tft lcd lifespan made in china

The Displaytech DT028 series LCD is a 2.8in active matrix TFT module with 240 x 320 resolution (RGB). The device is available now from RS Components. This touch screen provides an active viewing area with a width of 43.2mm and a height of 57.6mm. It uses a-Si-based TFT LCD that employs Ilitek ILI9341 as a chip driver. This display provides a response time of 10ms. The device has a width of 50mm, a height of 69.2mm and depth of 2.7mm.

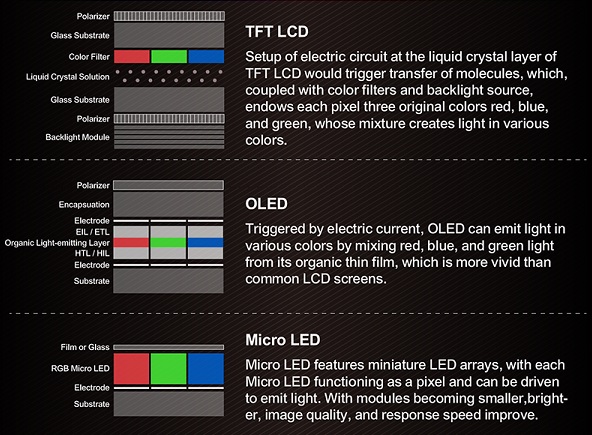

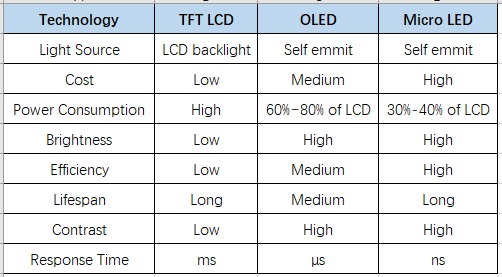

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

To choose the right TFT LCD display for a medical application, engineers and decision-makers need to have a comprehensive understanding of how TFT LCD display specifications affect final products. And it is important to know how a display differs from industrial or consumer LCD.

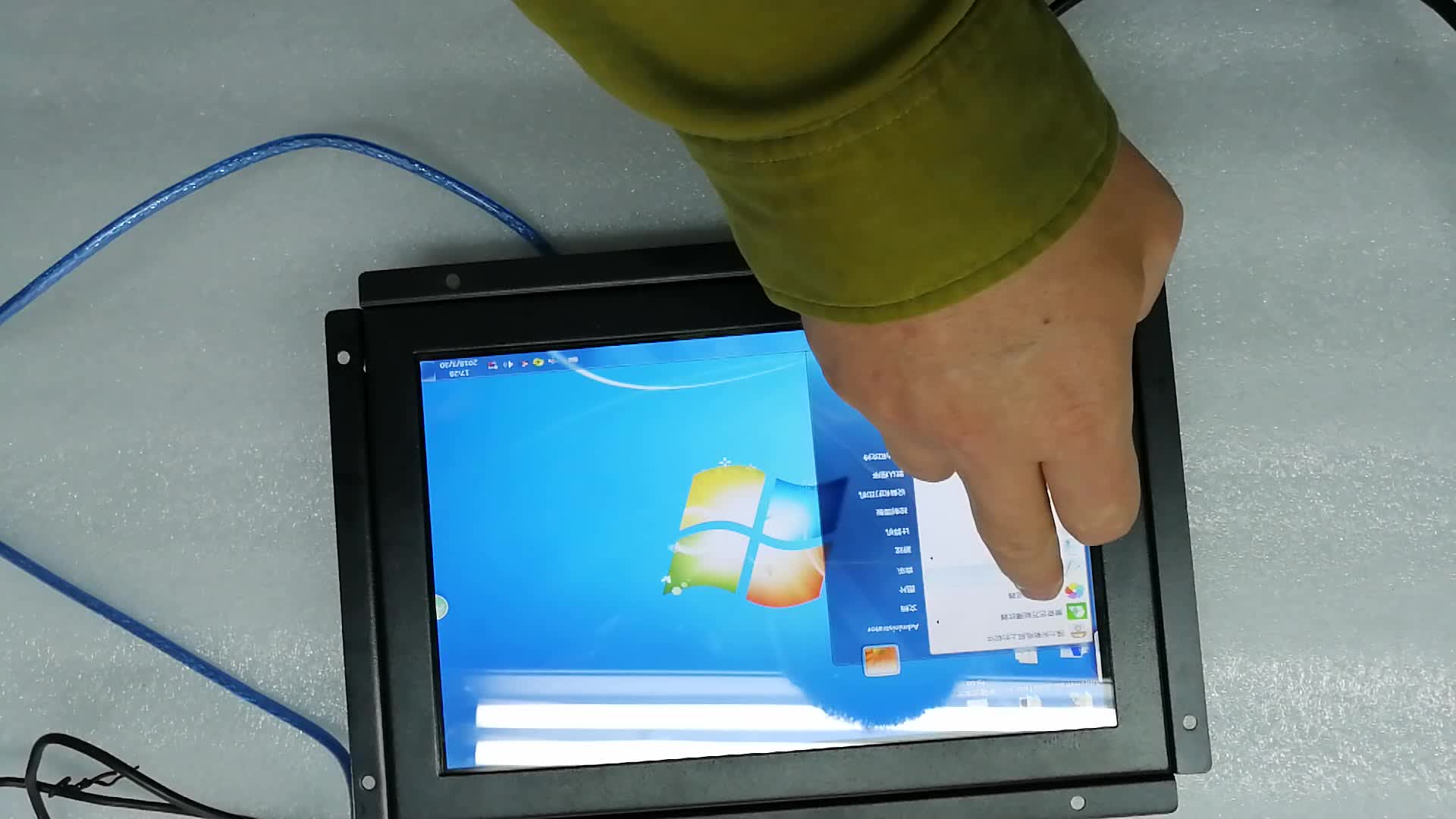

In the old days, medical device with a display was usually bulky and had many dials & buttons. A machine with buttons and knots makes for a good breeding space for harmful pathogens, as it is harder to clean than modern one with flat touch screen interface. Using TFT LCD touch screen on medical device not only makes disinfecting easy, but also save a lot of front panel spaces for displaying vital medical information.

Medical device can be put through extreme temperature, vibration and shock, moisture and variable ambient lighting. Thus, it demands highly reliable TFT LCD screen, and possibly the use of clear protective cover that safeguards the display from the rigors of day-to-day use.

While normal LCD display"s performance is not sufficient, medical TFT supplier like Topway can add enhancements such as optical bonded front panel with anti-reflection coating, transflective display that combines both reflective and transmissive properties.

Medical TFT LCDs are typically used in three kinds of applications: standard (e.g. bedside monitor), life-support (e.g. glucose meter) and life-critical (e.g. ventilator). These applications have drastically different requirements on functionality, reliability and MTBF (mean time between failure). Two well-known standard organizations" acceptance test rules are generally accepted by the industry, European DIN and American Association of Physicists in Medicine. The two organizations have well defined standard on resolution, noise, viewing angle, glare, color uniformity, distortion, reflection, luminance response and luminance uniformity.

Qualification process for these standards is very tedious and expensive. Device manufacturers are not willing to modify an approved system and are demanding long-term availability for LCD display. Topway guarantees the TFT LCD module"s longevity. A lot of the color LCD models" life span even last over ten years.

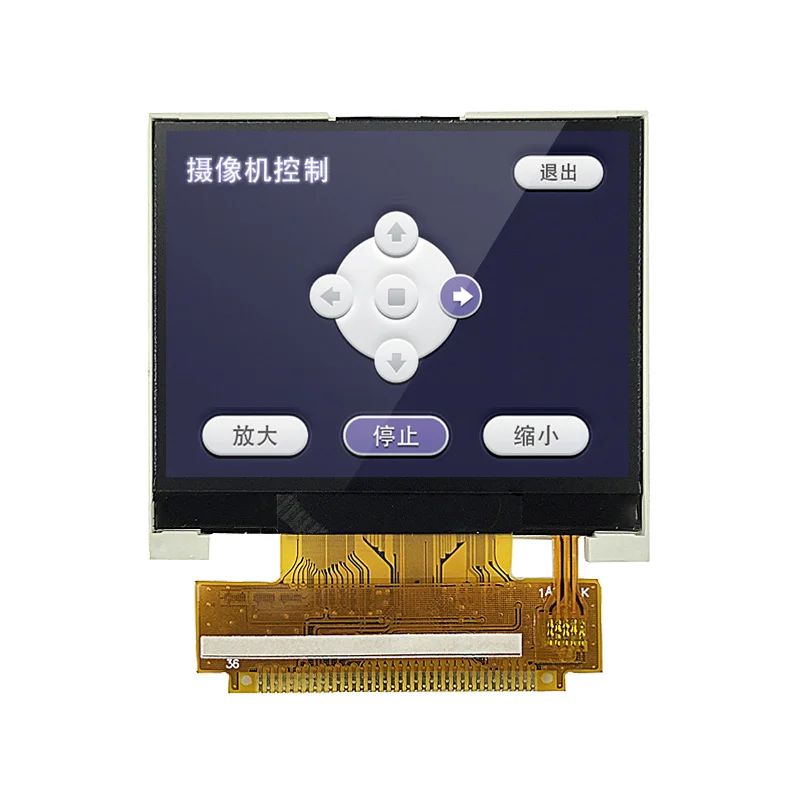

Infusion pump is a medical device used to deliver fluids into a patient’s body in a controlled manner. There are many different types of infusion pumps, which are used for a variety of purposes and in a variety of environments. Infusion pumps are better than manual fluid administration pumps because they can deliver fluids at precise frequencies, volumes, and intervals. This device embeds a2.8" color TFT LCD module from Topway.

ECG monitor is a life-saving device that is used to measure the electrical activity of your heart to show whether your heart works normally or not. 8" TFT LCD module is the one, our client chose.

With such a significant role to play, medical device manufacturers understand the importance of sourcing them from trusted display manufacturers like Topway Technology. The company has been providing custom display solutions to medical device manufacturers and pharmaceutical companies for more than 20 years. All Topway medical TFT LCD modules have passed through stringent tests: high/low temperature test, salt spray, EMC test & RoHS.

The global TFT-LCD industry has entered its mature stage. In the past 5 years, the overall output value of TFT-LCD is relatively stable and fluctuates around $130 billion. Among which, China has become the world’s largest TFT-LCD producer.

TFT-LCD (thin film transistor liquid crystal display) is an outcome of microelectronics technology and liquid crystal display technology, a kind of LCD, belonging to the active matrix LCD. TFT-LCD has a three-layer structure, among them, the upper glass substrate is a color filter, the lower glass substrate contains a transistor, and the liquid crystal is located between them. TFT-LCD has the following advantages: High resolution, strong interference immunity, low working voltage, low power consumption, long lifetime and wide application range.

TFT-LCD is widely used in TV, PC, laptops, tablets, projectors, car monitors, smart phones, wearable devices, smart homes and many other fields. The large global shipments of smart phones and computers as well as rapid development of wearable devices and smart home market, have brought robust demand for TFT-LCD.

Compared with the overseas market, China"s TFT-LCD production capacity has expanded rapidly in the past five years, and the output value has continued to grow. According to the "China Thin-Film Transistor Liquid Crystal Display Device (TFT-LCD) Industry Market Research Report in 2022-2026" released by the Newsijie Industry Research Center, China"s TFT-LCD production capacity accounted for more than 50% of the total global production capacity for the first time in 2020; China’s TFT-LCD production capacity accounted for 57% of the total global production capacity and its output value reached about 74 billion dollars in 2021. In 2021, Chinese enterprises including BOE, CSOT, Innolux Display Group, AUO and HKC had high shares in the global TFT-LCD market, among which, BOE is the world"s largest TFT-LCD manufacturer with strong competitiveness in the field of large-size TFT-LCDs.

With the continuous improvement in global display panel technologies as well as the incremental iteration and update of products, CRT has been eliminated and LCD has become the mainstream, meanwhile, OLED is squeezing the LCD market due to its lighter, thinner, flexible and transparent display and other advantages. The global TFT-LCD production capacity is concentrated in Chinese mainland, Taiwan and South Korea. In South Korean market, the panel makers such as Samsung and LG are phasing out LCD production lines to expand OLED production capacity. Although TFT-LCD is the current mainstream LCD product, only LG still has some large-size TFT-LCD production lines. TFT-LCD production capacity in overseas market is shrinking, therefore, although China"s TFT-LCD production capacity is expanding rapidly, the output value of global TFT-LCD is still stable.

The experts of Newsijie expressed that the shipment of TFT-LCD still accounted for 65% in the global display panel industry in 2021, far ahead of OLED"s 20%. In comparison, TFT-LCD shipment is relatively stable, and OLED has become the upgrade target of display panel with rapid growth in shipment. In the short term, TFT-LCD will still be the mainstream product in the display panel market, but in the future, its demand will gradually decline under the pressure of OLED; in the long term, the development space of TFT-LCD will shrink. China has become the world"s largest TFT-LCD producer with enterprises developed in scales and products with cost-effective advantages; China will further squeeze the development space of the TFT-LCD manufacturers in South Korea and Taiwan. In the future, Chinese TFT-LCD manufacturers are expected to lead the global TFT-LCD market.

KING TECH is a TFT LCD IPS supplier solution specialist since 2003, we are the group company combined byAn Innolux authorized LCD panel&IC distribution company

We Provide Different Kinds of Custom TFT Display ServicesIf needed we can make custom size tft displays for customers, we have a good relationship with original TFT display module factories, and we can negotiate with them to tool up an LCD panel mask. The tooling cost will be very high and paid by the end customer, and MOQ is at least 25K/lot.

We are capable to change every structure of the TFT display module. To increase backlight brightness and make it sunlight readable, the highest brightness we’ve ever reached was 6500cd/m2.To change the display FPC shape and length. To customize a resistive touch panel(RTP) or capacitive touch panel(CTP/PCAP), we have a long-term cooperation supplier to work with us on such tooling, for CTP, we can also make different shapes and thicknesses of cover glass, single touch, and multi-touch, AG/AR/AF is also available.

With our own PCBA hardware& software design company, we can design different kinds of TFT display modules for our customers, from simple convert boards to complete motherboards, from HDMI driver boards to Android controller boards, from non-touch function boards to capacitive touch function boards, they are all part of our working.

We have our own TFT display module panel and driver distribution department, if you want to switch to another structure of display, we can also help, cause we know which TFT display module panel and the driver is more match, and which suit’s supply is more stable, which one we can get the lowest price.

In order to give the customer the best support, Kingtech, as one of the best TFT LCD IPS suppliers in China, also can provide industrial solutions such as developing a mother board, serial port UART board, T-CON board, HDMI board, and monitor according to the customer"s requirements.

Kingtech also has existing industrial solutions for the PV135 motherboard, PV901 Linux board, and PV804 motherboard. They can be connected between Raspberry pi and our TFT display module, which can make them work together.

For serial port UART board, Kingtech has a 2.8inch 240x320 LCD with serial port UART board, 3.5inch 320x480 module with serial port UART board, 4.3inch 480x272 display with a resistive touch with serial port UART board, 7inch 800x480/1024x600 TFT with capacitive touch with serial port UART board.

For exisiting monitor products, Kingtech has 8inch 1280x800 IPS monitor, 10.1inch 1280x800 monitor, 15.6inch 1280x800 LCD monitor, 12.3inch 1920x720 IPS 850nit LCD monitor, 18.5inch 1366x768 1000nits LCD monitor.

For the HDMI board, Kingtech has a 1.39inch 454x454 AMOLED round with HDMI board, 3.34inch 320x320 TFT round with HDMI board, 3.4inch 800x800 TFT round with HDMI board, 5inch 1080x1080 TFT with HDMI board, 4.3inch 800x480 TFT with HDMI board, 5inch 800x480 LCD with HDMI board, 7inch 800x480/1024x600 LCD display with HDMI board, 10.1inch 1280x800 LCD module with HDMI board.

Above all TFT display modules with board products can be used for industrial equipment, medical, smart-home, or others. Kingtech can also have industrial custom TFT display solutions according to the customer’s requirements. Ware is welcome to contact us. If you are interested in any tft display module products, we can negotiate with you at a reasonable TFT LCD display price. Thank you.

TFT display module is a Thin Film Transistor, and AMOLED is Active-matrix organic light-emitting Display. The TFT display module is backlight-on the liquid crystal panel; AMOLED is a panel that emits light on its own; TFT display module structure is more thick and strong, AMOLED is very thin and also weak, TFT display module is used widely than AMOLED, AMOLED is used in consumer products the most, like a smartwatch, mobile phone, and TV.

IPS is In-Plane Switching, It is also known as free viewing angle, which means the viewing angle of the display on 4 sides is the same, a normal display has its best viewing angle like 6 o’clock or 12 o’clock. While the TFT display module contains normal viewing angles and IPS display,IPS display is a kind of TFT display module.

TFT display module belongs to LCD, LCD is Liquid Crystal Display, it contains mono(single color) LCD and color LCD, single color LCD is barely used now, and color LCD has STN and TFT two types. Therefore, TFT display module is a kind of LCD display.

OLED is Organic Light Emitting Display, it is a display that emits light on its own, and it does not need an extra backlight, so it requests lower power consumption than TFT display module but its lifetime is shorter than TFT(5000 hours), AMOLED is a kind of OLED but it is more colorful. TFT display module requests a backlight to light on and power consumption are higher than OLED, but its lifetime is much longer(20000 hours).

The LED display is working by lighting up the LED lights, the TFT display module is lighted up by the backlight and the liquid crystal starts to work and shows contents. TFT display module has brighter and more true color, and lower price and LED display has lower power consumption, smaller heat, and longer lifetime.

Compares to other types of display, TFT display module is the more widely used, it can be made in different shapes and sizes, from very small sizes to big sizes. The resolution now is higher and higher, and the price of custom TFT display modules is more and more competitive. Its lifetime is longer than the OLED display, and its color is brighter than OLED.

ITD industrial monitor LCD displays are fully-integrated‚ waterproof and dustproof that combine high-performance different touch screen technologies in industrial-grade TFT-LCD flat panels, with sleek, IP65 / NEMA 4-4 x Ingress rating flat front surface industrial design. ITD industrial display monitors provide reliability, durability, and long expected product life. Impervious to environmental conditions such as liquid spills, splashes and wash-downs, these screens are the most contamination-resistant units available in the market. ITD industrial IP65/ NEMA 4 touch display monitors are designed for process control, food processing equipment, machine control, human interface, automation equipment and in-vehicle use applications. ITD full-range selection is provided in screen sizes from 5” to 82”.

The LED backlight lifetime in twenty-six of its TFT LCD modules has been increased by Kyocera. The Japanese display manufacturer will increase the backlight lifetime to 100,000 hours across a range of displays to provide greater usability and improved reliability. The long-life backlight portfolio includes display modules from Kyocera"s range of Advanced Wide View (AWV) displays, Super High Brightness (SHB) panels and a number of popular standard modules.

In terms of the material, the selection of the 10.1 TFT LCD monitor material is very strict. It uses a hard screen material, and based on the characteristics of the hard screen material, it can work normally in complex environments. At the same time, it also has the characteristics of high brightness, high definition and high contrast, which further meets the needs of the LCD display in an industrial environment. In terms of size, 10.1 inches is not large, it has the advantages of small size and lightweight. And it also has the characteristics of a large display area and an accurate and stable display effect.

The lifespan of the LCD screen is very long. Even if it is in working condition 24 hours a day, its service life is mostly more than 5 years. It is more durable than normal LCD screens. 10.1 TFT LCD monitors have low power consumption. Energy-saving, environmental protection and non-radiation are the advantages of the 10.1 TFT LCD monitor. The most important thing is that it consumes little power. Take the CRT monitor as an example. Under the same size, the power consumption of the industrial LCD display is only one third of that of the CRT display.

With the rapid development of technology, there are some industries that have developed rapidly in recent years, including industrial enterprises. Behind the vigorous development of the industry, the development of the 10.1 inch TFT LCD display is bound to be inseparable. Of course, LCD screens are not only useful in the industrial field, but also can be applied in many industries and fields such as the military industry, medical care, and home furnishing. Let"s take a look at the 10.1 TFT LCD monitor.

First of all, we need to know that the LCD screen is designed and produced according to the technical requirements of the industry, which is very different from the traditional household display screen. This difference is mainly due to the fact that the LCD screen used in the industry has high requirements on service life and technology, and its most important characteristic is wide temperature and high brightness.

Wide temperature refers to the ambient temperature at which the LCD screen can operate normally. Generally speaking, different industries have different requirements on wide temperature, such as -20℃~70℃, -30℃~80℃, etc. Of course, the wider the operating temperature range, the higher the price. The high brightness refers to the highlight and contrast of the LCD screen, which can provide a better display effect under strong ambient light.

After understanding these two characteristics, it is not difficult for us to find that the 10.1 TFT LCD monitor is very suitable for complex industrial environments. Whether you need to work outdoors for a long time, or the temperature of the working environment is very different from the temperature in the general scene, these LCD screens can overcome it. That"s why 10.1 TFT LCD monitors are popular.

In recent years, China and other countries have invested heavily in the research and manufacturing capacity of display technology. Meanwhile, different display technology scenarios, ranging from traditional LCD (liquid crystal display) to rapidly expanding OLED (organic light-emitting diode) and emerging QLED (quantum-dot light-emitting diode), are competing for market dominance. Amidst the trivium strife, OLED, backed by technology leader Apple"s decision to use OLED for its iPhone X, seems to have a better position, yet QLED, despite still having technological obstacles to overcome, has displayed potential advantage in color quality, lower production costs and longer life.

Zhao: We all know display technologies are very important. Currently, there are OLED, QLED and traditional LCD technologies competing with each other. What are their differences and specific advantages? Shall we start from OLED?

Huang: OLED has developed very quickly in recent years. It is better to compare it with traditional LCD if we want to have a clear understanding of its characteristics. In terms of structure, LCD largely consists of three parts: backlight, TFT backplane and cell, or liquid section for display. Different from LCD, OLED lights directly with electricity. Thus, it does not need backlight, but it still needs the TFT backplane to control where to light. Because it is free from backlight, OLED has a thinner body, higher response time, higher color contrast and lower power consumption. Potentially, it may even have a cost advantage over LCD. The biggest breakthrough is its flexible display, which seems very hard to achieve for LCD.

Liao: Actually, there were/are many different types of display technologies, such as CRT (cathode ray tube), PDP (plasma display panel), LCD, LCOS (liquid crystals on silicon), laser display, LED (light-emitting diodes), SED (surface-conduction electron-emitter display), FED (filed emission display), OLED, QLED and Micro LED. From display technology lifespan point of view, Micro LED and QLED may be considered as in the introduction phase, OLED is in the growth phase, LCD for both computer and TV is in the maturity phase, but LCD for cellphone is in the decline phase, PDP and CRT are in the elimination phase. Now, LCD products are still dominating the display market while OLED is penetrating the market. As just mentioned by Dr Huang, OLED indeed has some advantages over LCD.

Huang: Despite the apparent technological advantages of OLED over LCD, it is not straightforward for OLED to replace LCD. For example, although both OLED and LCD use the TFT backplane, the OLED’s TFT is much more difficult to be made than that of the voltage-driven LCD because OLED is current-driven. Generally speaking, problems for mass production of display technology can be divided into three categories, namely scientific problems, engineering problems and production problems. The ways and cycles to solve these three kinds of problems are different.

At present, LCD has been relatively mature, while OLED is still in the early stage of industrial explosion. For OLED, there are still many urgent problems to be solved, especially production problems that need to be solved step by step in the process of mass production line. In addition, the capital threshold for both LCD and OLED are very high. Compared with the early development of LCD many years ago, the advancing pace of OLED has been quicker.While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen?

Liao: I want to supplement some data. According to the consulting firm HIS Markit, in 2018, the global market value for OLED products will be US$38.5 billion. But in 2020, it will reach US$67 billion, with an average compound annual growth rate of 46%. Another prediction estimates that OLED accounts for 33% of the display market sales, with the remaining 67% by LCD in 2018. But OLED’s market share could reach to 54% in 2020.

Huang: While different sources may have different prediction, the advantage of OLED over LCD in small and medium-sized display screen is clear. In small-sized screen, such as smart watch and smart phone, the penetration rate of OLED is roughly 20% to 30%, which represents certain competitiveness. For large size screen, such as TV, the advancement of OLED [against LCD] may need more time.

Xu: LCD was first proposed in 1968. During its development process, the technology has gradually overcome its own shortcomings and defeated other technologies. What are its remaining flaws? It is widely recognized that LCD is very hard to be made flexible. In addition, LCD does not emit light, so a back light is needed. The trend for display technologies is of course towards lighter and thinner (screen).

But currently, LCD is very mature and economic. It far surpasses OLED, and its picture quality and display contrast do not lag behind. Currently, LCD technology"s main target is head-mounted display (HMD), which means we must work on display resolution. In addition, OLED currently is only appropriate for medium and small-sized screens, but large screen has to rely on LCD. This is why the industry remains investing in the 10.5th generation production line (of LCD).

Xu: While deeply impacted by OLED’s super thin and flexible display, we also need to analyse the insufficiency of OLED. With lighting material being organic, its display life might be shorter. LCD can easily be used for 100 000 hours. The other defense effort by LCD is to develop flexible screen to counterattack the flexible display of OLED. But it is true that big worries exist in LCD industry.

LCD industry can also try other (counterattacking) strategies. We are advantageous in large-sized screen, but how about six or seven years later? While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen? People may not watch TV and only takes portable screens.

Some experts working at a market survey institute CCID (China Center for Information Industry Development) predicted that in five to six years, OLED will be very influential in small and medium-sized screen. Similarly, a top executive of BOE Technology said that after five to six years, OLED will counterweigh or even surpass LCD in smaller sizes, but to catch up with LCD, it may need 10 to 15 years.

Xu: Besides LCD, Micro LED (Micro Light-Emitting Diode Display) has evolved for many years, though people"s real attention to the display option was not aroused until May 2014 when Apple acquired US-based Micro LED developer LuxVue Technology. It is expected that Micro LED will be used on wearable digital devices to improve battery"s life and screen brightness.

Micro LED, also called mLED or μLED, is a new display technology. Using a so-called mass transfer technology, Micro LED displays consist of arrays of microscopic LEDs forming the individual pixel elements. It can offer better contrast, response times, very high resolution and energy efficiency. Compared with OLED, it has higher lightening efficiency and longer life span, but its flexible display is inferior to OLED. Compared with LCD, Micro LED has better contrast, response times and energy efficiency. It is widely considered appropriate for wearables, AR/VR, auto display and mini-projector.

However, Micro LED still has some technological bottlenecks in epitaxy, mass transfer, driving circuit, full colorization, and monitoring and repairing. It also has a very high manufacturing cost. In short term, it cannot compete traditional LCD. But as a new generation of display technology after LCD and OLED, Micro LED has received wide attentions and it should enjoy fast commercialization in the coming three to five years.

Interestingly, quantum dots as light-emitting materials are related to both OLED and LCD. The so-called QLED TVs on market are actually quantum-dot enhanced LCD TVs, which use quantum dots to replace the green and red phosphors in LCD’s backlight unit. By doing so, LCD displays greatly improve their color purity, picture quality and potentially energy consumption. The working mechanisms of quantum dots in these enhanced LCD displays is their photoluminescence.

For its relationship with OLED, quantum-dot light-emitting diode (QLED) can in certain sense be considered as electroluminescence devices by replacing the organic light-emitting materials in OLED. Though QLED and OLED have nearly identical structure, they also have noticeable differences. Similar to LCD with quantum-dot backlighting unit, color gamut of QLED is much wider than that of OLED and it is more stable than OLED.

Another big difference between OLED and QLED is their production technology. OLED relies on a high-precision technique called vacuum evaporation with high-resolution mask. QLED cannot be produced in this way because quantum dots as inorganic nanocrystals are very difficult to be vaporized. If QLED is commercially produced, it has to be printed and processed with solution-based technology. You can consider this as a weakness, since the printing electronics at present is far less precision than the vacuum-based technology. However, solution-based processing can also be considered as an advantage, because if the production problem is overcome, it costs much less than the vacuum-based technology applied for OLED. Without considering TFT, investment into an OLED production line often costs tens of billions of yuan but investment for QLED could be just 90–95% less.

Peng: Good questions. Ligand chemistry of quantum dots has developed quickly in the past two to three years. Colloidal stability of inorganic nanocrystals should be said of being solved. We reported in 2016 that one gram of quantum dots can be stably dispersed in one milliliter of organic solution, which is certainly sufficient for printing technology. For the second question, several companies have been able to mass produce quantum dots. At present, all these production volume is built for fabrication of the backlighting units for LCD. It is believed that all high-end TVs from Samsung in 2017 are all LCD TVs with quantum-dot backlighting units. In addition, Nanosys in the United States is also producing quantum dots for LCD TVs. NajingTech at Hangzhou, China demonstrate production capacity to support the Chinese TV makers. To my knowledge, NajingTech is establishing a production line for 10 million sets of color TVs with quantum-dot backlighting units annually.China"s current demands cannot be fully satisfied from the foreign companies. It is also necessary to fulfill the demands of domestic market. That is why China must develop its OLED production capability.

Huang: The importance of China"s LCD manufacturing is now globally high. Compared with the early stage of LCD development, China"s status in OLED has been dramatically improved. When developing LCD, China has adopted the pattern of introduction-absorption-renovation. Now for OLED, we have a much higher percentage of independent innovation.

units for LCD and electroluminescence in QLED. For the photoluminescence applications, the key is quantum-dot materials. China has noticeable advantages in quantum-dot materials.

Huang: When OLED was compared with LCD in the past, lots of advantages of OLED were highlighted, such as high color gamut, high contrast and high response speed and so on. But above advantages would be difficult to be the overwhelming superiority to make the consumers to choose replacement.

It seems to be possible that the flexible display will eventually lead a killer advantage. I think QLED will also face similar situation. What is its real advantage if it is compared with OLED or LCD? For QLED, it seems to have been difficult to find the advantage in small screen. Dr. Peng has suggested its advantage lies in medium-sized screen, but what is its uniqueness?

Liao: Due to their lack of kernel technologies, Chinese OLED panel manufacturers heavily rely on investments to improve their market competitiveness. But this may cause the overheated investment in the OLED industry. In recent years, China has already imported quite a few new OLED production lines with the total cost of about 450 billion yuan (US$71.5 billion).Lots of advantages of OLED over LCD were highlighted, such as high color gamut, high contrast and high response speed and so on …. It seems to be possible that the flexible display will eventually lead a killer advantage.

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

These different technological approaches to display technology have big impact in some features including contrast, brightness, viewing angles, lifespan, black levels, image burn-in, and price.

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

In this article, we are looking at the benefits of looking for Chinese TFT LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with STONE Tech.

Handbags, wallets, phone cases, and other similar items have become the favorites of wholesalers and bulk buyers. These products are directly sold to end consumers. However, the fascinating thing about the Chinese production and manufacturing business is that it does not only cover the end-consumer products. Rather, you can also acquire raw and basic materials needed for the further manufacturing of goods and products. One such product is LCD displays.

LCD displays have become something of a necessity in today’s world of tech advancement. Many things in our daily life have been automated, and are operated using an interactive user interface. For these kinds of machines and gadgets, LCD displays are typically necessary.

In this article, we are looking at the benefits of looking for Chinese LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with Stoneitech.com.

STONE Tech is an LCD manufacturer located in Beijing, China. It was founded back in 2010, and it has been developing TFT LCD display modules ever since. These modules can be used for a variety of different machines including electric equipment, precision instruments, and civil electronics etcetera.

The same applies to LCD displays. When you save up on costs when buying LCD displays, you can set a lower price for the whole machine or gadget that you are producing.

When it comes to LCD modules, the orders are not received by the hundreds or thousands as is the case with other smaller products such as handbags and wallets etcetera. One module can cost around $250, and it is for this reason that the dynamics are a little different with this business. That is why STONE offers single pieces for sale as well as multiple pieces. This encourages smaller businesses to make their purchases since they can easily purchase as many modules as they like. As long as you meet the limit stated by the supplier, you are good to go.

In the case of LCD modules, this benefit relates to a reselling business. For example, if you are planning on buying some modules to use in your machines etcetera, then there is not a very suitable opportunity for you to expand. If you want to start a business in another country, you will have to open a manufacturing unit there so that your products can be produced and then get sold. Or, you will have to transport your final products to the other country in order to run your business.

However, if you are buying the LCD modules to resale at a profit, you can use the Chinese markets to grow your business. You can buy the modules at a reduced price and then sell them at a profit in a different area or city where the people will be willing to pay more.

Now that we have seen the benefits of choosing Chinese manufacturers for LCD modules, let us narrow it down a bit and look at why you should choose STONE specifically.

One of the main things that you have to look at in any supplier is the level of reliability and trust. This is usually determined by the level of experience and the time that the supplier has spent in the market. STONE was founded in 2010 and has been producing LCD modules for the past 10 years.

If you are looking to buy LCD modules in bulk, look no further than the Middle Kingdom. China has become the hub of mass manufacturing and is the favorite spot for wholesalers and business owners.

In case you need some convincing about buying from the Chinese, we have compiled a list of benefits that you can enjoy when looking for TFT LCD manufacturers in China.

For most mainstream LCD sizes, we have a solid and continuous relationship with upstream panel and IC manufacturers. And our main employees are from LCD upstream companies and have the most extensive resource information and personal connections in the industry. So we can guarantee the supply.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey