different types of touch screen monitors quotation

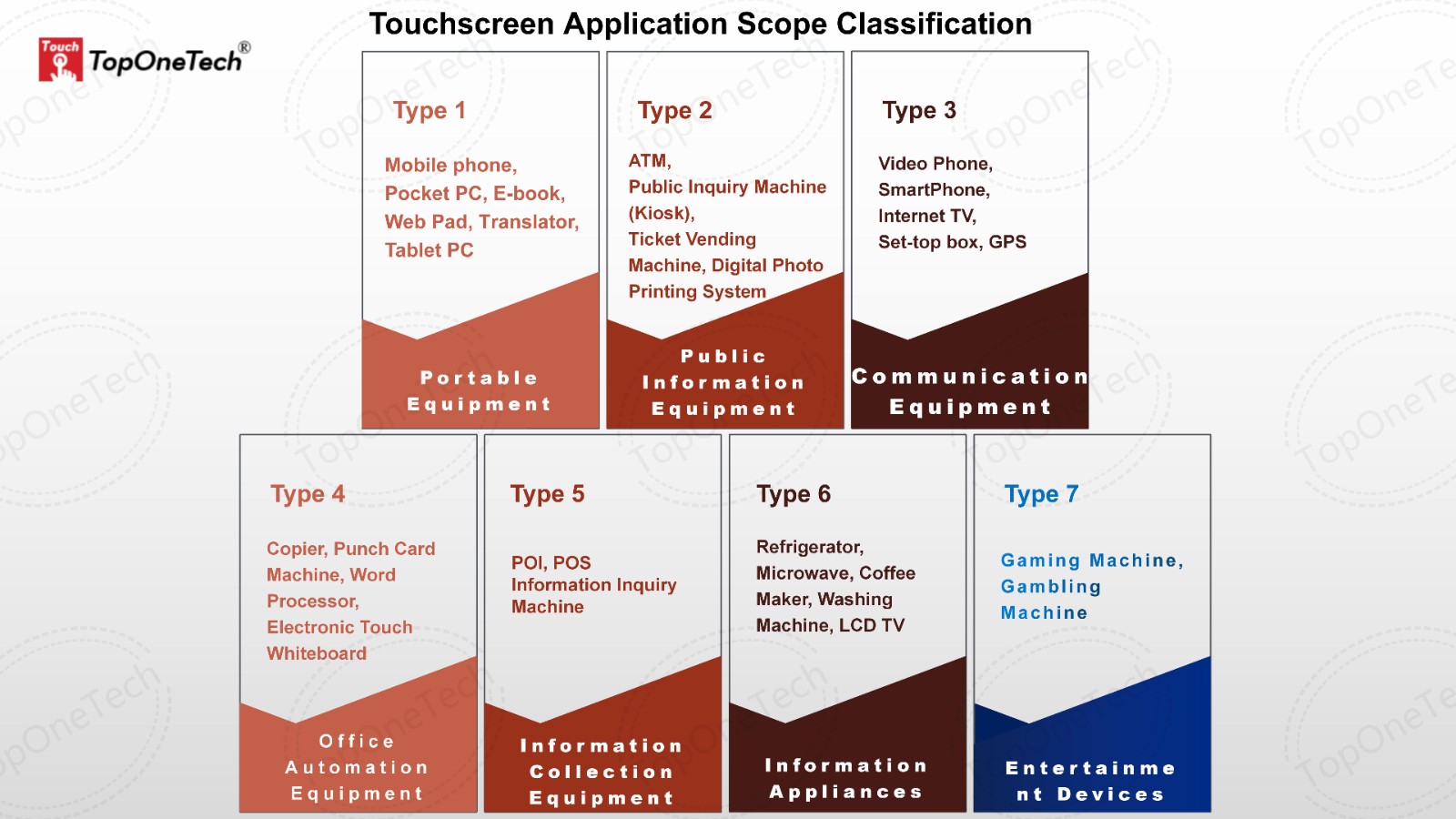

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

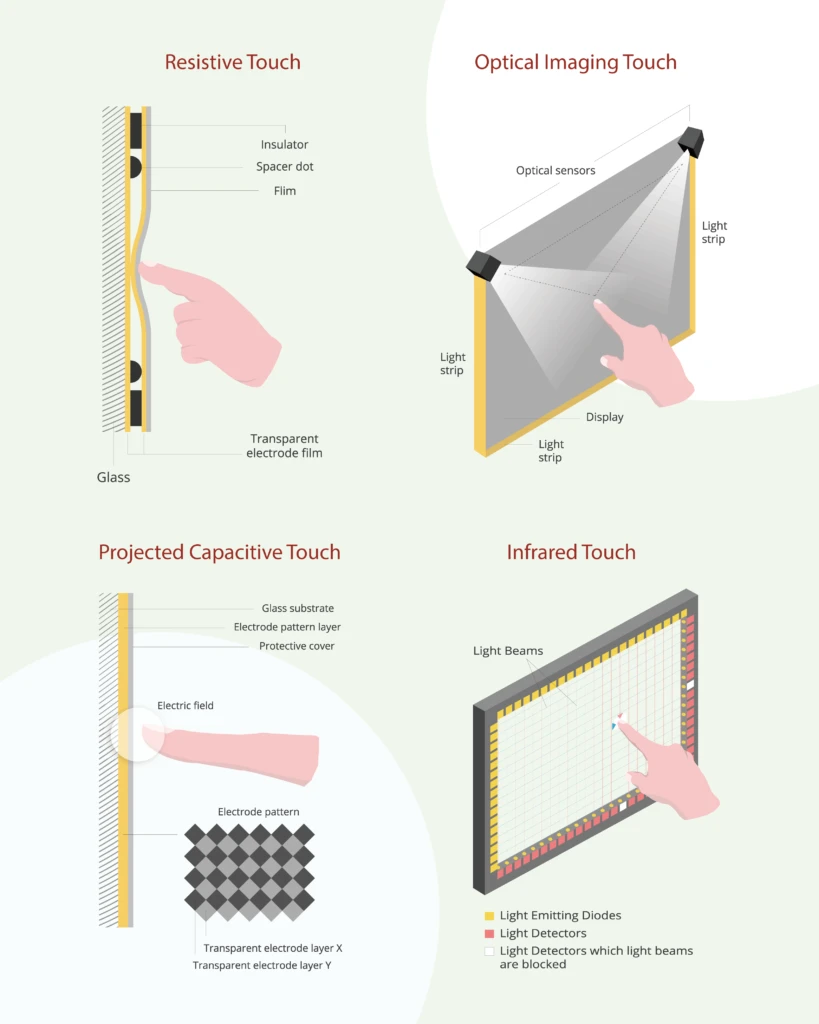

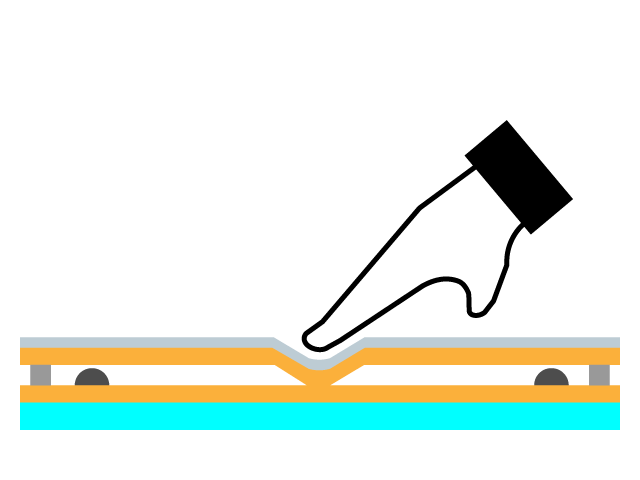

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

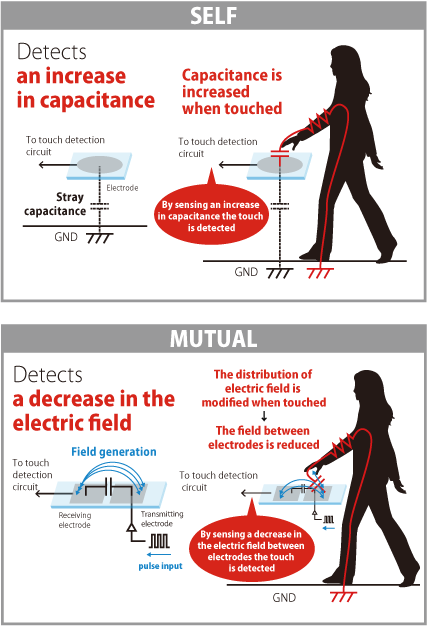

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Whether you want to interact with an application, browse the internet, scroll through galleries, utilise wayfinding maps, or access general information about a business – a touch screen monitor makes a convenient tool.

A touch screen monitor looks like a normal monitor, but responds to the touch of a finger or stylus. They provide faster response to the touch to perform a particular action. So, it is essentially a screen where users need to perform direct touch on the surface to enter data and send orders to the devices. Usually touch screen monitors have a really solid base so that the screen doesn’t wobble when touched. Well designed touch screen monitors intended for public use have a similar look and feel to a mobile phone screen so that the user understands that they are a touch screen and know that they can interact with them.

Resistive touch screens work on the basis of pressure being applied to the screen. A resistive touch screen has a glass panel, film screen, and a metallic layer. Once the user touches the screen, it results in an electrical flow.

Capacitive touchscreens work by sensing the conductive properties of an object, usually the skin on your fingertip, but also a stylus or other item. This is the leading technology today, used in most smart phones and is the technology that InTouch uses.

Surface capacitive touchscreens have a conductive coating on the front surface.Wires are attached to each corner, and a small voltage is applied to each of the corners. When the screen is touched, a small current flows to the touch point, causing a voltage drop.When a finger touches the monitor screen, the electrical charge transfers inside. They are only activated through the touch of human skin or stylus.

Touch screens that use surface capacitive technology are mostly obsolete now as they have been superseded by the far superior Projected Capacitive technology.

Surface Acoustic Wave (SAW)touch screen monitorswere popular some years ago, but have also largely been superseded by touch screens using Projected Capacitive technology. When you touch a touch screen that uses Surface Acoustic Wave (SAW) technology your finger interrupts the acoustic waves across a clear glass panel with a series of transducers and reflectors.

The panel is all glass, so there are no layers that can be worn, or damaged over time. This makes SAW touch screen technology highly durable and suitable for applications where high clarity is desired.

Infrared (IR) touchscreen devices support touch-based input just like any other touchscreen device, but these monitors identify touch by looking for interruptions in a uniform beam of light. They have a grid-like array of LED lights and photodetectors (sensors) around the edges of the screen. While invisible to the naked eye, these LEDs are constantly emitting and projecting light. When you touch the surface, it creates a disturbance in this light, and this is how the touch point is identified.

Extremely cheap to produce, especially in large sizes. (They are very scalable for larger sizes, as the light beam just goes further, and so are cost effective solutions for screens 65” and larger)

They must have a bezel for the LED lights, and these are relatively deep. See all the disadvantages of screens requiring bezels above. In our COVID new normal many customers are insisting on screens that are easy to clean and do not have bezels to attract dust and germs.

In most situations Projected Capacitive touch screens are the preferred technology. However, if you require a touch screen that is 65” or larger you may like to consider infrared technology.

With plenty of options on the market for touch screens and kiosks, working with a dedicated touch screen team will ensure you have the best outcome – talk to our Sales Team today for more information on our entire range 1300 557 219 oremail

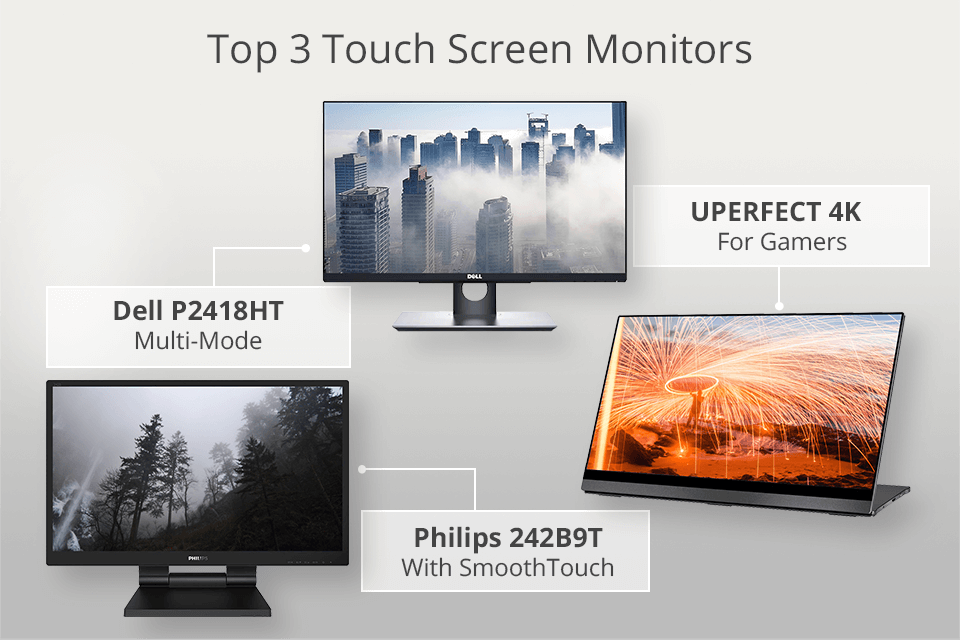

As with shopping for a conventional monitor, some core considerations include: resolution, price, size, and panel type. The resolution of a monitor will determine the how much detail it is able to display, and you should aim for a 1920 × 1080 monitor if your budget allows. You should also consider what type of panel technology a touch screen monitor uses, as it can affect color accuracy, response time, and viewing angles.

The most common panel technologies for touchscreen monitors are: twisted nematic (TN), vertical alignment (VA), and in-plane-switching (IPS). Twisted nematic (TN) is the most common LCD monitor panel technology due to its low cost but has narrower viewing angles and less color accuracy than other panel technologies. VA and IPS panels offer superior viewing angles and color accuracy, but are more expensive. If you expect that the touch screen monitor will be used by a single user looking at it straight on, then a TN panel will be just fine. However, if it is going to be constantly viewed from the sides then you will need to look for a VA or IPS display.

When shopping for a non-touchscreen monitor, the importance of the stand is often downplayed and the focus is more on the display. For touch screen monitors though, the stand plays a central role. Because users will be touching the monitor with varying amounts of force, the stand will need to be sturdy enough to hold the monitor in place. Also, it needs to offer a large amount of adjustability for customizable ergonomics.

Touch screens have become a very common part of our daily lives. Smartphones, handheld video games, car navigation systems, ticket vending machines, kiosks, bank ATMs, and more all use touch panels to enable users to interact with a computer or device without the use of a keyboard or mouse. Even though they are all touch screens, there are several uniquely different types of touch panels. The term touch panel incorporates varied technologies for sensing the touch of a finger or stylus. The most common types are resistive, surface capacitive, projected capacitive, surface acoustic wave, infrared optical imaging, and electromagnetic induction. This article will mainly focus on resistive, surface capacitive, and projected capacitive as these are the touch panels Acnodes Corporation primarily uses for the products.

A major factor influencing the widespread of touch panels is the benefit offered in the way of intuitive operation. They are easy to understand and easy to use even by people who are inexperienced with computers since they can be used for input through direct icons and buttons. Touch panels also contribute to miniaturizing and simplifying the devices by fusing display and input into a single piece of equipment. Since touch panels are software, not hardware, their interfaces can be easily changed through software. A touch panel requires a wide range of characteristics like precision in position sensing, rapid response to input, durability, installation costs, and most importantly display visibility, their characteristics vary significantly depending on the methods used to sense touch input. Below are the three common types of touch screens integrated into Acnodes" industrial monitors and displays.

The resistive film is the most widely used sensing method in the touch screen panel market. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers come into contact, resulting in electrical flow. The point of contact is detected by this change in voltage. The front surface is scratch-resistant with a coating of a conductive material.

The surface capacitive is the second most popular type of touch screen on the market. It is often used in relatively large panels. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel and covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body; some of the electrical charges transfer from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touchpoint. Capacitive touch screens can only be activated by the touch of human skin or stylus holding an electrical charge.

Projected capacitive touch panels are often used for smaller screen sizes than capacitive touch panels. Smartphones and handheld devices use this method to accomplish high-precision multi-touch functionality and high response speed. Projected capacitive is similar to surface capacitive, but it offers two primary advantages: in addition to bare fingers, it can also be activated with surgical gloves or thin cotton gloves and it enables multi-touch activation. A project capacitive is composed of a sheet of glass with embedded transparent electrode films and an IC chip, which creates a three-dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touchpoints.

- Surface Capacitive touch screens have a protective barrier to defend the screen from scratches and weakening. Even with the problems of spills, dents and abrasions, it sustains its maximum capabilities and maintains its functionality by remaining unaffected by demanding external environments.

- Secure Touch Surface Wave touch screens use exceptionally reliable and dependable glass for imitable picture and resolution quality. Made with all glass, this scratch resistant technology is suitable for environments with harsh conditions.

- AccuTouch technology qualifies as the most contaminant-resistant touch screen due to its ability to withstand and protect itself against moisture. Even under the toughest conditions such as including liquid spills, sprays, sprinkles, and splashes, this touch screen maintains its durability.

- CarrollTouch Infrared touchscreen uses a choice of glass or acrylic overlay for protection, making it the optimal option for environments with critical surroundings. Because this is the only technology that does not depend on a substrate, the touchscreen works flawlessly even when used with a gloved hand.

- Put together with pure glass, the IntelliTouch surface wave is state-of-the-art touchscreen technology making it the most scratch-resistant obtainable equipment out there. With its durable glass surface, it provides the utmost quality for image clarity, resolution, and light transmission.

Capacitive touch screens depend on our electric impulses for it to work. Depending on when and where touched, the human body sends signals to the screen. Capacitive touch screens cannot function if used with a stylus or a gloved hand, because of their reliance on the light touch of a finger. Surface Capacitive touch screens have a protective barrier to defend the screen from scratches and weakening. Even with the problems of spills, dents, and abrasions, it sustains its maximum capabilities and maintains its functionality by remaining unaffected by demanding external environments. Although this type of screen cannot function when using with a gloved hand, special application gloves with an embroidered patch of conductive threads are now available for more functionality. Most hand-held technologies use a capacitive touch screen because of its thin and more accurate sensor.

The Accutouch Five-Wire Resistive touchscreen is composed of a glass panel with a resistive overlay plus a cover sheet with a conductive layer. This technology is essential due to its proficiency in stability and long product life. These are primarily used on voting machines, office retail mechanization, and medical industrialization. This type of screen is made from three different sheets: conductive, resistive, & a protective layer which is why it is so durable. Resistive touch screens are very common because it is affordable and generally has a longer life. The most important layers include two electrically resistive layers, which form a gap between each other. The part we touch, the outermost part of the screen, is called the protection layer which protects the screen from scratches, water spills, and other types of damage.

The Secure Touch Surface Wave touch screen is made out of pure glass and has a scratch-resistant surface that can tolerate extreme physical wear and tear damage over time. This type of touch screen is used primarily in ATMs, amusement parks, kiosks, and banking applications. This screen has what’s called “X & Y axes” to convey and pick up piezoelectric transducers. This transducer device receives five-megahertz electrical signals which are modified into ultrasonic waves amidst the glass. When the screen is touched, a coordinate is calculated depending on how much of the signal is absorbed.

What is it and how does it work?The CorrollTouch is ideal for brutal industrial applications and used predominantly in the hospital setting. Because of its vandal resistance capabilities, it is physically impossible to weaken the touch screen, making it the top-notch touch screen technology thus far. The touch screen technology allows the display to become viewable under the brightest luminance, including direct sunlight. This high-tech technology uses photoreceptors and LEDs to create IR light beams touched and is able to perform flawlessly even under extreme temperatures from -20ºC to 70ºC (operating temperature) to -40ºC to 85ºC (storage temperature).

What is it and how does it work?The IntelliTouch Surface Wave touchscreen technology has a sensitive touch response that determines the location and amount of pressure applied and can be used with a gloved hand, stylus, or even a fingernail. It has a scratch-resistant surface, making it durable enough to withstand vandal environments while maintaining its functionality. This screen has what’s called “X & Y axes” to convey and pick up piezoelectric transducers. This transducer device receives five-megahertz electrical signals which are modified into ultrasonic waves amidst the glass. When the screen is touched, a coordinate is calculated depending on how much of the signal is absorbed.

Science fiction has always served as a window into a potential future, namely in the way of technology. But what was once regulated to episodes of Star Trek is quickly becoming the stuff of reality. Many fixtures of these kinds of shows and books have begun to inspire real-life counterparts, including - but not limited to - touchscreen technology.

One only has to look at how far cell phones have come since their inception. Physical keyboards, like those from BlackBerry, gave people about as much of a solution as is possible for those who found themselves doing more on the devices as they became more advanced. Where tactile options came up short, touchscreens graciously stepped up to bat, providing a much fuller experience. This kind of functionality then spread to tablets, which are considered by many to be rivals of laptops and even standard PCs.

While there are still some things that are best done on a desktop computer, that does not change the fact that many users find themselves longing for the same abilities on their PCs afforded by many of their mobile devices. This is what helped breed the touchscreen monitor market, which has many viable options for people seeking the best of both worlds. With stronger computing power and a finer ability to control actions occurring in the screen, users can get more work done in new and exciting ways.

Traditionally, computer mice are what have allowed us to "touch" in a virtual context, but touchscreen monitors are changing all that. It might be said that the reason that mice were used in the first place was because the technology had not evolved to a responsive enough level to enable that natural solution. Now that people have the touchscreen technology, they want it everywhere.

If one thing is for certain, it is that the burgeoning adoption of touchscreen technology is no fad. Proliferation has already come too far to turn back now, and computer manufacturers are taking notice. Everyone is trying to get a piece of the action, including ELO Touch Solutions, Laiputuo Electronics, Planar, HP, 3M, Touch Systems, ViewSonic, Dell and ACER as well. Getting into the touchscreen monitor game is a no-brainer for the companies involved in this generation of computing. With so many different applications made for touchscreen monitors, options exist for all sorts of interested parties.

Touchscreen monitors are becoming the new standard in both private and enterprise settings. Here are some of the ways they can be leveraged effectively for business: touchscreen monitors for workstations, touchscreen monitors for hospitals, and touchscreen monitors for POS systems.

Newegg offers a large selection of touchscreen monitors which vary according to the type from 5-wire Resistive touchscreen monitors, and Accu Touch touchscreen monitors, to Capacitive touchscreen monitors, and more. Newegg’s wide selections will definitely meet your needs.

You have probably interacted with a touchscreen monitor regularly in your daily activities. You may have seen them in ATMs, vending machines, computers, and more. The keyboard is no longer the best way to interact with your electronic devices. With just a finger tap, pinch, or swipe, you can navigate the pages of your device quickly and conveniently, making modern touchscreen monitors more reliable than the keyboard and the mouse.

However, if you’re not familiar with the industry, you may not know that there are different types of touchscreen monitors, and each has unique functions and benefits. But the question we seek to answer is; what are the top two types of touchscreen monitors? Learn more about the most commonly used types of touchscreen monitors from the experts at ACS Industrial Services.

A touchscreen monitor responds to the touch of a finger or a stylus and provides a faster response to act. A user should perform direct touch on the surface to enter data and send orders to the devices. Touchscreen monitors have a strong base to prevent the screen from wobbling when touched. Most touchscreen monitors have the same feel and look as mobile devices to help users understand how to interact with them.

The functionality of a 5-wire resistive touchscreen monitor depends on the pressure being applied to the screen. This is the most used touchscreen in industrial applications. It has a glass panel and a film screen separated by a thin metallic layer. Whenever a user touches this screen, the layers come into contact, creating an electrical flow that indicates the presence of a point of contact.

The capacitive touchscreen is the leading technology today, used in most smartphones and computers. They work by sensing the conductive properties of an object, usually the fingertip or stylus. Capacitive touchscreen monitors come in two types; projected capacitive touchscreen and surface capacitive touchscreen.

This is the second most prevalent touchscreen monitor type in the market. It has a glass panel below a transparent electrode layer that is under a protective screen.

While it’s similar to a surface capacitive touchscreen, the projected touchscreen can be operated even when the user has gloves on, making it ideal for use in many industries, such as the medical field. This touchscreen is more resistant to scratches, and it has a multi-touch function. The only disadvantages of a projected capacitive touchscreen are that it is expensive to produce and needs to form an electric circuit, so it must be configured for glove use.

Now that you know the top two types of touchscreen monitors, reach out to ACS Industrial Services for all your industrial electronic repair services. Our team of professionals will provide you with a free evaluation and repair quote.

A touchscreen monitor incorporates the function of the pointing device into the display, replacing both mouse and keyboard. Interaction with the computer takes place via a system which detects contact with the screen surface.

These devices are used for the control of industrial machinery or production lines. They provide the operator a comprehensive view of the needed data and controls.

Resistive screens are differentiated by the number of wires they have. The five-wire system compensates for their fragility, making them more durable and less prone to scratches and cracks.

Capacitive models respond to the transfer of electrical charges when touched, and cannot be used while wearing a glove. They are very bright, but have a fragile surface coating. Projected capacitive versions take advantage of the proximity transfer effect. Their surface is protected by reinforced glass.

Infrared technology uses light detection, the screen responding even before it is touched. However, it offers limited resolution and is prone to accidental activation. The most common type is the surface acoustic wave (SAW) screen. It responds to a wide variety of touch techniques, some screens even taking into account the amount of pressure applied. It is very bright and has excellent resolution.

In addition to size and resolution, choice of touchscreen will depend on the conditions under which it will be used and the possible need for multi-touch capability.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

Select from a wide selection of industrial touch and non-touch LCD displays. We offer many different types of Industrial LCDs, including VESA-capable, panel-mountable, and rackmountable displays with a wide variety of touch interface options.

Select from a wide selection of industrial touch and non-touch 12" LCD monitors. We offer many different types of Industrial LCDs, including VESA-capable, panel-mountable, and rackmountable displays with a wide variety of touch interface options.

When you are renting touch screen monitors, think about how and where you will be using them. You may find that you need to have more than just a single monitor running at the same time. In addition, consider the size and the placement of the monitors before you rent or lease them just to be sure they are adequate for your space. Also, consider the audio for the monitor. Many will have speakers, but you may need to connect a separate audio source, if you even need to have audio. Read our KWIPPED Tip on how to rent or lease a touch screen monitor by clicking here.

The main feature of the device is the screen, naturally. The screen should be high quality, providing the best possible picture. It should also be sensitive to touch so that it is easy to use. This is true no matter how large or small the screen might be. Often, the screen may also have a remote control, a stylus, and other features to help make it very easy to use.

Touch screens are found everywhere from our smartphones to self-serve kiosks at the airport. Given their many uses, it should come as no surprise that there are several touch monitor types. Each has its advantages and disadvantages and is suited to specific tasks.

That’s right. Long before your precious smartphone entered the market in the late 00s, touch panels had already been an established technology for nearly 4 decades.

It’s quite possible that you’re not clear on exactly what a touch panel is, what the touch panel types are, or how they’re applied in your daily life, beyond that of your smartphone. For that and more, we’re here to help.

Quite simply, touch panels, which are also known as touchscreens or touch monitors, are tools that allow people to operate computers through direct touch. More specifically, via the use of internal sensors, a user’s touch is detected, then translated, into an instructional command that parlays into visible function.

Delving deeper into the technical side of things, touch panels are not as cut-and-dry as they may seem. In fact, the way they sense and react to touch can widely differ based on their inherent designs. As such, there are 4 touch panel types in regular use – Resistive, Optical Imaging, Projected Capacitive, and Infrared. Below, we’ll dig into their specifics, which include their advantages, disadvantages, and real-life product applications.

Resistive touch panels are cost-effective variants that detect commands by way of pressure placed on the screen. This pressure sensitivity is generally limited to single-point touch, with a 20-inch maximum screen, which is fine for many usage cases. These range from styluses to fingertips. As a result, if used correctly, resistive touch panels will remain functional even if a water drop has landed on the screen.

As a result of this versatility, however, many will find that resistive touch panels are less durable than their competitors. Moreover, with its reliance on single-point touch, this touch panel type is not actually capable of multi-touch functionality. Regardless, resistive touch panels are often found in grocery stores, where stylus-based signatures are typically required after credit card purchases.

Some like it hot and some don’t. Infrared touch panels definitely fall into the latter category. By setting up a grid of infrared beams across the panel, which may be up to 150-inches, touch is detected by way of this panel’s disruption.

Although infrared touch panels are durable and support multi-touch functionality, it does possess one potential drawback. Depending on where you sit, literally.

Despite infrared implying heat, infrared touch panels actually perform rather poorly in it, particularly in direct sunlight. In those circumstances, the infrared light beams can be disrupted by the sun’s rays, as opposed to your fingers. As such, be sure to place your infrared touch panel device in an appropriately dark location.

Light, and the disruption thereof, is not just a great way to produce a shadow, but also to design a touch panel type. To take advantage of this principle, optical imaging touch panels are designed to sense touch through infrared cameras and the disruption of light strips. This can be achieved through any input you want, across its 100-inch maximum size, from gloves to bare hands, and beyond.

All in all, optical imaging touch panels are just about the most versatile option the touch-based world can offer. From durability to multi-touch, and universal input prospects, the possibilities may truly be endless. Although its only disadvantage may be its non-compact design, common applications of optical imaging touch panels include certain varieties of interactive whiteboards.

If you identify with the phrase, “go with what you know”, then projected capacitive touch panels are the touch panel type for you. For now, you can guess where you know it from.

By way of their electrical-based touch detection, Projected Capacitive touch panels are known for their high precision and high-speed response times. What’s more is that they possess multi-touch functionality and can be used within small, compact, yet expensive, devices. Due to their underlying technology, it has proven challenging to scale up to larger sizes. Figured it out yet?

Assuming you haven’t, or would like to enjoy the gratified feeling associated with being right, allow us to reveal where you interact with projected capacitive touch panels on a daily basis – Smart Phones! What’s more is that they’re not alone, with tablet computers and GPS devices also utilizing projected capacitive touch screens.

It would be a mistake to assume that the applications of all these touch panel types are limited to that of consumer-level devices, or even those that have been previously mentioned. Really, these touch panel types can be found throughout everyday life and in a variety of industries.

What’s more is that in many of these industries, these touch panel types are used less to market products to consumers, and more to sell solutions to businesses. Whether it be in regards to finance, manufacturing, retail, medicine, or education, there is always a need for touch-based solutions. In conjunction with the so-called ‘Internet-of-things’, these touch-based solutions play a key role in practices related to industry 4.0.

In practice, these solutions largely offer a form of personnel management. In hospitals, stores, or banks, for instance, these touch panel types can be used to answer basic questions, provide product information, or offer directions, based on the user’s needs. When it comes to manufacturing, on the other hand, these solutions enable employee management in the possible form of workplace allocation or attendance tracking.

At the end of the day, touch panels are here to stay. In the four decades since their inception, the level of adoption this technology has experienced is remarkable. They transform how we teach in classrooms and collaborate with colleagues.

Although you may not have been clear on the specific details of each touch panel type, we hope that you are now. This knowledge will absolutely serve you well, particularly if you’re interested in ViewSonic’s selection of touch-based solutions.

Touchscreens are popular, innovative technology applications found in various entertainment, communications, and customer service devices. Touchscreens control devices and use interfaces without the aid of instruments like physical mouse devices and keyboards. Touchscreen interaction works by either tactile digit or stylus pointing and gesturing. While the technology was heavily developed in the past two decades, touchscreens emerged in the 1940s.

Some touchscreen interaction methods require stylus use, while others can be operated by the human hand. These methods rely on different grid controls that pinpoint cursor location based on resistive touch, heat sensors, acoustic disturbance, and electric conductance. Because of certain ergonomic concerns related to user comfort and capabilities, there are general principles for designing and implementing touchscreen technology in specific non-mobile applications.

A resistive touchscreen involves an electrical current that is disrupted by touch from both inorganic and organic instruments. There are multiple layers around this current: two metallic layers, one conductive and one resistive, which are separated by a very small space through the current flows. The metallic layers are above a pane of glass, and below a scratch-resistant layer. When an instrument such as a stylus or a finger touches the top layer, the slight pressure causes the metallic layers to connect. The computer elements of the touchscreen device can then calculate the precise location of the current disruption, allowing interface operation.

Surface acoustic wave technologies transmit ultrasonic acoustic waves across a layer of reflectors. When a finger touches the screen, the waves are disrupted, and the computer can calculate the touch location. Surface acoustic wave is generally one of the crispest image quality touchscreen technology options because it does not use metallic parts and allows 100 percent light translucency.

Capacitive touchscreens incorporate electric charges beneath a charge-storing glass panel. When a conductive instrument touches the panel, the charge is directed by chips beneath the panel that determine the touch location. The screen can detect capacitance at more than one point at once, and it can follow a light touch as it moves. Capacitive touchscreens also provide good image clarity, because of the tendency to use glass parts with them.

In addition to touchscreen type, there are ergonomic concerns for touchscreen user consideration. Because touchscreens have become standard features of mobile devices, arm strain is not typically a concern, but when applying touchscreen functionality to a mounted device, it can cause problems. Mouse and keyboard use for a typical desktop or laptop computer relies on the user’s arms being horizontal on the table, but a touchscreen requires the user to extend his or her arms and hold them aloft for longer periods. This can cause strain and exhaustion, and result in the user choosing a different device.

Additionally, touchscreens rely on various types of physical input. Because capacitive touchscreens operate via conductive touch, typically a user’s fingers, the screen can be dirtied by fingerprints. Most capacitive touchscreens have incorporated oleophobic coatings, which are chemicals that resist adherence to oils, specifically oils common on human skin. For other types of touchscreens that rely on a stylus or other inanimate tool for interaction, it is necessary to find scratch-resistant glass or coating for the upper layer of the device, to prevent dents and discoloration on the touchscreen.

Touchscreen devices are common on portable devices, such as cellular telephones, digital music devices, and handheld organizers, some of which are intended for use in rugged environments. Touchscreens rely on sensitive working properties, so an extreme environment can have adverse effects on their behavior and performance. For example, touchscreens intended for cold environments should probably not be capacitive, because a user will probably be wearing protective gloves and will not be able to properly physically contact the screen.

This article presented an understanding of the different types of touchscreens. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

The built-in pixels are perfect to fit your business needs. Start buying from small touchscreen monitors now on Alibaba.com and start buying small touchscreen monitors now.

Contact a supplier of Alibaba.com to provide the customers with a great variety of touch screen monitors and start buying from USD3.00 per unit. Check out the wide and of the computer monitors available at wholesale prices on Alibaba.com today. Don ’ t miss the chance to buy a computer monitors for your customers now.

Most touch screen displays provide easy-to-use displays and are a for way to display branded products. They also provide textility, a range of touch colors monitors with the functions of a machine, for for, or for retail use. touch screen displays provide textility, range of colors, sizes, and styles.

touch screen monitors are a great option for displaying large screens. Wholesalers on Alibaba.com offer a wide variety of touch screen monitors for commercial and industrial purposes. touch panel monitors are available in a wide range of colors, sizes, and styles to match the customers" needs.

You do not need to calibrate the image projector before lecturing; with LED lighting technology, IFPDs provide a clear image all the way; and thanks to the IR touchscreen, you can annotate your presentation with almost anything, a dry/wet finger, pen, or stylus.

Commonly, the overlay is a piece of protective glass hemmed in by the IR touch frame, in which Infrared LEDs and photodetectors are embedded. A kind of optical bezel will be inserted between the glass and the frame to fix the frame and transmit infrared light emitted by those LEDs.

Through the optical bezel, IR LEDs emit invisible infrared beams forming grids on the surface of the overlay, Photodetectors are installed across from the LEDs to detect interruptions of beams if touch events on the overlay happen.

There are two rows of IR LEDs, which generate horizontal and vertical invisible IR beams. They form a large beam grid that covers the surface of the overlay. In the meantime, two rows of photoreceptors are installed on the opposite side of the LEDs.

As long as an opaque object touches the surface, it will blot out the light beams. Photoreceptors in both directions (vertical and horizontal) can detect this interruption by that object, finally localize the x and y coordinates, and then send the signal to the processor to respond with relevant action.

To know more details of its structure and workings, you’d better walk into a workshop to learn its assemble process. Most of the time, we do not have that chance, however, regular maintenance work offers you the opportunity to check its components inside.

Better display – without other substance between the LCD and overlay, IR touch screens offer the best light transmission, so they can render more vivid images without color and brightness loss.

Supports multi-touch – with windows and android 9.0 double OS, it can support as many as 40 touchpoints simultaneously. That means it can support up to 4 students interacting together on an IFPD.

Short response time – commonly less than 8ms, IR touch screens localized touch events by detecting light interruption, so they are accurate and quick to respond with actions.

More flexible in customizing screen sizes – by adjusting the numbers of LEDs and photodetectors embedded in the overlay frame, you can fit any custom-made monitor with an infrared touch interface

Clear images – compared with many camera or projector-based systems, equipment with IR touch screens often adopts backlight LED. So, wherever lighting environment they perform in, they can provide clear images to the audience.

No loss of screen display– Since LEDs and sensors are designed to be fixed in the frame that is around the monitor, the screen can display an unrestricted view.

Write with any object – you can write on an IR touch screen with anything, a bare finger, a gloved finger, wet hands, or a pen, as long as it is not transparent.

No calibration – a traditional smart projector board may require regular calibration to display correct pictures, however, devices with IR touchscreen do not need to calibrate the IR LEDs and sensors to guarantee a normal function.

No pressure is required to write – Resistive touch screen technology perceives the writing track by pressure, which can damage the screen after a long time of usage, while IR touch screen technology by detecting light interruption, so you can write freely without having to push hard on the screen.

Of touch screen technologies, infrared and projected capacitive are the top two types that are mostly utilized. However, they are applied to different applications due to the differences between them.

For PCAP touch screens, There is a layer of transparent electrode film that is fixed between the LCD panel and the cover glass, when the human finger touches the screen, the current through that film changes, and the signal of x and y position will be transferred to the computer.

For IR touch screens, the equipment detects the finger’s position by detecting the block of invisible lights from the infrared LEDs that are embedded in the touchscreen frames.

So you will often see a bezel in the IR touchscreen, which is used to transfer the infrared light to the surface of the overlay, while the PCAP touchscreen does not require the bezels.

IR touchscreen can be activated by anything that is not transparent, whereas PCAP types only accept bare fingers, thin surgical gloves, or cotton gloves.

The electrode film in PCAP touchscreens is expensive, especially when it comes to large screens, but for IR ones, when it is applied to large-scale screens, you only need to add a few LEDs and correspondent detectors, apparently, the IR touchscreen solution is more cost-effective in large interactive displays, such as the interactive digital board, which are used for presentation in business meetings.

The TSItouch Glass Retention Bezel System (GRBS)* provides an alternative solution to bonding cover glass. The GRBS is a cost effective, serviceable, and modular solution that allows protective glass (clear, anti-reflective, and anti-glare) to be mounted directly to each display, providing protection to the OEM bezel and displays’ panel. In the event of a monitor failure, the GRBS can be removed, avoiding any issues associated with servicing a bonded display.

The owner of this website (www.beetronics.com) has banned the autonomous system number (ASN) your IP address is in (20473) from accessing this website.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey