lcd display temperature limits price

Liquid crystal displays (LCD) have become an essential component to the industry of display technology. Involved in a variety of contexts beyond the indoors like LCD TVs and home/office automation devices, the LCD has expanded its usage to many environments, such as cars and digital signage, and, thus, many temperature variations as well.

As with any substance that requires a specific molecular characteristic or behavior, LCDs have an operating temperature range in which the device, if within, can continue to function properly and well. In addition to that, there is also an ideal storage temperature range to preserve the device until used.

This operating temperature range affects the electronic portion within the device, seen as falling outside the range can cause LCD technology to overheat in hot temperatures or slow down in the cold. As for the liquid crystal layer, it can deteriorate if put in high heat, rendering it and the display itself defective.

In order for the LCD panel to avoid defects, a standard commercial LCD’s operation range and storage range should be kept in mind. Without adaptive features, a typical LCD TV has an operating range from its cold limit of 0°C (32°F) to its heat limit of 50°C (122°F) (other LCD devices’ ranges may vary a bit from these numbers).

The storage range is a bit wider, from -20°C (-4°F) to 60°C (140°F). Though these ranges are quite reasonable for many indoor and even outdoor areas, there are also quite a few regions where temperatures can drop below 0°C or rise above 32°C, and in these conditions, LCDs must be adapted to ensure functionality.

Heat, can greatly affect the electronics and liquid crystals under an LCD screen. In consideration of heat, both external heat and internally generated heat must be taken into consideration.

Seen as the liquid crystals are manipulated in a device by altering their orientations and alignments, heat can disrupt this by randomizing what is meant to be controlled. If this happens, the LCD electronics cannot command a certain formation of the liquid crystal layer under a pixel, and the LED backlighting will not pass through as expected, which can often lead to dark spots, if not an entirely dark image. This inevitably disrupts the display’s readability.

Depending on the upper limit of the operation temperature range, LCD device can be permanently damaged by extreme heat. With long exposure to extreme heat, besides the destruction of the liquid crystals, battery life can shorten, hardware can crack or even melt, response time may slow to prevent even more heat generation from the device.

The LED backlight and the internal circuitry, typically TFT-based in the common TFT LCDs, are components that can generate heat that damages the device and its display. To address this concern with overheating, many devices use cooling fans paired with vents.

Some devices that are used in extremely high ambient temperatures may even require air conditioning. With air vents to carry the heat out, the device can expel it into the surroundings.

But this leads to another problem: how can moisture be prevented from entering through the vent? If moisture enters the device and high heat is present, condensation can occur, fogging the display from inside, and in some cases, short-circuiting may cause the device to turn off. In order to circumvent this issue, the shapes of the air vents are specific in a way that allows only for air movement, not forms of moisture.

In the opposite direction is extreme cold. What typically occurs in the cold is “ghosting” (the burning of an image in the screen through discoloration) and the gradual slowing and lagging of response times. Like heat-affected LCD modules, the extreme temperature can affect the liquid crystals. This layer is a medium between the liquid and solid state, so it is still susceptible to freezing.

An LCD device can be left in freezing temperatures because it will likely not be permanently damaged like in the heat, but it is important to understand the device’s limits and how to take precautions when storing the device. The standard and most common lower-bound storage range limit is -20°C, below freezing, but if possible, it would be best to keep it above that limit, or else there is still a risk of permanent damage.

If the device is not adapted for the cold, it would be good to keep it bundled up, trapping the heat within layers. However, this is only a temporary solution. Adapted, rugged devices have advantages such as screen enclosure insulation for heat level preservation and, in more extreme cases, heaters to generate extra heat to raise the internal temperature to a level above the minimum.

When selecting the appropriate module, it is necessary to understand the device’s expected primary application. The application will decide factors such as display type, environmental conditions, whether or not power consumption is a factor, and the balance between performance and cost. These factors can have an effect on the operation and storage temperature ranges for the device.

Display types have a lot of variation. Choices like alphanumeric or graphic LCD, human-machine interactive LCD modules and touchscreen panels capabilities, the width of the viewing angle, level of contrast ratios, types of backlighting, and liquid crystal alignment methods are often considered. For example, the twisted nematic LCD provides for the fastest response time at the lowest cost, but cannot offer the highest contrast ratio or widest viewing angle.

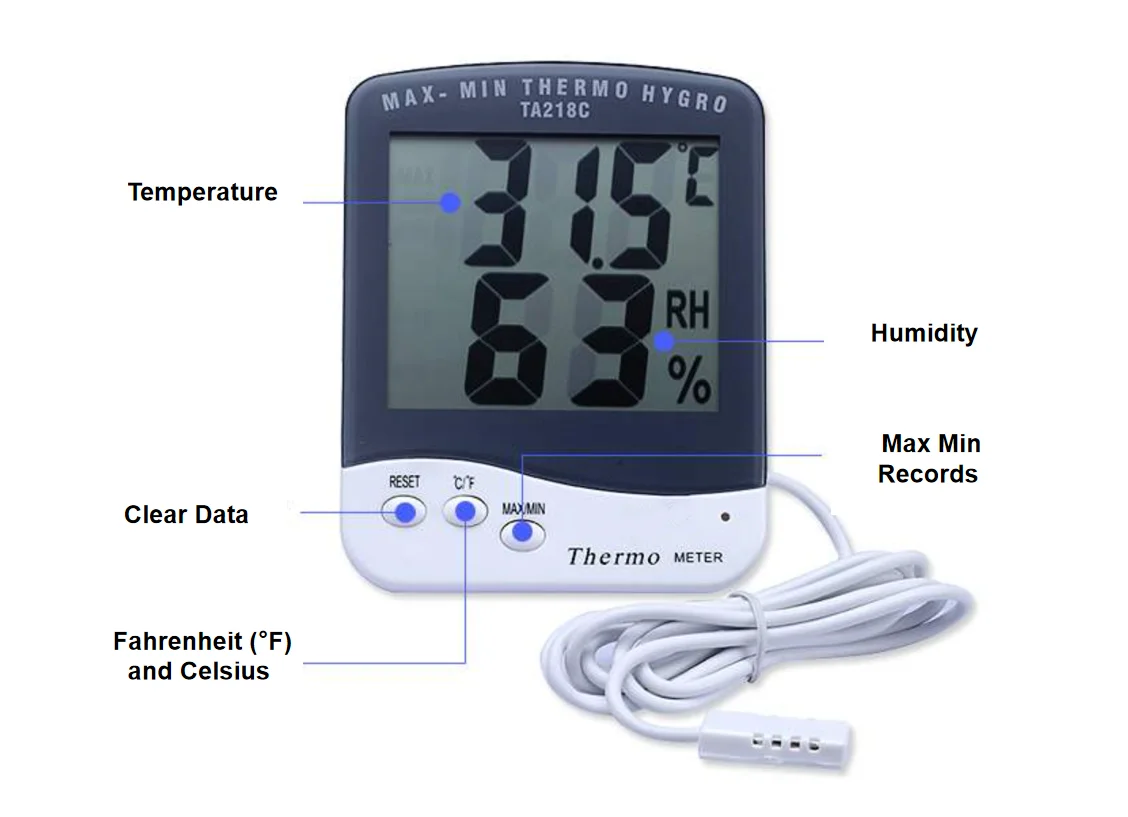

Environment-based factors must consider things besides the obvious temperature like UV exposure and humidity/moisture, as they all are necessary in finding the perfect fit extreme temperature LCD module.

Besides the LCD modules, recent new products have opened doors in wide temperature range displays, such as OLED displays. OLED displays offer better displays in regard to contrast, brightness, response times, viewing angles, and even power consumption in comparison to traditional LCD displays.

These benefits, in addition to its ability to achieve a wide temperature range, provide more options for consumers in search of high quality displays for extreme climates.

Modern LCD screens have a great many uses. Not only are they now the system of choice for our home TVs and computers but their use in digital signage has made them a common sight in many shopping malls, airports and other locations with high quantities of people.

Even outdoor locations are no barrier to the use of modern LCD screens with outdoor digital signage a rising medium now seen in many town centers, car parks, front of stores and train station platforms.

All this out of home use means many screens operate in locations test the temperature limits of LCD displays. While waterproof screens and LCD enclosures designed for rugged applications provide the ability of the screen to operate-even in outdoor locations, one consideration often overlooked, is that of temperature.

LCD screens have a limited temperature range. Not only will the electronics inside an TV screen overheat and cause failure if the screen gets too hot, but the liquid crystal itself will begin to deteriorate under hot conditions.

The same is true of environments where temperatures fall below zero, causing a screen to stop functioning. A typical LCD TV has an operating range between 0°C (32°F) and 32°C (90°F).

Of course, many indoor and outdoor locations don’t suffer temperatures outside of this range, but many locations do and placing screens in these areas can prove challenging.

One of the problems with using a screen in hot locations is that the screen itself produces quite a bit of heat. When housed in an outdoor enclosure, the heat has to be continuously removed. While cooling fans combined with an air-vent normally carry out this task on an LCD, the need to prevent moisture from getting to the screen makes the task more complicated.

To get around this problem, specially shaped vents provide an exit for hot air while preventing rainfall and other moisture from getting in. In some locations where ambient temperatures are extremely high, screens need air conditioning to ensure they don’t exceed the maximum operating temperature.

In cold climates the opposite problem occurs. The need to keep heat in often requires insulation of the screen enclosure. Often this can trap enough of the heat generated by the screen itself to keep the internal temperature above minimum, but in some locations, even this isn’t enough. Heaters, controlled by thermostats provide extra heat in these circumstances, which enables the use of LCD displays in extremely cold locations such as ski-resorts and in Arctic regions.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

The first step is to select temperature sensors that can be affixed to the display while being small enough to fit within a restricted envelope. Thermistors, thermocouples, or RTDs are all options to consider since they represent relatively low-cost and high-reliability ways to measure the display’s surface temperature. These types of sensors also provide an electrical output that can be calibrated for the desired temperature range.

The next step is to determine the number of temperature sensors and their approximate location on the display. It’s recommended that a minimum of two temperature sensors be used to control the heater. By using multiple sensors, this provides the circuit redundancy and allows for a weighted average of the temperature measurement to mitigate non-uniform heating. Depending on the temperature sensors location, and the thermal mass of the materials involved, the control loop can be optimized to properly control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Insulating materials, air gaps, or other means can be incorporated in the design to manage the way heat travels throughout your system on the way toward an eventual “steady state” condition. During development, prototypes can be built with numerous temperature sensors to map the heat transfer, allowing for the optimal placement of temperature sensors, an adequately sized heater, and a properly controlled feedback loop.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

The higher the mux rate, the less time a given group of segments is being addressed , and the worse the display will look. If you refer to our "Basic Operation of an LCD" page, it is easy to see that this is not a good situation.

display will not really damage the contrast and viewing angle very much. For mux rates above 4:1, serious degradation sets in. At that point, a switch of drivers or a move to STN technology are the options.

The T-57152GD042H-LW-AAN and the T-55923GD050J-LW-ABN, small-format TFT LCD modules designed for use in harsh environments, have been introduced by Kyocera.

The T-57152GD042H-LW-AAN, which measures 4.2”, features a resolution of 480x272px, a brightness of 700cd/m², a digital 18-bit RGB interface, a contrast ratio of 1200:1, and horizontal and vertical viewing angles of 160° each. The design is based on automotive requirements and boasts an expanded operating temperature range of -30 to +85°C and a storage temperature range of -40 to +95°C. In addition, the anti-glare surface treatment improves readability in bright surroundings.

Measuring 5.0”, the T-55923GD050J-LW-ABN is a portrait-mode display that features a resolution of 480x640px. Optical characteristics include 800cd/m² brightness and a 500:1 contrast ratio. The viewing angle amounts to 140º horizontally and 110° vertically. This module comes with a 24-bit digital RGB interface and has a wide operating temperature range of -30 to +80°C.

“Portable outdoor devices are liable to fall down and are exposed to low temperatures, heat and humidity. Even in these conditions, they should always work reliably, and our components are designed for that purpose,” says Eberhard Schill, Manager Distribution and Marketing, Kyocera Display Europe.

There are several industrial applications that require LCD displays to operate in extreme temperature environments such as in military, food processing, gas/fuel pumps, medical, manufacturing, and non-climate-controlled facilities, among others. Take note that typical monitors can only be used in environments with 0�C~50�C temperature range. UV exposure, moisture, and humidity also affect the overall temperature within a specific environment. iTech Company offers a range of LCD monitors that can function properly in a wide working temperature range from -30℃ to +80℃. These products are already proven and tested to maintain its original luminance under such temperatures.

While the range of operating temperature is a relevant consideration for the device to withstand extreme hot or cold environments, other factors must also be taken into account for the overall performance of the device. These includethe clarity of the image, environmental protection, LED backlighting, quality of the components, andvarious options available.

iTech Company’s products are equipped with these useful features to deliver great performance even in harsh working conditions. These are available in different monitor sizes and resolutions. It offers superior image quality with wide viewing angle. Some of the optional features include the touch screen functionality for interactive application and the level of brightness to ensure that the screen content is highly visible in all lighting conditions. Moreover, these wide operating temperature LCD displays are available in different types including open frame, panel mount, andchassis mount.

Typically, standard LCD modules provide a temperature range of -20°C to +70°C. To meet the need of customers, EVERVISION has developed a series of wide temperature TFT LCD modules with operating temperatures ranging from -30°C to +80°C, and the maximum for some models can reach 85°C.

EVERVISION developed LCD Heater to integrate with our TFT Display Module so that can show optimal view even in low temperature. For materials, heaters can be used with transparent resins, such as glass and poly-carbonate. Our LCD Transparent Heater is made of glass substrate, so we name it “Glass Heater”. It can not only improve the LCD image sticking issue efficiently, but also have heat and humidity resistance advantage.

As the result, it shows 4.3 inch TFT LCD Module display functionally under normal operating conditions. However, there is an overlapping at low temperature, because of LC"s physical characteristics. From this experiment, we know that overlapping can be solved by turning on Glass Heater.

A number of TFT solutions are offered. Serial TFT, I2C TFT, USB TFT, RS422 TFT, SPI TFT and Parallel 24bit RGB TFT. TFT, or Thin Film Transmissive, display technology uses the same control techniques as an LCD, but permits larger screen sizes by adding transistors to address pixels by row and column rather than individually. Additionally, TFT units offer red, green, and blue elements for each pixel to produce a full range of colour output. The brightness of each colour element is individually controlled by a number of bits, typically between 5 and 8, to produce up to 16 million colours. These units are driven by an LED backlight which requires moderate power input, and can be varied to control brightness, typically up to 600 nits. These units have an operating range similar to LCDs of -20C to 70C, but offer increased contrast performance, typically up to 500:1, and viewing angles of up to 140 degrees. High display resolution and touch overlay options make this technology attractive to higher end HMI applications. TFT is available on GTT, EVE, HTT and Parallel Displays.

A lot of consumers wonder how manufacturers determine the LCD display panel prices. After all, display solutions such as TFT LCDs and HMI touch screens do not always come cheap. And sometimes, a few products that can indeed be purchased for lower prices may come with several quality issues.

Hence, we’ve rounded up a list of factors that influence how to display modules such as TFTs, LCD, and touch screens are priced. You can also use these factors to evaluate to whom you should place your next orders for your display solutions.

LCD fluids are used in altering the light orientation passing through glass substrates. Hence, this causes the panel’s active pixels to darken. Different kinds of LCD panel fluids provide unique characteristics and change a panel’s viewing angle, temperature range, and display clarity.

TN fluid contains liquid crystal substances that allow light to pass through by twisting and untwisting at a 90-degree angle. This display technology is available in monochrome; that is, black characters against a gray background.

The viewing angle is limited in a panel containing TN fluid. This means that the text or image display becomes harder to read if you rotate the device away from its center. The display is also not that sharp compared to displays using other technologies.

Another characteristic of this fluid is that it works well even in colder temperatures. It’s because TN fluid has the quickest response time among the other LCD fluid types.

TN fluid is considered the cheapest LCD fluid type. However, this doesn’t mean that TN isn’t widely used. The display technology is greatly utilized in digital clocks, pagers, and gas pumps.

LCD modules with STN fluid enjoy a wider display angle, greater multiplexing, higher image contrast, and sharper response than devices using TN fluids. However, modules with STN fluids may have slower response times when used in lower temperatures due to the fluid freezing inside the device.

STN fluid falls under the moderately cheap LCD module price. Furthermore, STN fluid is widely utilized in several monochrome LCD devices such as POS machines, inexpensive feature phones, and informational screens of some devices.

The CSTN fluid technology takes away the monochrome finish of the typical STN fluid devices. Red, green, and blue filters are added to the fluid module to allow a colored display. New versions of CSTN often feature a viewing angle of 140 degrees and 100ms response times.

CSTN is a bit pricier than TN and STN fluids. But it’s a good choice if you need to display color images on your LCD device. In fact, a lot of color feature phones use CSTN as an alternative to the TFT displays, saving almost half the manufacturing costs.

A device using FSTN fluid has better viewing angles and can produce a sharp black-and-white coloration. It is a good choice for devices that need to display small yet easy-to-read images.

In terms of cost, the LCD display module price of a unit with FSTN is higher compared to TN and STN. But this is concerning the better visual quality that FSTN offers.

To cap off this part, the fluids used in a screen is a big factor in determining the overall LCD screen display panel price. As you can see, the four fluid types often used in LCD screens rise in costs with respect to the visual quality produced by each technology.

The temperature range in which LCD screen displays may work varies intensely. Some displays continue to work at optimal performance even when used in cold or hot outdoor temperatures. Lower-quality LCD panels may start having glitches at the slightest change of temperature and humidity. Hence, the temperature range may have a huge impact on the LCD display panel price as well.

In hot environments– The liquid crystals may begin to deteriorate, while the electrical components will start overheating and cause damage to the display screen performance.

Now, most LCD screen panels don’t experience such temperature extremes. In fact, a typical LCD TV can operate properly between approximately o°C and 32°C (32° – 90° F). Meanwhile, other screen modules (usually the industrial-grade ones) have unique capabilities to work in even more extreme ends of the temperature scale.

If you want to look for the most cost-effective type of LCD panel for your device, then you must consider the following standard LCD unit temperature types:

Normal temperature units work well in environments that have indoor temperatures at approximately 20-35°C (68-95°F). Some LCD modules may work well above up to 50°C (122°F). Such LCD modules can be used in daily settings by the typical consumer public.

LCD units under this type are made to withstand lower and higher temperature ranges. Extreme operating temperatures may range anywhere from -30°C to 85°C (-22-185°F). Most LCD modules with wide/extreme temperature capabilities are used in extremely cold areas such as Artic places and ski resorts, as well as humid and moisture-rich hot outdoor areas.

Generally, the LCD module price goes up if the entire display unit can withstand higher temperature ranges. Those who can operate under normal temperature ranges only are usually cheaper.

Hence, you must consider the places where you’ll be installing your LCD display devices. You can’t just use cheaper LCD modules for an industrial-grade display machine. Treat your LCD panel as an investment and select a panel that will yield better screen performance that’ll last several years for you and your business.

It’s an unspoken rule, but monochrome modules are generally cheaper than color-capable ones. However, color-capable display modules may also have cost variations depending on their display capabilities.

Color LCDs have three subpixels that hold red, blue, and green color filters. Each subpixel can have as much as 256 color shades, depending on the variation and control of the voltage applied to it.

Now, when you combine 256 shades of both red, blue, and green subpixels, color LCDs can display a color palette of up to 16.8 million colors. And all these are made possible by millions of transistors etched onto the glass modules.

Display size also plays a large role in an LCD device’s color capability. Smaller screens need fewer pixels and transistors since they have smaller display sizes. These screens are also less costly to make. Now, larger screens with high color resolution and huge display sizes require more transistors and pixels, justifying the higher prices of such monitors.

A touch screen display module is more costly than a non-touch monitor module. Touch capability is integrated into Human Machine Interface (HMI) modules and is generally used in kiosks, bank ATMs, hospital equipment, and similar devices in other industries.

Capacitive touch screens are the most common in the display industry today. This technology uses transparent conductors, insulators, and glass to create the panel. An electrostatic field change in the screen’s module happens when a human finger touches the screen surface. This ultimately creates signals that are sent to the touch screen controller for processing.

We’ve explained the following factors at length for both public consumers and business clients to understand the variations in TFT, LCD, and HMI touch screen prices.

Cheap doesn’t necessarily mean low-quality. Also, expensive options aren’t always a wise choice, either. You can maximize your buying or manufacturing options if you know how to compare LCD modules and panels depending on the specifications you truly need for your display machines and devices.

I always finding it interesting when a new customer of ours calls to let us know that they can find cheap LCD displays, the same LCD we supply, for almost half the price. After all, cheap LCD displays are the same no matter where you purchase it. Right?

Let me assure you that the phrase, ‘You get what you pay for’ is just as true for LCD displays as it is for insurance, fine jewelry, car repairs and open heart surgery. You will always be able to find a lower cost product or service, but many times you are not comparing apples to apples.

The word “cheap” is so polarized in that in one instance you can revel in the victory of finding that super low price and yet simultaneously it is no victory at all if someone looks at your product and says, “Wow, that looks cheap.” So, let’s talk about Cheap LCD displays.

The long and short of it is that LCD’s are in investment. In many cases, they are the most expensive component in your product, but you need to balance that with the fact that they are also what the customer looks at the most. If you are building a hand held device that measures the PH of pool water, it’s a safe bet that people will be looking at the display far more than the battery compartment on the back of the unit. The cheap LCD display may save you a fraction of what other suppliers are quoting, but what is it costing you? Return customers. Good online reviews. Word-of-mouth advertising.

There is a rule of thumb statistic that says it costs a company 7 times more money to earn a new customer, than it does to keep a current customer. So why would you save 20% or even 40% off the cost of an LCD and in return lose your current customers. The savings will not offset the increased advertising cost to bring in new customers.

There are three main fluids used in a monochrome LCD module. They are TN, STN and FSTN. Each fluid has its own niche in which it operates well. One of the main factors impacted by the different fluids is acceptable viewing angle of the display.

TN, twisted nematic, is the lowest cost fluid and has the smallest viewing angle. That means that as you rotate the display farther from center, it will become harder to read. A mistake would be to assume that a TN display is junk; rather, it serves as an excellent unit for a very specific set of products.

An example of a TN display is the display found on gas pumps. You can easily read the gallons and dollars as they quickly fly by. Since most people see the display straight on, there is no need for a higher cost fluid. TN is the right choice and keeps the cost of the product down.

FSTN, film super-twisted nematic displays, are on the other end of the spectrum. They are more expensive than TN and STN, but it offers a sharper contrast and a much wider viewing angle. If you are building a portable device that measures radiation, you want to make sure you can see the numbers on the display from as wide of viewing able as possible. Using a TN in the application may save you as much as 15% on the cost of the display, but is this type of product an investment or expendable?

LCD displays are quite diverse when it comes to the temperatures in which they can operate well. Some even have as much and more than 100 degrees window of successful operation. There are three main temperature ranges of an LCD unit:Normal temperature (indoor temps—think of your living room)

Ultra wide temperature (-40C/-40F--think of extreme cold and hot environments like in Alaska, Minnesota, and Wisconsin or Florida, and specifically Phoenix where it gets hot, hot, hot!).

The cost difference between normal temp and ultra wide temperatures can be as much as 30%. Therefore, identifying the appropriate temperature range is critical to have the best device for the best price.

Take for instance one customer of ours who needed the display to work properly on oil rigs near the North Pole. Their product monitors the safety equipment on the rig. Is it worth spending the extra $5 on a display that can survive working in all conditions? Is the LCD display an investment or expendable?

When a supplier is promising you the cheapest deal out there, you need to make sure that you are again dealing with an apples-to-apples comparison. Make sure that they aren’t saving you money by offering you a display that has the cheapest temperature range or the narrowest viewing angle, especially when those aren’t what will suit your product and your situation. They may just be choosing the cheapest alternatives of all the many options available, all to have you wind up with a unusable or inferior product. Then, you not only have a product you aren’t thrilled about but you face the problem of shipping the product back to the foreign country from which it came. This is not a convenient way to deal with the fallout from the “cheap” product! There is a real advantage to buying a product that has American support and part of that advantage is simply the convenience of speaking the same language and being within one shipping day apart from your customer support.

We understand that frustration and at Focus Display Solutions we offer uncompromising customer service and we provide it in a way that we would want to be served. We strive to pick up the phone on the first ring. We can talk to you about the products from a knowledge based on years of experience and not from a script that someone else wrote to troubleshoot only the most common problems. When you call us you talk to humans, not machines. We offer personal service to get the product right the first time and we do it in a way that works with your personal style.

The engineer took our price and specs and called back a few days later saying that another LCD vendor came in with a similar product that would cost in the low $5 range. Red flags immediately went up in my mind. Something was not right about this cheap LCD display. The display was similar, but upon inspection there were some ‘strings’ attached.

This is critical if you plan to build your product for the next few years. You will need to purchase more of these exact LCD displays in the future. When that time comes and you find out that the LCD modules are discontinued, you are in deep trouble. Your only option is to redesign your product for the current LCD.

Keep in mind that if you plan to repair your customer’s product, it is critical to have a supply of the original LCD. You cannot use a new LCD in an old product in the same way you cannot use a VHS tape (for those of you over the age of 20) in a blue ray player.

A simple tip is to do a little research on the product. Google can be your best friend. When someone offers you a screaming deal on a cheap LCD display, type in the part # and manufacture into Google; you may quickly find out why the prices are so cheap.

There are companies that contact us to buy our surplus/returns. These companies are providing a valuable service by keeping displays out of the landfills. If you need to be able to purchase the exact same LCD in the future, stay away from refurbished units. Once they are gone, there are no rain checks. Many of these displays can be found on eBay and other online auctions.

Focus Displays Solutions prefers to include the cost of the freight of those component parts from the Far East to Chandler, AZ. This way the customer only has to pay for the shipping from Arizona to their location.

That engineer quickly realized that asking the three critical questions makes all the difference in the price of the product! Getting cheap LCD displays is not always a mistake, just remember to ask questions and really think through whether this is an investment or an expendable item.

The LCD has been widely used in different applications, such as automotive, home appliance, medical, industrial, communication, entertainment, consumer devices, etc. It has been the most popular display technology for more than a decade after surpassing CRT. But the LCD has its genetic drawbacks, such as narrow viewing angle, slow response, and low contrast, limiting its use in some applications. These drawbacks also make LCDs venerable for other new display technologies, OLED (Organic Light Emitting Diode) and Micro LED. Engineers have been working on different ways to improve the LCD drawbacks. Today, we will discuss the LCD contrast affected by temperature and improve LCD contrast with the temperature changes.

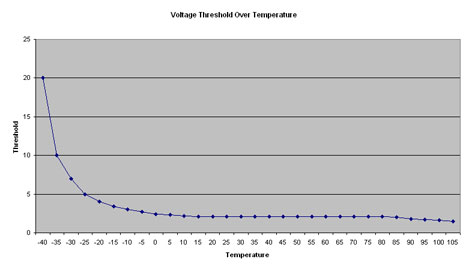

From Figure 2, when the voltage increases, the LCD’s transmission is getting lower. When the transmission level reaches 90% of the no voltage applied, we can see the LCD shows images but very light. We call it the threshold voltage (V90 or Vth).

From Figure 3, we can see the LCD voltage decreases with the temperature. From -15oC to +60oC, the curve relatively flat, but when the temperature is lower than -20oC and higher than +70oC, the voltage changes dramatically with temperature, that is why most LCD has an operating temperature of -20oC to +70oC. Some LCD manufacturers stated that the LCD has an operating temperature range of -30 oC to +80oC, but be ready that the poor contrast has to be accepted with both ends of the temperature.

From Figure 4, we can see the LCD contrast is optimized at a temperature of around +20oC, which is room temperature. The contrast (CR) decreases with higher and lower temperatures, which can be a big issue for some applications.

Scientists and Engineers of different areas have been trying to improve the LCD contrast under low and high temperatures. But the facts are all of them having trade-off. The users have to balance all the factors to choose the best solutions for their applications. We will explain the most popular ways for LCD to deal with temperature.

It is easier to do. The contrast dramatically changes at a higher temperature because liquid crystal material is close to its clearing point. The material in the LCD is no longer liquid crystal material anymore; it becomes liquid (like water). Then, the solution will be to increase the clearing point of the material used. Most commercial LCDs use liquid crystal material with a clearing point of around 80oC, making it useable at +70oC. Still, for those conditions, the liquid crystal material used as a clearing point closer to 130oC makes it useable over +100oC theoretically.

Of course, we can imagine that material is costly. Another issue that the high-temperature performance LCDs have a bad performance at low temperature. The response time at low temperatures can be very long.

The heater can be used to heat LCD when the temperature drops below -20oC. Of course, the temperature sensor can be used to switch on/off the heating. Usually, there are 3 kinds of heaters to be used. 1) wire heater, 2) ITO heater on flex, 3) ITO heater on the glass. Depending on the heating speed needed, the heating power can be designed.

Of course, you can see the issue of using a heater in an LCD. The first is the cost; the second is the power of heating. Please prepare to use around 1 to 2w/inch2 power budget in your design.

The biggest liquid crystal material manufacturer in the world, E. Merck claimed that they developed “Flat Fluids,” which makes the curve in Figure 3 LCD Operating Voltage (Vop) vs Temperature relatively flat from -30oC to +80oC. It is good news for most applications. But the limitation is that Flat Fluids can only be used in TN-type displays also costly.

The good news that many modern LCD controllers include temperature compensation circuitry in the IC design, dramatically makes the design work easier by simply setting the function. But all the LCD temperature compensation circuitry is linear, which can’t match the liquid crystal material voltage curve with temperature. But it is good enough for most applications. See Figure 6.

In cooler climates, the LCD fluid will slow down and change the response time of the display. We can install transparent heater films through an optical bonding process to maintain a sleek and modern display, as well as maintain display response time. The display heater will become active when the built in sensor detects a pre-set ambient temperature. This will protect the display from becoming overheated and conserve display power. We also work with you to ensure your display is in a proper enclosure that will retain the heat generated to prevent battery drainage. E3 enhancements to wide temperature displays can operate in the most rugged environments, maintain battery life, and exceed aesthetic standards.

Made for any rugged application this 7.0″ TFT comes with a high resolution of 1280x768dot, super-wide viewing angles, high brightness 1000cd, high contrast 1000:1 and a wide operating temperature range of -40 to +80C. It also manages high vibration and shock for outdoor industrial devices.

Mitsubishi Electric also offers 7.0” / 8.0” / 12.1” / 15.0” and 19” TFT with pcap-touch for rugged applications! In total they have more than 34 TFT-LCD modules with super-wide viewing angles.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey