stm32 nucleo lcd display brands

Worldwide,Asia,Europe,Africa,North America,South America,Oceania,Afghanistan,Bahrain,Bangladesh,Bhutan,Brunei,Burma (Myanmar),Cambodia,China,East Timor,India,Indonesia,Iraq,Japan,Jordan,Kazakhstan,Kuwait,Kyrgyzstan,Laos,Malaysia,Maldives,Mongolia,Nepal,Oman,Pakistan,Philippines,Qatar,Russian Federation,Saudi Arabia,Singapore,South Korea,Sri Lanka,Taiwan,Tajikistan,Thailand,Turkmenistan,United Arab Emirates,Uzbekistan,Vietnam,Yemen,Albania,Andorra,Armenia,Austria,Azerbaijan,Belarus,Belgium,Bosnia and Herzegovina,Bulgaria,Croatia,Cyprus,Czech Republic,Denmark,Estonia,Finland,France,Georgia,Germany,Greece,Hungary,Iceland,Ireland,Israel,Italy,Latvia,Liechtenstein,Lithuania,Luxembourg,Macedonia,Malta,Moldova,Monaco,Montenegro,Netherlands,Norway,Poland,Portugal,Romania,San Marino,Serbia,Slovakia,Slovenia,Spain,Sweden,Switzerland,Turkey,Ukraine,United Kingdom,Vatican City,Algeria,Angola,Benin,Botswana,Burkina,Burundi,Cameroon,Cape Verde,Central African Republic,Chad,Comoros,Democratic Republic of Congo,Djibouti,Egypt,Equatorial Guinea,Eritrea,Ethiopia,Gabon,Gambia,Ghana,Guinea,Guinea-Bissau,Ivory Coast,Kenya,Lesotho,Liberia,Libya,Madagascar,Malawi,Mali,Mauritania,Mauritius,Morocco,Mozambique,Namibia,Niger,Nigeria,Rwanda,Sao Tome and Principe,Senegal,Seychelles,Sierra Leone,Somalia,South Africa,Swaziland,Tanzania,Togo,Tunisia,Uganda,Zambia,Zimbabwe,Antigua and Barbuda,Bahamas,Barbados,Belize,Canada,Costa Rica,Dominica,Dominican Republic,El Salvador,Grenada,Guatemala,Haiti,Honduras,Jamaica,Mexico,Nicaragua,Panama,Saint Kitts and Nevis,Saint Lucia,Saint Vincent and the Grenadines,Trinidad and Tobago,United States,Argentina,Bolivia,Brazil,Chile,Colombia,Ecuador,Guyana,Paraguay,Peru,Suriname,Uruguay,Venezuela,Australia,Fiji,Kiribati,Marshall Islands,Micronesia,Nauru,New Zealand,Palau,Papua New Guinea,Samoa,Solomon Islands,Tonga,Tuvalu,Vanuatu Active TouchGFX advanced and free of charge graphical framework optimized for STM32 microcontrollers STM32Cube Expansion Packages ST X-CUBE-TOUCHGFX

The aim of thisBluetooth LE projectis to read air quality sensor data and show it on an LCD display which is connected to STM32 board. A web browser will read the sensor data and pass it to STM32 board using BleuIO.

For this project, we will needtwo BleuIO USB dongles,one connected to the Nucleo board and the other to a computer running the web script and aHibouAir – Air quality monitoring device.When the BleuIO Dongle is connected to the Nucleo boards USB port the STM32 will recognize it and directly start advertising. This allows the Dongle on the computer port connect with the web script.

With the web script on the computer, we can scan and get air quality sensor data from HibouAir. Then we send these data to LCD screen connected to STM32 using Bluetooth.

We have used a STM32 Nucleo-144 development board with STM32H743ZI MCU (STM32H743ZI micro mbed-Enabled Development Nucleo-144 series ARM® Cortex®-M7 MCU 32-Bit Embedded Evaluation Board) for this example. This development board has a USB host where we connect the BleuIO dongle.

What we will needA board with a STM32 Microcontroller with a USB port. (A Nucleo-144 development board: NUCLEO-H743ZI2, was used developing this example. (https://www.st.com/en/evaluation-tools/nucleo-h743zi.html)To connect the dongle to the Nucleo board a “USB A to Micro USB B”-cable with a USB A female-to-female adapter can be used.)

Connect the BleuIO dongle to the computer. Run the web script to connect to the other BleuIO dongle on the STM32. Now you can send sensor data to the LCD screen.

Create a simple Html file called index.html which will serve as the frontend of the script. This Html file contains some buttons that help connect, read advertised data from the HibouAir to get air quality sensor data, and send this data to the LCD screen which is connected to stm32.

The script has a button to connect to COM port on the computer. There is a text field where you can write sensor ID of the air quality monitor device. Once connected, the script will try to get advertised data from the sensor and convert it to a meaningful data. After that it will send this data to the STM32 board which then display on the LCD screen.import * as my_dongle from "bleuio"

Follow the steps to get the MAC address of the dongle that is connected to STM32- Open this site https://bleuio.com/web_terminal.html and click connect to dongle.

For this project, we will need two BleuIO USB dongles, one connected to the Nucleo board and the other to a computer, running the web script.When the BleuIO Dongle is connected to the Nucleo boards USB port the STM32 will recognize it and directly start advertising. This allows the Dongle on the computer port connect with the web script.

We have used a STM32 Nucleo-144 development board with STM32H743ZI MCU (STM32H743ZI micro mbed-Enabled Development Nucleo-144 series ARM® Cortex®-M7 MCU 32-Bit Embedded Evaluation Board) for this example. This development board has a USB host where we connect the BleuIO dongle.

What we will needA board with a STM32 Microcontroller with a USB port. (A Nucleo-144 development board: NUCLEO-H743ZI2, was used developing this example. (https://www.st.com/en/evaluation-tools/nucleo-h743zi.html)To connect the dongle to the Nucleo board a “USB A to Micro USB B”-cable with a USB A female-to-female adapter can be used.)

Connect the BleuIO dongle to the computer. Run the web script to connect to the other BleuIO dongle on the STM32. Now you can send messages to the LCD screen.

Create a simple Html file called index.html which will serve as the frontend of the script. This Html file contains some buttons that help connect and read advertised data from the remote dongle, which is connected to stm32.

The script has a button to connect to COM port on the computer. There is a text field where you can write your message. Your messages will be displayed on LCD screen connected to STM32 board.

Follow the steps to get the MAC address of the dongle that is connected to STM32- Open this site https://bleuio.com/web_terminal.html and click connect to dongle.

In this tutorial, we’ll discuss the alphanumeric LCD 16×2 interfacing with STM32 microcontrollers. Starting with an introduction to the LCD 16×2 display, then how to implement a driver for it on STM32 blue pill board. We’ll set up all the configuration parameters and get our first ECUAL layer driver done, so we can make our next applications more portable. This will be detailed by the end of this tutorial and in the next one, so let’s now get started!

We typically add a 16×2 Alphanumeric LCD to small embedded systems & projects to enhance the user experience and UI of the device/project. You can use it to display text messages to the user, number, etc. Other types of LCDs provide different features such as the number of columns and rows (characters) and maybe colored display, and also different interfaces (parallel, spi, i2c, etc).

For this tutorial, we’ll consider the 16×2 LCD with a 16-pin header interface. Assuming it has the standard Hitachi LCD driver HD44780 controller. The Alphanumeric LCD 16×2 Tutorial did highlight everything you need to know. That’s why I highly recommend that you check it out right now. In order to know, the internals of the LCD driver IC, it’s registers, commands, and how it works and gets initialized, etc.

Today’s tutorial is built upon the previous LCD one, and it’s assumed that you’ve got a basic understanding of the topics discussed earlier. We’ll port the LCD driver in 4-Bit mode to make it easily configurable and portable across most STM32 microcontroller devices.

The best way in my opinion for interfacing alphanumeric LCD screens is using an external I2C LCD driver chip. In this way, you save up a lot of valuable GPIO pins for other uses and it only requires 2 wires on the I2C bus. However, it’s going to be a topic for a future tutorial as we didn’t cover the I2C in STM32 MCUs yet.

Therefore, in this tutorial, we’ll be interfacing the LCD 16×2 display in the 4-bit mode which requires 6 GPIO pins. And as you know the STM32 microcontroller is a 3.3v logic device and the LCD is 5v. But it is not a big deal, as the STM32 output (3.3v) pins will be correctly detected by the LCD (5v) input pins. And the only 5v line that is required is the LCD VDD, and you can supply it from the blue pill board 5v pin.

Don’t also forget to connect the contrast control potentiometer as indicated in the diagram shown above. Low contrast may seem to you like a not-working-LCD and hence unnecessarily waste so much time debugging a code that actually works!

After flashing the code to your microcontroller, the LCD may not work from the USB programmer set up. It’s recommended to un-plug the programmer and use external power supply or USB power bank. The LCD may not work at all from the laptop USB or in some cases misbehave, so stay safe with an external power source.

The STM32 microcontroller has to first initialize the LCD display before it can actually send any characters to be displayed correctly. The initialization procedure is step-by-step indicated in the LCD driver datasheet for both modes 4-bit and 8-bit. And it requires a few delay instructions, so I’ll be using the DWT delay which we’ve developed in the previous tutorial.

The available instructions that the LCD driver IC can execute are listed in the datasheet. As well as the execution time for each instruction. Therefore, you should be careful at this time! you can use an extra pin to read the busy flag bit from the LCD to know whether it did execute the last instruction or not. Otherwise, it’s mandatory to use time delays according to the datasheet specs. Here is a list of the LCD instructions.

I’ve received a lot of questions and suggestions from you since the last LCD tutorial that I’ve published. The conclusion that I’ve settled for is that maybe there are various versions of the LCD modules and drivers ICs that can be the direct reason why the signal’s timing differs from a user to another.

Here I’m speaking about the enable pulse that you should send to the LCD driver after each command in order to transfer the 8-bit CMD word (whether at once or at 2 stages in 4bit mode).

The datasheet says it should be no less than 200nSec. However, an old LCD with me didn’t receive any data until this pulse delay was up to 500uSec (which is so long in fact). Another LCD could work just fine with 50uSec pulses but no less than that. Another one with a different color did work absolutely fine with a 1uSec pulse. Which is pretty reasonable amount of delay.

The LCD 16×2 driver is going to be our first ECUAL (ECU Abstraction Layer), driver. This software layer is added to abstract the hardware dependencies from the application layer. All the onboard ECU peripherals, sensors, memory, and so on do depend on the MCU peripherals and their HAL drivers. The procedure followed by calling some HAL drivers and doing some initialization and calculations work will also get abstracted from the application by introducing the ECUAL layer.

The software component (LCD Driver) in the ECUAL layer will call some HAL_GPIO pin manipulation functions, DWT_Delays, and other HAL & utilities. So that the application code can be more portable, and you can easily change the platform (microcontroller) and have your application running with a high level of portability. And you’ll also have configuration files in each driver to add further adjustability to our software.

The first step is to create the source code directory for the ECUAL layer in which we’ll also create the first driver directory called LCD16x2, and finally create the following 4 files.

The purpose of having these files in our driver is to make it easily configurable by the user (the application programmer). We shall put all the important parameters in there in a structure that encapsulates all the config parameters together. I’ve chosen to put in there the LCD GPIO pins, GPIO port, and the enable pulse width time.

This means that my driver in this way of implementation assumes that the user will hook the LCD pins to the sam MCU port whatever the pin numbers are. But you can actually make it even more portable so that the user can use pins from multiple GPIO ports! but the config structure will be a bit larger and it’s not a big deal however, it’s a design decision that I’ve made and preferred to tell you that I did that for simplicity’s sake and can be adjusted by you if it’s really needed.

Note that the configuration parameter structure is externed to the header file so that in the LCD16x2.c source code we can include the configuration header file LCD16x2_cfg.h and see that global config parameter and do our pin manipulations on these defined ones. This type of configuration is called linking configuration, as it gets resolved during the compilation time in the linking stage and the user (the programmer) doesn’t have to compile the whole project in order to change the configurations, only compile the configuration source and link it with your application object files. This topic and other types of configurations will be discussed in the next tutorial as well.

It is a bit long file 150 lines of code, and it’s found in the download link down below as well as the other files. The thing you need to know about this source code file is that it’s an implementation for all the declared functions in the header file above to initialize the LCD, write char, string, and all other stuff. It’s a direct implementation for what is documented in the LCD datasheet and we’ve previously done it in This LCD tutorial. So it should be easily ported to the STM32 ecosystem.

In this LAB, our goal is to build a system that initializes the LCD driver. Which in turn initialized the configuration-defined GPIO pins and therefore send the initialization commands to the LCD as described in its datasheet. After this, we can easily call the LCD driver functions to set the cursor position, print strings, and shift the entire display on the LCD right and left. It’s a very basic and simple LAB.

My main aim is to just display 1 character I have gone through datasheet and forums and have taken everyones"s suggestion accurately I still can"t figure out what"s wrong with my program..

This application note uses the 1.8” TFT display with 4-wire resistive touch and the ST Nucleo-L476RG microcontroller. Here we will discusses how to program a digital push button activated by the resistive touch panel. A section of this application note requires information from FAN4205.

The display used in this project is a 1.8” TFT with 128x160 pixels of resolution. The microcontroller used is the Nucleo-L476RG from ST. The TFT display will be interfaced with the microcontroller via a 4-wire serial connection. This application note is a continuation of FAN4205 to further demonstrate the features of this display.

In just a few steps the TFT can be wired and programmed to display up to 65K colors and 128x160 pixels of resolution. Various wiring and interface options are available, from 3-4 wire serial, to 16/18-bit RGB and 8/9/16/18-bit MCU parallel. Additional features of this display are below. As always, check out the data sheet for the specs of this specific display. (datasheet)

First you will need an IDE to program the display. This ST microcontroller lets you use a range of IDE’s so it is up to personal preference. I am going to use the Arduino IDE, any IDE that supports C++ and is compatible with the ST microcontroller will work. There is a list of options on ST’s website. We will come back to this after the hardware is setup.

Now to program the microcontroller. For this example, the Arduino IDE was used. There are alternative IDE’s that can be used to program the display. This was chosen from preference and the accessibility of a variety of TFT graphics libraries that are available. If you choose to go this route, refer to the previous application note on how to interface the ST Nucleo with the Arduino IDE.

Here is the example program that displays a push button that switches between the play and pause symbol once pressed. The locations of the pins are defined below. These include the serial input locations and the four resistive touch terminal connections

This 1.8” TFT with a 4-wire resistive touch screen is a good option for creating digital push buttons and 65K color images. This display is compatible with a variety of microcontrollers and can store bitmaps and images with using a small amount of on-board memory. This is beneficial for flash memory storage on the microcontroller can be used which leads to faster data uploading speeds. 4-wire resistive touch screens are a cheaper alternative to capacitive and are a great choice for smaller applications such as this.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

MCUFRIEND_kbv works out of the box with every "Mcufriend style" parallel Shield on a Nucleo. i.e. it supports more controllers than TFT_eSPI. But TFT_eSPI is more sophisticated and probably faster.

As I said. I don"t have the Waveshare Shield. It is definitely convenient to plug a Shield into a Nucleo. I would expect it to run pretty fast with TFT_eSPI. So I am wondering what you have done in your User_Setup.

It is unfortunate that I do not want to buy a Waveshare. I can probably test most other display types. (on AVR, Due, Nucleo, Teensy, ESP8266, ESP32, RPi Pico, ... targets)

Regarding Red SPI displays and Shields. I mount headers and solder wire routeing on a custom ProtoShield. This means that I can run different displays on different targets.

You will see that most of the Display contributors have similar arrangements. i.e. Protoboard or ProtoShields that receive the popular TFT, OLED, GLCD, ...

The STM32 Nucleo U575ZI-Q is a Nucleo-144 development boards with an STM32U575ZIT6Q MCU on-board and connectors for Arduino, ST Zio and morpho accessories. The MCU features an ultra-low-power Arm Cortex-M33 core with a built-in FPU unit, running at 160 MHz. The MCU also packs 2 MB of Flash memory. Additionally, the board features a programmable USB port for interfacing through code.

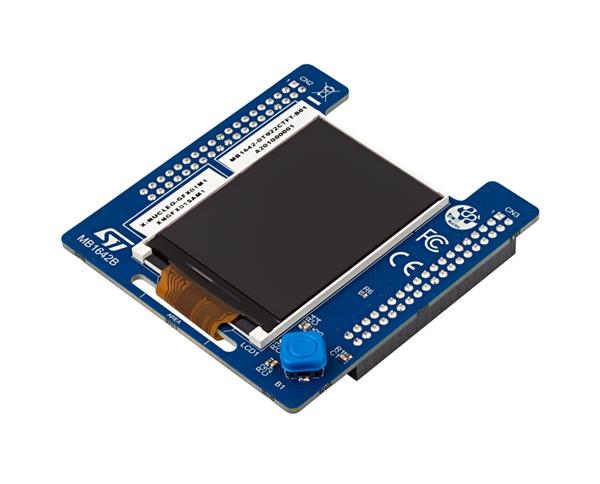

For a little test, we paired the X-Nucleo GFX02ZI full-color 320×240 LCD screen with the dev board. As of the time of writing, this development board is the only Nucleo-144 model which features full support of such add-on screens using the TouchGFX Designer suite – available from STM’s own website.

Unfortunately, the X-Nucleo GFX02ZI display doesn’t have the highest resolution – if it were any lower, many applications would be unsuitable for such a low number of pixels. Still, it’s the best currently supported Nucleo screen. If you want to create a device using an ultra-low-power but high-performance ARM MCU, the Nucleo U575ZI-Q is an excellent starter kit – with its wide range of IOs and the aforementioned USB port which can support various external devices, like keyboards or other UART devices. The board can truly provide days and days of development opportunities just on its own – and we definitely recommend it.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey