in re tft lcd factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

applEcon helped a class of U.S. consumers to obtain settlements totaling $1.082 billion from a cartel of manufacturers of liquid crystal display (LCD) panels. LCD panels are flat video displays used in computer monitors, laptop computers, and televisions. The nine manufacturers that comprised the cartel supplied approximately 98% of the worldwide market for large LCD panels during the period the cartel operated, 1999-2006. Sales of LCD panels at issue to class members were approximately $23.5 billion during this period. Representatives of the cartel’s member companies, including senior executives, met about once a month for years to collude on capacity and output, and to fix prices.

The value of applEcon’s approach to such cases, combining deep knowledge of the industry and information available in the case with strong analytical skills, are highlighted by this engagement. In July 2011, defendants submitted nine separate expert reports all responding to Dr. Netz’s analysis. Given only three weeks to file a reply, applEcon analyzed and responded to these reports with factual and analytical evidence countering their various claims. The depth of applEcon’s knowledge of the industry led class counsel to also rely on applEcon to provide critical assistance on issues related to both the Foreign Trade Antitrust Improvements Act of 1982 (FTAIA) and ascertainability, both of which are primarily legal, as opposed to economic, matters. applEcon’s depth of knowledge also led other firms in related litigation to rely on us for our understanding of the massive volume of disparate data produced by the various defendants.

Over the course of the four and a half year engagement, applEcon supported class attorneys at virtually every stage of this complex case. applEcon submitted nine expert reports and affidavits and helped class attorneys address a wide range of issues, including: class certification, discovery, damages, pass-through of overcharges to indirect purchasers, class de-certification, cartel effectiveness and causation of antitrust harm, class members’ ability to ascertain their claims, a Daubert challenge, a motion to dismiss based on FTAIA, and responses to several additional motions for summary judgment. applEcon was preparing trial testimony when the last of the defendants, AUO, LG, and Toshiba, settled with the indirect purchaser class shortly before trial was to begin.

Suit was brought by representatives of a putative class of U.S. purchasers of products containing large LCD panels, alleging that the cartel caused the prices they paid for LCD products to be above competitive levels, in violation of U.S. antitrust laws. Attorneys for the indirect purchaser class faced a myriad of complications: an LCD panel may change hands several times as it passes from the LCD manufacturer to product manufacturers, distributors, and retailers before an end consumer ultimately takes it home as a component of a monitor, laptop, or television. Proof of antitrust harm required establishing that defendants overcharged their direct customers and that the cartel’s overcharges were passed through the length of the distribution chain resulting in elevated prices for end consumers purchasing products containing LCD panels. Calculating damages to end consumers required quantifying both the overcharge to direct purchasers as well as the pass-through rate.

Because the cartel members were based in foreign countries, class attorneys also faced the challenge of demonstrating that the cartel’s actions had a “direct, substantial, and reasonably foreseeable effect on domestic commerce” in order to meet FTAIA requirements. applEcon drew upon its extensive experience in demonstrating pass-through and common proof of damages as it helped attorneys for the class to meet these challenges. Judge Susan Illston relied on applEcon’s pass-through analyses when she certified the indirect purchaser class, and cited Dr. Netz’s pass-through testimony in her order denying Defendants’ motion to dismiss based on FTAIA, writing that the “increased price of the components caused the prices of finished products in the United States to increase. If that’s not ‘direct,’ it’s difficult to imagine what would be.”

Complications multiplied due to the fact that the conspiracy involved nine defendants based in three foreign countries, with multiple divisions across the globe, some involved in multiple stages of production. For example, Samsung was a producer of both LCD panels and televisions containing LCD panels. Whereas applEcon has long been accustomed to large, complex cases, with mountains of documents and data, we soon discovered that ordinary complications are compounded by multiple defendants, multiple teams of opposing attorneys and expert witnesses, and multiple datasets, each with unique characteristics. We enjoy developing systems that improve the efficiency of our operations, and methods we developed in previous complex litigation allowed us to meet the challenges of this case in a cost-effective manner.

The TFT-LCD (Flat Panel) Antitrust Litigationclass-action lawsuit regarding the worldwide conspiracy to coordinate the prices of Thin-Film Transistor-Liquid Crystal Display (TFT-LCD) panels, which are used to make laptop computers, computer monitors and televisions, between 1999 and 2006. In March 2010, Judge Susan Illston certified two nationwide classes of persons and entities that directly and indirectly purchased TFT-LCDs – for panel purchasers and purchasers of TFT-LCD integrated products; the litigation was followed by multiple suits.

TFT-LCDs are used in flat-panel televisions, laptop and computer monitors, mobile phones, personal digital assistants, semiconductors and other devices;

In mid-2006, the U.S. Department of Justice (DOJ) Antitrust Division requested FBI assistance in investigating LCD price-fixing. In December 2006, authorities in Japan, Korea, the European Union and the United States revealed a probe into alleged anti-competitive activity among LCD panel manufacturers.

The companies involved, which later became the Defendants, were Taiwanese companies AU Optronics (AUO), Chi Mei, Chunghwa Picture Tubes (Chunghwa), and HannStar; Korean companies LG Display and Samsung; and Japanese companies Hitachi, Sharp and Toshiba.cartel which took place between January 1, 1999, through December 31, 2006, and which was designed to illegally reduce competition and thus inflate prices for LCD panels. The companies exchanged information on future production planning, capacity use, pricing and other commercial conditions.European Commission concluded that the companies were aware they were violating competition rules, and took steps to conceal the venue and results of the meetings; a document by the conspirators requested everybody involved "to take care of security/confidentiality matters and to limit written communication".

This price-fixing scheme manipulated the playing field for businesses that abide by the rules, and left consumers to pay artificially higher costs for televisions, computers and other electronics.

Companies directly affected by the LCD price-fixing conspiracy, as direct victims of the cartel, were some of the largest computer, television and cellular telephone manufacturers in the world. These direct action plaintiffs included AT&T Mobility, Best Buy,Costco Wholesale Corporation, Good Guys, Kmart Corp, Motorola Mobility, Newegg, Sears, and Target Corp.Clayton Act (15 U.S.C. § 26) to prevent Defendants from violating Section 1 of the Sherman Act (15 U.S.C. § 1), as well as (b) 23 separate state-wide classes based on each state"s antitrust/consumer protection class action law.

In November 2008, LG, Chunghwa, Hitachi, Epson, and Chi Mei pleaded guilty to criminal charges of fixing prices of TFT-LCD panels sold in the U.S. and agreed to pay criminal fines (see chart).

The South Korea Fair Trade Commission launched legal proceedings as well. It concluded that the companies involved met more than once a month and more than 200 times from September 2001 to December 2006, and imposed fines on the LCD manufacturers.

Sharp Corp. pleaded guilty to three separate conspiracies to fix the prices of TFT-LCD panels sold to Dell Inc., Apple Computer Inc. and Motorola Inc., and was sentenced to pay a $120 million criminal fine,

Chunghwa pleaded guilty and was sentenced to pay a $65 million criminal fine for participating with LG and other unnamed co-conspirators during the five-year cartel period.

In South Korea, regulators imposed the largest fine the country had ever imposed in an international cartel case, and fined Samsung Electronics and LG Display ₩92.29 billion and ₩65.52 billion, respectively. AU Optronics was fined ₩28.53 billion, Chimmei Innolux ₩1.55 billion, Chungwa ₩290 million and HannStar ₩870 million.

Seven executives from Japanese and South Korean LCD companies were indicted in the U.S. Four were charged with participating as co-conspirators in the conspiracy and sentenced to prison terms – including LG"s Vice President of Monitor Sales, Chunghwa"s chairman, its chief executive officer, and its Vice President of LCD Sales – for "participating in meetings, conversations and communications in Taiwan, South Korea and the United States to discuss the prices of TFT-LCD panels; agreeing during these meetings, conversations and communications to charge prices of TFT-LCD panels at certain predetermined levels; issuing price quotations in accordance with the agreements reached; exchanging information on sales of TFT-LCD panels for the purpose of monitoring and enforcing adherence to the agreed-upon prices; and authorizing, ordering and consenting to the participation of subordinate employees in the conspiracy."

On December 8, 2010, the European Commission announced it had fined six of the LCD companies involved in a total of €648 million (Samsung Electronics received full immunity under the commission"s 2002 Leniency Notice) – LG Display, AU Optronics, Chimei, Chunghwa Picture and HannStar Display Corporation.

On July 3, 2012, a U.S. federal jury ruled that the remaining defendant, Toshiba Corporation, which denied any wrongdoing, participated in the conspiracy to fix prices of TFT-LCDs and returned a verdict in favor of the plaintiff class. Following the trial, Toshiba agreed to resolve the case by paying the class $30 million.

On March 29, 2013, Judge Susan Illston issued final approval of the settlements agreements totaling $1.1 billion for the indirect purchaser’ class. The settling companies also agreed to establish antitrust compliance programs and to help prosecute other defendants, and cooperate with the Justice Department"s continuing investigation.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

In the LC filling process, if the quantity of LC injected is not enough, the spare space will form bubbles. And loose LC containing sealant will result in LC leakage.

Point defect is a kind of defect that some point on your screen don’t display correctly. There are mainly three situations: the point keeps displaying black or whitewhen the screen is working or the point can only display a single color.

For the first two situations, that’s because the circuit on the TFT and CF controlling that defective pixel point is shorted or broken. While the third situation is caused by damaged color pixel.

The production of the circuit and color pixel is under micro scale, and the technology is similar to semiconductor technology. Hundreds of thousands micro materials will be printed during the production process, you can understand some of the materials not being printed correctly, which result in the point defect.

Unlike point defect, this larger scale defect is caused by the failure of external FPC or PCBA, or a bad connection between FPC and cell. Therefore, a bunch of pixels connected to these IC are out of control, and we see those defects.

Usually, assembly of cell and IC is under heat and should be positioned accurately. Problems with IC connection will be checked out very soon, followed by the adjustment on machine parameter.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

To avoid this problem, we have to pay attention to the gap distance parameter in sealing process. By the way, newton’s rings has became a method to exam the glass sealing process in reverse .

You may notice there are some screens have uneven display, which means some white area appears in dark picture or vice versa. We call this ‘mura’, a word originated from Japanese.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Among the causes listed, thickness of the whole cell is the most critical one, and there are many factors related to that. Researches provide a lot of advice to adjust the thickness of the whole cell:

Note: We do not own the images used in this post. Feel free to contact us if they belong to you, and we’ll take them down as quickly as we possibly can.

/cdn.vox-cdn.com/uploads/chorus_asset/file/16236679/jlott_190508_3414_0028.0.jpg)

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

In order to enhance productivity, in this step we’ll do a series of procedure on a large glass, which will be cut into smaller pieces in the following step.

First, let me introduce a crucial material, ITO, to you. ITO, abbreviation of Indium tin oxide, has the characteristic of electrical conductivity and optical transparency, as well as can be easily deposited as a thin film. Thus it’s widely used to create circuit on glass.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

◇ Use glue to build a boundary for LC on both glass. And on CF glass, apply one more layer of conductive adhesive. This enable LC molecule link to the control circuit.

◇ Put the diffuser film and prism film on light source in turn. Together with reflector film, these two films are used to turn the point light from light source into area light and enhance light intensity.

We want to make sure you do not miss the announcement of the historic settlement of one of our cases that could mean $25, $100, $200 or more in your pocket.

Since 2007, Minami Tamaki partner Jack Lee has served as the Court-appointed Liaison Counsel for consumers, known as “indirect purchasers,” in a class action against ten leading international companies for unlawfully conspiring to fix prices of LCD panels used in laptops, desktop monitors, and flat screen televisions. The case is IN RE TFT-LCD (FLAT PANEL) ANTITRUST LITIGATION, MDL Case No. 1827, pending in the United States District Court for the Northern District of California in San Francisco.

The indirect purchasers we represent include individual and private companies in 24 states and the District of Columbia that purchased laptops, monitors, and TVs containing LCD panels for use (and not for resale) from January 1, 1999, to December 31, 2006.

This litigation has resulted in settlements totaling approximately $1.1 billion, the largest amount ever obtained for consumers who bought products indirectly from retailers and resellers, and not directly from the original manufacturer. The net proceeds of the settlement, after attorneys’ fees and costs, will be distributed to consumers and businesses that submit claim forms.

We believe it is likely that you, like tens of millions of other consumers, may have purchased one or more of the products at issue in this case during the seven year period that the price-fixing occurred. We hope that you will take advantage of the opportunity to recover any unlawful overcharges you paid as a result of this conspiracy.

Consumers and businesses in the District of Columbia and the following 24 states are eligible to participate in this settlement: Arizona, Arkansas, California, Florida, Hawaii, Iowa, Kansas, Maine, Massachusetts, Michigan, Minnesota, Mississippi, Missouri, Nevada, New Mexico, New York, North Carolina, North Dakota, Rhode Island, South Dakota, Tennessee, Vermont, West Virginia and Wisconsin.

Eligibility requirements and instructions on the claims process are available online at the web site: https://lcdclass.com/Home.aspx.The deadline for filing claims is December 6, 2012. Eligible consumers will be able to collect $25, $100, $200 or more by answering a few simple questions about the number of LCD flat screen TVs, monitors, and laptops they bought from 1999 to 2006. The exact amount of each payment will depend upon the number of products purchased and the number of claims filed. No receipts or other documents are required for small claims.

We believe that the eligibility requirements and claims process described on the web site are clear and simple. However, if you have questions or would like assistance in preparing your claim, we invite you to contact our toll-free LCD help line at 1-855-225-1886 or via e-mail at info@lcdclass.com.

While Minami Tamaki LLP is pleased to announce this settlement and to have played a substantial role in this momentous litigation, we will ultimately measure our success by the benefits actually received by consumers eligible to share in the proceeds, including our friends and clients. We are therefore notifying you of this opportunity, urging you to submit your claim, and offering whatever assistance you feel you may need to realize the maximum benefit available to you. We also encourage you to pass this information on to your friends, family members, and colleagues who may be interested in making claims for their share of this settlement.

STONE-Technologien sind der weltweit führende Anbieter von TFT-Displays und Hersteller von LCD-Displays in China.STONE bietet seinen Kunden das hochwertige TFT-LCD Modul Touchsc…

Raystar is a global leading LCD panel supplier and specialized in producing TFT LCD Panel, including Color TFT, Monochrome TFT Display and bar type TFT Display. Raystar Color TFT displays are available in various resolutions and offers a wide product range of small to medium-sized TFT-LCD modules from 0.96” to 12.3". The interface options are in MCU / RGB / SPI / UART / 8080 / LVDS. TFT Panel with control board or TFT LCD Panel with micro controller are also available.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

On the surface level is the other glass substrate. Just beneath this glass substrate is where the actual pixels and sub-pixels reside, forming the RGB color filter. In order to counteract the electrodes of the previously mentioned layer, this surface layer has counter (or common) electrodes on the side closer to the liquid crystals that close off the circuit that travels between the two layers. In both these substrate layers, the electrodes are most frequently made of indium tin oxide (ITO) because they allow for transparency and have good conductive properties.

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

Fig. 2: On the left is the twisted liquid crystal layer in which polarized light passes freely; on the right is after the electric field is charged into the layer, completely re-aligning the molecule orientations so that light is not polarized and cannot pass through the surface polarizer.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Lcd Module Tft Graphic, Tft Lcd Digital Color Monitor, Touch Screen Display Module, Tft Lcd Interface,Automotive Touch Lcd Panel. All the time, we have been paying attention on all details to insure each product satisfied by our customers. The product will supply to all over the world, such as Europe, America, Australia,Lebanon, Danish,Surabaya, Nairobi.Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers" expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

In a typical LCD factory, a large number of product types are produced concurrently, 24 hours a day and 365 days a year, and there exist various constraints and re-entrant flows in the manufacturing processes. As a result, efficient planning and scheduling of LCD production is a big challenge. Presented in this paper is a simulation-based DPS (daily planning & scheduling) system that was developed by the authors and is being used in a modern LCD Fab in Korea. Also presented in the paper are a business architecture of LCD production management, internal structure of the DPS system, and Fab scheduling logic. The DPS system was installed at a large-size LCD Fab in 2006, and the system has been successfully used for two years leading to a considerable increase in on-time production of LCD panels and a sharp decrease in turn-around time.

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

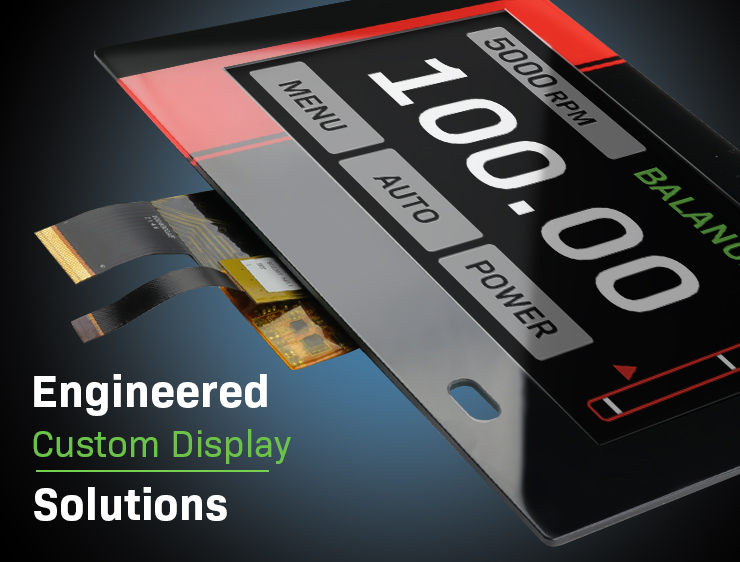

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey