tasmota lcd display quotation

The display driver is able to display predefined setups of text or user defined text. To display text using DisplayText set DisplayMode to 0, or set DisplayMode to 1 for the HT16K33 dot-matrix display.

To use the seven-segment-specific TM1637, TM1638 and MAX7219 Display- commands, set DisplayMode to 0. Parameter LCD Display OLED Display TFT Display 7-segment Display (TM163x and MAX7219) 0 DisplayText DisplayText DisplayText All TM163x Display- functions

The DisplayText command is used to display text as well as graphics and graphs on LCD, OLED and e-Paper displays (EPD). The command argument is a string that is printed on the display at the current position. The string can be prefixed by embedded control commands enclosed in brackets [].

In order to use the DisplayText command the DisplayMode must be set to 0 (or optional 1 on LCD displays) or other modes must be disabled before compilation with #undef USE_DISPLAY_MODES1TO5.

In the list below p stands for parameter and may be a number from 1 to n digits. On monochrome graphic displays things are drawn into a local frame buffer and sent to the display either via the d command or automatically at the end of the command.

Pfilename: = display an rgb 16-bit color (or jpg on ESP32) image when file system is present, Scripteditor contains a converter to convert jpg to special RGB16 pictures See ScriptEditor Ffilename: = load RAM font file when file system is present. the font is selected with font Nr. 5, these fonts are special binary versions of GFX fonts of any type. they end with .fnt. an initial collection is found in Folder BinFonts

Draw up to 16 GFX buttons to switch real Tasmota devices such as relays or draw Sliders to dimm e.g. a lamp Button number + 256 - a virtual touch toggle button is created (MQTT => TBT)

When a file system is present you may define displaytext batch files. If a file named "display.bat" is present in the file system this batch file is executed. The file may contain any number of diplaytext cmds, one at a line. You may have comment lines beginning with a ;

E-Paper displays have 2 operating modes: full update and partial update. While full update delivers a clean and sharp picture, it has the disadvantage of taking several seconds for the screen update and shows severe flickering during update. Partial update is quite fast (300 ms) with no flickering but there is the possibility that erased content is still slightly visible. It is therefore useful to perform a full update in regular intervals (e.g., each hour) to fully refresh the display.

The data sheets of the TFT and OLED displays mention burn-in effects when a static display is shown for extended periods of time. You may want to consider turning on the display on demand only.

The EPD font contains 95 characters starting from code 32, while the classic GFX font contains 256 characters ranging from 0 to 255. Custom characters above 127 can be displayed. To display these characters, you must specify an escape sequence (standard octal escapes do not work). The ~character followed by a hex byte can define any character code.

The I2C address must be specified using DisplayAddress XX, e.g., 60. The model must be specified with DisplayModel, e.g., 2 for SSD1306. To permanently turn the display on set DisplayDimmer 100. Display rotation can be permanently set using DisplayRotate X (x = 0..3).

E-Paper displays are connected via software 3-wire SPI (CS, SCLK, MOSI). DC should be connected to GND , Reset to 3.3 V and busy may be left unconnected. The jumper on the circuit board of the display must be set to 3-wire SPI.

Waveshare has two kinds of display controllers: with partial update and without partial update. The 2.9 inch driver is for partial update and should also support other Waveshare partial update models with modified WIDTH and HEIGHT parameters. The 4.2 inch driver is a hack which makes the full update display behave like a partial update and should probably work with other full update displays.

In black and white displays, a local RAM buffer must be allocated before calling the driver. This must be set to zero on character or TFT color displays.

Universal Display Driver or uDisplay is a way to define your display settings using a simple text file and easily add it to Tasmota. uDisplay is DisplayModel 17. It supports I2C and hardware or software SPI (3 or 4 wire).

Initial register setup for the display controller. (IC marks that the controller is using command mode even with command parameters) All values are in hex. On SPI the first value is the command, then the number of arguments and the the arguments itself. Bi7 7 on the number of arguments set indicate a wait of 150 ms. On I2C all hex values are sent to I2C.

bit 2: enable async DMA, 0 wait for DMA to complete before returning, 4 run DMA async in the background. This later mode is only valid if the SPI bus is not shared between the display and any other SPI device like SD Card Reader.

# Scripter is the nost convenient way to edit and develop a uDisplay driver. On every scripter save the display is reinitialized and you immediately see results of your changes.

There are also many variants of each display available and not all variants may be supported. #define directive Description USE_DISPLAY Enable display support. Also requires at least one of the following compilation directives

It’s surprisingly easy to make your own simple air quality sensor. All you need is a cheap laser-scattering particulate matter sensor, a Wemos D1 Mini, a soldering iron, and Tasmota.

Part 1 showed how to make the simplest possible air quality sensor. Make sure you’ve seen that first, because Part 2 continues from Part 1 to add a 128×32 pixel OLED display and a mode button. We’re also going to install custom firmware to make the sensor last longer.

Printing a case is totally optional, of course. You can use whatever enclosure you like. My case has been designed to be a press-fit over the PMS5003, which holds the two halves together by friction. See the link above to download the STLs if you want to print it yourself, or you can buy a case from me if you don’t have access to a printer. I’ll include a 6x6x9mm tact switch with the “Display” version of the case:

After the sketch has uploaded the Air Quality Sensor will reboot, connect to your WiFi and MQTT broker, and show values on the display once it has successfully received data from the PMS5003.

This is a never-ending story about Theo Arends’s much-loved alternative firmware for IOT (http://ota.tasmota.com/tasmota/tasmota.bin.gz) as Tasmota is now at stable release version 8.5.1 “Hannah” (update October 2, 2020) and development version 9.0.0.1– I’ve upgraded my various ESP8266-based devices including Itead Sonoff BASIC, TH10, 4CH Pro, ProR2, Powr2, Shelly One, Blitzwolf and others). Warning, there are SOME devices out there which cannot accept Tasmota or other alternative firmware. My overall advice would be to avoid them where possible unless you wish to rely on cloud services). This entry will assume you want local control of devices.

Well, as, until recently in the UK, the bars were closed and we still can’t really travel freely over there, sitting at home updating Tasmota seems a sensible (and safe) way to pass time. Be sure to check the Tasmota docs site for upgrades etc. and for COMMANDS in Tasmotago here.

Noteably, with Tasmota “Elliot”, we can now leave off all sensor checking if we don’t have any sensors – and the number of .bin file permutations has gone up… and I’ve just added a DHT22 sensor to a Sonoff Basic board (rev 2, the ones currently going for a song). I used gnd, 3v3 and RX pins on the 4 way header and included a 10k pullup for the data line. For this I used tasmota-sensors.bin – if I were not using any sensors I’d use tasmota-lite.bin

The new Tasmota docs site replaces the older WIKI and there is also a new flasher utility therein. Firstly we have the updates to Tasmota itself (9.0.0.1 development version) and the Tasmota Device Manager software (TDM)version 0.2.6 and now TASMOTIZE as a Windows executable (tasmotizer-1.2.exe) – for flashing Tasmota onto various IOT devices. But not just flashing – EASY flashing – with WIFI, MQTT and module setup all in the same place. For TDM, if you want the Windows EXE versions then head directly to theRELEASES page.

I grabbed TASUIon Dec 21, 2019 but not done a lot with it… http://tasui.shantur.com – and what is THAT I hear you ask? Well, it is a web-browser based UI for Tasmota devices – apparently for Tasmota 7.0.2.4 or later so please don’t bother until you update your devices… my friend Antonio confused the hell out of me by referring to “CORS http://tasui.shantur.com” – what is that I asked. Well if you want to have a play, just take that text without the quotes, paste it into the CONSOLE in one or more of your Tasmota-equipped devices to test – and immediately they know about this new UI (even after a reboot). In a browser on your local network, enter the link (top of this para) and the UI will start up.

Let’s back-track for a second for those new to the subject… when it comes to controlling devices from simple WIFI-controlled on-off switches through to RGB lighting, LCD displays and so on, Tasmota is one of several free firmware alternatives to the almost endemic numbers of (largely) cloud-based IOT solutions. I should point out that font support remains very limited in Tasmota (Feb 2021).

For obvious commercial reasons, many manufacturers of IOT products would like us to use their own proprietary solutions, often relying on their own control APPS and cloud-based storage/control. Some folk don’t trust cloud-based solutions (for a variety of reasons). Another issue is that every manufacturer seems to have their reasons why you should use THEIR cloud solution. I’m happiest with local control (Tasmota most of the time for ESP8266 – and using Node-Red on a Raspberry Pi for my central controller).

Tasmota started off as an alternative to control Itead Sonoff and other boards, something you could (can) freely download and “flash ” onto said boards and then either control your devices via simple web commands or something like MQTT. There are other solutions: “Espurna” comes to mind as well as “ESP-GO”. The latter is covered extensively earlier in this blog and I spent many months developing this with help from Aidan Ruff and others.

Recently, Tasmota has been coming on in leaps and bounds and is now THE dominant alternative IOT (ESP82666) device firmware as it now supports a WIDE variety of IOT WIFI-controlled devices not to mention Zigbee and features which are growing constantly.

SO, here we are, Tasmota can be installed on, for just one example, Itead Sonoff BASIC (110v-220v power control) boards and used to control them over WIFI, even adding lots of different sensors for the more ambitious. In my case this is all controlled centrally using a Raspberry Pi running Node-Red and MQTT protocol. Others may prefer to control devices directly via a browser as the Tasmota WebUI is in fact excellent.

What’s new? Well, Tasmota now offers support for a LOT of devices, has a NICE interface as well as TASMOTA DEVICE MANAGER (TDM), a new website putting it all together, TASMOTIZER, software to easily FLASH (program) boards with Tasmota – and it is all getting easier by the day. And NOW we have TasUI – lovely.

Tasmota is easy to install on various devices using (in some cases TUYA-CONVERT or a serial convertor (FTDI) and is also easily upgradeable “LIVE” via OTA – I have many devices, some hidden away in the loft, some in another country – all of which I can now safely update while they are running using TDM – which in my case runs on Windows 10.

Talking of devices in another country – especially one with less than perfect electric power – you should be aware in the Tasmota commands referred to above – SETOPTION commands… “setoption 13 1” disables special button tricks like long press and double press – always do that (once only, non-volatile) if you don’t NEED that. Another non-volatile command “SETOPTION65 1” – set this once a controller is in place and working – the option defaults to 0 to get you out of a jam if you tend to mess up passwords etc, but can also result in Tasmota returning to default settings after repeated power cycling. Set “SETOPTION65 1” to STOP this from happening.

Xmas DIY projects part 2: ESP8266 based central heating monitor (up to 4x DS18B20 thermal sensor; up to 3x 230V AC input to keep track of when which pump is enabled). Hardware athttps://gitea.osmocom.org/laforge/esp8266-projects/src/branch/master/esp8622_heating_monitoring…using stock Tasmota as software, feeding mosquitto->influxdb->grafana

Hello Rogerio, thanks! I"m sorry, I don"t have the original firmware v1.0.6. I converted my own test device to Tasmota before any original firmware update could take place (it was in version 1.0.2). Nevertheless (not sure if is true or not), I read that Tuya firmwares can contain device specific data, preventing a firmware image extracted from one device, to work in another device.

10:04:52 MQT: tele/StudioPower/INFO1 = {"Module":"Generic","Version":"8.1.0(tasmota)","FallbackTopic":"cmnd/DVES_593705_fb/","GroupTopic":"cmnd/tasmotas/"}

I cannot promise when but I have the ambition of implementing logic on Tasmota side for doing the parsing, and exposing the calculated values as sensors, making the integration simpler and similar to other sensors/meters.

I included the baudrate command inside the system boot rule, because I have the same issue, when you restart the tasmota, it loses the configuration of the baudrate

With Tasmota 8.2 (the only one I have tested with), the serial data does not flow until the Baudrate command is issued after boot (even though it is set to the same value).

@Unknown, regarding the "SerialReceived" with the hex data not delimited by " ", there is a fix for that already in the Tasmota project (is currently in the development branch, should go in the next release).

Hello! You did a fantastic job of reverse engineering this device. I reflash it on tasmota 8.1 and it works great. But my question is: is it possible to make the relay remember its previous state? It is very inconvenient when the relay always turns off when power is applied. Regards

Hi, I"m new in IOT and have no deep knowledge of Tasmota but I hope my humble experience will help someone who also is researching this field and/or wants investigate it more deeply than I am.

It appears that both PCB layout and internal communication architecture have been changed in new version of device. Some GPIOs became disconnected from the PCB as long as Button/Led/Relay controls - now everything is connected to V8921 chip and all control from ESP is performed now via TuyaMCU (https://tasmota.github.io/docs/TuyaMCU). ESP chip sends serial commands to MCU and MCU responds: turns on and off the relay, report measured power metrics and probably turns on/off the LEDs. I guess that earlier self resets could have been caused by serial tx on GPIO 13 which was interpreted as 40-second button pressing. When GPIO 13 setting has been changed from button no more self resets was observed. Finally module type/GPIO assignment has been set up as at screenshot(I"m not sure if double set of tx/rx communication lines need to be configured. Also since it appeared to be working with all GPIOs set to none probably some settings are already embedded into TuyaMCU tasmota module and therefore GPIO assignment is not needed.)

It appears that there is only 4 metrics now(full list of metrics is exposed with "SerialSend5 55aa0001000000" command as described in Tasmota TuyaMCU documentation article). The metrics are following:

I"m not sure if TuyaMCU tasmota module poll the MCU itself or MCU by itself reports the status periodically but no further polling settings (like described Rule1 creation) need to be done manually. Probably if you need to poll more frequently you need to create a Rule with "SerialSend5 55aa0001000000" command.

According to my understanding Tasmota at the moment does not support integration for Total W/h metric (DpType2Id17). Tasmota"s values for total Kw/h appears to be calculated from momentary Voltage/Current/Power measurements and since that can"t be accurate. But because I"m planning to read Total W/h counter into Zabbix via mqtt it"s not an issue for me.

If you don"t mind, I can make reference to you and your findings in the Tasmota discord channel, as the community members more related to the TuyaMCU integration may have some ideas regarding additional commands that may potentially exist (given that the metering chip is the same, it wouldn"t be surprising that the measurements exposed in the previous version are also available in this one too, via different commands).

22:46:21 RSL: tele/tasmota_DF55AE/RESULT = {"TuyaReceived":{"Data":"55AA0301002A7B2270223A226136646A61627A6D7062627036326777222C2276223A22312E302E30222C226D223A307DE8","Cmnd":1,"CmndData":"7B2270223A226136646A61627A6D7062627036326777222C2276223A22312E302E30222C226D223A307D"}}

22:46:21 RSL: tele/tasmota_DF55AE/RESULT = {"TuyaReceived":{"Data":"55AA03070005010100010011","Cmnd":7,"CmndData":"0101000100","DpType1Id1":0,"1":{"DpId":1,"DpIdType":1,"DpIdData":"00"}}}

22:46:21 RSL: tele/tasmota_DF55AE/RESULT = {"TuyaReceived":{"Data":"55AA03070008110200040000000028","Cmnd":7,"CmndData":"1102000400000000","DpType2Id17":0,"17":{"DpId":17,"DpIdType":2,"DpIdData":"00000000"}}}

22:46:22 RSL: tele/tasmota_DF55AE/RESULT = {"TuyaReceived":{"Data":"55AA03070008120200040000000029","Cmnd":7,"CmndData":"1202000400000000","DpType2Id18":0,"18":{"DpId":18,"DpIdType":2,"DpIdData":"00000000"}}}

22:46:22 RSL: tele/tasmota_DF55AE/RESULT = {"TuyaReceived":{"Data":"55AA0307000813020004000000002A","Cmnd":7,"CmndData":"1302000400000000","DpType2Id19":0,"19":{"DpId":19,"DpIdType":2,"DpIdData":"00000000"}}}

22:46:22 RSL: tele/tasmota_DF55AE/RESULT = {"TuyaReceived":{"Data":"55AA0307000814020004000000002B","Cmnd":7,"CmndData":"1402000400000000","DpType2Id20":0,"20":{"DpId":20,"DpIdType":2,"DpIdData":"00000000"}}}

I can get data when I first configure my device in tasmota, but after a power down - up cycle of the device (not relay) I can"t get real data until I send in console

They both work fine, the front display seems to be accurate and I can read the output via MQTT in Home Assistant (eventually, took me a while to figure it out).

Both are configured as [Tuya MCU(54)] units and both show the same problem on the Tasmota Web page for the 2 devices, the problem is minor but annoying.

The important things to know about those strings is that the ["Total":3416.192] value should be the same as the ["DpType2Id17":55000] except for the decimal point so it should display ["Total":55.000] kWh the same as the meters LCD display but it never does. The other values ("Yesterday" & "Today")aren"t shown on the display but simple maths on yesterdays usage and todays usage shows these are always incorrect too. I have been using one of these meters for months with this problem by just ignoring the Web page and using the MQTT values for Volts; Current; Power & Total kWh in HA instead.

Good day. What do you think about the new version of the electricity meter. The tui module costs WB3S (not really!). Tasmoto is not stitched. I changed the module to esp-12 and tasmota 9.2 through the programmer.

Good day. What do you think about the new version of the electricity meter. The tui module costs WB3S (not really!). Tasmoto is not stitched. I changed the module to esp-12 and tasmota 9.2 through the programmer.

It uses a somewhat different protocol and has only more basic readings (total consumption, voltage, current and power). You can only utilize the relay (i think it was dpId 16) with the current development firmware of tasmota. I submitted a pull request for my changes, which make it possible to get the rest of the data.

I have a ZMAI-90 with WB3S Wifi module. I replaced the module with an ESP12F and I have flashed on it a Tasmota 9.3.1. I have tried to run the above commands in console, but I get some errors. I guess this version is not supporting these features yet:

https://www.amazon.de/AZDelivery-ESP8266-ESP-12F-verbesserte-Version/dp/B01NASA1MV/ref=sr_1_4?__mk_de_DE=ÅMÅŽÕÑ&dchild=1&keywords=esp%2B12%2BTasmota&qid=1620306443&sr=8-4&th=1

https://www.amazon.de/AZDelivery-ESP8266-ESP-12F-verbesserte-Version/dp/B01NASA1MV/ref=sr_1_4?__mk_de_DE=ÅMÅŽÕÑ&dchild=1&keywords=esp%2B12%2BTasmota&qid=1620306443&sr=8-4&th=1

So I have managed sucessfully to run the new version with the TuyaMCU mode in tasmota. However, the values of kwh readings somehow inconsistent. More often the value of total kwh is getting reset after a power cycle.

14:57:03.635 MQT: tele/tasmota_936F2D/RESULT = {"TuyaReceived":{"Data":"55AA03070008110200040026D1EE0D","Cmnd":7,"CmndData":"110200040026D1EE","DpType2Id17":2544110,"17":{"DpId":17,"DpIdType":2,"DpIdData":"0026D1EE"}}}

So I think I can still display the correct value by manually entering mqtt config on yaml file. however I lack the skill to parse the text strings. Can anyone help me to parse 2544.110 to HA?

Found a minor bug, affecting the new version of the zmai-90 using tuyamcu protocols. the latest tasmota binaries (9.4.0) limited the power reports to around 6500W.

Hallo, erstmal Kompliment für Ihr gelungenes Tasmota-Flashen des ZMAi-90. Ich habe auch schon diverse Sonoff Produkte selbst geflasht aber beim ZMAi-90 glaube ich bin ich zu schwach. Wäre es möglich einen Tasmota geflashten ZMAi-9o von Ihnen zu erwerben? Konnten Sie schon eine Lösung zu Rückstellen des Zählers finden?

"Hello, first of all compliments for your successful Tasmota flashing of the ZMAi-90. I"ve flashed various Sonoff products myself, but I think I"m too weak with the ZMAi-90. Would it be possible to purchase a Tasmota flashed ZMAi-9o from you? Have you already found a solution to reset the counter?

Next we"ll hook up the the data wires for the display. The library github lists a couple of different pin layout examples, but only the labels seem to change between the different ones and mine didn"t have any labels at all! I wired the board as follows:

You"ll notice on the back of the display that there are two connectors, the one you want to wire to is the one where the arrows are moving away from it

Some of the pins are not needed depending on what display you have, these are the C, D and E pins. The library lists instructions for when you need to connect up these pins based on the scan rate of your display:Display PinESP8266 PinNote

The best way to check if they are required for your display is they seem to be connected to ground on displays where they are not needed. Get your multimeter in continuity mode and check these pins against the ground pin, if the pin is connected to ground you don"t need it

If you do want to power off the same supply, on the Wemos D1 mini board we can connect the 5v of the display power supply directly to the 5v pin. Two things to be careful about:If you plug in just the USB and not the larger power supply then display will try run off the USB power and it could cause overload your USB supply. You could fix this by putting a diode between the display power supply and 5v pin (so current can only flow towards the esp8266)

I connected an LCD2004 to a wemos d1 to show the info from a connected sensor (Z19b). I connected the display and the sensor to the 5V of the wemos (usb powered).

I"m wondering, is there also a possibility tot connect a reset button by which I wake up my lcd (so I can read the values) and after some time the LCD fells " in sleep" (I don"t want to see the whole time a blue screen). How do I connect this reset button?

Now starts the troubles: yes,the digital input usually has some pullup resistor to 3.3v, internal or external. Well, I tried to use some PIR sensor connected to some gpio ,to wake-up the display when someone is around. The problem is the PIR digital output is a positive pulse, when is no movement the output is low, tied to ground, when detects movement, the output goes high...In this hardware connection,the "Display button" is most of the time low, so LCD backlight is on,never goes off.

If the gpio is declared as "switch input" and "Inversed Logic:" is enabled, the "value" state of the switch is inversed, but not working as "Display button"..."switch to ground will wake the LCD"...Is there any way to use those pir sensors without a hardware inverter? ( a npn transistor,between pir and esp8255 gpio or any other solution...).It would be useful an option to choose for gpio assigned as "Display button", positive or negative pulse, positive or negative edge, or "Inversed Logic" feature,in the LCD menu...

"Inverted logic" should be the simple and effective way for LCD display timeout, related to the state of one gpio assigned to wake up the backlight...making easier direct connection with a cheap pir motion sensor, or some touch sensor like this: https://alltopnotch.co.uk/product/ttp22 ... e-arduino/

Suppose we have a LCD2004 display connected to a device.We have 4 rows available for some text. Let"s say task1 is a task where LCD displays temperature,pressure,humidity. On same device we have connected a current sensor Energy (DC) - INA219. This sensor reports Voltage,Current,Power. Now we create Task2, Display - LCD2004, same display, where we can see the voltage,current,power. Now we connect an hardware switch, retained, when switch is on 0, task 1 is enabled,display show temperature,pressure,humidity when switch is 1,task 1 is disabled,task2 is enabled, the display will show voltage,current,power. Can be done with some rule? somehow?

When sending commands to a specific LCD, you must (and always can) prefix the command with the "[taskname]." prefix, so if you have a LCDTEMP and LCDPOWER defined, your commands, either from rules or via http, should be [lcdtemp].lcdcmd,on, or [lcdpower].lcd,4,1,"[INA219#Volt] V"

If you do not prefix with the taskname. moniker (square braces are optional) the command will be sent to the first display device found (from top to bottom) that handles the command, then stops.

- Please test the "Inversed logic" option, now available on the Device Configuration page for the LCD2004 (when enabled, the GPIO pin should be made high (3.3V) to turn the display on).

Suppose we have a LCD2004 display connected to a device.We have 4 rows available for some text. Let"s say task1 is a task where LCD displays temperature,pressure,humidity. On same device we have connected a current sensor Energy (DC) - INA219. This sensor reports Voltage,Current,Power. Now we create Task2, Display - LCD2004, same display, where we can see the voltage,current,power. Now we connect an hardware switch, retained, when switch is on 0, task 1 is enabled,display show temperature,pressure,humidity when switch is 1,task 1 is disabled,task2 is enabled, the display will show voltage,current,power. Can be done with some rule? somehow?

No, I don"t want to use 2 (two) LCD 2004, unless I have no option...Most of the time the LCD will display temperature,pressure,humidity. With INA219 connected I want to measure the power consumption of my environment devices: routers,ipcamera,switches,anything is plugged to mains and demand power...So, with a simple switch, *-* * or * *-* ,and two different alternative tasks, I will deactivate lcd with t,h,p sensor and activate lcd with current/voltage/power when I want to make some current/voltage measurement. Just a rule : on switch#state=0 enable task1 disable task2 endon ... on switch#state=1 disable task1 enable task2 endon ...something like that

With a simple switch, two tasks on same LCD, more parameters can be displayed...otherwise two displays it would have been needed. Especially when second task is used occasionally...

Meantime,playing with LCD2004, came to me the idea to frame this nice display,via some command... like I already said, measurement of voltage/current/power is occasionally,not constant monitoring...

Meantime,playing with LCD2004, came to me the idea to frame this nice display,via some command... like I already said, measurement of voltage/current/power is occasionally,not constant monitoring...

On my display unit the backlight is driven from Vcc (5V) via a jumper to collector of a npn transistor with emitter grounded. The transistor base is driven from PCF 8574T via I2C (software on/off backlight)

Sounds interesting with display 1st set of data and display 2nd set of data. Maybe you can develop further the plugin, my knowledge on programming is very limited...My method with two different task has a drawback, when changes the display, LCD2004, reload all data and black-out for a second ,displays "EspEasy" shortly, then come the final image...Go further, for you it"s a piece of cake, two sets of data in the plugin...available when needed, moreover no hope for scrolling...

For the moment we set a rule to activate lcdpower for 60s or 120s ,on longpress, to make some measurement, after that lcd will revert to lcdtemp. Shortpress will wake the lcdtemp for 15s,display timeout...

Instead you should send the desired data to the display from the rules, as I sketched before. In general the command to send data there is "LCD,

- The Display button can be configured as desired, as well as the timeout (should be a multiple of 2 x the count (=10 sec) so both value sets are shown)

I understand now, no need for two LCD task, each of them with own sets of text/values, just send directly to LCD, the content of Line text. Needs more skil to manage rules,timers,variables etc...If I understand well. your code display 1st set of data for 5s then display 2nd set of data for another 5s and so on.

2.Even the "interval" for LCD2004 plugin is set to 1s, the time is loaded only once,after longpress, then remain frozen...maybe all values are not refreshed,yes,checked... the values are loaded on longpress and remains unchanged forever,even the shortpress have no effect.

Works perfectly,displays time&data every second,you have 2 minutes for power measurement ,cannot switch back to temp&pressure readings, via longpress...I tried to use doubleclick instead and is ok, just some mindtwisted to use longpress AND doubleclick, in my opinion

I don"t know why you keep returning to your 2xLCD devices setup, it"s not needed, and has the side-effect of initializing the display when switching tasks.

OK,now we have something on display after boot...done. Now we have to refresh data sended to display,or else will have the values captured on last flip change,forever. On temp/humid/baro will be sufficient 10s, maybe more...But on current/power we need fast reading , one/sec and fast display on this specific scenario...Plus enable/disable ina, we don"t need every second interogation of ina sensor via I2C bus,then send data to LCD once/second, ONLY during measurement,otherwise ina can be disabled...

Getting to this point,one major improvement to this LCD2004 plugin,with no scrolling and framing, would be to implement in the plugin some frames/pages, aka set of data, with enable/disable option, and adressable via LCD command : LCD,

LCD 2004 requires 5V voltage supply. The i2c chip will work also at 5V . My LCD I2C board has also pullup resistors to Vcc, so the i2c lines will be pulled up to 5v also. Now , the ESP chip works at 3.3v,including the two gpio assigned to i2c bus. Normally, it requires a level shifter.

I agree with you, commander in chief.I have to, because my limited knowledge in programming. But, in that case, a gifted programmer can rebuild a new LCD2004 plugin, the existing one,less demanding,remains as is and the new,enhanced one, LCD frames, like OLED 1306 has...

When switch#state happens, the LCD also remains ON until somebody longpress "display button" to switchback the LCD to the main screen.If the alarm switch happens more times before a longpress , the display will show the latest events.

ESPEasy,or Tasmota does not fill my life entirely.Let"s say low-level hardware is my playground,somehow,my youth ,my formation are on that field.Unfortunatelly, my job did"t alow me to perform neither on software,neither on hardware, so let"s say esp is a kind of hobby. Flashed my first sonoff with tasmota almost 2 years ago , very happy to click/clack the relay...after that,step by step, with the help of they discord support, started to discover the power hidden "behind the hood".Not so easy,to learn from the scratch,with trial and error...Small projects,anyway,with specific task,not big home automation,mqtt,whatever...Then,a month ago,decided to try ESPeasy,somehow different approach,enhanced webgui,more accessible,more visible,but also with major (or minor) weak points.

PS: tried "LCD,1,1,DateTime" but does not display "Datetime:2021-05-16 17:43:41" which results in console, only "Datetime"...what"s the correct synthax?

How does monitoring Temperature, Humidity, Pressure, Illuminance, and Air quality sounds like? Well, it sounds great especially if we can do it in under 50 US $ budget, and it even has some basic weather prediction functions, when combined with Tasmota and Domoticz.

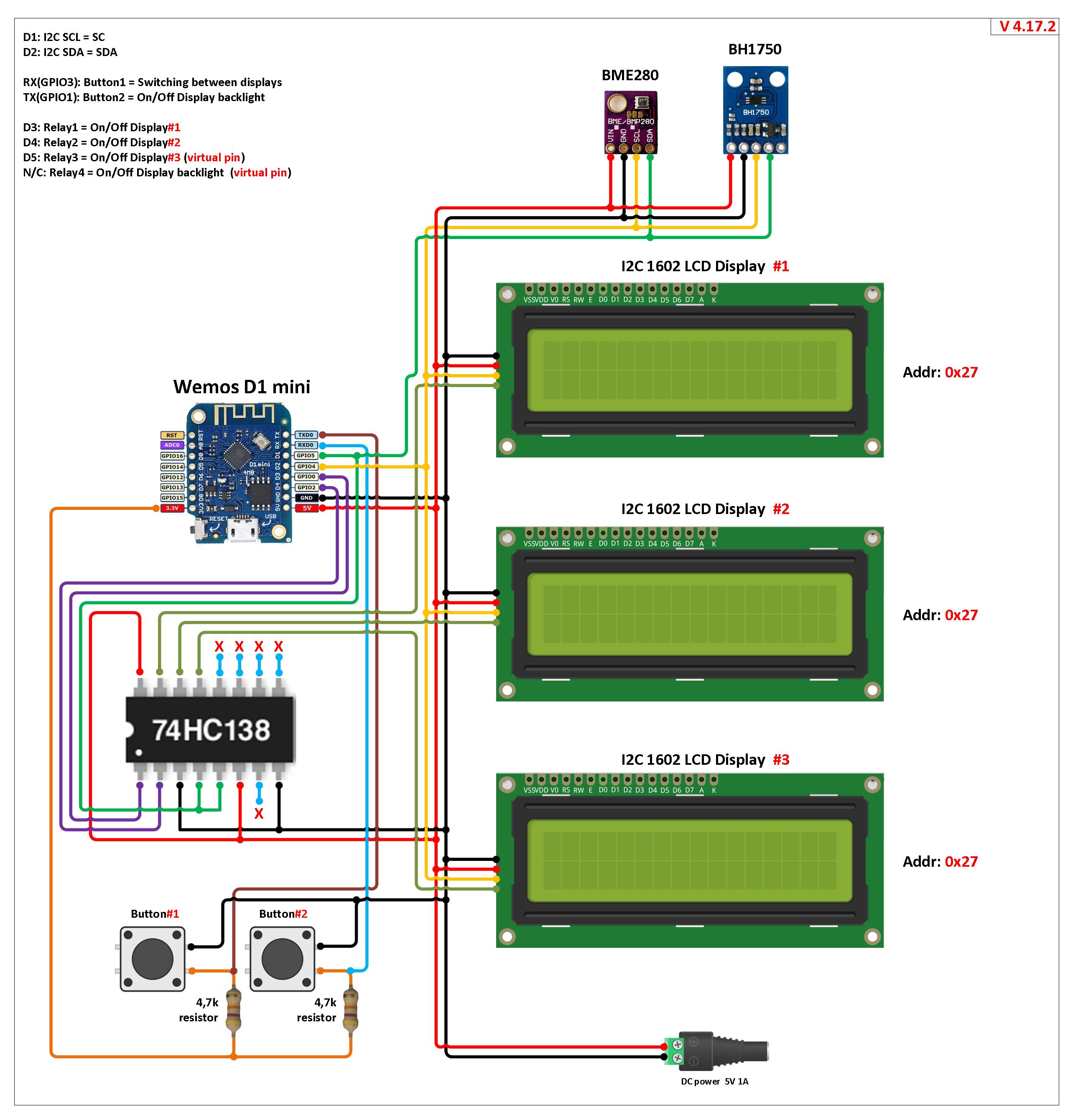

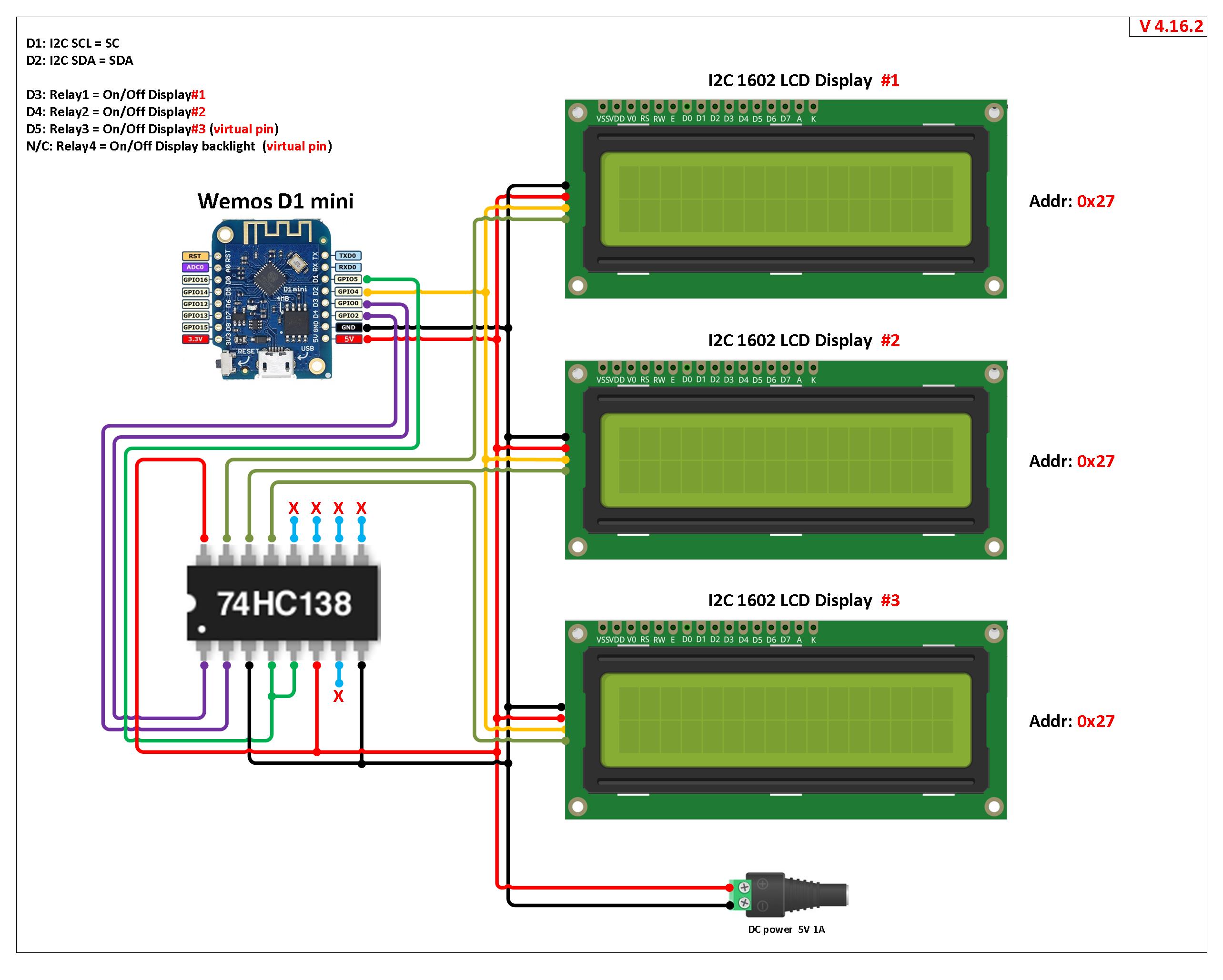

First I put everything together to see how it works. I had a doubt regarding connecting two i2c sensors in parallel (doubt was about addressing not about can it work or not). BME280 and BH1750 are both connected to scl and sda pins of ESP, and I did not now will Tasmota firmware be able to discover them both without fine tuning. But it worked like the charm from the start.

Tasmota had been flashed on to the ESP. Tasmota will be sending data from sensors to Domoticz. I will not enter into many explanations here, you can find needed information at those two links. I also uploaded flasher and two needed .bin`s here. Firmware is 7.2.0, and it will be obsolete very soon. I put it for those of you that like shortcuts

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey