lcd module 16x2 soldering quotation

Yes, it is - almost. The other option is to buy an LCD on a shield, thereby absolving you from any soldering, and ensure it will arrive and everything will be together in the time available. One thing you can be pretty sure about is that it won"t take two weeks to learn how to solder.

An LCD shield is a pretty good idea and something you might have latched onto before since "use shields - not solder" is a major feature of the Arduino concept, but soldering isn"t that hard and, if you intend to continue in the Arduino arena, the skill will eventually be an asset.

I assume the display in your hand has a row of holes along the edge. You could get by with just soldering a pinrow in same . This has a plastic strip to hold the pins straight while you work. Once done, everything else can be done with jumper wires, possibly using a breadboard as well. If you take that path, you need male/male as well as male/female jumpers. Alternatively, you could simply cut some jumpers and solder the bare ends into the display. Whatever you do, you never need to solder into the Uno.

In this project, we are going to build a backpack circuit to enable communication between the Onion Omega2 and the 16x2 LCD display. By doing that, we"ll be able to pull data from the web to show in the display!

Our objective is to power the ATmega328 and the LCD using the 5V output available at the Onion Omega expansion dock. Also we"ll connect the Omega TX1 to the ATmega328 RX0 in order to enable communication between them. It should fit the pins at the dock and occupy as less space as possible.

When everything is in place, we can start the software side. We"ll be talking to the ATmega328 using the Omega TX1. There is a script calledlcd-16x2for that. You can download it and place it at/usr/sbinon the Omega.

An Onion App as far I could understand (I"m new to the platform) is a folder inside/www/console/appsthat includes an icon (icon.png) a description file (app.json) and the app file itself (onion-lcd-16x2.htmlin this case). There may also be other files related to the app, like images, javascript (js) and style sheets (css).

Feel free to download it and modify to fit your needs. You can uncompress it by using the following commands (assuming you placed lcd-16x2.tgz right there):cd /www/console/appstar zxvf lcd-16x2.tgz

The LCD display needs to be calibrated to show the text correctly. In order to do that, just tune the 10k Trimmer Potentiometer until you see the best contrast.

.png.jpg)

Bought this from Robotshop retailer. Worked right away like a charm. I even changed splash screen to display my software version. However at some point it stopped displaying text, then backlight started spontaneously switching off several seconds after powering on. I connected LCD to different device and started experimenting just sending one command at a time.

My only complaint with this product is the difficulty in mounting. Finally had to drill out the holes to accept 4-40 standoffs. The Eagle files don"t include the complete board so making a screw hole template from the PCB is impossible. Otherwise works fine with my stand alone Atmega 328P using the SerLCD.h and SoftwareSerial.h libraries.

Does anybody know how to do a hard reset on this LCD? While I was uploading my code, I left it plugged into TX, and it doesn"t work anymore. I"m realizing that it probably got spammed with commands and the configuration got messed up. Does anybody know how to reset to factory defaults?

I have the same question. I now have the 3.3v serial enabled LCD (with backpack) and want to use this one for future usage. VDD of 5V can be supplied, but will the TTL work when its getting 3.3V signals from the TX from Netduino?

Is it just me, or are the solder holes for VDD, GND, and TX near the JST connector too small to accept standard pin headers? Perhaps I just need to use a little more force? I see that one of the pictures of this module shows what appear to be standard headers installed in that location, so I am confused..

I"ve put together some python code for sending serial data to these LCD screens. In particular, the code pulls my twitter status and writes it to the LCD. To work with the extra characters, I wrote functions to page the text (vertical scroll) or scroll the text (horizontal scroll). Details are available here: http://dawes.wordpress.com/2009/12/23/twitter-to-lcd/

Is it possible to wire this up in parrellel rather than use the serial function? I ran into a snag and am unable to use the serial function of this lcd? I see the pinouts on the schematic but when wired it doesn"t seem to work.

I"ve created a new splash screen for the Serial LCD, now I want to save it to the Serial LCD memory. So, exactly how do I write a "control-j" to the Serial LCD. I"ve put in the required line to transmit special character 124, but I can figure out how to format the "control-j" line of code. I"ve Googled this for about an hour and can"t find an explanation or sample code anywhere. Here"s my code...void setup() {

I"m not sure if you"re referring to comments on the website, or on your LCD screen. You can contact techsupport@ and they"ll be able to assist you further.

I have used a Labview program for this LCD. When i send character "a", the display is "0". Does anyone having a same problem. How should I troubleshoot this problem.Tq

Why do I get power out of the VDD port with only RX and GND hooked up? I have a 5V rail that I use to power everything on my board - and when I added this SerLCD I now have a bridge between the arduino power and my 5v line ... which I dont want. Can I add a diode to the VDD to stop reverse voltage from powering my board?

Quick suggestion... It"d be very helpful for some people if you guys added a note in the description pointing people to the correct 3-pin JST jumper wire to be used with these serial LCDs. Two reasons... it"s not clear that the jumper is not included, and you have 3-pin jumpers in your catalog which don"t work with this serial LCD.

I have ported LiquidCrystal library for use with the serial LCD you can look at my code here. Still working on finishing all the documentation. But putting up for now hopefully someone will find it usefull.

I"m also having the same problem after accidentally sending the control character "|" followed by "\", "-", "/" to the LCD as I was trying to animate a rotating bar to indicate a busy status.

Having ordered this exact LCD myself, I can say that aside from the issue mentioned in my other comment, it looks exactly like the picture. No bulky backpack module, everything is on a single board. Pretty sleek, really.

Edit: Got mine fixed. If you checked the soldering on all the terminals, check them again. I also sometimes was getting strings of garbage if I wriggled the terminals on the LCD (I suspect because I was getting a partial connection on the bad terminal). Resoldered and it is working fine now.

Wait, so I get the 3 pins for power and control, but whats with all the other pins on the sides? Can it be used to control another LCD besides the one built in?

The other pins are used if you want to control the LCD without using the serial standard. There"s some tutorials on how to do that with the arduino below. You have more control over what you can do with it, but it takes up more pins on the arduino. If you want to wire it up this way, don"t spend the money on the serial interface, they have cheaper LCD"s that allow you to do it this way, without the serial.

Are you a starter with Croduino? Or a newbie when it comes to electronics? You fancy a specific module, but you don"t know how to use it? Don"t worry, we have our How To Use series!

How to Use is a series of blog tutorials by e-radionica where you will find everything you need to begin working with your favorite modules. Tutorials include technical characteristics, operating principles, instructions on how to connect the module with Croduino and basic coding. Everything else is up to you and your imagination.

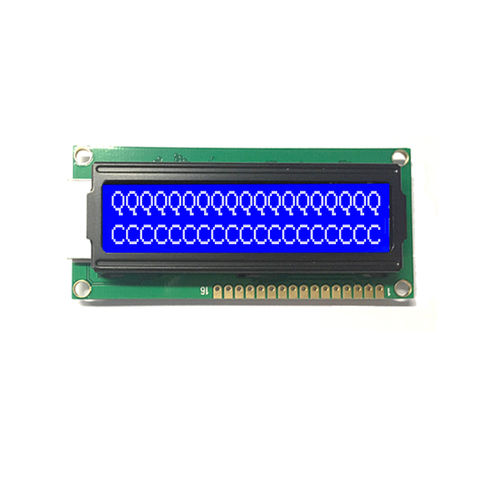

LCD ( Liquid Crystal Display) is probably one of the most used modules because it is truly useful. It allows you to get any kind of information on an easy-to-read LCD screen. The LCD in our offer has a blue backlight with white lettering. Both LCDs, 16x2 and 20x4, have identical pin assignment and this tutorial is universal for both. Also, the IIC adapter will work with both LCDs.

Explaining how LCD works cannot be done in only few sentences. It is based on liquid crystals (which, suprisingly, are discovered in 199th century). Each liquid crystal creates one pixel. These are located between two polarizers and they are rotating the light. When a certain voltage faces them, they are correcting themselves and polarization doesn"t rotate the light and passes towards our eye. As a result, we can see active pixels. For all those interested in more details regarding the working principle of LCDs, we suggest an article on Wikipedia.

Before connecting, IIC adapter must be soldered on the LCD screen. Insert the adapter from the back of the LCD pins and solder them. The result should be something like the picture below.

• lcd.setCursor(x,y);- sets a cursor (e.g. like one in Word) to a specific position. First coordinate (x) determines the position from left to right (e.g. 0 would be the first character), while second coordinate determines the position from top to bottom (e.g. 0 would be the first row, 1 would be the second row). Example of use: lcd.setCursor(0,1); - sets the cursor to the beginning of the second row. Now we can use lcd.print (); toprint something in the second row.

Newhaven 16x2 character Liquid Crystal Display shows characters with dark pixels on a bright yellow/green background when powered on. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0216BZ-FL-YBW display has an optimal view of 6:00. This display operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

It appears that this LCD module is meant to be attached to a PCB with very thin double-sticky tape (the D.S.T. abbreviation in the drawing) - if I am reading the drawing correctly, then it says that the thickness of the DST is only 0.05 mm. Such a tiny gap between the LCD module and the application PCB is possible because the LCD"s FPC connection tail is soldered down rather than connectorized.

Now the really strange part is that some other LCD modules out there have FPC tails that are meant to go into a ZIF connector (not soldered down like this one), yet they still somehow expect the LCD to sit flat against the application PCB, even though the thinnest FPC connector I could find (Hirose FH33 series) takes up 1.20 mm of vertical space (height above PCB). I still haven"t figured out how those are supposed to be mounted - but your LCD and other LCDs with solder-down tails are easy in comparison.

LCDs usually come without a microcontroller to control the display. To connect, you will need a strip of header pins, a potentiometer to adjust the contrast of the display, breadboard, and wires. Depending on the LCD, you may need a current limiting resistor to to limit the current to the LED backlight. You will need to solder the header pins of your choice to the display in order to plug it into your breadboard. If you have not soldered before, we recommend looking at our soldering tutorial.

While you can use any standard 16x2 alphanumeric LCD, the white on black display supplied with the kit looks übercool. The photographs in this guide are of a standard black on green display so yours may look different. The "16x2" refers to the display having two rows of sixteen characters each — other displays are available which are 8x1 or 20x4.

It is pretty straightforward to solder the header pins to the LCD module. Make sure to keep the soldering iron in contact with the joints for no more than about three seconds. There small risk of the damaging the existing components on the board with excess heat. You also need to be careful to keep the soldering iron away from the already soldered components on the board — you"re probably not yet ready to do surface mount soldering repair.

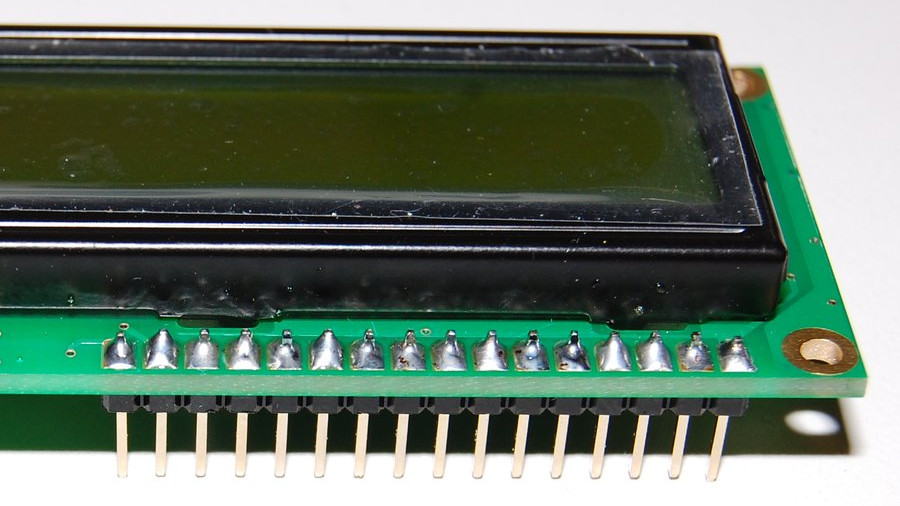

Before soldering, perform a "test fit" of parts. A test fit gives you a chance to double check if you"ve got the parts you need and ensures that they fit together. For this connection, break a row of 16x1 male headers and insert the header pins into the holes on the LCD module as shown in the image below. If you are using an RGB LED, you will need a row of 18x1 male headers.

Ensure that you don"t have one pin too many or too few in your header strip. Also make sure the black plastic strip of the header is positioned on the underside of the printed circuit board (PCB) so that you have plenty of pin length below the PCB to plug into your breadboard or a socket. The longest part of the pins should be below the PCB. The pin header provides connections that carry the data signals for controlling what the display... displays. They also carry power to the small microcontroller behind the black blob on the module and to the LED backlight if your display has one.

Because there"s not a lot of room it is easiest to feed the solder from behind pin while the soldering iron tip is between the pins, resting on the PCB pad with the side of iron against the side of pin you"re soldering. The reason we start with just one pin is because it makes it easier to obtain the correct alignment and fix any mistakes.

Once you"re happy with the alignment of the header you can solder another pin into place — we recommend soldering the pin at the opposite end of the header to the first pin you soldered. The reason for this is that once the two end pins are in place, the alignment won"t change.

Your display module should now look like the image below. One additional detail to note is that the pin header is usually at the "top" of the display — so keep that in mind if you plan to mount it anywhere. Remember to always test the display out before mounting to a project.

A Graphic LCD display is just as its name implies. This LCD module is able to display images, letters and numbers that are generated through the customer’sread more...

If you want to add some visual output to your Arduino projects, you’ll need a display. If you need only a little to display, the Standard LCD 16x2 Display is a quite good solution. RoboticsBD

This is Standard LCD 16x2 that provides a simple and cost-effective solution for adding a 16×2 Black on RGB Liquid Crystal Display into your project. The display is 16 character by 2 line display that has a very clear and high contrast black/white text upon a yellow/Blue background/backlight.

This is the great yellow/blue backlight LCD Display. It is fantastic for Arduino-based projects. This Standard LCD 16x2 with Yellow/Blue Backlight is very easy to interface with Arduino or Other Microcontrollers.

One thing to consider is you’ll waste about 8 Pins on your Arduino for the display to get working. Luckily there exists an I2C adapter that you can solder right onto the pins of the display. So all you need to connect are the I2C pins, which shows a good library and little of coding. We have the same LCD module with a pre-assembled I2C adapter, click on the name below to check it

Note: This is Standard LCD 16x2 where color can either be BLUE (white text on blue background) or YELLOW(black text on yellow background), If you want to buyBLUE LCD specifically visit here.

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

This Shield makes it easy to use a blue and white 16x2 Character LCD. While using only 2 wires you can control the 16x2 character LCD, 3 backlight pins and 5 keypad pins! The best part is you don"t really lose those two pins either, since you can stick i2c-based sensors, RTCs, etc and have them share the I2C bus. This is a super slick way to add a display without all the wiring hassle.

This product comes as a kit! Included is a high quality PCB and all the components (buttons, header etc). A 16x2 Character blue/white LCD is included! Assembly is easy, even if you"ve never soldered before and the kit can be completed in 30 minutes.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey