white LED is usually formed in two ways on the process structure. The first is the use of blue light technology to match the phosphor to form white light; the second is a variety of monochromatic light mixing methods. These two kinds

Methods have been successful in producing white light devices. The system shown in Figure 1 the first method to produce white light, blue chip LEDGaM diagram (2 p=465NM), and YAG (yttrium aluminum garnet) phosphor package together, when a yellow light phosphor can be excited by blue light and the blue and yellow light mixed into white light (consisting of LED structures such as as shown in Figure 2). The second method uses different colors of the chip to wrap together and produces white light by mixing each shade of light.

3. Application foreground of white light LED lighting new light source. In order to explain the characteristics of white light LED, first look at the current situation of the lighting source. The incandescent lamp and halogen tungsten lamp have a luminous efficiency of 12~24 lumens / watt, and the luminous efficiency of fluorescent lamp and HID lamp is 50~120 lumens / watt. The white LED: in 1998, light white LED is only 5 LM / W, in 1999 has reached 15 LM / W, this index is similar to general household incandescent lamps, and in 2000, light efficiency of white LED has reached 25 LM / W, the index and the tungsten halogen lamp is similar. Some companies predict that by 2005, LED light efficiency of 50 lumens / watt, by 2015, LED light efficiency is expected to reach 150~200 lumens / watt. At that time, the working current of white light LED can reach ampere level. Thus, the development of white LED writers using lighting sources, will become possible reality.

Incandescent lamps and halogen lamps for general lighting purposes although cheap, but the low light efficiency (wasted power consumption thermal effect lamp), short service life, maintenance workload, but if using white LED for lighting, not only high light efficiency, and long service life (more than 100000 hours of continuous work), almost no maintenance. At present, the German company Hella LED developed using white light aircraft reading a street lamp; the Australian capital Canberra has used the white LED lighting lamp; city traffic management in China is also white LED to replace the early order of traffic lights. It is foreseeable that in the near future, white light LED will enter the family to replace the existing lighting.

LED light source with the use of low-voltage power supply, low energy consumption, strong applicability, high stability, fast response time, no pollution to environment, color light etc., although the price is compared with the existing lighting equipment is expensive, it will inevitably existing lighting devices.

(Thin Film Transistor) refers to a liquid crystal display on which each liquid crystal pixel is driven by a thin film transistor integrated behind it. Thus, high speed, high brightness and high contrast display screen information can be achieved. The TFT belongs to the active matrix liquid crystal display.

Added: TFT (ThinFilmTransistor) refers to a thin film transistor, which means each liquid crystal pixel is composed of an integrated thin film transistor in the pixel back to drive, which can achieve high speed, high brightness and high contrast display screen information, LCD is the best one of the color display device, the effect is close to the CRT display. Now the mainstream notebook computer and desktop display equipment. Each pixel of TFT is controlled by TFT integrated with itself, which is the active pixel. Therefore, not only the speed can be greatly improved, but also the contrast and brightness have been greatly improved, and the resolution has also reached a high level.

TFT (Thin Film Transistor)screen, it is currently widely used in high-end mobile phone screen, 65536 color and 260 thousand color, 16 million color three, the display is very good.

Unlike the TN technology, the TFT display uses the "back" mode of illumination - the hypothetical light path, not from top to bottom like the TN LCD, but from the bottom up. In this way, a special light tube is arranged on the back of the liquid crystal, and the light source is illuminated upwards through the lower polarizing plate. The electrode under dissection into the FET electrode and the common electrode, the FET electrode is conducted, the performance of the liquid crystal molecules will change, can be light and shading to achieve the purpose of the show, the response time greatly increased to about 80ms. Because of its higher than TN-LCD contrast and more colorful, faster screen refresh rate, the TFT called "true color".

Compared with DSTN, the main feature of TFT-LCD is to configure a semiconductor switching device for each pixel. Because each pixel can be directly controlled by point pulse. As a result, each node is relatively independent and can be continuously controlled. This design method not only improves the reaction speed of the display screen, but also controls the display gray level accurately. This is why the TFT color is more realistic than the DSTN.

At present, the majority of notebook computer manufacturer"s product uses TFT-LCD. Early TFT-LCD was mainly used for the manufacture of notebook computers. Although TFT had a huge advantage over DSTN at that time, for technical reasons, TFT-LCD had a big gap in response time, brightness, and viewing angle compared to traditional CRT displays. Coupled with a very low yield, resulting in its high prices, desktop TFT-LCD become unattainable.

However, with the continuous development of technology, the yield increasing, the emergence of some new technology and makes TFT-LCD have made great progress in the response time, contrast, brightness, viewing angle, and narrow the gap between the traditional CRT display gap. Today, the response time of most mainstream LCD monitors is below 50ms, which paves the way for LCD to mainstream.

LCD application market should be said to have great potential. But in terms of production capacity of LCD panels, the world"s LCD is mainly concentrated in China, Taiwan, Korea and Japan, the three major production bases. Asia is the LCD panel research and development and manufacturing center, and Taiwan, Japan, Korea, the three major sources of development are different.

The development of science and technology change rapidly, display technology has produced a revolution, especially since 90s, with the rapid growth of technology breakthrough and the market demand, so that the liquid crystal display (LCD) panel display (FPD) as the representative of the rapid rise of technology. According to Stanford forecasts, FPD market growing at an annual rate of 16.2%, 2000 FPD and CRT industry has reached 30 billion U.S. dollars, CRT average annual growth rate of less than 6.3%, the average growth rate is much lower than that of FED, and the FPD growth rate continues to improve, continue to decline in CRT, instead of the trend is very clear, can be said that the flat-panel display will become the mainstream display technology in twenty-first Century, the industry and the market in the continuous expansion.

The plasma light emitting display is formed by plasma discharge excited luminescence material cavity of the vacuum discharge chamber of small, low power consumption and high luminous effect is its disadvantages (only 1.2lm/W, while the luminous efficiency is more than 80lm/W, with the lamp of 6 watts per square inch display area), but in the 102 ~ 152cm diagonal large screen display has the strong competitive advantages in the field. Industry expert analysis, CRT, LCD and digital micro mirror (DMD) 3 projection display with PDP competition, from the current large screen TV market, CRT TV prices cheaper than the PDP, PDP is the most powerful competitors, but the brightness and clarity as PDP, LCD and DMD projection of the pixel and the current price also the lack of competitive advantage. Although PDP in color image quality, display area and capacity etc. has been significantly improved, but its luminous efficiency, brightness, contrast is not up to the intuitive color TV, the most important is the price is not accepted by the majority of domestic consumers, which to a certain extent, restricted the color PDP market development. At present, the application of public media has begun to become popular.

A semiconductor light emitting diode (LED) display solutions due to the successful development of GaN blue light emitting diode, which has obtained the absolute control of large screen video display market power, but the display is only suitable for large outdoor display, small screen video display is not its market.

Thin film electroluminescent materials provide true paper - like thin displays. Organic thin film electroluminescent true, light and thin, low power, wide viewing angle, high response speed (sub subtle) solid flat panel display. The cost of large-scale industrial production is very low and the service life is only a few thousand hours. OLED will be the primary competitor for TFT-LCD in the foreseeable future, but it is still in the stage of research and manufacture.

The liquid crystal display panel, especially TFT-LCD, is currently the only and display more than CRT fully catch up with the comprehensive performance of brightness, contrast, power, life, size and weight, its excellent performance, large-scale production of good properties, high degree of automation, raw materials, low cost, broad space for development, will become the mainstream the product of the new century, is one of the highlights of the twenty-first Century global economic growth.

In the fierce competition of many flat-panel displays, why TFT-LCD can stand out as a new generation of mainstream display, is by no means accidental, is the inevitable trend of human technology development and thinking mode development. The liquid crystal has avoided the difficult luminescence problem, and has used the liquid crystal as the light valve"s excellent characteristic to decompose the light emitting display device into two parts, namely, the light source and the control of the light source. As a light source, brilliant achievements have been achieved, no matter luminous efficiency, full color, or life span, and are still deepening. Since the invention of LCD, the backlight has been continuously improved from monochrome to color, from thick to thin, from side fluorescent to flat panel fluorescent. The latest results in the light source will provide the LCD with a new backlight. With the development of light source technology, newer and better light sources will appear and be applied to LCD. The rest is to source control, the semiconductor integrated circuits technology and technology transfer over the development of thin film transistor (TFT) process, the successful realization of the matrix addressing liquid crystal light valve control, solve the light valve and controller of the liquid crystal display with LCD display, so that the advantages can be achieved

(1) how the work of TFT TFT is "Thin Film Transistor" referred to in general refers to the film liquid crystal display, which actually refers to the thin film transistor (matrix) - can be "active control" of the individual pixels on the screen, which is also called TFT (active matrix TFT active matrix). So how did the image come about? The basic principle is simple: the display is made up of many pixels that can emit arbitrary colors of light, so long as you control each pixel to display the corresponding color, you can achieve your goal. In the TFT LCD backlight technology commonly used, in order to accurately control every pixel color and brightness will need to install a similar shutter switch after each pixel, when the shutters open time line through, and "blinds" closed after the light was unable to through. Of course, technically, it"s actually not as simple as it was. LCD (Liquid, Crystal, Display) is the use of liquid crystal characteristics (when heated as liquid, cooling crystallization as a solid state), general liquid crystal has three forms:

The most commonly used TFT TFT TFT (Twisted Nematic LCD) is the most common one, and the diagram below illustrates the working principle of this type of display. The existing technology is very different and will be described in detail in the second part of this article.

The upper and lower two layers are provided with grooves, wherein, the grooves on the upper layer are arranged in a longitudinal direction, while the lower layers are arranged transversely. The lower layers are arranged crosswise. When not in a natural state after the voltage of liquid crystal, light emitting from figure 2A twisted nematic TFT display principle schematic layer over the divergent light through dissection occurred in 90 degree twist, which can smoothly through the lower.

Color filters are divided into three colors: red, green and blue. They are arranged on a glass substrate, forming a set (dot, pitch) corresponding to one pixel, and each monochromatic filter is called a sub-pixel. That is, if a TFT display supports a maximum of 1280 * 1024 resolution, then at least 1280 x 3 x 1024 sub pixels and transistors are needed. For a 15 inch TFT display (1024 x 768) then a pixel is about 0.0188 inches (equivalent to 0.30mm), for a 18.1 inch TFT display part (1280 * 1024), is 0.011 inches (equivalent to 0.28mm)

As you know, pixels are decisive to the display, and the smaller each pixel, the greater the resolution that the monitor can reach. However, due to the physical limitations of transistors, the size of each pixel in the TFT is currently 0.0117 inches (0.297mm), so for a 15 inch monitor, the resolution is only 1280 * 1024

(1) TFT technology is developed in 1990s, large-scale use of new materials and new technology of semiconductor integrated circuit manufacturing technology, liquid crystal (LC), inorganic and organic thin film electroluminescent (EL and OEL) based flat panel display. TFT is in a glass or plastic substrate, such as non single chip (also in wafer) by sputtering, creating a chemical deposition process necessary for the production of large-scale film circuit, semiconductor integrated circuit processing through the membrane (LSIC). Using non single crystal substrate can greatly reduce the cost, and is the extension of traditional large-scale integrated circuit to large area, multi-function and low cost. It is more difficult to manufacture TFT on a large area of glass or plastic substrate for controlling the switching performance of IC (LC or OLED) than on silicon wafer. Requirements for the production environment (degree of purification is 100), yes

(1): a large area at the beginning of 90s the first generation of large area glass substrate (300mm * 400mm) TFT-LCD production line, the first half of 2000 glass substrate area has been expanded to 680mm * 880mm), recently 950mm * 1200mm glass substrate will be put into operation. In principle, there is no area limit.

(2) high integration: the 1.3 inch TFT chip for LCD projection has a resolution of XGA and contains millions of pixels. SXGA resolution (1280 x 1024) non crystal silicon 16.1 inch TFT array film thickness is only 50nm, TAB, ON GLASS and SYSTEM ON GLASS technology, the IC integration of equipment and supply technical requirements, technical difficulties are more than the traditional LSI.

(3) powerful: TFT was used as the matrix location circuit as early as possible to improve the light valve characteristics of liquid crystals. For high resolution displays, precise control of the object elements is achieved by voltage regulation in the 0-6V range (typically 0.2 to 4V), making it possible for LCD to achieve high quality, high resolution display. TFT-LCD is the first flat panel display in human history to display quality over CRT. Now, people are starting to integrate drive IC onto the glass substrate, and the whole TFT will be more powerful, which is incomparable to the traditional large-scale semiconductor integrated circuit.

(6) a wide application field, LCD flat panel display based on TFT technology is the pillar industry in the information society, the technology also can be applied to an organic thin film transistor is rapidly growing in the photoluminescence (TFT-OLED) flat panel display is in rapid growth.

With the maturity of TFT technology in the early 90s, the color LCD panel display developed rapidly. In less than 10 years, TFT-LCD has grown rapidly into the mainstream display, which is inseparable from its advantages. The main features are:

1) the use of good characteristics: low voltage, low driving voltage, solid use safety and reliability is improved; flat, and thin, save a lot of raw materials and the use of space; low power consumption, the power consumption is about 1/10 CRT display, reflecting TFT-LCD even only about one percent of CRT, saving a lot of energy; TFT-LCD products and specifications, size series, variety, flexible and easy to use, maintenance, update, easy to upgrade, long service life and many other features. The display range covers the range of applications from 1 inches to 40 inches, and the projection of large planes is a full-size display terminal From the most simple monochromatic character graphics to high resolution, high color fidelity, high brightness, high contrast, high response speed of the video display of various specifications; display has a direct type of projection type, perspective, also reflection type.

(2) environmental protection is good: no radiation, no flicker, no harm to the health of users. Especially the emergence of TFT-LCD electronic books and periodicals will bring human beings into the paperless office and paperless printing era, triggering a revolution in human learning, dissemination and recording of civilized ways.

(3) the range of application is wide, and can be used normally in the temperature range from -20 DEG C to +50 DEG C, and the low temperature working temperature of TFT-LCD can reach 80 degrees below zero after being treated with temperature. The utility model can be used as a mobile terminal display, a desktop terminal display, and a large screen projection television, and is a good performance full size video display terminal.

(4) the automation of manufacturing technology is high, and the characteristics of large-scale industrial production are good. TFT-LCD industry mature technology, mass production rate of more than 90%.

(5) TFT-LCD is easy to integrate and update. It is the perfect combination of large-scale semiconductor integrated circuit technology and light source technology, and continues to have great potential for development. At present, there are amorphous, polycrystalline and monocrystalline silicon TFT-LCD, there will be other materials in the future TFT, both glass substrate and plastic substrate.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

We insist over the principle of enhancement of "High high quality, Efficiency, Sincerity and Down-to-earth working approach" to offer you with superb assistance of processing for Difference Between Lcd And Ips Display, Tft Lcd Color Display, Medical Lcd Panel, Industrial Tft,Lcd Screen Panel. We also ensure that your selection will be crafted with the highest quality and reliability. Please feel free to contact us for further information. The product will supply to all over the world, such as Europe, America, Australia,Somalia, Belize,Toronto, Namibia.Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

What is the difference between LCD display and LED display? LED backlight is power saving, high priced, vibrant and saturated. LCD is power consuming and cheaper compared to LED backlight. On the screen, LED backlighting is more vivid and saturated. LED display"s individual element response speed is 1000 times faster than LCD LCD, which can also look good under strong light and adapt to low temperatures of -40 degrees. Here"s a detailed look at LED and LCD displays with me.

LCD is the full name of Liquid Crystal Display, mainly TFT, UFB, TFD, STN and several other types of LCD can not locate the program input point on the dynamic link library.

TFT (Thin Film Transistor) is a thin film transistor, each LCD pixel point is driven by a thin film transistor integrated behind the pixel point, thus allowing high speed, high brightness, high contrast display screen information, is currently one of the best LCD colour display devices, is now the mainstream display device on laptops and desktops. It is one of the best LCD colour display devices available and is now the dominant display device on notebooks and desktops. Compared to STN, TFT has excellent colour saturation, reproduction ability and higher contrast ratio, and can still be seen very clearly under the sun, but the disadvantage is that it consumes more power and is also more costly.

LED is the abbreviation for Light Emitting Diode. LED applications can be divided into two main categories: one is LED displays; the other is LED single tube applications, including backlight LEDs, infrared LEDs and so on. Now in terms of LED display, China"s design and production technology level is basically synchronized with the international. LED display is a display device composed of an arrangement of light-emitting diodes 5000 yuan computer configuration list. It uses low voltage scanning drive, with: less power consumption, long service life, low cost, high brightness, less failure, large viewing angle, visual distance and other characteristics.

Compared to LCD displays, LED displays have more advantages in terms of brightness, power consumption, viewing angle and refresh rate. Using LED technology, a thinner, brighter and clearer display than LCD can be manufactured.

3, LED provides a wide viewing angle of up to 160 °, can display a variety of text, digital, colour images and animation information, can play TV, video, VCD, DVD and other colour video signals.

4, LED display of the individual elements of the response rate is 1000 times faster than LCD LCD, can also be seen in bright light, and adapt to the low temperature of minus 40 degrees.

Simply put, LCD and LED are two different display technologies, LCD is a display made up of liquid crystals, while LED is a display made up of light emitting diodes.

3, If the viewing distance is far and the area is large, please choose LED display, the spacing can be based on the size of the area, choose more than 2mm spacing LED display.

5, Cost, LED display spacing is probably the watershed in the 2mm spacing, 2mm below the LED display unit area is higher than the LCD splicing display. 2mm spacing above the LED display unit is lower than the LCD splicing display.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

A 2016 study by the University of California (Berkeley) suggests that the subjectively perceived visual enhancement with common contrast source material levels off at about 60 LCD local dimming zones.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

Using PWM (pulse-width modulation), a technology where the intensity of the LEDs are kept constant but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources,

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Because LEDs can be switched on and off more quickly than CCFLs and can offer a higher light output, it is theoretically possible to offer very high contrast ratios. They can produce deep blacks (LEDs off) and high brightness (LEDs on). However, measurements made from pure-black and pure-white outputs are complicated by edge-LED lighting not allowing these outputs to be reproduced simultaneously on screen.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

LED backlights are often dimmed by applying pulse-width modulation to the supply current, switching the backlight off and on more quickly than the eye can perceive. If the dimming-pulse frequency is too low or the user is sensitive to flicker, this may cause discomfort and eyestrain similar to the flicker of CRT displays at lower refresh rates.

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

LED TVs: 10 things you need to know; David Carnoy, David Katzmaier; CNET.com/news; 3 June 2010; https://www.cnet.com/news/led-tvs-10-things-you-need-to-know/

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; http://www.cta.tech/cta/media/policyImages/policyPDFs/Fraunhofer-LCD-TV-Power-Draw-Trends-FINAL.pdf Archived 1 August 2017 at the Wayback Machine

There’s a variety of display panel out there and even more on the way. But looking at all the different types of panels can be baffling. They come in various acronyms, and many of those acronyms are confusingly similar. How do LCD, LED and OLED compare? What about the different types of LCD panels? And how do these different technologies impact your viewing experience for things like gaming? To help, we’ve created this guide so you can gain a firm understanding of today’s display panel technology and which features really matter.

The first type of panels we’ll cover are LCD (liquid crystal display) panels. The main thing to understand about LCD panels is that they all use a white backlight (or sidelight, etc.). They work by shining a bright white light into your eyes, while the rest of the panel is for changing this backlight into individual pixels.

LED stands for light-emitting diode. You’ll often see LCD panels that are LED, but that doesn’t necessarily mean much when choosing an LCD. LED is just a different type of backlight compared to the old cold cathode backlights. While you could congratulate yourself on not using mercury, which is found in cathodes, at this point all LCDs use LED backlights anyway.

The second thing to understand is that LCDs take advantage of a phenomena known as polarization. Polarization is the direction in which the light wave is oscillating, or swinging back and forth at the same speed. Light comes out of the backlight unpolarized. It then passes through one polarizer, which makes all the light oscillate the same way.

Now you have an on and off (and between) switch for light. To produce color all that’s needed is three color filters, red, green and blue, that block all light other than that color from coming through. The difference between different types of LCD panels is mostly in how this in-between liquid crystal part works.

IPS stands for in-plane switching. These panels debuted after TN panels in the mid-1990s. The crystals are always horizontal to the two polarizers and twist 90° horizontally to go from off to on. Part of this design requires the two electrodes (which apply current to the liquid crystal to change its state) to be on the same glass substrate, instead of aligned with each other on the sandwiching glass substrates above and below the crystal (as in other types of LCDs). This, in turn, blocks a bit more light than both TN and VA panels.

IPS panels have the best viewing angles and colors of any LCD monitor type, thanks to its crystal alignment always lining up with the viewer. And while they don’t offer as fast a response time or refresh rate as TN panels, clever engineering has still gotten them to 144hz, and with nice viewing angles you’re not necessarily going wrong with an IPS gaming panel.

How do LCD panels go about reaching HDR brightne

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey