lcd screen yellowing made in china

The above-mentioned optical properties are of course the basic requirements of LOCA adhesives. The next challenge is to be certain that these optical qualities will be retained and consistent over time under real-world operating conditions. It is in this regard that b* number becomes a useful tool. The b* number is especially important in its consistency over time as yellowing of screens is considered highly undesirable and indicative of aging or failure in the eyes of consumers.

Many environmental conditions have been shown in the past to lead to a yellowing of LOCA materials over time and a corresponding deterioration in image quality. By measuring the CIELAB coordinates of a given device after initial manufacture, it is then possible to expose the device to harsh conditions and measure any changes in CIELAB numbers.

Each of these tests and all of them combined is designed to simulate years of real-world aging in environments such as in automobiles and appliances. By showing consistency over time under these conditions of the b* value, manufacturers can be confident of resistance to yellowing for LCD displays. In addition, customized testing is not uncommon in cases where a product may be exposed to unique or especially harsh conditions.

Chase Corporation, Westwood, Ma., founded in 1946, is a leading manufacturer of industrial products for high-reliability applications with a global customer base operating in diverse market sectors. Our HumiSeal® group specializes in the manufacture of polymers for the protection of PCBs. In addition, the HumiSeal group produces the Vivid Cure line of LOCA adhesives for LCD display manufacture. Our outstanding manufacturing and technical support groups can provide your organization with a reliable global supply, unmatched quality, and superior technical support.

Hey Andi, I need someone trustworthy from China to help me buy the Oppo Find 7, Would you be that person for me please? Ill even throw in my old Xiaomi Mi2 for free(LCD Gave up on me) lol..

I would suggest you get the Vivo Xplay 3S. I have the Xplay 3S and after using it for 2 months, I must say that this is the best phone I have ever handled. It has everything that I have ever wanted except no dual sim and replaceable battery options.It’s very fast on 4G, beautiful 6″ 2K screen which is excellent in viewing videos and mp4 movies, regular firmware updates, light and pocketable and most importantly, the sound from the internal built in DAC ES9018 and TI Opamp is really awesome coming out from a phone!! A premium look and feel!

Hey Andi, I need someone trustworthy from China to help me buy the Oppo Find 7, Would you be that person for me please? Ill even throw in my old Xiaomi Mi2 for free(LCD Gave up on me) lol..

I would suggest you get the Vivo Xplay 3S. I have the Xplay 3S and after using it for 2 months, I must say that this is the best phone I have ever handled. It has everything that I have ever wanted except no dual sim and replaceable battery options.It’s very fast on 4G, beautiful 6″ 2K screen which is excellent in viewing videos and mp4 movies, regular firmware updates, light and pocketable and most importantly, the sound from the internal built in DAC ES9018 and TI Opamp is really awesome coming out from a phone!! A premium look and feel!

I’m waiting to get a replacement because the yellow tint on the bottom of the screen. According to my tracking of the package they got my device at 19th of May, but they have not yet been able to “verify it”..

I’m waiting to get a replacement because the yellow tint on the bottom of the screen. According to my tracking of the package they got my device at 19th of May, but they have not yet been able to “verify it”..

In this article, we"ll focus on color temperature, a fundamental parameter in picture quality adjustments. While color temperature dramatically affects the picture quality of an LCD monitor, more often than not, people simply use the default settings. A good understanding of the meaning of color temperature will enable better adjustments of LCD monitor picture quality.

Note: Below is the translation from the Japanese of the ITmedia article "Altering a color dramatically with a single setting: Examining color temperature on an LCD monitor" published March 30, 2009. Copyright ITmedia Inc. All Rights Reserved.

Most of today"s LCD monitors feature color-temperature adjustment options in their OSD menus. Since color temperature settings affect color reproduction significantly on an LCD monitor, if a user wants to display an image with the appropriate color cast, he or she must choose the correct color temperature.

While any object will radiate various light frequencies when heated to high temperature, the temperature at which the light becomes a certain color differs from object to object. For this reason, a black body is an idealized object, used to generate standard values by matching specific colors of radiated light to specific temperatures. While this is a complex topic with detailed explanations grounded in physics and mathematics, we do not need to understand this in depth to adjust the color temperature of an LCD monitor. Anyone with a deeper interest is encouraged to consult reference works.

As mentioned in passing at the start of this session, most current LCD monitors allow users to adjust color temperatures using the OSD menu. As we would expect, reducing the color temperature on an LCD monitor gives the entire screen an increasingly reddish cast, while increasing the color temperature makes the color cast increasingly blue. The menu items for adjusting color temperature vary from product to product. Some ask users to choose from terms like "blue" and "red" or "cool" and "warm"; others ask users to set numerical values like 6500 K or 9300 K.

It helps to be able to specify precise Kelvin values when we adjust the picture quality of an LCD monitor. For example, on most EIZO LCD monitors, users can choose from about 14 levels (in 500-K intervals from 4000 to 10,000 K, plus 9300 K). This is industry-leading precision. Some other LCD monitors allow users to designate color temperature by Kelvin value. Most offer significantly fewer options in the OSD menu: 5000, 6500, and 9300 K, for example.

On most EIZO LCD monitors, users can adjust color temperature precisely from the OSD menu in 500-K intervals (photo at left). Using the bundled ScreenManager Pro software for LCD monitors to configure various display settings from the PC, users can easily adjust color temperatures simply by moving the position of a slider at the top of the screen (photo at right).

A color temperature of 6500 K is standard for ordinary PC use and for the sRGB standard. Most LCD monitors offer a setting of 6500 K among their color temperature options. If a monitor offers an sRGB mode, setting it to this mode should present no problems. In most cases, even products whose color-temperature settings use terms like "blue" and "red" will be adjusted to close to 6500 K for standard mode, although accuracy may be lacking. The LCD monitors on some laptop PCs are set to higher color temperatures.

In the field of video imaging—television, for example—the current standard under Japanese broadcasting standards (NTSC-J) is 9300 K. This is significantly above the 6500 K standard for PC environments. Television pictures actually have a pronounced blue cast. However, most people appear to be accustomed to television and often perceive PC screens as having a reddish cast. Some products offer a picture mode with a color temperature around 9300 K as a "movie" or similar mode. When viewing the picture from a television tuner in a PC environment, one can generally choose a color temperature of 9300 K for color reproduction similar to a home television display.

On the other hand, the U.S. broadcasting standard (NTSC) calls for a color temperature standard of 6500 K. The international standard for digital high-definition television (ITU-R BT.709) also specifies a color temperature of 6500 K. When watching video on a PC, users should set the LCD monitor"s color temperature between 6500 K and 9300 K, checking for differences in color reproduction.

As a rule of thumb, most Japanese film titles assume a 9300 K environment, while non-Japanese films assume a 6500 K environment. This means one is highly likely to achieve color reproduction close to that intended by filmmakers by setting the color temperature of an LCD monitor to 9300 K when viewing a Japanese film and 6500 K when viewing a non-Japanese film. (Naturally, this doesn"t apply universally.) When using a model with a wide range of choices in Kelvin values—an Eizo Nanao LCD monitor, for example—users can adjust the color temperature to whatever looks best.

The preceding page explained the basics needed to set the correct color temperature based on the intended application. However, for applications like retouching digital photographs or color adjustments for printing or video editing, where users are professionals or high-end amateurs for whom color reproduction significantly affects the final quality of the work, managing LCD color temperatures with greater accuracy is critical. If colors differ between the output of photo retouching and the color reproduction in printing, or colors appear unnatural when a video is viewed on another computer, it could not only impair the work itself, but also significantly reduce the efficiency of image processing.

Addressing these demands adequately requires an LCD monitor that supports color management based on hardware calibration. A hardware calibration system uses a color sensor to measure colors on screen and controls the look-up table (LUT) in the LCD monitor directly. This makes it possible to correct for differences in color temperature attributable to differences between individual LCD monitor units or to an aging display and to generate accurate colors, an important feature when handling color.

Here we"ll use an EIZO LCD monitor with a good reputation for enabling high-precision color management to briefly explain the knowledge and specialized tools required to work with color temperatures at a deeper level. We also recommend reading the articles below for more information on hardware calibration, color gamut, and look-up tables.

EIZO offers the ColorEdge series of color management-capable LCD monitors. All models in the ColorEdge series support hardware calibration, allowing users to manage in detail all aspects of color reproduction, including screen color temperature and color gamut.

Designed for advanced color management, the ColorNavigator software is bundled with all models in the ColorEdge series. ColorNavigator offers a wide range of functions, including a function for matching the color temperature of the LCD monitor with the white of a particular paper. Using a color sensor (sold separately), users can measure a white point on the paper and set this to white when performing a hardware calibration of the LCD monitor. This makes it possible to precisely match the on-screen white and the paper white, ensuring that colors on screen are very close to those on the printed paper.

ColorNavigator also offers an advanced function for emulating any color gamut. This lets users reproduce on screen, with high precision, the Adobe RGB, sRGB, or NTSC color gamut, using a wide color-gamut panel. ColorNavigator can also be set to emulate color gamuts by reading existing ICC profiles, rather than relying on preset software gamuts. For example, for commercial applications, emulating the client"s LCD monitors using their ICC profiles lets users streamline the color-proofing workflow by reproducing the color reproduction of the client"s monitors on a ColorEdge monitor.

ColorNavigator also features functions that encourage users to perform periodic hardware calibration of their LCD monitors and to maintain accurate color reproduction through precise manual adjustments. Since screen brightness and color reproduction change as a monitor is used over many years, color temperatures will also change. In applications for which accurate color reproduction is paramount, merely selecting preset color-temperature settings is not enough. It"s a good idea to perform hardware calibration once a month or so.

Based on a special-purpose EX1 sensor and special-purpose software, EasyPIX lets users easily match on-screen and printed colors. This is done by visually comparing the white displayed on screen with the white of the paper and manually adjusting on-screen tint and brightness using the special software until both tints look the same. The special sensor is used to measure on-screen color and to bring it more in line with the white of the paper. EasyPIX also offers functions for adjusting color casts closer to those of natural light or flashbulbs (color temperature: 5500 K) and to standard color casts for Web content and general PC applications (color temperature: 6500 K).

In addition to adjusting LCD monitors with special tools like ColorNavigator or EasyPIX, one should closely examine worksite (environmental) lighting and LCD hoods.

Most worksites use fluorescent lighting. Some fluorescent lighting is suitable for working with color; others are not. The majority of fluorescent lights sold to the general public are not suitable for color work. Ordinary fluorescent lights have a highly biased light spectra, and color divergence is readily apparent if we compare the LCD monitor screen to paper. Accurately printed colors, for example, may appear greenish under fluorescent light.

Fluorescent lights suitable for working with color are known as high color-rendering fluorescent lamps or fluorescent lights for color evaluation. These lamps feature light spectra similar to the sun and generate very little color divergence between the LCD monitor screen, printed paper, and human color recognition. Color rendering describes the color an object appears to have under a certain light. Color-rendering performance is expressed in terms of the average color-rendering index (Ra). An Ra value of 100 means the lighting is identical to natural light. The closer the value to Ra, the higher the color-rendering performance. The International Commission on Illumination (CIE) recommends fluorescent lighting with an Ra of 90 or above at locations where art is viewed or colors evaluated.

An LCD hood is attached to the top and sides of an LCD monitor to reduce the effects of environmental lighting on the screen display and to make it possible to view the true screen colors while working.

An LCD hood specially designed as an option for an LCD monitor is ideal, but if no such option is available, the user can make an LCD hood by cutting a piece of cardboard, plastic sheet, or polystyrene board to the size of the display and painting the entire surface facing the LCD monitor screen matte black to minimize light reflections. In the end, the hood simply needs to block environmental light from reaching the screen of the LCD monitor and not reflect display light back onto the screen. Make sure the hood doesn"t also block the heat release vents on the LCD monitor; heat buildup inside the monitor can damage the unit.

We"ve examined some basic aspects of color temperature and of using and adjusting color temperatures on an LCD monitor. The color cast of an LCD monitor varies dramatically with color temperature settings—the difference is hard to miss. If you"ve used nothing but your monitor"s default settings up to this point, we encourage you to explore the OSD menu and see how colors change at different color temperature settings. While 6500 K, sRGB mode, or "standard" mode is recommended for general PC use, you might find that you prefer a different color temperature for watching films, playing computer games, or other uses.

Chemicals leaking from millions of computer screens in homes, offices and schools could damage human health, according to research by Chinese scientists.

Chemistry professor Su Guanyong and colleagues at Nanjing University of Science and Technology in eastern Jiangsu province studied more than 360 types of chemicals used in computer and mobile phone screens and found that 87 of them could be a danger if they got into the environment.

Some chemicals in liquid crystal displays (LCDs) could alter genes, they said. Animal cells mutated unexpectedly if exposed, and preliminary results of their ongoing study published in Proceedings of the National Academy of Sciences on Monday showed that one of the most polluted places was the home.

Researchers said about a quarter of the chemicals from screens they tested might be pollutants. Photo: Getty alt=Researchers said about a quarter of the chemicals from screens they tested might be pollutants. Photo: Getty

Studies found that excessive radiation from screens could speed up the ageing of skin and blue light from diodes could harm the retina of the eye. "But nobody has looked beyond the brightness to unveil the dark secrets behind," Su said.

Over the years, screen panel manufacturers have pushed LCD technology to higher resolutions and faster refreshing rates, but the chemical composition of the liquid crystal that fills their screens has hardly changed.

Smartphones mean booming demand for components such as screens. Photo: Ben Sin alt=Smartphones mean booming demand for components such as screens. Photo: Ben Sin

They exposed embryonic chicken cells to liquid crystal taken from the screens and compared them to cells grown in normal conditions. They found genetic changes that suggested the exposed cells had mutated.

The Nanjing team was baffled by the amount of liquid crystal in the air. They knew screens were made in dust-free factories and sealed, but their surveys of hotels, school buildings, canteens, dormitories, electronic product repair centres, homes and laboratories revealed surprising results.

Scientists say cracked screens and leaking chemicals are a worldwide problem. Photo: Shutterstock alt=Scientists say cracked screens and leaking chemicals are a worldwide problem. Photo: Shutterstock

The lowest levels were found in a canteen, a dormitory and classrooms. Su said they were not sure where the drifting liquid crystals came from. Some screens might have been cracked or broken, he said. If a screen was left on for a long time, heat and radiation might cause liquid crystal to evaporate.

"Electric device recycling plants could be a major source of emissions, with broken screens dumped everywhere and little protection. This practice must stop," he said.

Tesla has started rolling out its fix to an issue that caused the border of some of its in-car screens, also know as the Media Control Unit (MCU), to turn yellow. The fix involves a new UV light fixture tool that is just now starting to roll out to service centers.

The issue affected a lot of screens in Tesla’s Model X and S vehicles and caused minor riots in several online forums. Friend of CleanTechnica and longtime Tesla supporter Bonnie Norman posted an update on Twitter and the Tesla Motors Club about her experience with the new fix in her Tesla, and also emailed info and pics to us.

Bonnie said the fix had already been developed and that the new UV fixture tool was making its rounds to different service centers to get technicians trained up. Bonnie shared on the forums that she believes, “yellowing is from incorrectly cured adhesive that appeared over time — if that’s the case, it makes sense that finishing the cure would be permanent.” That makes more sense and should give owners with yellowing screen borders some hope. The fix does not involve replacing the MCU or the screen itself — just a bit of UV light.

Another TMC member posted what is claimed to be an email from Tesla that indicates the UV light fix is only a temporary measure. “Tesla has developed a procedure which uses ultraviolet light to remove the yellowing condition for a period of time and we will apply it as a one-time goodwill gesture once this procedure is available.”Emphasis added.

The issue, while minor and not affecting the function or safety of the vehicle, has already resulted in some owners entering into arbitration with Tesla over the yellowing border. Tesla’s response as part of arbitration was released and offers insights to Tesla’s position on the screen yellowing. It specifically notes that the banding is caused by, “exposure to temperature, humidity, and oxygen over time.” The arbitration document from the California Dispute Settlement Program clearly states that Tesla does not believe the issue is substantial enough to require replacement of the MCU under warranty.

It is exciting that Tesla has identified a fast fix to the screen yellowing that has tainted the ownership experience for so many owners. As with any fix, time will tell if this one stands the test of time.

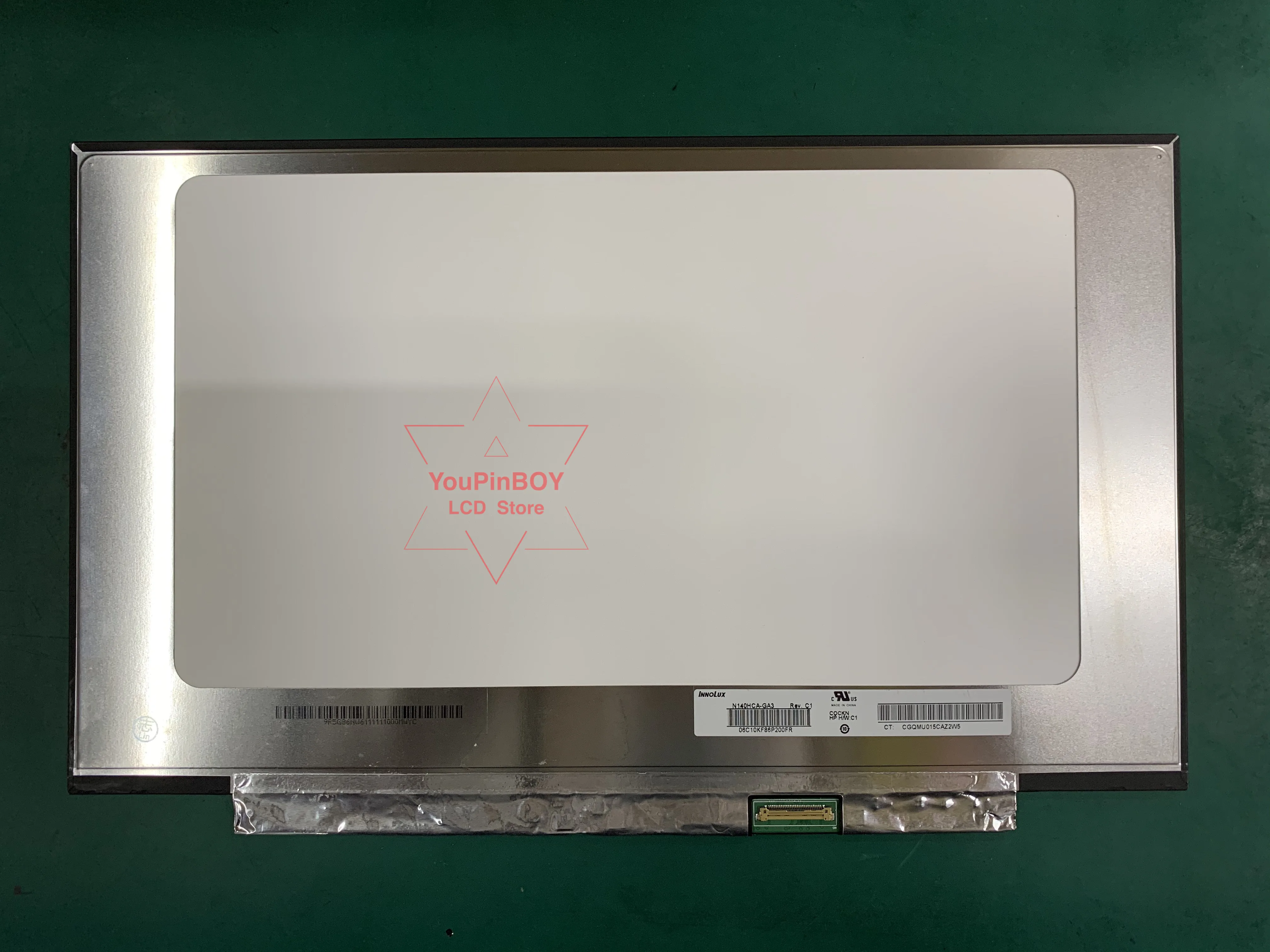

Broken screen replacement service is provided from thousands of repairs stores and phone parts wholesalers worldwide, iPhone of which are mostly engaged in. So how to purchase reliable LCD screens among so many quality grades from China suppliers? Let me firstly elaborate on the quality grades of the iPhone LCD digitizer assembly that most repair stores and traders used to replace the broken ones.

According to the investigation, 90% of the Chinese iPhone LCD screen suppliers are found selling third-party manufactured screens and seldom sell genuine original LCD screens. Therefore, if your phone screen is broken, there would be a high chance for your screen to be replaced with a non-original one. Why? Maybe the cost and quality are relatively competitive, so why not?

As known, Foxconn is authorized to assemble iPhone, so there are some original iPhone LCD screens leaked from the assemble factory. And there are brought out from the factory for replacement. However the price is definitely high and still, some people care more about the quality of the screen than how much they cost, so for this group of customers, the Original Quality of LCD digitizer assemblies are preferred.

For some LCD digitizers, the LCDs are still working while the front glasses are broken, which can be recycled. Some factories recycled these broken screens by removing the broken front glass and attach a new one, then the LCD digitizer assembly would be new again, which is what called refurbished. Brand new original LCD screens are limited, and the refurbished ones can replenish the shortage of the new original LCD digitizer assemblies, for their quality would be more stable than the third-party manufactured.

Some Chinese factories purchase the original single LCD display, not compete LCD screen from the original factory, and then attach high copy front glass, backlight, etc, materials into a complete LCD screen, which quality is not stable and the display color is slightly different from the ones with high copy backlight. Well, their price would be cheaper and loved by many repair shops and wholesalers.

Under the shortage of original LCD screens, many Chinese factories begin to produce the high copy LCD screen. The stock and supply are getting less and less since about 2015, which leads the price goes higher and higher. Therefore the Chinese manufacturer starts to produce LCD screens with high copy raw materials. With competitive prices and good quality that meet most iPhone users’ needs, they are also popular among many wholesalers and repair shops.

With the premium quality of LCD and OLED screens tested strictly, we’ve helped many clients enlarge their markets worldwide. If you wholesale the LCD digitizer assembly or retail them in your repair shop, more information and sample are supported for your reference, please do not hesitate to contact us or leave your comment to discuss more.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey