defective lcd panel symptoms made in china

The difference between a LED TV and a LCD TV is that they are both LCD TV’s except one has LED stripes and the other has CCFL Backlights- (Florescent Tubes). I used a Philips Magnavox Emerson LG TV when testing these repaird, but they should work on other TV brands that are similar. Before you do any Repair, check to see if you are still under warranty, or are covered by a recall of your TV!!

If your Plasma or LCD/LED or CCFL/LCD TV or monitor has stopped working, or is displaying one of the following symptoms, then it *may* need some new capacitors in the power supply board or a replacement board

If the TV is still locked and will not respond to any commands from the front panel control buttons or the remote control unit, it is apparently locked in a failure or diagnostic mode, and would probably have to be diagnosed and repaired by a reputable TV repair facility. Good luck.

If it is a thin vertical line that appears on certain video resolution/image then it is normal and is indicated in the users manual under troubleshooting. If the line is almost half the screen, it could be a problem with the cable connection between the LCD panel and logic board, or the LCD panel itself. Try reseating the cable first if it’ll solve the problem. I’ve done similar issue in the past. Reseating the cable worked for a couple of months till eventually the LCD panel is the problem. Replacing the LCD panel is quite costly and impractical.

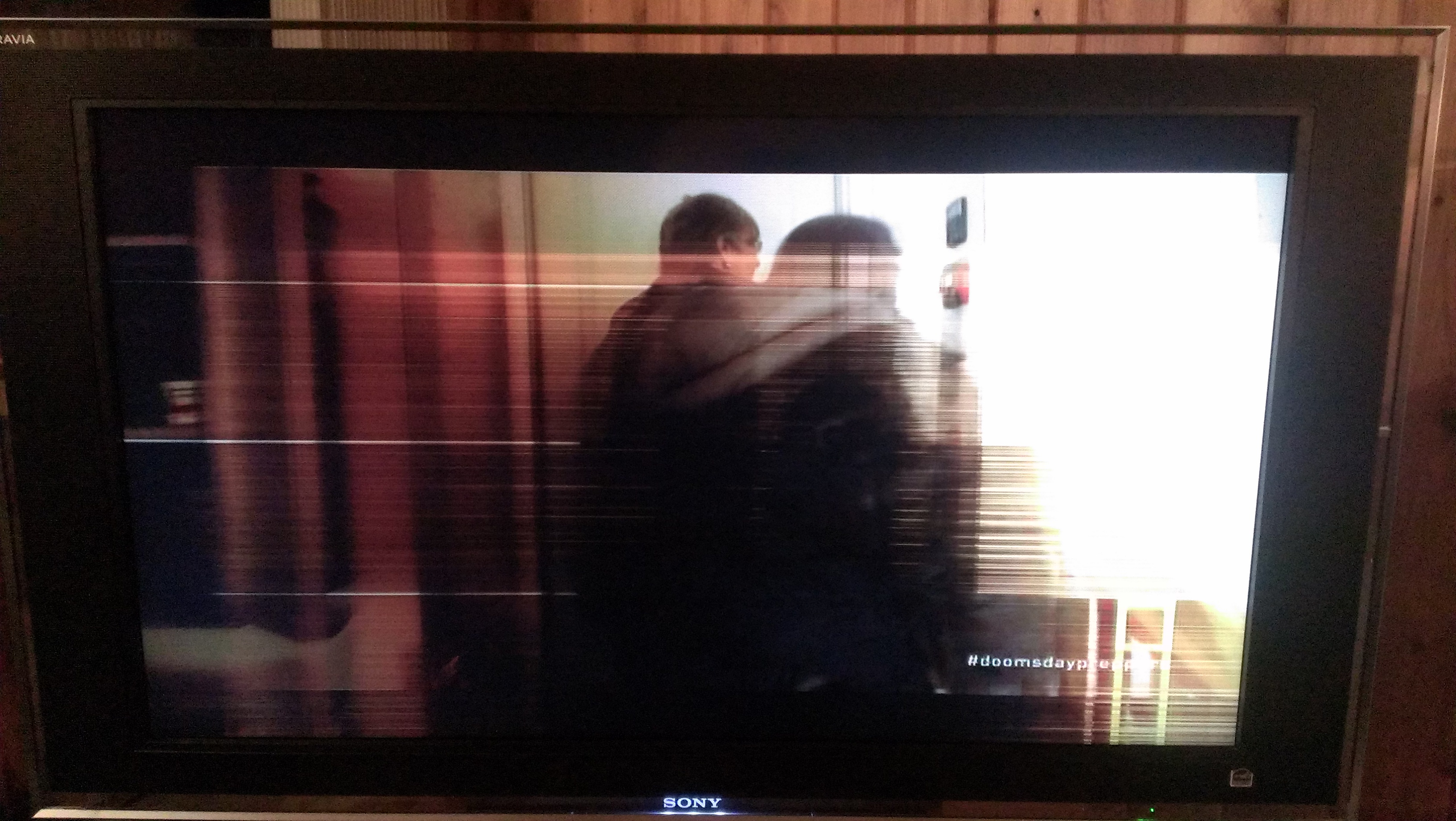

If the lines are there all the time or intermittent but in the same location it is an indication of a bad panel. The panel driver can also be the cause of this symptom.

If the lines/bars are across the OSD Menu, and all the video signal inputs also same result, that means the TV LCD Panel is defective Most of the time this symptom is caused by a bad LCD Panel 95%. You can try refitting LVDS Cable or replacing Main Board capacitors or replacing Main Board—5%

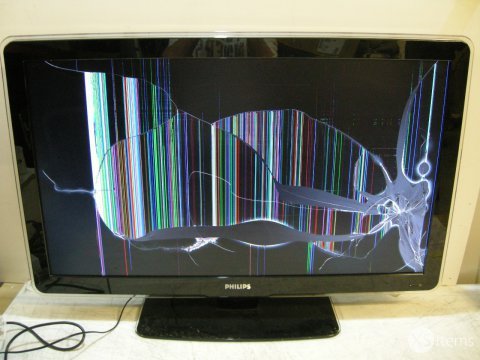

Bad news unfortunately, their are two possible causes for what you have described, one would be a fault with the picture drive pcb ( Power Control Board ), and the other is physical damage to the LCD cell matrix, (screen).

There’s videos on how to fix this. It has to do with putting foam, in between panel frame and screen, which applies pressure to solder joints, which then completes the circuit- Contact my10cents, for better explanation.

Is the OSD menu affected as well? If yes then possibility could be the LCD Panel or the t-con board. Since you have replaced the t-con board then possibility is the LCD panel. There could be also a possibility of mainboard where upgrading the firmware could restore the picture. If the OSD menu is not affected then the LCD panel is good.

If the lines are across the OSD menu then chances is very high the LCD panel is the cause of the problem otherwise it can be due to bad T-con board or even Mainboard. Have you tested on the OSD menu to see if the lines are really across the menu?

White Lines– There are several possibilities that can cause white lines on an lcd screen. One would be high temperature on the logic board. Logic board drives the LCD panel and when it overheats can cause this display problem. One solution would be to clean the vent holes around the TV. One possibility that I have experienced myself servicing is a bloated capacitor on the power supply board. The worst possibility is a defective LCD panel, which is costly to repair, and sometime more practical to buy a new TV set.

There are several problems that could cause this problem. It could be the connection from the T-Con board to the panel, try wiggling these cables around and see if the picture comes up even for a second. The Mainboard or it’s cables are not the issue in my opinion. The isdsue is either going to be a bad capacitor, faulty output from the power supply to the T-Con board, a bad connection from T-Con to panel, or the T Con or the panel itself are faulty.

It could be the connection from the T-Con board to the panel, try wiggling these cables around and see if the picture comes up even for a second. The Mainboard or it’s cables are not the issue in my opinion. This is due to either a bad capacitor, faulty output from the power supply to the T-Con board, a bad connection from T-Con to panel, or the T Con or the panel itself are fault. Also, it’s possible the A/V receiver’s Video On feature was turned off by an electrical surge or something else.Turn the Video feature back to On and suddenly that bad blue screen was gone.

Now we need to know if PSU Board has all the correct output voltages. This means checking the secondary side output voltages of Power Board. Probable causes are the Power Supply, the T-Con board, Main Board or the LCD panel itself has failed.

You will have to go into the TV and check for capacitors or burn marks or cracked solder around the pins–Main board could be IC’s, or regulators–Panel–Disconnect panel and see if your TV stay’s on—

The flashing green light indicates a fault on the power board inside your TV. This will be due to a faulty component like a capacitor or voltage regulator. Faulty electrolytic capacitors on the power board are the most common cause of this problem. These capacitors will often leak and stop working as the TV set gets older,but could also be caused by the Main Board or the inverter board. (LCD TV ONLY) So we will have to take a look inside and maybe do some circuit testing and a visual of your boards-

In a dark room take a flashlight and at an angle shine it on the screen and see if you can see any movement. If you can see movement or see your menu then its backlight failure. If totally black screen with sound then its T-Con board. So if you see movement on a led screen, then it’s your LEDs inside the panel. If on a LCD TV you see movement and lamps are not turning on, replace inverter. If with a LCD TV your lamps turn on, with no picture replace T-Con Board.

Plasma is the most durable in terms of panel failure. LED/LCD is terrible for panel failure. (But every model gets bad apples. Samsung LED/LCD panels die frequently. LG panels are a lot more reliable.) Overall I’d say plasma is more reliable, and even if it fails, in most cases plasma is repairable, LED/LCD is expensive to repair and often difficult to troubleshoot.

A blurry image on a high-definition LCD TV is typically the result of a mismatch between the TVs resolution capabilities and the resolution of the signal that is coming from connected devices, such as a DVD player or satellite TV receiver. Typically, blurry pictures result when a peripheral device connects to the TV through non HD cables and jacks.

Troubleshooting CRTs versus LCDs begins with similar steps, but diverges due to the differing natures of the two display types. The first troubleshooting steps are similar for either display type: power down the system and display and then power them back up; make sure the power cable is connected and that the outlet has power; verify that the signal cable is connected firmly to both video adapter and display and that there are no bent pins; verify that the video adapter is configured properly for the display; try the problem display on a known-good system, or try a known-good display on the problem system; and so on. Once you"ve tried the "obvious" troubleshooting steps, if the problem persists, the next step you take depends on the type of display. The following sections cover basic troubleshooting for CRTs and LCDs.

If your LCD displays no image at all and you are certain that it is receiving power and video signal, first adjust the brightness and contrast settings to higher values. If that doesn"t work, turn off the system and LCD, disconnect the LCD signal cable from the computer, and turn on the LCD by itself. It should display some sort of initialization screen, if only perhaps a "No video signal" message. If nothing lights up and no message is displayed, contact technical support for your LCD manufacturer. If your LCD supports multiple inputs, you may need to press a button to cycle through the inputs and set it to the correct one.

Unlike CRTs, where increasing the refresh rate always reduces flicker, LCDs have an optimal refresh rate that may be lower than the highest refresh rate supported. For example, a 17" LCD operating in analog mode may support 60 Hz and 75 Hz refresh. Although it sounds counterintuitive to anyone whose experience has been with CRTs, reducing the refresh rate from 75 Hz to 60 Hz may improve image stability. Check the manual to determine the optimum refresh rate for your LCD, and set your video adapter to use that rate.

First, try setting the optimal refresh rate as described above. If that doesn"t solve the problem and you are using an analog interface, there are several possible causes, most of which are due to poor synchronization between the video adapter clock and the display clock, or to phase problems. If your LCD has an auto-adjust, auto-setup, or auto-synchronize option, try using that first. If not, try adjusting the phase and/or clock settings manually until you have a usable image. If you are using an extension or longer than standard video cable, try connecting the standard video cable that was supplied with the display. Long analog video cables exacerbate sync problems. Also, if you are using a KVM switch, particularly a manual model, try instead connecting the LCD directly to the video adapter. Many LCDs are difficult or impossible to synchronize if you use a KVM switch. If you are unable to achieve proper synchronization, try connecting the LCD to a different computer. If you are unable to achieve synchronization on the second computer, the LCD may be defective. Finally, note that some models of video adapter simply don"t function well with some models of LCD.

Not all analog video cards synchronize perfectly with flat panels. The gray Shutdown screen exaggerates the problem, so don"t worry if very tiny movements are visible after you"ve adjusted clock and phase as well as possible. After you"ve set the clock and phase controls for the best image possible on the gray screen, cancel Shutdown and the image should be optimized.

Your video card is supplying a video signal at a bandwidth that is above or below the ability of your LCD to display. Reset your video parameters to be within the range supported by the LCD. If necessary, temporarily connect a different display or start Windows in Safe Mode and choose standard VGA in order to change video settings.

This occurs when you run an LCD at other than its native resolution. For example, if you have a 19" LCD with native 1280x1024 resolution but have your display adapter set to 1024x768, your LCD attempts to display those 1024x768 pixels at full screen size, which physically corresponds to 1280x1024 pixels. The pixel extrapolation needed to fill the screen with the smaller image results in artifacts such as blocky or poorly rendered text, jaggy lines, and so on. Either set your video adapter to display the native resolution of the LCD, or set your LCD to display the lower-resolution image without stretching the display (a feature sometimes referred to as display expansion), so that pixels are displayed 1:1, which results in the lower resolution using less than the entire screen.

This is a characteristic of LCDs, particularly older and inexpensive models, caused by defective pixels. Manufacturers set a threshold number below which they consider a display acceptable. That number varies with the manufacturer, the model, and the size of the display, but is typically in the range of 5 to 10 pixels. (Better LCDs nowadays usually have zero dead pixels.) Nothing can be done to fix defective pixels. Manufacturers will not replace LCDs under warranty unless the number of defective pixels exceeds the threshold number.

Some people claim that leaving the unit powered off for a day or two will "erase" a persistent after-image. Others suggest leaving a neutral gray screen (like the one used for phase adjustment) up on the screen to "equalize" the display. I dunno. FWIW, I"ve seen this problem on older Samsung panels but never on the Sony or NEC/LaCie panels I use.

Again, this is a characteristic of LCDs, particularly older and inexpensive models. The after-image occurs when the display has had the same image in one place for a long time. The after-image may persist even after you turn the display off.

Transistor-based pixels in an LCD respond more slowly than the phosphors in a CRT. The least-expensive LCDs exhibit this problem even with slow image movement, as when you drag a window. Better LCDs handle moderately fast image movement without ghosting, but exhibit the problem on fast-motion video. The best LCDs handle even fast-motion video and 3D gaming very well. The only solution to this problem is to upgrade to an LCD with faster response time.

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

Now we simply have to test each strips individually to see if they light up or not. For each that doesn’t completly, it will mean it has at least one defective LED.

After repeating this operation on all strips, I found only 1 defective LED, the same we thought looked burnt when we first had a look at the backlight (3rd strip from the top, 6th LED from the left). For a better understanding at what a burnt LED looks like here are 2 pictures of a burnt one and an OK one. Mind the roasted color compared to the regular one.

There might be a lot of other root causes for similar symptoms, a black screen often looks like something very serious and therefore expensive to repair, but this case is the perfect example that taking some time to look for the root cause can sometime lead to a good surprise: here a 1$ fix!

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

A display issue is an anomalous condition that prevents the screen from displaying a normal image. There are numerous causes for display issues, and diagnosis is a process of elimination: rule out the causes that can"t be the problem and narrow down on the one cause possible. The first step in diagnosing display issues is to identify whether or not it occurs on all monitors, only your monitor, or a certain type of monitor such as LCD monitors or CRT monitors. If it only occurs on your monitor or one specific type of monitor then you know where to start looking. Next, check if there"s any distortion in your image: if there"s none then check if there are any color patches on the screen; if they"re present then check if they fade when you look at them from a different.

1. Defective LCD cable or bad video card - displays are built on screens that are controlled by a video card, so this is one of the most common causes. If you put your laptop screen in an area where there is high electromagnetic interference, such as near wireless signals, then the screen could malfunction. This can also happen if you spilled liquid on your laptop and didn"t dry it properly before turning it back on.

3. If a picture on your screen is magnified, then this means that there’s something wrong with your webcam lens or the brightness. There are various causes for display issues. This blog will focus on the most common issues, their symptoms, and solutions.

Many display issues can occur on your computer. They often happen because the settings on the computer are incorrect or because the hardware is not set up correctly. Some of these problems will only affect one user whereas others will affect all users in a workplace. When people are using a computer to display text and images but see them differently from other people, it may be an issue with their monitor"s color settings or its physical alignment. Users may also have faulty video card drivers or installed applications that interfere with their display settings. A symptom of a problem with an LCD monitor could include blurred text, black screens, flickering images, colored boxes on the screen, and more.

Broken screen replacement service is provided from thousands of repairs stores and phone parts wholesalers worldwide, iPhone of which are mostly engaged in. So how to purchase reliable LCD screens among so many quality grades from China suppliers? Let me firstly elaborate on the quality grades of the iPhone LCD digitizer assembly that most repair stores and traders used to replace the broken ones.

According to the investigation, 90% of the Chinese iPhone LCD screen suppliers are found selling third-party manufactured screens and seldom sell genuine original LCD screens. Therefore, if your phone screen is broken, there would be a high chance for your screen to be replaced with a non-original one. Why? Maybe the cost and quality are relatively competitive, so why not?

As known, Foxconn is authorized to assemble iPhone, so there are some original iPhone LCD screens leaked from the assemble factory. And there are brought out from the factory for replacement. However the price is definitely high and still, some people care more about the quality of the screen than how much they cost, so for this group of customers, the Original Quality of LCD digitizer assemblies are preferred.

For some LCD digitizers, the LCDs are still working while the front glasses are broken, which can be recycled. Some factories recycled these broken screens by removing the broken front glass and attach a new one, then the LCD digitizer assembly would be new again, which is what called refurbished. Brand new original LCD screens are limited, and the refurbished ones can replenish the shortage of the new original LCD digitizer assemblies, for their quality would be more stable than the third-party manufactured.

Some Chinese factories purchase the original single LCD display, not compete LCD screen from the original factory, and then attach high copy front glass, backlight, etc, materials into a complete LCD screen, which quality is not stable and the display color is slightly different from the ones with high copy backlight. Well, their price would be cheaper and loved by many repair shops and wholesalers.

Under the shortage of original LCD screens, many Chinese factories begin to produce the high copy LCD screen. The stock and supply are getting less and less since about 2015, which leads the price goes higher and higher. Therefore the Chinese manufacturer starts to produce LCD screens with high copy raw materials. With competitive prices and good quality that meet most iPhone users’ needs, they are also popular among many wholesalers and repair shops.

With the premium quality of LCD and OLED screens tested strictly, we’ve helped many clients enlarge their markets worldwide. If you wholesale the LCD digitizer assembly or retail them in your repair shop, more information and sample are supported for your reference, please do not hesitate to contact us or leave your comment to discuss more.

Modern flat screen TV"s have a known problem with capacitors going bad. If your LCD or LED TV won"t turn on, or makes repeated clicking sounds, there is a very good chance that you can save hundreds of dollars doing this simple repair yourself.

I know, I know. You"re thinking, "Tinker inside my LCD HDTV. Are you crazy?" No, I"m not crazy. This is a repair almost anyone can do and this fix will work for any TV.

Gm I have a proscan plcd3717A tv. It comes on for a while and shut off. 37 LCD tv at school tuner. S/n a1212089790001040. I changed the power supply board. But still doing the same thing. Should I change the main board then.

Hi my 40inch LCD TV comes on on standby then I press the button and the light turns blue. There is no pic or lights on the screen and also no sound. Model no,m40/57g-GB-ftcu-UK. Product code ,um40d57bftcug107, serial no, 105571 03650. Thanks

Have 32″ Philips LCD TV. Was watching it while it was sitting on the carpeted floor and it got knocked forward. It didn’t hit hard, the picture is still perfect but now it is only Black and White (no color). I hooked up another TV to the source and it’s color.

I have here two Samsung LCD 32 inch model LA32D403E2 that has tiny horizontal lines but the second one will show very well for about five to ten minutes and start pouring white dews on the screen.

My two year old threw a toy at our 60 inch Samsung LCD tv. We have sound but no picture. There is no visible external damage, but where it was hit there are thin vertical rainbow stripes about 4 inches tall and wide. Trash? Thanks for any help you can provide.

I have a jvc lcd tv my daughter stuck a butter knife between the black plastic edge and the tv screen and bow there is a black spot where the knife was and a small thin horizontal white lone and a little thicker vertical pinkish line the screen is not cracked just black spot and lines how can I fix this?

My 3yr old son threw a plastic toy into the screen of my 60inch led lcd 3d tv now theres vertical and horizontal line in the middle part where the toy hit do you think its as good as gone?

I have an lg 55lv5500 LED LCD. I have power, sound and picture. However, the picture has vertical lines that are discolored over the whole screen (blacks are green, etc.). I have taken off the back and when I unplug the smaller LVD cable connected to the left of the TCon board, the picture clears but every other vertical line is black (meaning the vertical lines that are displayed when I do this appear to be the correct color). Is the LCD or the TCon board bad? Suggestions on how to further diagnose the problem? While I wasn’t present, my wife who was watching at the time said she heard a “pop” when the problem originated.

If your LG TV has vertical lines that are changing colors and you heard a “popping” noise while watching the TV, then this is most likely the T-con board (Timing Control Board) has a bad cap or another board has a capacitor on it that is bad. Check to see if you can find an obvious sign of a bad cap on any board. If so, replace the cap. Also, check to be sure all ribbon cables are connected and they are not damaged. If you cannot find a popped cap, then the T-con is most likely causing your issue from what you have explained. As long as the LCD panel is not cracked or broken, then a board or bad cap is causing the issue.

FYI – The T-CON board is the part of the LCD screen, it relays messages between the device’s processor and the display. The T-CON board synchronizes different parts of the screen with the info it gets from the processor. If the T-CON board malfunctions then the timing between parts of the board is disrupted and this leads to both horizontal and vertical lines that will display on the screen. It can also cause pixelation issues on your TV screen.

Thanks for your reply, the person who was supposed to lift the TV gently had pressed with his thumb on the last third of the right corner about 30 cm from right edge, which had resulted defective black triangle in that area, then from edges of the triangle vertical and horizontal lines appeared just as shown in the links below: Am not sure if this damage is fixable, if it can you please guide me to.

I have a HiSense flat LCD, model number 50K610. The screen got hit on the bottom right corner and now it has lines going up it. I am wondering where I can order a new screen at?

It will cost more to fix the screen than a new LCD TV. If you really want to check around look for screens on eBay. OR… Go on Craigslist for the same busted TV but with a good screen and swap it out.

I recently bought a Samsung 65″ curved 4k TV (JS9000) and the screen received a somewhat deep vertical scratch near the top of the screen. About 3/4 – an inch long. Not an actual crack and no other problems with the picture, but it’s annoying because I know it’s there and the TV is less than a month old. And expensive. If I look closely, the pixels still seem to work, but the outer surface has been removed where the scratch is. Does anyone fix curved panels yet, or am I just going to have to live with it?

If the picture is fine but there is a small scratch on the screen, there is not much you can do. There are screen scratch repair kits but may not work properly if applied to an LCD or LED screen. Check YouTube for ways to remove scratches and marks from flat screen TVs.

Our Vizio E472VL was working fine until recently the picture was replaced by about 4 inch narrow band of vertical lines. I thought this might be the ribbon cables connecting the main board to panel but now not sure. I press on the top of the cables to improve connection and the band will widen, change color or move around; however I never get any picture not even the menu. Therefore, I am at a total lost on what the problem might be. Any suggestions? Thanks in advance – Bill

I have an LG LCD. Light horizontal lines just started to appear. No damage visible, mounted to a wall closer to the ceiling. Happens more visibly when showing greens or blues, but seems to fade in and out. Can you tell me what the problem might be, and a possible solution. Thank you.

I have a Sanyo TV DP46849. When you turn it on you get a white screen with thin color vertical lines. You see some of the lines start getting lighter and lighter and then go white. There is no sound before this happened the right side of screen would roll like so i had the t-con replaced but no change. I spoke to a repair shop they say it may be a the main board just went out it powers up fine and the repair shop said the LCD screen was not cracked what do you think the problem may be.

If the screen is cracked on the inside, it is most probable that it is a heat related thermal crack. Call Emerson and claim a thermal crack has appeared and it is defective from the factory and should be fixed. If they will not honor the warranty, your only option is to replace the inner screen.

Even if the screen on your Sony Bravia TV is not cracked, it is most likely damaged. It may have a cracked inner screen or when the screen fell over. The TVs front panel may have hit and made contact with a board inside the TV. Is the front panel of screen depressed inward on any part of the front screen surface? Look at the TV screen from a side angle with a flashlight to see. If there is no damage to the front panel, then the inner panel may have cracked. You should be able to see any damage to the inner or outer screen panel when using a flashlight.

The outer screen panel of my Sony Bravia took a hit and is cracked, only a small portion of the screen has images coming out and the rest of the screen has vertical lines and black patches. Can it be fixed at home or do i get a replacement outer screen panel?

Philips 47″ LCD…comes on works fine occasionally, but usually when turning it on, a horizontal gray bar with vertical lines inside it blinks and the screen will slowly fade to white. I can see about an inch of video at the top sometimes. So I turn it off for a few minutes and try again. After an hour or so of repeatedly turning off and on, it will eventually come on and work perfectly…until I turn it off, then I have to try turning it off and on for an hour or two until it decides to work. I’ve opened the back and noticed no bad capacitors and wiggled all connectors.. Any idea?

You may have a bad power board if you need to take an hour of time trying to turn the TV on or off. What is the model number of your Philips 47″ LCD TV? Has anything come in contact with the screen? Did this problem suddenly appear or did this issue happen over time? If the screen was not hit then a board may be on the fritz. When you opened the TV did you check to be sure all boards are secure and the wire harness/ribbon cables are tight and in place correctly?

Had an incident where my 60″ Vizio Smart TV got hit on the left side of screen. Came home to turn on TV and the TV had back glow but no picture (still has sound) and a nice size point of impact. Cracked out internally (exterior panel is fine). Looking for best advice in fixing the TV, really hate to just get rid of it. The p.o.i maybe lit up kinda rainbowish and the rest of the screen is blacked out but still has glow. I realize that the internal glass panel needs replaced at the very least, based on further symptoms is there anyone that may know what needs to be done?

If the inner glass is cracked, the only way to fix the TV is to replace what is broken. The inner glass or panel for the TV can be found online but may cost more than the TV. Finding a used TV with an intact screen is the cheapest way.

I have a rca smart led lcd 65 inch I purchase the tv about a month ago from Aaron’s furniture the tv fell over now it’s cracked on the bottom right corner is this fixable and how much will it cost or will my warranty cover the tv still turn on & you can still see the picture on the tv but it’s just crack

May just have a defective led or may be heat related issue. You should call Samsung and ask them if there has been an issue with this on your exact model TV. It may not be under warranty but it won’t hurt to call them and see if there are known issues. Sometimes they recall TVs and if you did not register it, you will never know.

I have a Phillips 9,000 Series Flat HDTV, 119 cm LCD. Most of the screen is blocked by a white screen, with some rainbow vertical lines within it. To the right of the main crack (which is a little to the right of the center of the screen), the white is darker and there are more rainbow lines there. Only at the very top of the screen in the middle can you see the actual channel. The TV does work overall in terms of turning on, the cable, etc. and you can still hear the sound, its just the crack. I am assuming that I would only need to change the screen in this situation. Do you have any cheap suggestions?

My question would be is there a T-Con that needs to be replaced or something else. I asked someone and he said it could be a video cable or power board defective but my opinion is T-Con board needs replace. I found some T-Con boards online but there are for models UN55D8000 and my tv is UN55D7000. Is there any difference between those series and what is your opinion to buy used or new one? What would you suggest?

You may have a bad board. If there are no cracks on the screen, a board could have shorted or become damaged. You will have to take the TV apart and check each individual board to see what may be causing the issue. Plan on trying to find a T-con board for your Samsung TV model. That is the board that controls the LCD’s lines and pixels.

A Vizio 42″ inch replacement TV screen can be found on eBay. If it just the LCD screen that is cracked there is one for around $95 dollars US. Here is the link to the Vizio TV replacement screen.

You may want to open the TV up and see if you can find a bad board affecting the screen. However… If pixels are affected then your screen is most likely bad. You can try finding a replacement board or screen (once you are done troubleshooting to find out what actually is needed) and order it online. If you open the TV, have a look at the circuit boards to make sure there is no obvious signs of burns or popped capacitors. If all boards look good visually, have a look at the inner screen for damage. Look on LCD PARTS as they have many parts you may need to fix your TV.

You need to first find the generic panel and be sure the size is the exact same, obviously. Then, make sure the panel you are looking at says COMPATIBLE with your model and size TV. Not all generic screens are made the same. Be sure the different cable connections match yours and the areas where it slides into your TV match up. The word COMPATIBLE is what you need to read. If you have a Vizio 55″ 4k M series TV, then make sure the generic replacement screen says COMPATIBLE with Vizio 55″ 4k M series TV.

I have a 32″ Westinghouse flat screen LCD TV. A small horizontal bluish red line appeared on my television about a year ago and I chose to ignore it since it was small. Well a year later, the line has spread and there are more throughout the screen. It wasn’t dropped or hit so I don’t know what happened. The warranty is out so I cant call the manufacturer. I was looking at screen repair shops but if there’s and easier/cheaper fix, I would rather go that route.

My flat screen TV has had these weird vertical lines for the past week, so knowing how to get rid of them will make my TV watching experience more enjoyable. Determining whether the glass panel on my screen or the LCD or LED part of it is broken seems like something I should do right now. Both of those things seems really easy to fix.

I have a Toshiba LCD TV 32CV500E and have had it for around 4 yrs. Suddenly its showing light grey like flashing light.. still I can hear sound. What the issue and can someone advise ?

I have a 65″ RCA LCD LED backlight. While moving I must have put to much stress on it because it is now cracked in the top right corner with some spider Web action. Is this fixable and if so how would I go about it.

Are you aware of the screen getting hit or damaged by even though there is no physical damage? The screen could be damaged… LCD screens on TVs are made up of two thin layers of glass containing liquid crystal material between them. When the glass becomes damaged, debris infiltrates the crystal layer. If there is no damage to the screen, you may have a board or boards issue.

You should be able to buy any 32″ JVC replacement screen but they are usually not cheap. You could try Alibaba as they have just about every type of replacement screens for LED and LCD flat screen TVs.

Do you have an LED. LCD, or Plasma TV? Is the complete screen gray? Are they gray lines now or is the complete area of the screen gray? Can you still hear sound? What is the make and model of your TV?

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, digital clocks, calculators, and mobile telephones, including smartphones. LCD screens are also used on consumer electronics products such as DVD players, video game devices and clocks. LCD screens have replaced heavy, bulky cathode-ray tube (CRT) displays in nearly all applications. LCD screens are available in a wider range of screen sizes than CRT and plasma displays, with LCD screens available in sizes ranging from tiny digital watches to very large television receivers. LCDs are slowly being replaced by OLEDs, which can be easily made into different shapes, and have a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile (because OLEDs use a single glass or plastic panel whereas LCDs use two glass panels; the thickness of the panels increases with size but the increase is more noticeable on LCDs) and potentially lower power consumption (as the display is only "on" where needed and there is no backlight). OLEDs, however, are more expensive for a given display size due to the very expensive electroluminescent materials or phosphors that they use. Also due to the use of phosphors, OLEDs suffer from screen burn-in and there is currently no way to recycle OLED displays, whereas LCD panels can be recycled, although the technology required to recycle LCDs is not yet widespread. Attempts to maintain the competitiveness of LCDs are quantum dot displays, marketed as SUHD, QLED or Triluminos, which are displays with blue LED backlighting and a Quantum-dot enhancement film (QDEF) that converts part of the blue light into red and green, offering similar performance to an OLED display at a lower price, but the quantum dot layer that gives these displays their characteristics can not yet be recycled.

Since LCD screens do not use phosphors, they rarely suffer image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs are, however, susceptible to image persistence.battery-powered electronic equipment more efficiently than a CRT can be. By 2008, annual sales of televisions with LCD screens exceeded sales of CRT units worldwide, and the CRT became obsolete for most purposes.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs, along with OLED displays, are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at B

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey