transmissive lcd display quotation

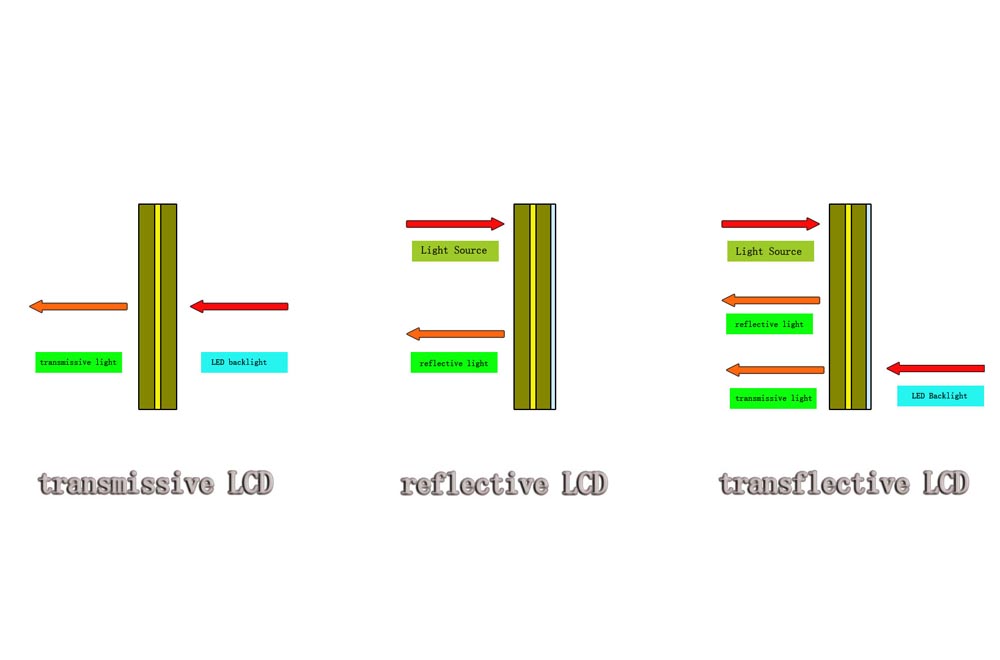

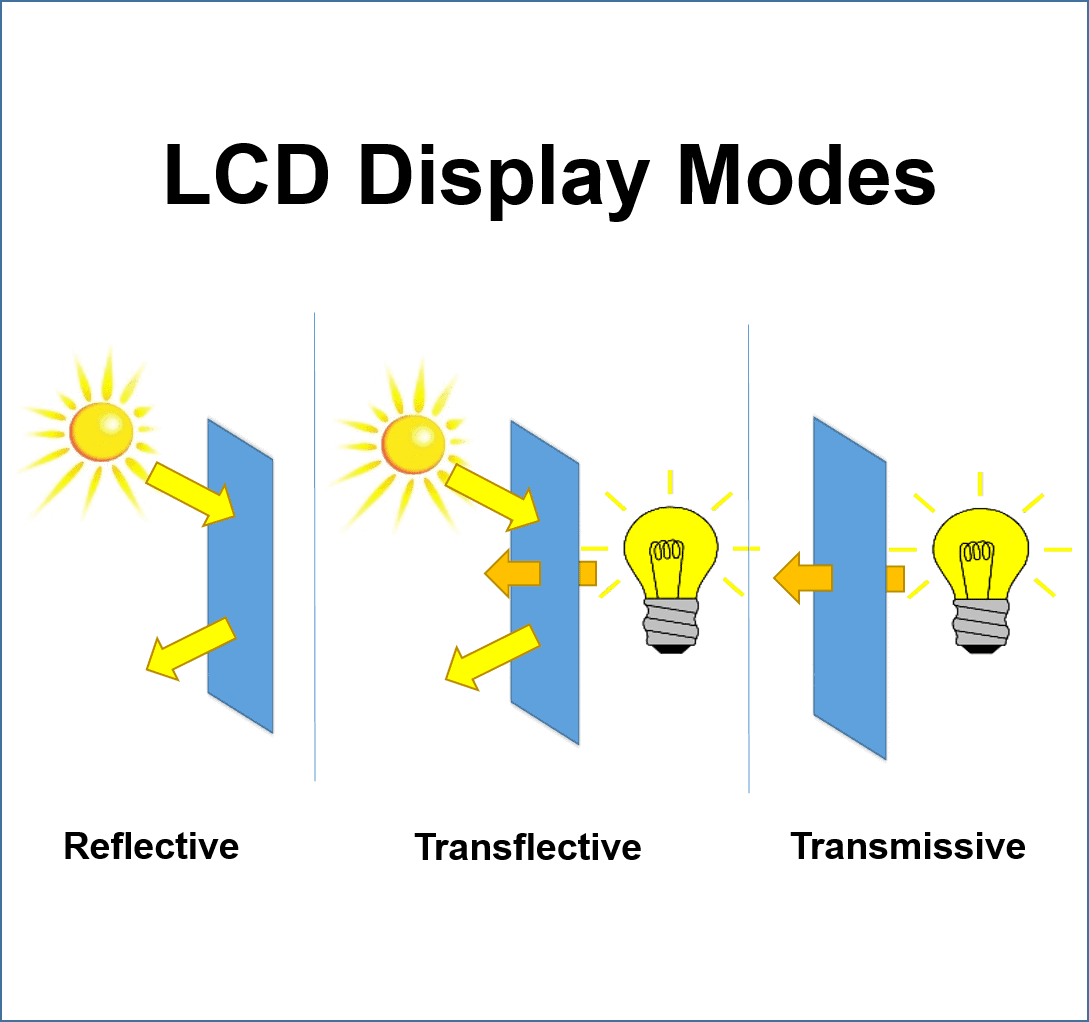

Transmissive LCD is the most common LCD screen, which requires a backlight as the light source and there is no reflective film at the back of the LCD screen.

Advantage: we can see the graphic and character on the screen very clearly if there is only little light. It is such a mature and cheap technology that 90% of LCD screens in the market are transmissive LCD display.

Reflective LCD is the cheapest LCD screen because there is no backlight, which uses light from outside as the light source, such as sunshine or lamplight and there is a reflective film at the back of the LCD screen.

Transflective LCD is the best and most expensive LCD screen, which has a semi-reflective film at the back of the LCD screen. The front light can’t go through the semi-reflective film, but the backlight can go through it. Like sunglasses.

Advantage: it has the advantages of both transmissive LCD and reflective LCD. We not only can see it very clearly in the outdoor like the reflective LCD, but also can see it vividly when we are in a dark place like a transmissive LCD. We see the transflective LCD in the front as the reflective LCD because it can reflect the sunshine, but the LED backlight panel can also supply the light which can penetrate the semi-reflective film at the back of LCD screen.

ISO 9001:2000 & ISO 13485:2003 certified manufacturer of standard & custom transparent EL displays including transparent EL displays. Features include rugged construction, thin film, display text or graphics layouts, insulating layers, glass substrate, transparent electrodes & holes can be drilled directly into the panel. Specifications include viewable size up to 10.4 in., viewing angle less than 60 degrees, transmission 84 percent & operating temperature range from minus 50 degrees C to plus 85 degrees C. Drilled, curved or cut glass panels are also available. Applications include transportation, premier pro-consumer electronics & architectural. CE, UL & FDA approved. RoHS compliant.

Golden View Display wants you to make an informed choice among our LCD products. The tech center provides you with most of the information you will need to understand liquid crystal displays.

Here is a guideline to select a LCDs to meet your requirements in many aspects, such as cost, performance, and utility. We hope it can help you have a good understanding on the characteristics and properties of LCDs.

2) From TN to 240 twist STN, the response time become slower and slower, but the contrast gets better and better, and view cone gets wider and wider if the duty is determined, but the cost of LCD gets higher and higher as well.

.jpg)

Recently, the display industry began to reflective displays such as electronic paper and no backlight reflective LCD, as well as semi-translucent semi-translucent LCD hype, these in the process of evolution of display technology had fallen behind the “mature” technology, there are even people packaged as a “new display “innovation to promote the market, which in the end hides what mystery?

Electronic paper is actually industrialized in the market almost together with the black and white LCD. The only advantage of electronic paper is its picture retention after power loss, which only needs to consume power when refreshing the picture, so it can up energy-saving effect.

This characteristic of electronic paper is due to its material decision, the switch material of electronic paper is electrophoresis material, that is, the polar pigment material encapsulated in a liquid droplet, and then through the upper and lower substrate electrode direction change, to let the polar material droplet suspended in the temperature and pressure of the more inert liquid deflection, so as to refresh the different dot pattern for display.

The polar material color can be dyed according to the customer’s needs, and the color picking display can be realized with the pixel production process of the TFT substrate after and CORLOR FILLTLE color filter film.

However, because this electrophoretic material display technology is limited by the polar material deflection to overcome the viscous resistance of inert liquid, so the general response speed is very slow, and if the polarity of the polar material is not modified in place, the driving voltage is also much higher, so the electrophoretic display is less suitable for displaying dynamic images, more suitable for the scene with interval refresh time needs, such as paper-like display of books, newspapers Electronic terminals, signage and warning signs in well-lit venues, such as bus stop signs with scrolling content, price tags in stores, etc. As the electronic terminal that is used to replace the book is the most popular, so the industry regards it as the representative of electronic paper, and is customarily called electronic paper.

It can also be seen from the above, electrophoretic display is still mainly a switching display technology, and its light reflection mainly depends on its substrate background or inert liquid native color to achieve. With the traditional LCD display technology, the principles and production methods are almost the same, except for the switching materials compared with liquid crystal, one is a de-energized steady-state display and the other is an electrically maintained steady-state display.

Therefore, the so-called reflective LCD and semi-transmissive semi-transmissive LCD are only adding reflective layer and semi-transmissive semi-transmissive layer behind the substrate of the display, which does not change the principle of LCD display technology and mass production process. The difference is that reflective displays require a front light source if they are to be displayed in low light areas, while semi-transmissive and semi-transmissive displays can use the same back light source as ordinary LCDs.

In addition to the electrophoretic display, there is also a kind of electrolux display. The difference between the electrolux display and the electrophoretic display is that the switching material is the inert liquid itself, as long as the inert liquid is modified into an electrode material that can be self-assembled into a light-reflecting interface and a light-absorbing interface at both ends of the molecular chain, and then adapted to the molecular polarity of the package substrate, it can be reversed by reversing the direction of the electrode, so that the two inert liquid The substrate can be self-assembled to form a light-reflecting interface and a light-absorbing interface, which can form a corresponding dot pattern display. This self-assembled interface is reflected between the substrate and the inert liquid, more similar to the hydrophilic and hydrophobic interface effect in nature, and can take the method of liquid wetting to test the material, so it is called electro-wetting properties.

And electro-rheological display through different driving methods to deflect the angle of the molecular chain, but also to achieve light total reflection interface light interference display, so as to achieve imitation butterfly wings of color display, such as Qualcomm has used MEMS drive substrate, to achieve the electro-rheological display of color display.

The reaction speed of electro-immersion display is much faster than electrophoresis, but to achieve the same reaction speed as LCD, the liquid viscosity of electro-immersion material is still difficult to overcome, and even if its viscosity can reach the same as LCD, its molecular self-assembly still needs time, so the driving power of its backplane is higher than LCD.

At the same time to realize the color display of the electro-rheological display, it is necessary to color with very accurate TFT gray scale switching circuit, and because of its total reflection interface and interference between the package substrate, to get a very pure color display, the production process level requires very high, otherwise the display color because of the control circuit gray level stability restrictions, color accuracy, color gamut are very limited.

But the electro-moist display also has a very good feature, that is, its total reflection interface is composed of liquid molecular surface, so it can simulate most of the natural immersion organic matter color effect, such as the surface of living animals and plants, can do the same vivid, thus in some camouflage and anti-counterfeiting applications, excellent performance..

Reflective display from time to time will be repeatedly mentioned in the global carbon reduction promotion node and the energy crisis, but mainly confined to some application scenarios with paper-like display sentiment, the real commercial display field, with more and more advertising content display needs, and from the graphic interaction into the video interaction, reflective display technology dynamic display capabilities, picture quality fineness and accuracy, are not as good as the current The LCD switch display, as well as OLED and LED self-luminous display.

The main reason for the recent industry reintroduction of reflective displays, in fact, is also the global carbon reduction to a new node, as well as the European energy crisis caused by the emergence of regional conflicts. The increase in enthusiasm for electric display technology is due to BMW’s launch of a “chameleon” effect of electric car coat, which opened up the industry’s market imagination in body color change, body advertising, personalized car post, and dynamic color chameleon body.

1. We’re interesting in Embedded Display: ENHANCEMENT OF NEW TFT LCDS EQUIPPED WITH EMBEDDED DISPLAY PORT INTERFACE 11.6” – 15.6” – 18.5” – 30”. We would like to order 1 unit for testing and checking if it’s suitable for our needs. Please submit your best price & delivery time. Appreciate to have your soonest reply.

2. Hello, Hope this message finds you well. We are looking for a display that meets the following requirements: Diagonal Size 10.1” (256.5mm), Resolution – Higher than 1280x800, Max thickness 8mm. Annual quantity needed is 10,000/year, Ideal voltage is 24V, Production parts guaranteed to be available for 10 years, Connector interface: eDP. Would you recoment this display? -- TFT Color Display 10.1inch 1920X1200 resolution in Medical system. What is the pricing / lead time for an order of Quantity 100 & 10,000? Thank you for your help

4. Dear Sir/madam, We are interested in two displays that you have listed on your website. Could we please arrange to order one of each for our engineering team to test with them. Regards

5. Hello, My coworker had worked in past with you with regards to the 3.46" 800*340 resolution display. We really liked the samples and I am looking to know more about that display. I also wanted to know if you have a 3.46" 400*170 resolution display as the 800*340 is a bit of overkill for our application. Thank you

11. Hi, I am interested in the above product, but need transflective display. It must be able to be read in sunlight with the backlight off. We are seeking quantity about 5,000 per year. Can you provide this? Thank you

128 x 64 2.70” LCD Graphic Display The G-12864D5G-VA is a 2.70” 128 x 64 Monochrome LCD Display with a module size of 67.0 x 52.5 x 7.2 and an active area of 59.9 x 37.4. The G-12864D5G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864D5G-VA Display Format 128 x 64 Graphic Display Module Size 67.0 x 52.5 x 7.2 Diagonal 2.70 Active Area 59.9 x 37.4 Pixel Pitch 0.445 x 0.445…

128 x 64 2.70” Graphic Display The G-1286408C-VA is a 2.70” 128 x 64 Monochrome LCD Display with a module size of 78.0 x 70.0 x 12.0 and an active area of 56.3 x 38.4. The G-1286408C-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED or Electro Luminescent backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-1286408C-VA Display Format 128 x 64 Graphic Display Module Size 78.0 x 70.0 x 12.0 Diagonal 2.70 Active Area 56.3 x 38.4 Pixel Pitch 0.440 x…

2.70” 128 x 64 Graphic Display LCD The G-12864F2C-VA is a 2.70” 128 x 64 Monochrome LCD Display with a module size of 78.0 x 70.0 x 13.5 and an active area of 56.3 x 38.4. The G-12864F2C-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864F2C-VA Display Format 128 x 64 Graphic Display Module Size 78.0 x 70.0 x 13.5 Diagonal 2.70 Active Area 56.3 x 38.4 Pixel Pitch 0.440 x 0.600…

128 x 64 2.70” Graphic Display LCD The G-12864G6G-VA is a 2.70” 128 x 64 Monochrome LCD Display with a module size of 92.5 x 53.75 x 11.5 and an active area of 60.8 x 32.9. The G-12864G6G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864G6G-VA Display Format 128 x 64 Graphic Display Module Size 92.5 x 53.75 x 11.5 Diagonal 2.70 Active Area 60.8 x 32.9 Pixel Pitch 0.475 x 0.515…

2.70” 128 x 64 Graphic Display The G-12864J6G-VA is a 2.70” 128 x 64 Monochrome LCD Display with a module size of 69.9 x 70.1 x 9.0 and an active area of 56.3 x 38.4. The G-12864J6G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864J6G-VA Display Format 128 x 64 Graphic Display Module Size 69.9 x 70.1 x 9.0 Diagonal 2.70 Active Area 56.3 x 38.4 Pixel Pitch 0.440 x 0.600 Backlight…

2.70” 128 x 64 LCD Graphic Display The G-1286468G-VA is a 2.70” 128 x 64 Monochrome LCD Display with a module size of 71.0 x 52.0 x 2.8 and an active area of 58.84 x 35.79. The G-1286468G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with no backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-1286468G-VA Display Format 128 x 64 Graphic Display Module Size 71.0 x 52.0 x 2.8 Diagonal 2.70 Active Area 58.84 x 35.79 Pixel Pitch 0.460 x 0.560 Backlight…

2.80” 122 x 32 Graphic Display The G-1223232C-VA is a 2.80” 122 x 32 Monochrome LCD Display with a module size of 84.0 x 44.0 x 13.8 and an active area of 53.64 x 15.64. The G-1223232C-VA 122 x 32 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-1223232C-VA Display Format 122 x 32 Graphic Display Module Size 84.0 x 44.0 x 13.8 Diagonal 2.80 Active Area 53.64 x 15.64 Pixel Pitch 0.440 x 0.490 Backlight…

2.8″ 240 x RGB X 320 Transmissive Color TFT Display Phoenix Display International PDI28QV02A is a small-size 2.8” color TFT liquid crystal display (LCD) with a module size of 50.00 * 69.20 * 2.38 mm, and active area 43.20 * 57.60 mm. This product is a-Si TFT, Normally White, Transmissive glass with a 240 * RGB * 320 resolution. Its brightness is 280 nits with a contrast ratio of 800. Using a ILI9341V driver with a MCU interface and a zero insertion force (ZIF) type flex interconnect. This product offers improved contrast , color saturation…

2.90” 128 x 64 LCD Graphic Display The G-12864A4C-VA is a 2.90” 128 x 64 Monochrome LCD Display with a module size of 113.0 x 65.0 x 13.5 and an active area of 66.5 x 33.2. The G-12864A4C-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864A4C-VA Display Format 128 x 64 Graphic Display Module Size 113.0 x 65.0 x 13.5 Diagonal 2.90 Active Area 66.5 x 33.2 Pixel Pitch 0.520 x 0.520…

128 x 64 2.90” LCD Graphic Display The G-1286420C-VA is a 2.90” 128 x 64 Monochrome LCD Display with a module size of 94.0 x 70.0 x 9.5/13.0 and an active area of 66.5 x 33.2. The G-1286420C-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED or Electro Luminescent backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-1286420C-VA Display Format 128 x 64 Graphic Display Module Size 94.0 x 70.0 x 9.5/13.0 Diagonal 2.90 Active Area 66.5 x 33.2 Pixel Pitch 0.520…

2.90” 128 x 64 Graphic Display LCD The G-12864E1C-VA is a 2.90” 128 x 64 Monochrome LCD Display with a module size of 93.0 x 70.0 x 13.5 and an active area of 66.5.0 x 33.2. The G-12864E1C-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864E1C-VA Display Format 128 x 64 Graphic Display Module Size 93.0 x 70.0 x 13.5 Diagonal 2.90 Active Area 66.5.0 x 33.2 Pixel Pitch 0.520 x 0.520…

128 x 64 2.90” Graphic Display LCD The G-12864B7G-VA is a 2.90” 128 x 64 Monochrome LCD Display with a module size of 80.0 x 54.0 x 9.9 and an active area of 66.5 x 33.2. The G-12864B7G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864B7G-VA Display Format 128 x 64 Graphic Display Module Size 80.0 x 54.0 x 9.9 Diagonal 2.90 Active Area 66.5 x 33.2 Pixel Pitch 0.520 x 0.520…

128 x 64 2.90” Graphic Display The G-12864F3C-VA is a 2.90” 128 x 64 Monochrome LCD Display with a module size of 95.0 x 68.0 x 13.4 and an active area of 66.5 x 33.2. The G-12864F3C-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864F3C-VA Display Format 128 x 64 Graphic Display Module Size 95.0 x 68.0 x 13.4 Diagonal 2.90 Active Area 66.5 x 33.2 Pixel Pitch 0.520 x 0.520 Backlight…

2.90” 160 x 160 Graphic Display The G-16016012T-VA is a 2.90” 160 x 160 Monochrome LCD Display with a module size of 83.8 x 77..5 x 9.1 and an active area of 52.4 x 52.3. The G-16016012T-VA 160 x 160 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-16016012T-VA Display Format 160 x 160 Graphic Display Module Size 83.8 x 77..5 x 9.1 Diagonal 2.90 Active Area 52.4 x 52.3 Pixel Pitch 0.327 x 0.327 Backlight…

2.90” 128 x 64 Graphic Display The G-12864R1G-VA is a 2.90” 128 x 64 Monochrome LCD Display with a module size of 120.2 x 50.34 x 11.1 and an active area of 66.52 x 33.24. The G-12864R1G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-12864R1G-VA Display Format 128 x 64 Graphic Display Module Size 120.2 x 50.34 x 11.1 Diagonal 2.90 Active Area 66.52 x 33.24 Pixel Pitch 0.520 x 0.520 Backlight…

3.0” 128 x 64 Graphic Display The G-1286449G-VA is a 3.0” 128 x 64 Monochrome LCD Display with a module size of 93.0 x 70.0 x 13.0 and an active area of 66.5 x 37.5. The G-1286449G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with Electro Luminescent backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-1286449G-VA Display Format 128 x 64 Graphic Display Module Size 93.0 x 70.0 x 13.0 Diagonal 3.0 Active Area 66.5 x 37.5 Pixel Pitch 0.520 x 0.520 Backlight EL Display Type R,TF,TM…

128 x 64 3.0” Graphic Display The G-1286443G-VA is a 3.0” 128 x 64 Monochrome LCD Display with a module size of 69.5 x 50.0 x 2.8 and an active area of 65.5 x 38.0. The G-1286443G-VA 128 x 64 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with no backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-1286443G-VA Display Format 128 x 64 Graphic Display Module Size 69.5 x 50.0 x 2.8 Diagonal 3.00 Active Area 65.5 x 38.0 Pixel Pitch 0.475 x 0.515 Backlight…

160 x 160 3.0” Graphic Display The G-16016006T-VA is a 3.0” 160 x 160 Monochrome LCD Display with a module size of 63.0 x 67.5 x 6.9 and an active area of 54.385 x 54.385. The G-16016006T-VA 160 x 160 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-16016006T-VA Display Format 160 x 160 Graphic Display Module Size 63.0 x 67.5 x 6.9 Diagonal 3.00 Active Area 54.385 x 54.385 Pixel Pitch 0.340 x 0.340 Backlight…

3.0” 160 x 160 Graphic Display The G-16016017G-VA is a 3.0” 160 x 160 Monochrome LCD Display with a module size of 83.8 x 80.8 x 10.9 and an active area of 54.38 x 54.38. The G-16016017G-VA 160 x 160 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-16016017G-VA Display Format 160 x 160 Graphic Display Module Size 83.8 x 80.8 x 10.9 Diagonal 3.0 Active Area 54.38 x 54.38 Pixel Pitch 0.340 x 0.327 Backlight…

3.0″ 480 x 640 Transmissive Color TFT Display Phoenix Display International PDI030VGGP-02 is a small-size 3.0” color TFT liquid crystal display (LCD) with a module size of 50.6 x 71 x 202 mm, and active area 45 x 60 mm. This product is a-Si TFT, Normally White, Transmissive glass with a 480 * RGB * 640 resolution. Its brightness is 500 nits with a contrast ratio of 800. Using a TBD driver with a RGB interface and a zero insertion force (ZIF) type flex interconnect. This product offers improved contrast , color saturation and response…

3.0′′ 240 x 400 Transmissive Color TFT Display Phoenix Display International PDI2404009G(R)-KTCL1-V12 is a small-size 3.0” color TFT liquid crystal display (LCD) with a module size of 45.00mm x77.00mm x3.95mm and active area of 38.88mm x64.80mm.This product is a-Si TFT, Positive, Transmissive glass with a 262K color 240 x 400 resolution. Its brightness is 140 nits with a contrast ratio of 250:1. Using an ILI9327 driver with an 16-Bit Parallel interface and a zero insertion force (ZIF) type flex interconnect. This product offers improved contrast, color saturation and response time. Similar product(s): None. All our color displays…

3.0″ 240 x (RGB) x 400 Transflective TFT Color LCD Phoenix Display International PDI030WQBH-03 is a small-size transflective 3.0” color TFT liquid crystal display (LCD) with a module size of 76.65 x 46.48 x 2.97 mm and active area of 38.88 x 64.8 mm. This product is a-Si TFT, Normally White, Transflective glass with 240 x RGB x 400 resolution. Its brightness is 150 nits with a contrast ratio of 80. Using an HX8352-B00 driver with an CPU 8/16 interface and a Hot-Bar type flex interconnect. This product offers improved contrast, color saturation and response…

3.10” 160 x 128 Graphic Display The G-16012808T-VA is a 3.10” 160 x 128 Monochrome LCD Display with a module size of 74.0 x 66.1 x 5.4 and an active area of 62.38 x 49.9. The G-16012808T-VA 160 x 128 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-16012808T-VA Display Format 160 x 128 Graphic Display Module Size 74.0 x 66.1 x 5.4 Diagonal 3.10 Active Area 62.38 x 49.9 Pixel Pitch 0.390 x 0.390 Backlight…

3.10” 160 x 160 Graphic Display The G-16016010T-VA is a 3.10” 160 x 160 Monochrome LCD Display with a module size of 84.0 x 78.0 x 8.6 and an active area of 55.97 x 55.97. The G-16016010T-VA 160 x 160 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-16016010T-VA Display Format 160 x 160 Graphic Display Module Size 84.0 x 78.0 x 8.6 Diagonal 3.10 Active Area 55.97 x 55.97 Pixel Pitch 0.350 x 0.350 Backlight LED…

This LCD development kit includes a 128x64 backlit low power LCD mounted to a custom adapter board. We"ll wire it up to a Seeeduino 4.2 and load a demonstration sketch so when the kit arrives it simply needs to be plugged in to begin a demonstration.

The display is a graphic monochrome LCD with an external backlight frame. The LCD is extremely low power and only requires the backlight when viewed in the dark. The adapter board breaks the display"s ZIF tail out to a 0.1" header which means no soldering is required to wire up with display.

Use this kit to evaluate the CFAG12864U3-TFH and/or the CFAG12864U3-TFH-E1-1 for your product, or provides a great jumping off point for creating a project with this display.

“Reflective”, “transmissive” and “transflective” are terms often used in connection with liquid crystal display (LCD) technology. They describe the ways in which LCD display modules are illuminated. In contrast to the emissive display technologies, like OLED displays (organic light-emitting diode) and VFDs (vacuum fluorescence displays), LCDs require a light source such as the sun, or artificial room light, or an integrated backlight, which is typically lit by LED (light-emitting diode) semiconductors.

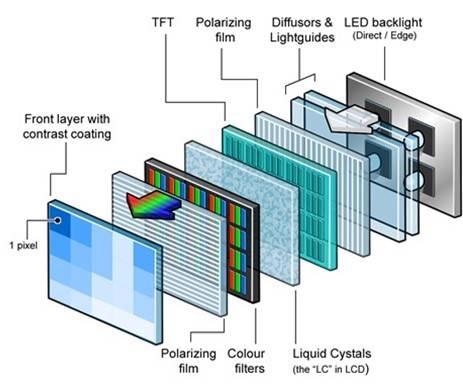

The mode of operation when light from a backlight passes through the LCD glass is called transmissive. The LCD glass or LCD panel functions as an “optical switch” where light from the backlight passes through the LCD cell depending on the orientation of liquid crystal molecules. The orientation can be “switched” on or off by an electrical field. Backlights produce a lot of light, making the display content very bright. The negative side of using backlights is that they require a significant amount of energy within an LCD display module, especially because the backlight is required to be on all the time even if there’s no content showing on the display. In direct sunlight, a transmissive LCD screen can become ‘washed-out’ if the sunlight overpowers the luminance of the backlight. Strong enough backlights to maintain sufficient contrast in direct sunlight – such as in aviation displays – are not compatible with the requirements of portable devices.

Some displays use ambient light rather than a backlight (View our Sun Vision Display brand of outdoor digital signage for an excellent example). This mode of operation is called reflective. In reflective mode, a mirror is installed behind the liquid crystal layer, either inside the LCD cell or on the rear polarizer. Ambient light passes through the LCD cell from the front side and is reflected by the mirror back to the viewer. The advantage is lower power consumption and excellent visibility in direct sunlight, making such displays excellent solutions for outdoor daytime applications. To be visible at night or in dark settings, reflective LCDs require additional lighting.

Transflective LCD displays have both transmissive and reflective characteristics. They contain an integrated backlight unit and a semi-transparent reflector or a reflector with a hole for each pixel. Again, the reflector can be behind the rear polarizer or inside the LCD cell behind the liquid crystal layer. Light from the backlight can pass the semi-transparent reflector and operate the display in the transmissive mode. At the same time, ambient light can be reflected so that the display is visible in direct sunlight as well. Care must be taken to account for the fact that in the transmissive mode of operation the light passes the liquid crystal layer once, while in the reflective mode it passes the liquid crystal layer twice. The appearance of transflective displays is a compromise. It is the most flexible solution as it allows for lower power consumption in bright environments and readability in any lighting condition. This comes at the expense of top performance in the pure illumination modes and sometimes significant additional manufacturing cost.

![]()

LED displays are a self-emitting display technology made up of a matrix of red, blue, and green LEDs forming the individual pixel elements. Standard LED displays have hundreds to thousands of LED pixels and project light directly to the viewer. These are often called “Direct View LEDs”, because there is no LCD layer at all in the display. MicroLED is one of the newest forms of these displays, which uses millions of microscopic LEDs producing a much higher-resolution image. However, they are still too expensive to be adopted by many applications. All types of LED displays provide excellent brightness and visibility both indoors and outdoors, but can also be heavy, bulky and require more complex installation. They tend to be expensive upfront but offer some cost savings over time since the light diodes that they rely on require little power. However, LEDs are at a higher risk for poor image retention or what many people refer to as “screen burn”.

Sometimes, LEDs are also used to form a backlight panel which is used to illuminate an LCD. These LED-backlit LCDs are frequently misnamed “LED displays”, however they are not true LED displays. True LED displays do not have an LCD layer.

Newhaven 20x2 character Liquid Crystal Display shows characters with white pixels on a black background when powered on. This transmissive LCD Display requires a backlight for visibility while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0220DZ-NSW-FBW display has an optimal view of 6:00. This display operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey