lcd display software factory

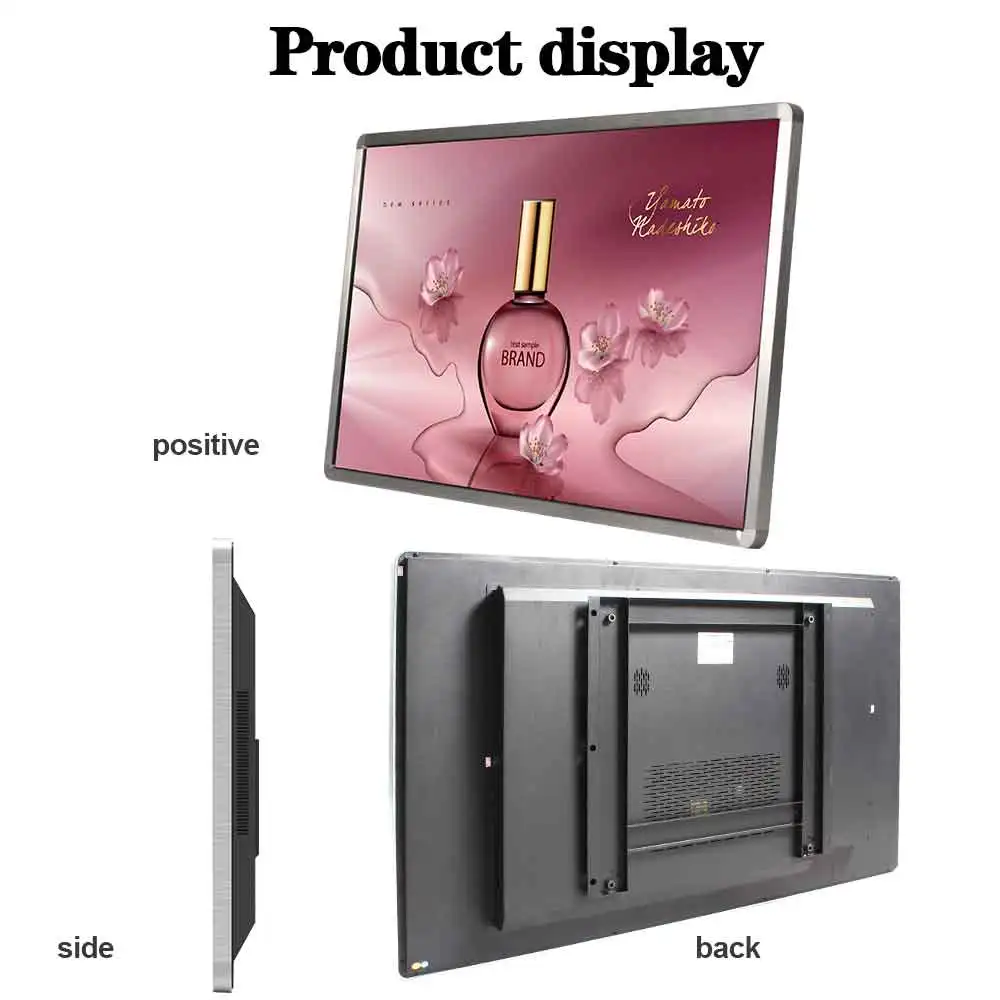

LED displays have been installed in manufacturing environments for years. Now there is a new, revolutionary standard that will instantly provide all of your plant employees with real-time, critical information, saving time and money – daily!

Display vital machine information, data, statistics, and disseminate that information directly to the people who need to see it the most. The workers on your production floor.

Pull your data from any network connected source. This can be anywhere on your intranet or even anywhere you can reach on the internet – world wide web (www). Allow your Ethernet connected PLC to send data directly to the display. Push or pull data from a centralized data collection PC. Update the display’s data elements from a centralized database. Let your current enterprise structure be your guide.

We will make it easy using XML data packets or SOAP application programming interface. This means no proprietary interfaces, syntax structures, or programming languages to learn. This flexibility also provides for ease of re-deployment if your needs for the display changes. No longer are you tied to proprietary software or servers.

This Windows application tests the capabilities of the video graphics system for 10-bit color support. It also generates images that demonstrate the benefits of 10-bit color depth on NEC MultiSync PA Series displays when using a DisplayPort video connection and a compatible video graphics card.

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

In LCD factories, implementing intelligent platforms has become the preferred method for monitoring mask aligners. In the past, data acquisition (DAQ) on mask aligners was done with oscilloscopes during the TFT array process. Electronic testing instruments displayed signal voltages as a two-dimensional plot. The waveform was then analyzed for properties such as amplitude, frequency, and rise time. However, while oscilloscopes processed data, they couldn’t capture and display signals. Processing time became dead time and the immediate management of mask aligners during the manufacturing process wasn’t possible. In addition to the difficulties with immediate monitoring, the high price of oscilloscopes was another essential factor influencing decisions to seek out an alternative approach. A brand new oscilloscope often reached the $1000usd range — rendering it unaffordable for many companies.

In this case, Advantech provided a one-stop solution with services. By introducing Advantech’s advanced measurement techniques, LCD factories achieved better system monitoring. Each LCD mask aligner was connected with the DAQ system, which then transferred facility data to the online platform. Devices deployed in this system included Industrial Ethernet switches EKI-5629CI-MB for wired network communication, cellular router BB-SR30310125-SWH for wireless data transmission, Intel 8th generation core i processor compact fanless system MIC 770, analog input universal PCI card PCI-1747U, and machine condition monitoring software WebAccess/MCM.

To provide a customized system with flexibility, the MIC-770 host computer was equipped with i-Module and flexible I/O interfaces. i-Module, an original flexible expansion module that provides 2~4 expansion slots for the PCIe/PCI interface; while flexible I/O interfaces, located in the front panel for convenient cabling, can support various displays, expansion I/O, and intelligent alarm functions to enable diverse machine automation applications. With the modular-design, MIC-770 let users add expansion cards or I/O corresponding to their own factory facility interface and save time on changing the existent interface design.

As the Ethernet switch was in charge of local network connectivity, the SmartFlex LET/LAN cellular router was there for remote wireless connectivity. Equipped with multi-interface design, the cellular router provided connectivity of I/O, serial and Ethernet devices. When the LCD factory status was delivered to the SmartFlex cellular router, it would be then sent to remote control center in real-time without any network infrastructural or geographical limitation.

As an alternative monitoring system, the host installed WebAccess/MCM offering multiple functions such as sensor signal collection, signal analysis, data management, and alert notification. Depending on different situations and managed targets, customers chose different application modes from MCM. For LCD factories, the Scope Mode presented a suitable alternative monitoring system with functions similar to oscilloscopes — including cursor measurement tools, automatic measurement functions which could be triggered under certain condition such as amplitude and frequency, and immediate display of the spectrogram.

As intelligent monitoring platforms increasingly enter the mainstream, companies are rushing to implement them into their factories. In LCD production facilities — where oscilloscope cannot capture signals from mask aligners during the processing phase — data is not collected and analyzed instantly. Due to the high price of oscilloscopes, companies are searching for alternative methods to manage mask aligners. To meet customization needs, Advantech provides a one-stop shop for equipment, including the EKI-5629 Ethernet switch, SmartFlex cellular router, MIC 7500 industrial computer, PCI-1747U DAQ cards, and WebAccess/MCM software. With the host offering flexible expansion modules, high-speed DAQ cards, reliably non-stop network transmission and software supporting immediate monitoring systems similar to oscilloscopes, customers will spend less time on facility management while improving production rates by accessing instantly visible data.

A liquid-crystal display (LCD) is a flat panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals. Liquid crystals do not emit light directly, instead using a backlight or reflector to produce images in color or monochrome.

Although it’s true that optical bonding is a highly-effective display enhancement (increasing contrast/readability and ruggedization of the unit, while decreasing distracting internal and external reflections), for some applications it is an unnecessary expense. A typical office or lab setting may not present many of the factors that an outdoor or rapidly changing environment will.

Sourcing from a single company creates better quality and efficiencies. This, in turn, leads to faster completion, which means a greater liklihood that product or software gets to market faster, and at a reduced cost. Read More

General Digital offers a no-obligation SSRA (Software Services Requirements Analysis), which identifies areas that you can handle in-house, and other areas where you would benefit by retaining outside help. Read More

All three of its business units—Display Systems, Software Services, and Optical Bonding Laboratories—are under one roof. This allows for efficient and effective interdisciplinary engineering, support and design efforts for seemless implementation. Read More

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

A robotic forklift picks up a sheet of glass thinner than a credit card and as big as two table-tennis tables, and effortlessly swings it 90 degrees before gently placing it into an oven where it will bake at 200 degrees Celsius. It’s a graceful and finely engineered process and one of several that takes place minute after minute, hour after hour, day after day in Sharp’s LCD factory in Sakai, western Japan.

The factory, built at a cost of ¥430 billion (US$5 billion), is the most advanced display factory in the world and on Monday Sharp opened it to reporters for the first time.

Operations at Sakai began in October, just in time for the competitive year-end sales period, and the factory is already a key supplier of panels for big-screen TVs and one of the reasons why LCD TV prices continue to fall.

At the center of the plant’s claim of world-class status is the size of glass sheets processed. Typically several LCD panels are made on a single sheet of glass to benefit from economies of scale before the glass is cut to produce individual screens. The Sakai plant handles sheets measuring 2.88 meters by 3.13 meters — almost double the size of those at Sharp’s other factory — so LCD panels can be made more efficiently and prices lowered.

The glass panels are made by Corning at a plant next to Sharp’s LCD factory and transported on a conveyer that connects the two. Across the street Dai Nippon Printing and Toppan have factories that produce color filters for the LCD panels. In total 19 companies contribute to a sprawling facility at the center of which sits the LCD factory. Sharp also has a solar cell factory on the land, and there is unoccupied space for expansion.

Sakai can currently handle up to 36,000 sheets of glass per month. Each sheet has enough space for 18 screens in the 40-inch size or 8 screens in the 60-inch size, and two sheets are sandwiched together in each finished screen. The plant is capable of making around 324,000 finished LCD panels per month for 40-inch LCD-TVs or 144,000 panels for 60-inch LCD-TV sets.

It’s a vital part of Sharp’s TV business and soon will play a similar role for Sony. On Dec. 29 Sony will invest ¥10 billion for a 7 percent stake in Sharp Display Products, the company that runs the factory, and gradually build its shareholding to 34 percent by the end of April 2011.

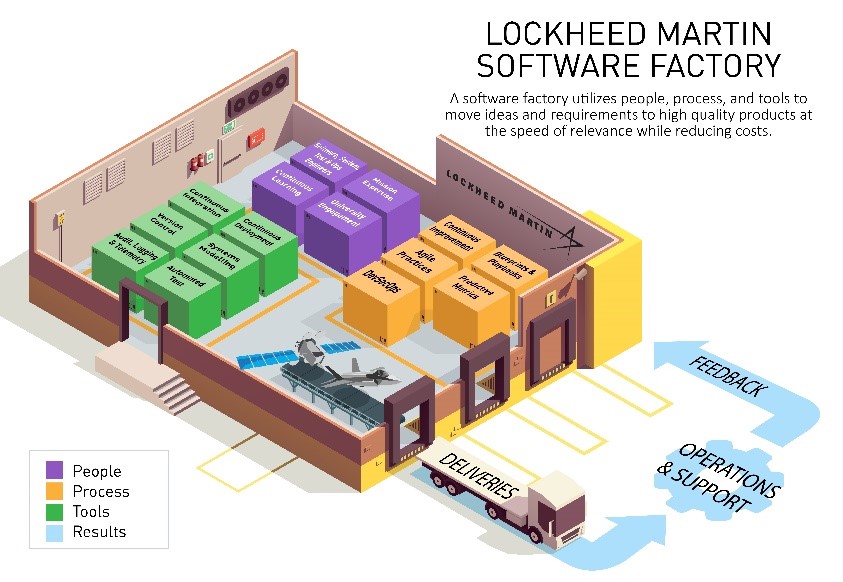

LevelUP is the cyber factory team for the Air Force and is the team behind Platform One. It is the centralized team that provides DevSecOps/Software Factory managed services with baked-in security to Air Force and Department of Defense programs. The team will provide the ability to deploy a DevSecOps Platform (CNCF-compliant Kubernetes stack) and Continuous Integration/Continuous Delivery (CI/CD) pipeline with a Continuous Authority to Operate (c-ATO).

Located in Colorado Springs, CO, Space CAMP is a software factory focused on the continuous development and deployment of USSF mission applications to the warfighter. As a software node of Platform One (the DoD Executive agent for DevSecOps) for Continuous Integration/Continuous Deployment (CI/CD), we aim to avoid vendor-lock by building an open platform (Kubernetes/Istio), embracing DevSecOps principles outlined by the DoD CIO and AF CSO, considering microservice/service mesh architectures early and often, leveraging event-driven behavior across the entire portfolio, and building a network of like-minded software shops for collaboration.

The Tron team is a group of Airmen from differing jobs and career fields working in collaboration with contractors who have knowledge in the industry best practices for software development, design, and management. The team utilizes agile methodologies, scrum techniques, test driven development, and human-centered design to ensure that the products being built will benefit the end user by reducing the manual processes and task saturation that many Airmen face in their day to day jobs.

CODE WITH HONOR. The 309th Software Engineering group at Hill AFB is recognized as a world leader in “cradle-to-grave” support systems. They encompass hardware engineering, software engineering, cybersecurity, cloud security, program management, consulting, data management, and much more.

Air Mobility Command’s premier agile software factory, delivering user-centered software supporting Mobility Air Force warfighters to provide rapid global mobility to the Department of Defense. Conjure partnered with Kessel Run for AMC’s Magellan application, and has built a partnership with Platform One to develop and host future AMC applications. Our logo is linked to the 375th Communications Support Squadron’s Wizard mascot and AMC’s heritage of the Phoenix.

Corsair Ranch, the ANG AFRC Test Center Software Division (AATC/DXW), exists to deliver Air Reserve Component (ARC) Capability Faster in line with the AATC mission. Corsair Ranch works across multiple weapon systems and directly with flight test stakeholders to engage users, continuously and incrementally deliver software capability, and field capability in support of combat, domestic, and acquisition outcomes. Corsair Ranch leverages Citizen Airman talent, Platform One, and relationships with like-minded teams – including Kessel Run, EDDGE, and TRON – to scale Total Force digital transformation.

Providing Air Force Mission Defense Teams with tailored software capabilities in order to detect, defend, and deter cyber threats across high-value weapons systems.

Hangar 18 delivers software and data capabilities to the Digital Engineering and Acquisition community, as well as others seeking innovative and agile solutions. Founded by the Air Force Research Laboratory and the Air Force Institute of Technology, we leverage a federation of digital teams and assets to engage in solutions engineering, DevSecOps, workforce development, education, training and community engagement.

Rogue Blue Software provides an expert software development, integration, and deployment platform across all enclave classifications up to the highest levels principally for Nuclear Command and Control (NC2), the Nation’s critical nuclear enterprise.

ODIN offers a Platform as a Service (PaaS) and Partybus Software Factory option. Both options provide Customers with develop, test and production environments on all three enclaves. Centrally funded, in part, by Headquarters Air Force, ODIN’s partnership with Platform One allows us to provide customers an accredited Partybus pipeline and continuous Authority to Operate (cATO).

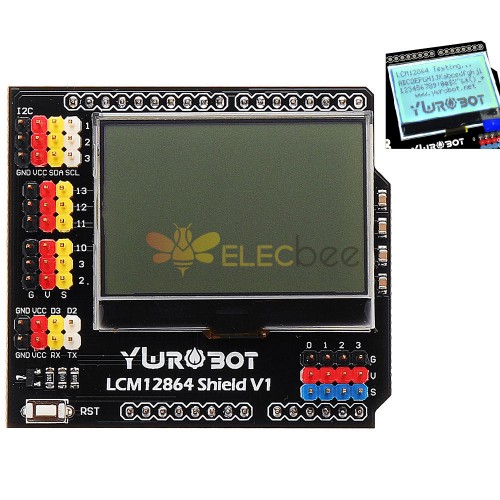

SoftwareGTT Support Software02.2306.13KiBSupport Software for the GTT Rev2.0 line, supports the GTT35A, GTT38A, GTT43A, GTT50A, and GTT70A. Version 2.2.0.0 adds support for firmware version 2.6 commands and fixes an issue with the Print UTF-8 command.

SoftwareGTT Support Software02.1231.11KiBSupport Software for the GTT Rev2.0 line, supports the GTT35A, GTT38A, GTT43A, GTT50A, and GTT70A. Version 2.1.0.0 adds support for byte and signed word array parameters.

SoftwareGTT Designer Software1.1437.44MiBDevelop and maintain gorgeous user interfaces and menu structures for your GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52B, and GTT70A.Changes from v1.13.0.10242:New Feature: Added Secure Communications Option Tick Box

SoftwareGTT Designer Software1.1336.64MiBDevelop and maintain gorgeous user interfaces and menu structures for your GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52B, and GTT70A.

SoftwareGTT Designer Software1.1236.64MiBDevelop and maintain gorgeous user interfaces and menu structures for your GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52A, and GTT70A.

SoftwareGTT Designer Software1.1136.6MiBDevelop and maintain gorgeous user interfaces and menu structures for your GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52A, and GTT70A.

SoftwareGTT Designer Software1.1013.87MiBDevelop and maintain gorgeous user interfaces and menu structures for your GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52A, and GTT70A. Version 1.10.0.9818 brings new tools, such as Axis Ticks and Two Colour Bargraphs, updates the Actions tab with options such as Set Bargraphs Colour and Set Gauge Test Colour, optimizations found in the updated Settings windows that allow even more loading options, and a number of bug fixes.Changes from v1.9.0.9645New Tool: Gui Axis Ticks

SoftwareGTT Designer Software1.813.82MiBDevelop and maintain gorgeous user interfaces and menu structures for your GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52A, and GTT70A. Version 1.8.0.9367 brings full support for the integrated keypad of the GTT29A, exciting tool updates that offer enhanced customization, new event actions that improve object interaction, and minor GUI improvements to the Designer, including additional gauge designs.Changes from v1.7.0.9105New Display: Added GTT52B support

SoftwareGTT Designer Software1.78.73MiBDevelop and maintain gorgeous user interfaces and menu structures for your revision 2.0 GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52A, and GTT70A. Version 1.7.0.9105 includes enhanced reporting for advanced tools, property additions to the gauge tick parameters, and GUI improvements.

SoftwareGTT Designer Software1.68.71MiBDevelop and maintain gorgeous user interfaces and menu structures for your revision 2.0 GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, GTT52A, and GTT70A. Version 1.6.0.8429 includes major feature improvements including new tools, such as gauges and bars, updates to exisiting tools, GUI improvements, the addition of a Links tab for connecting objects, and full support for new commands released in GTT Firmware Version 2.7.

SoftwareGTT Designer Software1.58.53MiBDevelop and maintain gorgeous user interfaces and menu structures for your revision 2.0 GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT29A, GTT35A, GTT38A, GTT43A, GTT50A, and GTT70A. Version 1.5.0.8080 includes minor updates to the deployment window, style updates, the addition of an Events tab for visual script creation, and full support for new commands released in GTT Firmware Version 2.6.

SoftwareGTT Designer Software1.48.41MiBDevelop and maintain gorgeous user interfaces and menu structures for your revision 2.0 GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT35A, GTT38A, GTT43A, GTT50A, and GTT70A. Version 1.4.0.7878 includes minor updates to the user interface, the addition of new Image Assets, and new tools such as Animations, Image Sliders, and Image Nine-Slices.

SoftwareGTT Designer Software1.36.4MiBDevelop and maintain gorgeous user interfaces and menu structures for your revision 2.0 GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT35A, GTT38A, GTT43A, GTT50A, and GTT70A. Version 1.3.0.7797 includes minor updates to user interface and features, as well as new tools, such as Triangle Buttons and Sliders.

SoftwareGTT Designer Software1.26.35MiBDevelop and maintain gorgeous user interfaces and menu structures for your revision 2.0 GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT35A, GTT38A, GTT43A, GTT50A, and GTT70A. Version 1.2.0.7732 includes major updates to user interface, features, and tools.

SoftwareGTT Designer Software1.12.86MiBDevelop and maintain gorgeous user interfaces and menu structures for your revision 2.0 GTT using this immersive Windows environment tool. Design Software for the GTT Rev2.0 line, supports the GTT35A, GTT38A, GTT43A, GTT50A, and GTT70A. Version 1.1.0.6970 includes fixes for labels and traces.

SoftwareGTT Support Software01.05.35MiBSupport Software for the Legacy GTT Rev1.0 line, supports the GTT480272A. Version 1.0.0.44 includes a small fix to add flow control back into the auto detect process.

SoftwareAlphanumeric Software1.0.0.0802.25KiBDisplay Tuner Pro (MOCD#) is an update to our popular uProject testing software for Matrix Orbital displays. It adds support for new features and displays, including legacy and graphic units, to our established base of features and scripting. This tool supports all Matrix Orbital Intelligent and Economy Series displays, including the following:GLK Series (GLK12232-25-SM, GLK12232-25, GLK19264-7T-1U, GLK24064-25, GLK24064R-25-1U, GLK240128-25)

SoftwareAlphanumeric Software524.62KiBBoot Edit is designed for modification of advanced features of the LK/VK/PK USB and MX series. This is a more advanced version of the Boot Logo software.

SoftwareAlphanumeric Software40.03KiBBoot Logo is designed for modification of the startup screen for some alphanumeric displays with startup screens.

SoftwareAlphanumeric Software407KiBThis basic application allows you to test and set LCD Contrast, Brightness, VFD Brightness, set baudrate and send text to the display.

SoftwareAlphanumeric Software1.42MiBuProject is an advanced testing software for Matrix Orbital displays. It allows testing of nearly all the features and allows test scripting and many other advanced features.

uProject (micro Project) is a series of different tools that should allow the testing of nearly all the features of most of our displays. uProject also features

SoftwareGraphic Software1.34MiBThis updated program is the new tool kit for all our graphic displays. It lets you upload fonts and bitmaps, set fonts and font metrics. As well, allows you test all the different features of the display. In addition this program allows you to create new fonts from existing fonts in your windows library. As well as convert graphic files, to a format that you can upload to the displays. This version supports all revisions of most graphic displays, including the following:

SoftwareGraphic Fonts17.12KiB\"Small\" is the 5 x 7 pixel monospaced font. It allows 40 characters per line and 8 lines of text on a 240 x 64 pixel display. Set font metrics to: character spacing = 1; line spacing = 1; left margin = 1; right margin = 0

SoftwareGraphic Fonts19.18KiB\"Small Filled\" is the 6 x 7 pixel monospaced font which is loaded as font 1 at the factory. It allows 40 characters per line and 8 lines of text on a 240 x 64 pixel display. Set font metrics to: character spacing = 0; line spacing = 1; left margin = 0; right margin = 0

SoftwareGraphic Fonts16.42KiB\"Small Inversed Filled\" is the 6 x 7 pixel monospaced font. It allows 40 characters per line and 8 lines of text on a 240 x 64 pixel display or 4x20 on a 122x32 pixel display. Set font metrics to: character spacing = 0; line spacing = 0; left margin = 0; right margin = 0

SoftwareGraphic Fonts15.88KiB\"Clean\" is a very small, but still remarkably readable proportional font designed by William Ferrell of LCDproc fame. Depending on the specific characters printed, this font allows approximately 59 characters across the screen and 9 lines of text (GLK24064-25). Set font metrics to: character spacing = 1; line spacing = 1; left margin = 0; right margin = 0

SoftwareGraphic Fonts18.68KiB\"Futura\" is the 14 pixel high proportional font which is loaded as font 2 at the factory. Depending on the specific characters printed, this font allows approximately 35 characters across the screen and 4 lines of text. Set font metrics to: character spacing = 1; line spacing = 0; left margin = 0; right margin = 0

SoftwareGraphic Fonts19.09KiB\"Lucida Mono\" is a 10 x 15 pixel monospaced font. It allows 21 characters per line and 4 lines on a 240 x 64 pixel display. Set font metrics to: character spacing = 1; line spacing = 1; left margin = 5; right margin = 0

SoftwareGraphic Fonts13.75KiB\"Recta\" is a fairly small proportional font. At 11x11 pixels, it is about as small as you can make a font and still have proper looking characters - especially lower case characters with \"decenders\" like \"j\" and \"g\". The font is clean and readable and allows about 40 characters per line and 5 lines on a 240x64 display. Set font metrics to: character spacing = 1; line spacing = 1; left margin = 0; right margin = 0

SoftwareGraphic Fonts21.08KiB\"Small Filled Spanish\" is the 6 x 7 pixel monospaced font which is has Spanish characters. It allows 40 characters per line and 8 lines of text on a 240 x 64 pixel display. Set font metrics to: character spacing = 0; line spacing = 1; left margin = 0; right margin =

SoftwareGX Series Software13.09MiBThe software contains update drivers for Windows 7/Vista/XP in 32 and 64 bits and updated LcdStudio, this completely replaces the 2008 pack.

You may need to install the digitally signed monitor .INF and .ICM files manually from the CD in the event of an installation error. Refer to the Monitor Driver Software Readme file on the CD.

You can optimize the screen performance for the VGA (analog) input by using the Auto button on the monitor or the auto-adjustment pattern software utility on the CD provided.

The following table lists the On-Screen Display (OSD) menu selections and their functional descriptions. Settings will be saved automatically after adjustments are made.

When adjusting the Pixel Clock and Phase values, if the monitor images become distorted, continue adjusting the values until the distortion disappears. To restore the factory settings, select Yes from the Recall menu in the on-screen display.

You may need to install the digitally signed monitor .INF and .ICM files manually from the CD in the event of an installation error. Refer to the Monitor Driver Software Readme file on the CD.

You can optimize the screen performance for the VGA (analog) input by using the OK/auto button on the monitor and the auto-adjustment pattern software utility on the CD provided.

Do not use this procedure if the monitor is using a DVI or DisplayPort input. If the monitor is using a VGA (analog) input, this procedure can correct the following image quality conditions:

If there is a problem with the display settings, try resetting the settings to the factory defaults by opening the OSD and selecting Factory Reset from the OSD menu.

If the buttons remain untouched for 30 seconds (factory default) while displaying a menu, the firmware will save the current adjustments and exit. Also, if the video controller changes video mode while the OSD is active, the current (adjusted) settings will not be saved, the OSD will be turned off, and the new mode will be displayed.

The following table lists the On-Screen Display (OSD) menu selections and their functional descriptions. After changing an OSD menu item, and if the menu screen has these options, you may choose to:

When adjusting the Clock and Clock Phase values, if the monitor images become distorted, continue adjusting the values until the distortion disappears. To restore the factory settings, select Yes from the Factory Reset menu in the on-screen display.

HP Display Assistant, included on the software and documentation CD, is a software utility that guides you through the tuning process with easy to understand instructions and background patterns designed for each monitor control. It provides:

Software control of the monitor image and color settings to eliminate dependence on the monitor’s front panel buttons and On-Screen Display (OSD) menu.

Asset Management and Power Management capabilities that include remote control for individual or a group of displays on the domain from a centralized console application.

Power Saving Plug-in feature that applies power saving modes to the display and a schedule power saving feature that allows the display to be set to idle (stand-by) mode or powered off after a pre-determined time of inactivity.

The HP Display Assistant Utility has two modes of operation: Wizard and OSD mode. The preferred method of use is Wizard mode, which takes you through a step-by-step process to accurately calibrate the monitor. This method relies on a sequence of steps that will obtain the best display results when completed.

Monitor Status—When the monitor is powered on or when the input source signal is changed, a Monitor Status message is displayed for five seconds. The message shows which input is the current active signal, the status of the auto-switch source setting (On or Off), the default source signal, the current preset display resolution, and the recommended preset display resolution.

OSD Lockout—The OSD can be enabled or disabled by pressing and holding the Menu button on the front panel for 10 seconds. If the OSD is locked, the warning message OSD Lockout displays for ten seconds.

Theft Mode Enabled—Indicates that theft deterrence mode has been activated. Theft deterrence is an optional feature that can be set up in HP Display Assistant. Theft deterrence mode is triggered if both the power and display cables have been disconnected from the monitor, the monitor is reconnected to a different computer, and the theft deterrence PIN number is not entered within the elapsed time. When the monitor is in theft deterrence mode, all front panel buttons are disabled other than the power button.

You must set the current local time before you reset the time for Sleep Time or On Time. Note that the time is displayed in a 24–hour clock format. For example, 1:15 p.m. is displayed as 13 hours 15 minutes.

HP Display LiteSaver is a software application, available on the CD, that increases monitor life and saves energy. It allows you to place the monitor into its low power sleep mode at predefined times by shutting down or reducing power to most internal circuits. This helps protect the LCD panel against image retention. Image retention can occur when the monitor is left on while displaying the same image for an extended period of time, leaving a shadow of the image on the screen.

After installing the software, click the HP Display LiteSaver icon in the Windows system tray or right-click the icon and select Configure from the pop-up menu.

Display OffSets the time when the monitor automatically turns off. This does not affect screen saver operation, which has priority over the HP Display LiteSaver.

Display OnSets the time when the monitor automatically turns on. This does not affect screen saver operation, which has priority over the HP Display LiteSaver.

Activity ExtensionSets the time in minutes before the monitor turns off if there is any keyboard or mouse activity after the Display Off time is reached. If the keyboard or mouse is used, then HP Display LiteSaver waits until the set amount of time before turning the display off again. Set to 0 to disable. If disabled, the monitor will turn off as soon as the Display Off time is reached, regardless of keyboard or mouse activity.

CAD/CAM mode provides increased image contrast to accentuate the lines and details of 3D and other technical illustrations. Modelling and rendering are that much easier, regardless of the software you use.

We develop, design, manufacture, and sell displays where it is necessary for the interface that deliver a lot of information at an instant and deliver it to the global market. We create interactive spaces that go beyond the expected, elevate everyday lives, and move people"s hearts. From bases in major cities in Asia, Europe, and North America, we build strong customer relationships by developing products that respond to market needs.

For most customers, visiting a professional repair provider with certified technicians who use genuine Apple parts is the safest and most reliable way to get a repair. These providers include Apple and Apple Authorized Service Providers, and Independent Repair Providers, who have access to genuine Apple parts.* Repairs performed by untrained individuals using nongenuine parts might affect the safety of the device or functionality of the display. Apple displays are designed to fit precisely within the device. Additionally, repairs that don"t properly replace screws or cowlings might leave behind loose parts that could damage the battery, cause overheating, or result in injury.

Depending on your location, you can get your iPhone display replaced—in or out of warranty—by visiting an Apple Store or Apple Authorized Service Provider, or by shipping your iPhone to an Apple Repair Center. Genuine Apple parts are also available for out-of-warranty repairs from Independent Repair Providers or through Self Service Repair.*

The iPhone display is engineered together with iOS software for optimal performance and quality. A nongenuine display might cause compatibility or performance issues. For example, an issue might arise after an iOS software update that contains display updates.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey