stn vs tft display manufacturer

First, what is the LCD junior physics to learn the material has three states: solid, liquid and gaseous. The following LCD screen manufacturers tell about the difference between STN LCD and TFT LCD. In fact, the so-called three-state is only a general distinction, some of the solid matter can be subdivided into different states of the state. Similarly, the liquid can also have a different "state", where the molecular arrangement of the direction of the liquid we call it "liquid crystal", referred to as "liquid crystal". Ordinary solid crystals have directionality, so many of their physical properties also have directionality. Liquid crystals have a general crystal in the direction of the same time with the liquid flow. If you want to change the direction of the solid crystal must rotate the entire crystal, and the liquid crystal is different, and its direction can be controlled by the electric field or magnetic field. Both STN and TFT use a so-called "nematic" liquid crystal (Nematic), it is filamentous, the use of electric field to control the "filament" liquid crystal direction is the application of commonly used method. Liquid crystals are usually made of liquid crystal in two pieces of glass. The surface of the glass is coated with a layer of substances called the agent, by its type and treatment methods can be controlled in the absence of external electric field when the liquid crystal arrangement. Second, STN LCD principle The world"s first liquid crystal display appeared in the early seventies, known as the TN-type liquid crystal display (Twisted Nematic, twisted nematic). In the 1980s, the STN type liquid crystal display (Super Twisted Nematic) appeared, while the TFT liquid crystal display (Thin Film Transistor) technology was proposed. We first talk about the principle of TN-type LCD, STN LCD and TN LCD display the same principle, but the distortion of the liquid crystal molecules are different. The nematic liquid crystal is sandwiched between two pieces of glass, and the surface of the glass is first plated with a transparent and electrically conductive film for the electrode, and then plated with a surface alignment agent on the glass with the film electrode so that the liquid crystal A specific and parallel to the direction of the glass surface. The natural state of the liquid crystal has a twist of 90 degrees, the use of electric field can make liquid crystal rotation, the refraction coefficient of liquid crystal with the direction of the liquid crystal changes, the result is light after TN type LCD polarized polarity changes. As long as the appropriate thickness is chosen so that the polarity of the light changes just 90 °, two parallel polarizers can be used so that the light can not pass at all. And a large enough voltage can make the liquid crystal direction parallel to the direction of the electric field, so that the polarity of the light will not change, the light can pass through the second polarizer. So, you can control the light of the light and dark. As mentioned earlier, STN-type liquid crystal and TN-type liquid crystal display the same principle, but it will be incident light rotation 180 ~ 270 degrees, rather than 90 degrees. Moreover, the simple TN-type liquid crystal display itself only two changes in light and shade. While the STN LCD is light green and orange-based. However, if the traditional monochrome STN LCD display with a color filter, and the monochrome display matrix for each pixel is divided into three sub-pixels, respectively, through the color filter display red, green and blue primary colors, you can display Out of color.

Due to the principle of TN and STN type liquid crystal display, if the display part of it is bigger and bigger, then the central part of the electrode reaction time may be longer. In fact, this is not a big problem for the phone, because the current mobile phone display are relatively small, the impact of liquid crystal reaction time is relatively small. But for notebooks and other equipment need large-screen LCD display, too slow LCD reaction time will seriously affect the display, so TFT LCD technology has aroused the attention of manufacturers. In addition, the color screen in the application of more and more mobile phones in a new generation of products are supported 65536 color display, and some even support 16 million color display, when the TFT"s high contrast, rich color advantage even more important The

LCD screen manufacturers STN LCD is a reflective LCD device, its advantage is small power consumption, but in a dark environment, poor resolution, so have to be equipped with external lighting. The TFT LCD with "back through" and "reflection" in combination, in the back of the LCD set a special light pipe. This is why we see some mobile phone next to the screen seems to have "lights", and some of the phone"s light is like the screen itself issued a reason. Moreover, the LCD screen manufacturers of liquid crystal display backlight technology is also constantly progress, from monochrome to color, from thick to thin, from the side of the fluorescent lamp to flat fluorescent lamp.

By the way, the reflective LCD device has black and white characters (NB) and black and white (NN) two, recently we see the V70 display is belonging to the NB type, of course, this is certainly the integration of the latest technology Enhanced NB. Well, we still get down to business, continue to TFT LCD display principle. TFT liquid crystal display technology using the "active matrix" approach to drive. Method is the use of thin film technology made of the transistor electrode, the use of scanning method "initiative" to control any one of the display points on and off. Light source when exposed through the lower polarizing plate up through the liquid crystal molecules through the light. When the electrodes are turned on, the liquid crystal molecules change like the TN liquid crystal arrangement, and also through the shading and light transmission to achieve the purpose of the display. Sounds like this and TN-type LCD display principle is almost, indeed so. But the difference is that since the FET transistor has a capacitive effect, it is possible to maintain the potential state, and the liquid crystal molecules that have been transmitted will remain in this state until the FET electrode is energized again to change its arrangement. And TN-type liquid crystal does not have this feature, liquid crystal molecules once the electric field, immediately return to the original state, which is TFT LCD and TN liquid crystal display the principle of the biggest difference.

TFT LCD for each pixel are equipped with a semiconductor switch, the processing technology is similar to large-scale integrated circuits. Because each pixel can be directly controlled by the point pulse, therefore, each node is relatively independent, and can be continuous control, this design not only improves the reaction speed of the display, and can accurately control the display gray, so TFT LCD The color is more realistic.

means Twisted Nematic Liquid Crystal Display. It is the first commercial success LCD technology which is still widely used in low cost and low power consumption applications. Of course, we mean it passive TN LCDs.

If TN technology combined with TFT (Thin Film Transistor), it becomes active matrix display which is widely available for full color display market. Because the name of TN is very technical, when we hear TFT display which we know it is for short of TN type TFT LCD displays. How TN display technology works, showing in Fig.1.

STN LCD means Super Twist Nematic Liquid Crystal Display. TN LCD displays have the advantage of low cost and low power consumption, but it also has its intrinsic disadvantages, such as narrow viewing angle, poor contrast and limit to be used in high multiplex (duty) application.

They can only be used for some alphanumeric displays. Scientists and engineers invented STN LCD to overcome the limitation of TN LCD to make high duty graphic LCD display possible.

Compared with TN LCD’s 90otwist degree, STN LCD increases the twist to 180oto 270o. With this change, STN display’s electro-optical performance changes greatly. See Fig. 2.

Japanese scientists and engineers used a layer of retardation film to compensate the color to make STN color changing to Black and White. Monochrome black and white FSTN makes CSTN (Color STN) possible.

Compared with TN displays, FSTN displays have much higher contrast and wider viewing angles. But FSTN technology are only limited to passive matrix application. They can’t be used together with TFT technology like TN technology to become active matrix displays.

As FSTN LCDs can be made high density together with COG (Chip on Glass) technology, the FSTN display modules can be made high compact to make thin and light possible.

Slower response time because of larger twist angles. The normal operating temperature range is -20oC to +70oC. The color is also changed with temperature, the improvement way is to use DSTN (double STN cells) which can compensate for the color changes and achieve high contrast ratio at low and high temperature.

The same as other LCDs, FSTN LCDs can’t emit the light themselves. They have to assembled with backlight to make them LCD display modules to be able to use in applications. But backlight will drive a lot of power.

– Liquid crystal material: Both use nematic LC materials but FSTN fluid has more cholesteric doping materials in it in order to help its molecular to twist higher degree.

– Viewing Angle: FSTN LCD has much better wide viewing angle than TN LCD especially at higher multiplexing application. TN LCD has a weak viewing direction, that is the reason we have to define 6 or 12 o’clock viewing angle. But FSTN LCD can be viewed clearly from all the viewing directions.

– Response time: Between FSTN LCD has higher twist angle, it takes more time to make a change. It has longer response time or slower response speed than TN LCD.

– Operation Temperature Range: Because of extremely slow response and background color change for FSTN LCDs at low temperature, FSTN LCDs can only be used within -20oC to +70oC, but TN LCDs can be used with -40oC to +90oC which can be easily used for outdoor applications. FSTN LCD response speed in extremely cold environment can be improved by adding a heater. FSTN LCD color change at low and high temperature can be solved by adding a reversed optical compensation cell as DSTN (Double STN), but the cost will be more than double.

– Power Consumption: Theoretically, FSTN and TN LCDs should consume the same level of power. But FSTN LCDs are normally used for high multiplex application, they use higher frequency drive and their LCD controllers and drivers normally consume more power than TN LCDs. While in general opinions, TN uses much less power than STN or FSTN LCD displays.

– Assembly (Display Module): Because most of TN displays have fewer contacts, it can use pins, zebra, FPC (Flex Printed Circuit) to make the connections. When assembled in the LCD modules, normally COB (Chip on Board) is used. While FSTN displays have more contacts, high density and more reliable assembly ways have to be used. COG (Chip on Glass) excels because of its low cost and compatible for high volume production.

– Sunlight Readable: It is a big advantage for both TN and FSTN LCD. By applying a reflective or transflective polarizer at the back of the LCD, the high contrast display can be achieved under sunlight.

This type of LCD was invented at the Brown Boveri Research Center, Baden, Switzerland, in 1983.twisted nematic (TN) LCDs with a 90 degrees twisted structure of the molecules have a contrast vs. voltage characteristic unfavorable for passive-matrix addressing as there is no distinct threshold voltage. STN displays, with the molecules twisted from 180 to 270 degrees, have superior characteristics.

The main advantage of STN LCDs is their more pronounced electro-optical threshold allowing for passive-matrix addressing with many more lines and columns. For the first time, a prototype STN matrix display with 540x270 pixels was made by Brown Boveri (today ABB) in 1984, which was considered a breakthrough for the industry.

STN LCDs require less power and are less expensive to manufacture than TFT LCDs, another popular type of LCD that has largely superseded STN for mainstream laptops. STN displays typically suffer from lower image quality and slower response time than TFT displays. However, STN LCDs can be made purely reflective for viewing under direct sunlight. STN displays are used in some inexpensive mobile phones and informational screens of some digital products. In the early 1990s, they had been used in some portable computers such as Amstrad"s PPC512 and PPC640, and in Nintendo"s Game Boy.

CSTN (color super-twist nematic) is a color form for electronic display screens originally developed by Sharp Electronics. The CSTN uses red, green and blue filters to display color. The original CSTN displays developed in the early 1990s suffered from slow response times and ghosting (where text or graphic changes are blurred because the pixels cannot turn off and on fast enough). Recent advances in the technology, however, have made CSTN a viable alternative to active matrix displays. New CSTN displays offer 100ms response times (for comparison TFT displays offer 8ms or less), a 140 degree viewing angle and high-quality color rivaling TFT displays – all at about half the cost. A newer passive-matrix technology called High-Performance Addressing (HPA) offers even better response times and contrast than CSTN.

Samsung had two proprietary technologies for STN LCDs, Ultra Fine & Bright (UFB), which delivered wide viewing angle (about 120 degrees), faster response time (about 60 ms) and less power consumption, while Ultra Fine & High Speed (UFS), delivered almost same color depths as TFT LCDs, greater color purity, much faster response time (about 14 ms) and same contrast ratio as TFT LCDs.

Dual Scan STN: An enhanced STN passive matrix LCD. The screen is divided into halves, and each half is scanned simultaneously, thereby doubling the number of lines refreshed per second and providing a sharper appearance. DSTN was widely used on earlier laptops. See STN and LCD.

FSTN: Film compensated STN, Formulated STN or Filtered STN. A passive matrix LCD technology that uses a film compensating layer between the STN display and rear polarizer for added sharpness and contrast. It was used in laptops before the DSTN method became popular and many early 21st Century cellphones.

CCSTN: Color Coded Super Twist Nematic. An LCD capable of displaying a limited range of colours, used in some digital organisers and graphic calculators in the 1990s

Scheffer, T. J.; Nehring, J. (1984-11-15). "A new, highly multiplexable liquid crystal display". Applied Physics Letters. AIP Publishing. 45 (10): 1021–1023. Bibcode:1984ApPhL..45.1021S. doi:10.1063/1.95048. ISSN 0003-6951.

From their discovery in 1888 to their first application within displays in the 1960s, liquid crystals have become a mainstream material choice with many impactful applications in the world of electronics.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

TFTs can be formed by amorphous silicon (denoted α-Si TFT), by poly-crystalline silicon (LTPS for Low Temperature Poly Silicon), or by semiconducting metal oxides (Ox-TFT or IGZO-TFT for Indium Gallium Zinc Oxide).

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

The above display technologies have liquid crystal molecules that are aligned nearly parallel to the display surface with more or less twisting when going from one substrate to the other. In VA (also called VAN) displays, the liquid crystal molecules are aligned vertically with respect to the display surface. Applying a voltage causes the molecules to lay flat, with or without twist.

The advantage of this arrangement is a very dark black state with very little light leakage. This allows making displays with a black mask and colored icons or symbols. These displays look like color displays with brilliant colors, however each image element or icon can only have its assigned color or black.

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Here, each color sub-pixel is further divided into zones (called domains) having a different direction of the molecular movement when voltage is applied. Again, the purpose is a much wider and more symmetric viewing performance and the elimination of color shifts and contrast inversion at shallow angles. MVA technology achieves that with carefully designed protrusions on the inside surfaces of the display, while PVA uses fine patterning of the electrodes on both substrates.

The integrated circuit is a patterned piece of silicon or other type of semiconducting material. A modern IC contains millions or even billions of tiny transistors. Their tiny size allows for the fabrication of smaller, faster, more efficient, and less expensive electronic circuits. The driver chips addressing electronics displays are ICs.

Often PCBAs are connected to the display with flexible printed circuits. It’s also possible to mount all necessary components on FPCs without the need of a PCBA in the display module.

Low Voltage Differential Signaling (LVDS) is an interface to the display, not a display technology itself. This technology is not specific to displays, as it’s used in many other applications as well. It’s a high-speed signal that provides some noise immunity for the display. It also allows for longer distances compared to parallel interfaces.

As display resolutions increase, data transmission rates must increase as well. At high frequencies, single-ended signaling circuits can begin to act as antennas to radiate and receive radiated noise. Low Voltage Differential Signaling (LVDS) addresses many of these shortcomings by using differential signaling at low voltages to transmit display data at high speeds.

Mobile Industry Processor Interface (MIPI®) is a high-speed Display Serial Interface (DSI) between the host processor and the display module. It has a low pin count, high bandwidth, and low Electro Magnetic Interference (EMI), and is commonly used in cameras, cell phones and tablets.

New Vision Display (NVD) has decades of experience designing and manufacturing custom display and touch panel assemblies for some of the world’s largest original equipment manufacturers (OEMs) in the automotive, medical, industrial, and consumer markets.

NVD’s state-of-the-art factories are equipped to build solutions using a wide range of display and touch technologies. To view our extensive portfolio, visit our Products Page.

With industry-leading certifications and expert engineers on staff, NVD can handle your design needs, even for the most rigorous and complex end environments. To learn more about what makes us the display manufacturer for your needs, contact us today.

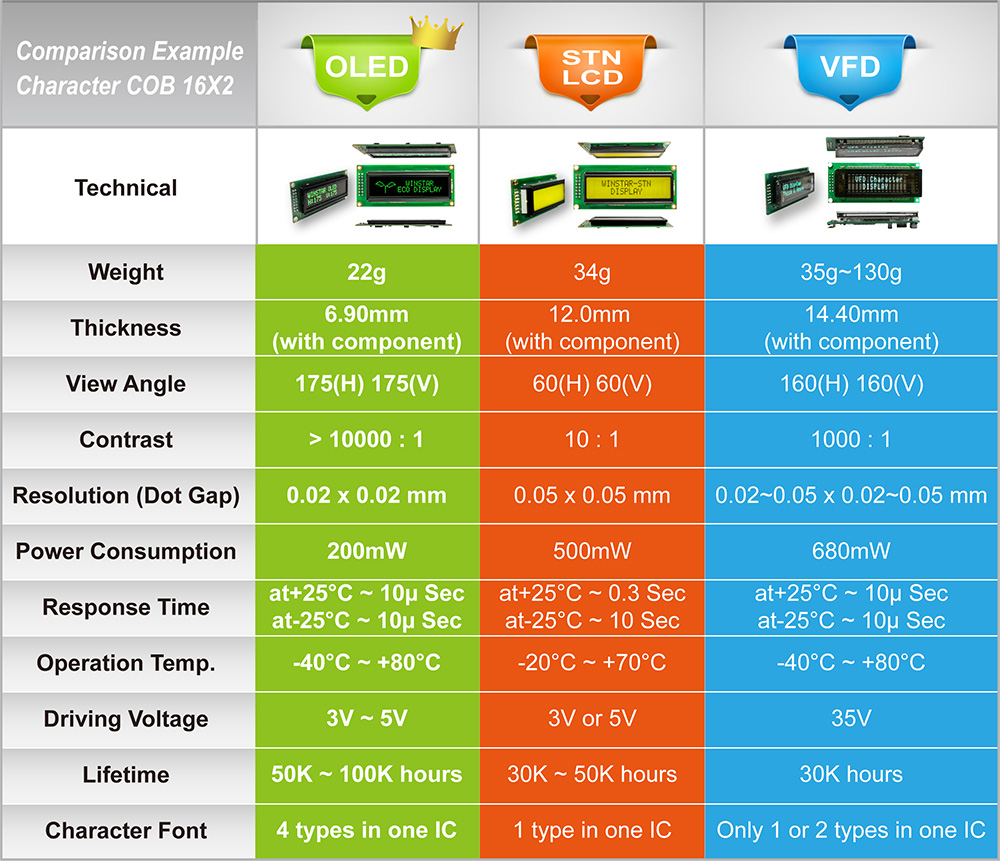

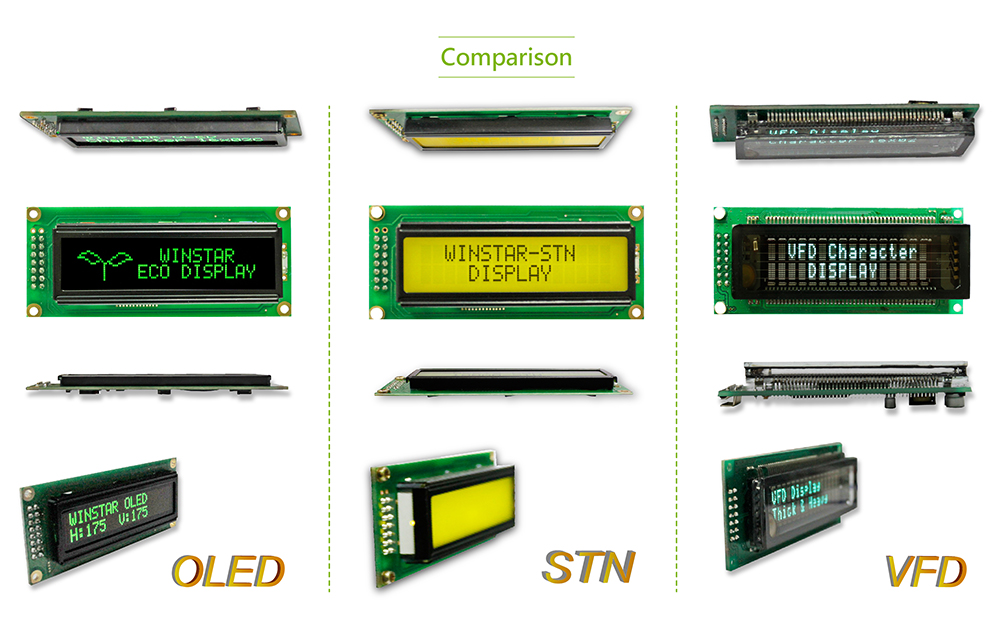

OLED (Organic Light Emitting Diode) has a far higher resolution with a faster response time, a wider viewing angle, superior brightness, thin, light weight and contrast in comparison with LCD (Liquid Crystal Display) and VFD (Vacuum Fluorescent Display).

The following table is the comparison of OLED/STN LCD/VFD displays. We used a character 16x2 COB structure module as an example. Welcome to explore the advantages of OLED displays, and you would find OLED display is not a choice but a necessity to your applications.

OLED"s emitting area is the entire front surface, it has the widest viewing angle because it does not need a backlight attachment like STN LCD displays. As to the VFD Display, the display surface is placed in a deeper position, the sealing frames and the grid frames make the viewing angles smaller.

Comparing with conventional STN LCD displays, OLEDs featured with wider operation temperature range -40 ℃ ~ 80 ℃. The nature of OLED technology is self-luminous; the OLED displays still can work at rugged environment. It is very obvious especially at lower operation temperature; the OLED display works excellent. Some STN LCD modules could be workable at lower temperature or with heater on LCD module, but the response time at lower temperature will be longer than normal temperature since the liquid crystal has been frozen.

A significant advantage of OLED displays over traditional liquid crystal displays (LCDs) is that OLEDs do not require a backlight to function, OLED is self emitting. OLED layers are applied directly to the surface of the glass substrate and this allows the display area to be extended to the edge of the glass substrate, which requires no backlight and make the displays very thin.

VFD display is self-luminous as well, but VFD needs the mechanical parts mounted around the display frame. VFD needs thick, strong sealing glasses for vacuum encapsulation which makes the VFD very thick.

OLED uses only the power needed to display what is displayed. The power consumption changes depending on each lighting ratio. The STN-LCD display usually requests a backlight such as LED which requests power to turn on LEDs. The VFD needs two power supplies for the pixel display and the filament. The filament power makes up a large percentage and is constant, regardless of the pixels displayed.

OLED layers are applied directly to the surface of the glass substrate and OLED using a high precision mask which allows OLED to produce high resolution display; its dot gap can lower to 0.02x0.02mm. As to VFD, it requires mechanical parts to produce emitting device. The mechanical parts for VFD require is very strict. The precision of VFD emitting mechanical parts is limited and that requires dot gap is 0.05x0.05mm.

Dr Pan: Hello, Greg. STN is the abbreviation for Super Twisted Nematic. The main difference between TN, HTN, STN and FSTN LCD is the view angle. From the definition, the maximum view angle of STN LCD is 210~255 degree. Take this STN positive LCD for example. The view angle is 12 o’clock direction and it can be seen very clearly in the full view angle: 12 o’clock direction, 3 o’clock direction, 6 o’clock direction, 9 o’clock direction and the front side.

When it is a positive and reflective display, it can display without LED backlight; when it is a positive and transmissive/ transflective display, it can’t display without LED backlight, we have two options for the background color: grey background and blue letters, yellow-green background and black/blue letters.

When it is a negative and transmissive/ transflective display, it can’t display without LED backlight, the background is blue and the color of the letters is the color of LED backlight.

By the way, no matter it is a positive or negative display, the background color is affected by the color of LED backlight on some level. That is why the color of LED backlight is usually white.

It seems there will always be a LCD manufacture on their way to bankruptcy. As is true in any industry, there will always be someone who has a lower price for a LCD display custom solution. Lower price does not necessarily equate to lower cost.

Liquid crystal display technology changes at a very rapid pace and requires an LCD company who deals with LCDs and LCDs only. Would you service your new car at a repair shop that also buys gold and sells low cost health insurance? You get what you pay for.

When designing your custom LCD make sure the LCD supplier knows the difference between STN and FSTN, or the advantages and disadvantages of EL backlight versus a LED backlight. Is this LCD supplier knowledgeable about the different LCD technologies available today. Do they know the pros and cons of each technology? Can they help you select the best LCD technology for your product taking into consideration the power source, environment exposure, best viewing angle of the display used in your product?

Focus Display Solutions (aka FocusLCDs) has been in business for 19 years. We deal strictly with LCDs and we know the industry and our product. We are also ISO 9001 certified.

Yes, you will save money if everything goes perfect. If you don’t mind making phones calls to the factory at 2am to resolve issues that come up; and you accept that many times off-shore LCD suppliers will modify your LCD display without notifying you.

If you are a company that purchases several different LCD’s a year and have a strong engineering department, you could realize a cost savings. On the other hand, if this is an ‘experiment’ and you need to get to market on time, your sample displays must match production displays; you may want to take a pass. If your LCD display is a low cost segment LCD and things go wrong, you may only be out a few thousand dollars, but if you need a larger color TFT display when things hiccup, your loss is increased to several thousand dollars.

Liquid Crystal LCD Display technology changes at a very rapid pace and requires an LCD company who deals with LCDs and LCDs only. Would you service your new car at a repair shop that also buys gold and low cost health insurance? You get what you pay for.

When designing your custom LCD make sure the supplier knows the difference between STN and FSTN, or the advantages and disadvantages of EL backlight versus a LED.

.jpg)

Established in 2007, Raystar has built its reputation by offering advanced products in PMOLED display and modules as well as in FSTN / STN LCD Display Module, COG LCD, TFT LCD Display.

Every valued customer of Raystar plays a key role in our current success. We promise to keep growing as your most trustworthy partner for display solutions in the decades ahead.

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for Stn Lcd Display, Digital Tft Lcd, Lcd Panel And Controller, Tft In Display,Round Tft Lcd Display. "Quality 1st, Rate least expensive, Provider best" is definitely the spirit of our company. We sincerely welcome you to go to our business and negotiate mutual small business! The product will supply to all over the world, such as Europe, America, Australia,Saudi Arabia, British,Sri Lanka, Argentina.As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

_2.jpg)

Sinocrystal is a high-tech Manufacturer mainly provides clients with the service of designing liquid crystal display(LCD), liquid crystal display module(LCM) & OLED Display, and is committed to the customized service, R&D, sales, after-sales service of display products. We have full Line of LCD Products include standard and customized TFT LCD modules, Touch screen display, segment (alphanumeric) displays, dot matrix character displays, graphic displays and OLED displays. We provide a large range of LCDs with different sizes from 0.39"" ~ 10.1"", and we can also provide different LCD types including TN, HTN, STN, FSTN, DFSTN.

Newhaven 16x2 character Liquid Crystal Display shows characters with white pixels on a blue background when powered on. This transmissive LCD Display requires a backlight for visibility while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0216SZ-NSW-BBW display has an optimal view of 6:00. This display operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

It iscommonlyknown that the LCD itself can generate noise in 3D barrier applications. This noise disturbs consumers. Many LCD makers solve this problem with an expensive technology during TFT-LCD manufacturing. Unicorn has invented and patented a special technology toeliminatesuch noise.This technology canbe carriedout during normal passive LCD manufacturing processes, thus offering a competitive cost to the customers.

Unicorn has installed an advanced and automated Japanese-made optical bonding machine, which has been used widely in world-class tablet and smart phone assembly. This liquid-type optical bonding machine can be used to perform all kinds of lamination between front cover, capacitive touch panel and displays for size up to 13″ and on non-flat surface.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey