edge-lit lcd panel manufacturer

Lean manufacturing capable custom manufacturer & distributor of precision parts, components & products. Products include advertising specialties, albums, awards & recognitions, frames, fixtures, boxes, gaskets, plates, bar & restaurant supplies, badges, balls, bar code labels, name plates, barometers, brass goods, bronze goods, books, beds, liners, patterns, carvings, cases, certificates, chalkboards, coasters, consoles, control panel overlays, copper parts, cork products, crafts, desk accessories, displays, tags, decals and more. Capabilities include product design & development, laser cutting, CNC routing, CNC engraving, photo-chemical etching, art designing, bending, forming, woodworking, sand etching, dye sublimation, CMYK process, screen printing, fulfillment services, selective plating, powder coating & Kanban inventory. Markets served include aerospace, architectural, automotive, military & bio-tech. JIT delivery available.

Lean manufacturing capable custom manufacturer & distributor of precision parts, components & products. Products include advertising specialties, albums, awards & recognitions, frames, fixtures, boxes, gaskets, plates, bar & restaurant supplies, badges, balls, bar code labels, name plates, barometers, brass goods, bronze goods, books, beds, liners, patterns, carvings, cases, certificates, chalkboards, coasters, consoles, control panel overlays, copper parts, cork products, crafts, desk accessories, displays, tags, decals and more. Capabilities include product design & development, laser cutting, CNC routing, CNC engraving, photo-chemical etching, art designing, bending, forming, woodworking, sand etching, dye sublimation, CMYK process, screen printing, fulfillment services, selective plating, powder coating & Kanban inventory. Markets served include aerospace, architectural, automotive, military & bio-tech. JIT delivery available.

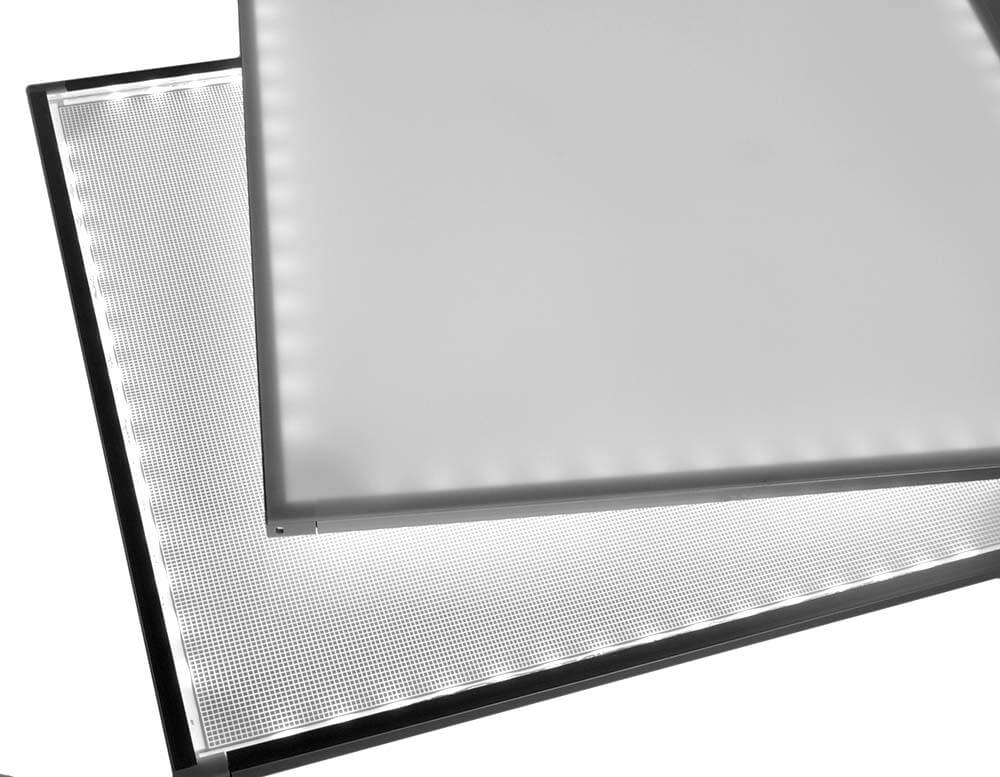

Here"s the "exploded" view of the edge-lit LED-based LCD display. In the foreground is the frame, followed by the LCD element, then the LED lighting assembly.

The heart of the beast is the LED lighting assembly. The LEDs themselves are arranged in strips on all four sides of the panel (the bottom strip was removed for this display). A series of filters, a "light guide," and a reflecting back serve to translate the LEDs" light toward the LCD display itself.

Here"s a closer look at the assembly. The rightmost, thinner three panels are the color filter, polarizing filter, and diffuser. The leftmost, notched white panel is the reflecting back, the only one of the five elements that sits behind the row of LEDs (top).

Second from the left is the clear-looking, thicker "light guide," a proprietary Samsung development that uses a series of tiny lens-like refractors to send light from the LEDs along edges toward the middle of the screen. The company claims its edge-lit LED-based LCDs have the same uniformity characteristics as its standard backlit LCD displays. If true, that would be an improvement on the only other edge-lit display we"ve reviewed so far, the Sony KLV-40ZX1M.

Here"s a closeup of the LEDs themselves, which are visible along the strip at the top. Despite their yellowish appearance, each produces white light, which is filtered and sent through the LCD panel. According to Samsung, the advantage of using white LEDs, as opposed to the multicolored "triluminous" LEDs in Sony"s XBR8 models, is purer reproduction of color-corrected primary and secondary colors at low luminance levels, as well as better energy efficiency.

Here"s where we mention that, unlike so-called local dimming LED based displays we"ve reviewed in the past, these edge-lit models can"t dim or turn off the LEDs selectively. That"s why we expect that the black-level performance of edge-lit LED-based LCD displays won"t match that of local dimming models, such as the Sony XBR8 or Samsung"s own A950 series.

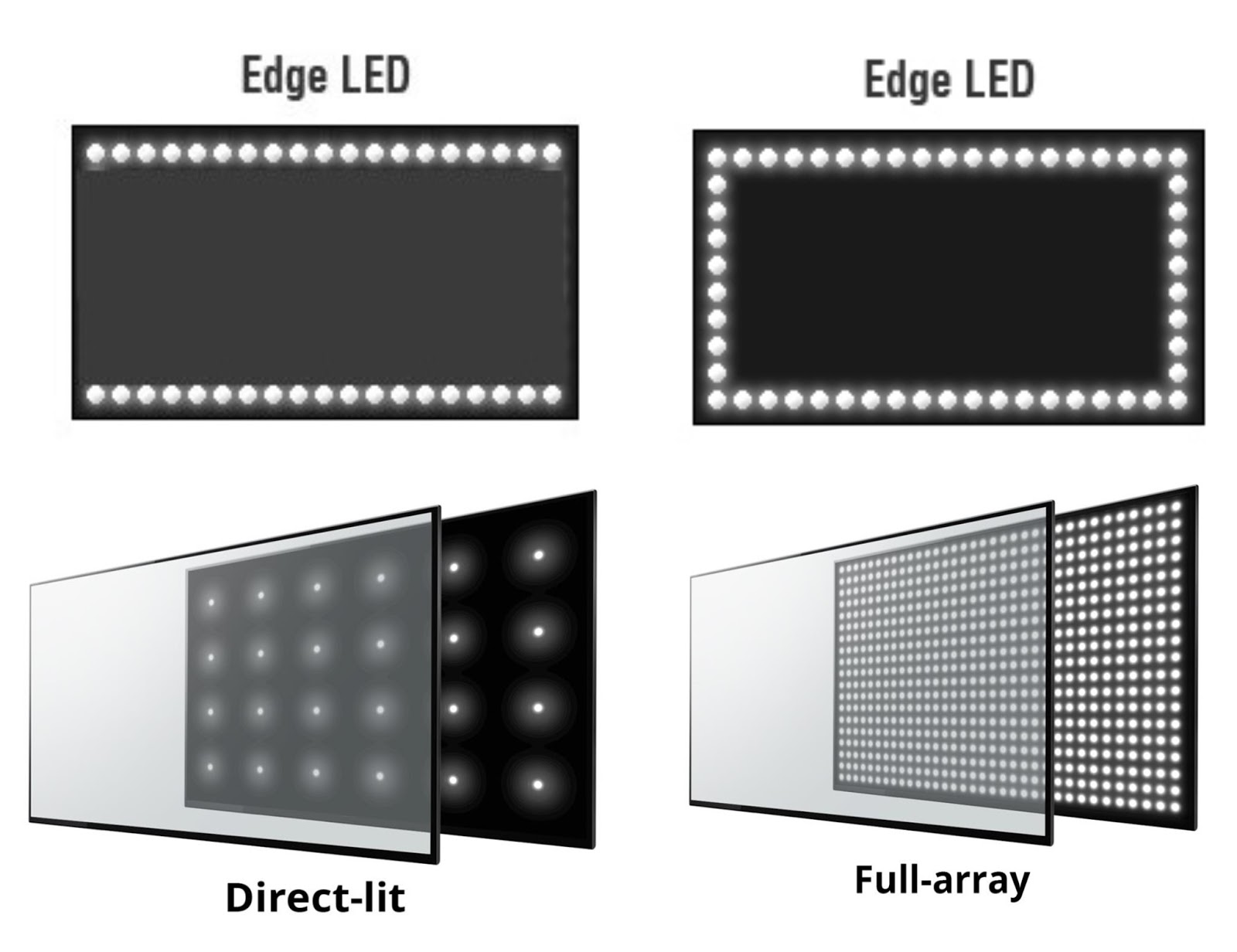

When comparing different models of televisions, you might see the term "edge-lit LED." All LED TVs are a type of LCD TV; the "LED" refers only to the kind of lighting source used to illuminate the LCD pixels in the television. There is more than one way to light the pixels. The two primary technologies are edge-lit and full-array.

In an edge-lit television, the LEDs that illuminate the LCD pixels are located only along the edges of the set. These LEDs face inward toward the screen to illuminate it.

In some poorer-quality edge-lit LEDs, uniform picture quality can be a problem. Because the LEDs are along the edges of the panel, quality declines as you approach the middle of the screen because a uniform amount of illumination is not reaching the pixels further from the edges. Again, this is more noticeable during scenes of darkness; the black along the sides of the screen is more gray than black (and corners can appear to have a flashlight-like quality of illumination emanating from the edges).

Full-array LED televisions use a full panel of LEDs to illuminate the pixels. Most of these sets also have local dimming, which means the LEDs can be dimmed in different regions of the panel while other areas are not. It helps improve black levels, which appear closer to black than dark gray.

In general, full-array LED is a superior technology when it comes to picture quality, but edge-lit sets have one significant advantage: depth. Edge-lit LED TVs can be much thinner than those lit with either a full LED panel or traditional fluorescent (non-LED) backlight. For that reason, most of the super-thin sets you see in stores will be edge-lit.

If you"re looking for the best possible picture quality, you are most likely to find it in a full-array LED display with local dimming. If you are primarily concerned about the appearance of the television and want an extremely thin screen, edge-lit is the style that will fit your needs.

LED-backlit LCD, which uses light-emitting diodes for backlighting is a common type of display on televisions and laptops. Unlike pure LED screens these LCDs are not self-illuminating and are reliant on the backlighting for illuminating the display. It is an advancement on the preceding cold cathode fluorescent technology and some manufacturers and retailers may advertise this type of screen as an LED TV.

Edge-lit is a type of screen backlighting that has LED lights lining either the top and bottom edges of the screen or the perimeter of the screen. This form of backlighting differs from others as the screen is not lit from behind, and often produces a more muted effect. An opaque piece of plastic called a diffuser light guide distributes the lighting across the rear of an LCD panel.

Edge-lit LEDs can be individually brightened or dimmed to provide the high degree of backlight control that screened content demands. Edge-lit screens can achieve this in one of two ways:

Direct-lit backlighting uses LED lighting across a television back panel. This form of backlighting initially used Cold Cathode Fluorescent Lamps (CCFLs) before transitioning to LED. The lighting is behind the LCD panel to provide consistent lighting across the entire screen.

Both types of backlighting provide the illumination LED screens required to produce a visible image. The main difference is that direct-lit backlights sit behind the LCD panel to provide the necessary lighting whereas edge-lit screens have LEDs sitting at the perimeter of the screen. Here are some other notable differences:

The first generation of LED backlighting was edge-lit. However, this early form of edge-lit technology caused the development of hotspots on the screen and the overall lighting was inadequate. As LED design became more efficient and effective, Samsung revisited this type of backlighting with a market-leading edge-lit LED television in 2009.

Direct-lit panels use a simple array of LEDs to provide uniform lighting across an entire LCD panel. The adoption of direct-lit screen technology in the 2000s was driven by the availability of white LEDs that could replace existing CCFL technology.

ST. PAUL, Minn.--(BUSINESS WIRE)--In an effort to meet LCD manufacturer design flexibility demands, the 3M Optical Systems Division today announced that it has developed a unique solution called Uniformity Tape that will allow LCD manufacturers to reduce the number of LEDs required for edge-lit LED LCD panels at a low cost, without sacrificing brightness or efficiency.

LEDs are becoming brighter and even more efficient-requiring fewer bulbs to achieve target brightness for a given display. Until now, there have been limitations as to how far LEDs can be spaced apart at the edge of an LCD panel because of dark areas that appear between LEDs when they are too far apart. This scenario is commonly referred to as "head-lighting" because it looks like the dark space on the road between the headlights of a car.

3M"s Uniformity Tape is a clear tape, which has adhesive on one side and a micro-replicated optical pattern on the other side. It is adhered to the edge of the light guide, which faces the LED light sources. The tape is designed to increase the spreading of light in the light guide from each LED, which greatly increases the allowable LED spacing. The optical pattern is spatially uniform, meaning that no positional registration of LEDs is required along its length. The Uniformity Tape keeps the edge of the display closest to the LEDs uniform in brightness when the spacing of light sources is increased. This allows panel manufacturers to save money by removing unnecessary LEDs. Uniformity Tape can also increase LED spacing by up to three times the current spacing, while maintaining edge uniformity for a given bezel size.

"As LED technology continues to improve and becomes even brighter, some backlight designs are currently using more LEDs than needed for a brightness specification in order to avoid head lighting or thick bezels. Uniformity constraints have also prevented manufacturers from removing LEDs to save on cost," noted Gilles Georges, 3M global marketing manager. "By spacing LEDs further apart for edge-lit LED LCD panels, 3M"s Uniformity Tape allows light to travel inside the light guide at wider angles-allowing manufacturers to design wider spacing between LEDs without any dark areas."

LCDs need to be supported by additional lights because they don’t produce their light. To create this light, you can either use edge-lit LEDs or backlit LEDs. The primary difference between edge-lit and backlit LEDs is in the lighting is arranged. The light sources of Edge-lit displays are placed on a diffuser (usually thin) behind the LCD to create light dispersion.

The significant advantage of using an Edge-lit flat panel lights LED display is the reduced thickness. As a result of this, the displays are placed on Edge and not directly behind the LCD. It leads to the thinness of the diffuser. Most thin diffusers are usually edge-lit and not backlit, and they transfer the majority of the components to a big stand.

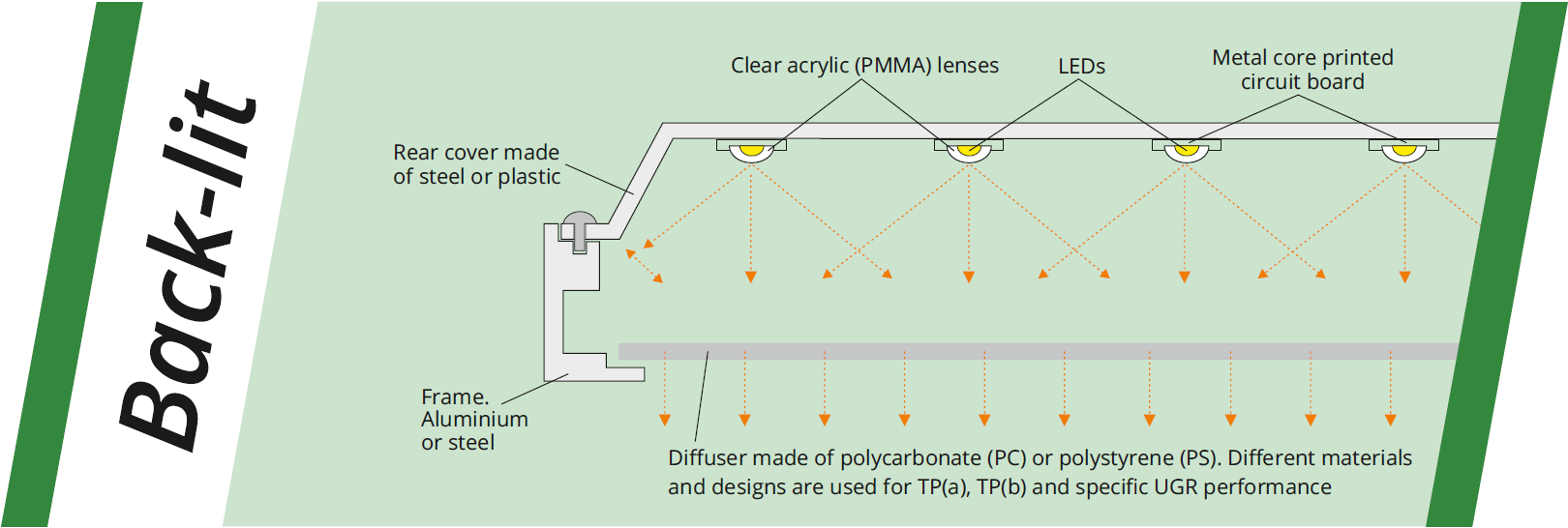

Switching from fluorescent troffer lights to LED troffer lights has its benefits, but the process could prove to be daunting and not so easy. You could either use Edge-lit panels or Backlit panels. Here are the significant differences between these panels.

Concerning the location of the LEDs, Edge-lit light panels are placed on the Edge of the frame. The light that emits is guarded by a light guard panel that directs it sideways. The light board is designed for the smooth and evenly distribution of light in a given space. The sleek look of the diffusers is a result of the small depth of the panel. The installation of Edge-lit can be done in a standard grid ceiling. And the sleekness and thinness of the board make it possible to install Edge-lit LEDs on walls and ceilings using suspension box or cable installation kits.

Backlit, as the name implies, is placed at the back of the frame instead of at the Edge. This position causes the LED to shine directly out, straight through the diffuser. In backlit LED, there is no light guard. As a result of this, the light shines directly outward and does not need to be directed. The straight direct light does not cause a glare because the backlit LED also has a diffuser which smoothens the light. The risk of yellowing of light guard is absent because there is no need for one. The directness of the LED light makes backlit more efficient than edge-lit. Unlike in edge-lit, where the light travels through the diffuser panel, light only passes through the thickness of the material in backlit.

The disadvantage of Backlit is the thickness of its diffuser. You cannot install it just anywhere. It has to be installed in a drop grid ceiling. Although its panel is thicker than Edge-lit, it is still easy to operate due to its lightweight around its surface.

There are two types of LED TV - edge-lit and back-lit televisions. So what is the difference, and is it important? Find out everything you need to know.

Different parts of the screen can have the blocks of lights switched on or off at any time, which gives the TV a much better contrast ratio than a traditional LCD TV.

A downside is that the power consumption of these TVs can be greater than standard LCD or edge-lit televisions – especially those models which use RGB LEDs.

The advantage over an edge-lit TV is that the lighting will usually be more uniform across the screen – eliminating the light-pooling of edge-lit screens.

The lights in edge-lit LED televisions are placed around the perimeter of the LCD screen – and the light they emit spreads across the back of the panel using a series of ‘light guides.’

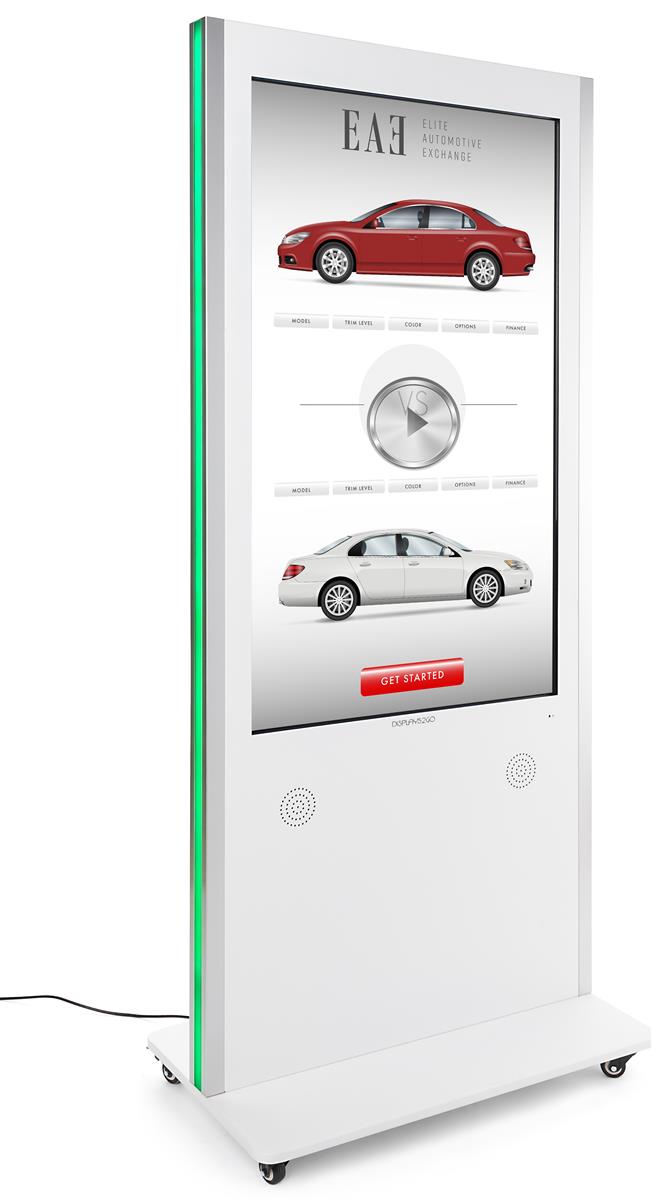

A loved classic household item – the TV is an essential piece of technology for the modern family. Our wholesale smart edge led panel tv offer great versatility. In addition to watching normal TV, viewers can connect to the internet and browse through programs online for instant streaming. For all of the family, these edge led panel tv can play games, use apps, and are set up for social networking. With built-in voice control and touch screen features, these smart TV"s really are one not to miss. They come in a range of sizes. For those wanting the big screen experience, try the following sizes (inches): 60, 65, 70, 75 80, and 85. For customers who want something smaller, then our range of 24-32-inch edge led panel tv are ideal.

TV definition improves vastly every day with constant new technology. With our wholesale 4k Ultra HD TVs, viewers can watch their favorite programs in ultra-high definition. These edge led panel tv come in the highest resolution for optimal viewing. For customers who want the latest technology at affordable prices, then choose from our range of 4k TVs.

Whatever your customer"s preference, we will have the TV for them. Choose from wholesale flat-screen edge led panel tv to curved edge led panel tv. Outdoor TVs are also great for those wanting to install a TV on their terrace or in their back garden. For the full range, then visit our online wholesalers at Alibaba.com.

:max_bytes(150000):strip_icc()/Untitled-8f9cd351586348eaa141a6167c8097a6.jpg)

Edge lit BLUs using light guide plates are mature technology and remain a cost effective back light for many types of displays. It creates uniform and bright light output in computer monitors, mobile devices, and commercial displays. LCDs driven by edge lit back light units are a mainstay in cost effective displays found in mobile phones, laptops, tablets, and automotive displays, to name a few. They are reliable and produce uniform light, but extracting the maximum light output can prove challenging. BrightView now offers Gain Enhancement films (GEFs) based on our micro lens array technology that provides a boost in brightness for edge lit displays. The GEF replaces the traditional down diffuser, resulting in a brighter, more efficient backlight.Up to 30% improvement in brightness compared to traditional down diffuser films

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

A 2016 study by the University of California (Berkeley) suggests that the subjectively perceived visual enhancement with common contrast source material levels off at about 60 LCD local dimming zones.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; http://www.cta.tech/cta/media/policyImages/policyPDFs/Fraunhofer-LCD-TV-Power-Draw-Trends-FINAL.pdf Archived 1 August 2017 at the Wayback Machine

Most television companies, as well as sellers, misguide consumers by saying that this particular TV is not LCD but LED. So, first of all, we need to understand that all TVs are basically only

LCDs. What we refer to as LED is simply an update to the existing LCD panels. The panel technology is the same, however, the backlight is entirely different. Those LCDs that use LEDs as a light source are generally termed as LEDs. In short, a LED-backlight is a replacement for the uniform CCFL (Cold Cathode Fluorescent Light) backlight that previously gave LCD TVs its brightness.

Initially, there were only CCFL-backlit LCDs, but with advancement in technology, these CCFL were replaced by LEDs, as not only they dramatically reduced power consumption by over 40 percent compared to conventional CCFL-backlit LCDs, we got more control over the image quality by modulating these individual LEDs.

In the LED-backlit LCDs, LED lights can switch on and off individually, which allows the image to have greater contrast, bright whites and deep black in the same image. Thus, producing a superior picture when compared to CCFL-backlit LCDs. LCD TVs with LEDs also offer better response time in comparison to CCFL-backlit LCDs.

In the traditional LCDs, the CCFL lights were spread all across the surface behind the display screen, but there was no control over them. It means that when we switched on our TV, the entire surface behind the screen used to get illuminated by these CCFL lights that were always ON, and we were unable to control their dimming in specific areas of the screen.

Because of this, even the dark part of the picture used to be illuminated like the rest and we were unable to achieve images with convincing blacks, as light passed through the dark part of the picture and made it appear grey. In other words, the contrast of CCFL-backlit LCD panels isn’t very good. However, a plasma TV doesn’t have this problem as each pixel can light up or switch-off according to the demand of the picture.

Now coming to LCDs that use LEDs as the source of illumination, there are basically three types. One is Full-array backlighting, another is Edge-lit backlighting (ELED) and third is direct-lit LED backlights (DLED).

The term full-array is used where LEDs cover the entire back-side of the LCD panel. Full-array TVs are high-ends TVs that are heavier and often thicker, but they provide better picture quality as all parts of the screen are evenly backlit. They offer the most effective local dimming, as the LEDs are more in number and are spread over the entire back surface of the panel. The independent dimming of each LED in these TV sets helps in achieving perfect blacks. But, as they are costlier to manufacture, they are rare.

This technology allows the designing and manufacturing of exceptionally thin TV sets. Edge-lit sets also have a cost-benefit over direct, local dimming versions (DLED) as fewer LEDs are used in them. Because of which, they are power efficient too.

Direct-lit LED backlights are an offshoot of full-array backlighting, though they use significantly fewer LEDs across the back of the panel. In this technology, several rows of LEDs are placed behind the entire surface of the screen.

As the LEDs are behind the LCD panel in DLED TVs, dual modulation works far more efficiently and the TVs can have better overall brightness and contrast. Using a feature called local dimming, the LEDs are divided into a number of zones that can be individually controlled, so some portions of the backlight can be dimmed while other remain illuminated.

Though different brand TVs might be using the same DLED or ELED backlighting, their image quality might differ considerably depending on how many lights are used and how they are aligned. In some budget Edge-lit TVs, LEDs are aligned on only one side, either upper or lower edge of the TV panel, while others might have LEDs on both upper and lower edges of the panel. The high end TVs might even have a row of LEDs on all four edges of the panel. Some manufacturers use both Edge and Direct LED systems for LCD TVs. The best professional monitors use direct LEDs.

Though bigger brands like Sony, Samsung and LG also prefer EDGE-lit LED backlighting in their TVs, they complement it with some of their indigenously formulated technology to enhance the picture quality.

TV manufacturers lay more stress on producing TVs with ELED technology as it not only cut down upon their expenditure but allows them the liberty of producing ultra-slim TV sets that can appeal the masses with their aesthetically designed panels.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey