fanuc lcd display free sample

There is a growing need for skilled workers competent in the setup, programming and operation of CNC’s. Since more manufacturers trust their operations to FANUC CNC’s than any other control platform, it’s important

The FANUC Machining Simulator takes the simulation a step further with a realistic machining simulation function so users can virtually manufacture parts in milling or turning environments with realistic kinematics and structure. The simulation

FANUC and Doosan Machine Tools have partnered to now offer secondary and post-secondary schools with hands-on skill development and industry-recognized certifications using world-class Doosan machine tools combined with FANUC’s industry-leading CNC controls.

In partnership with CNC Concepts, Inc., FANUC America offers two comprehensive CNC curriculum for machining (milling) and turning (lathe), including key concepts and lessons for machining center setup, programming and operation. Since more manufacturers trust their operations to FANUC CNC’s than any other control platform, it’s important

The CNC Guide academic package is FANUC CNC software running on a PC. CNC Guide is ideal for dedicated training rooms or development teams and is available with a single or multi-seat licenses. CNC Guide provides a realistic operation

FANUC’s Machining Simulation for Workforce Development offers virtual training on FANUC controls operation, part programming and more. The realistic simulation software, powered by ModuleWorks, can be operated now as 5-axis and 3-axis mills or a 2-axis lathe. Our platform creates a digital twin of the machine tool and simulates the cutting process. Using actual CNC position data, the digital twin provides an accurate and realistic depiction of actual machine behavior.

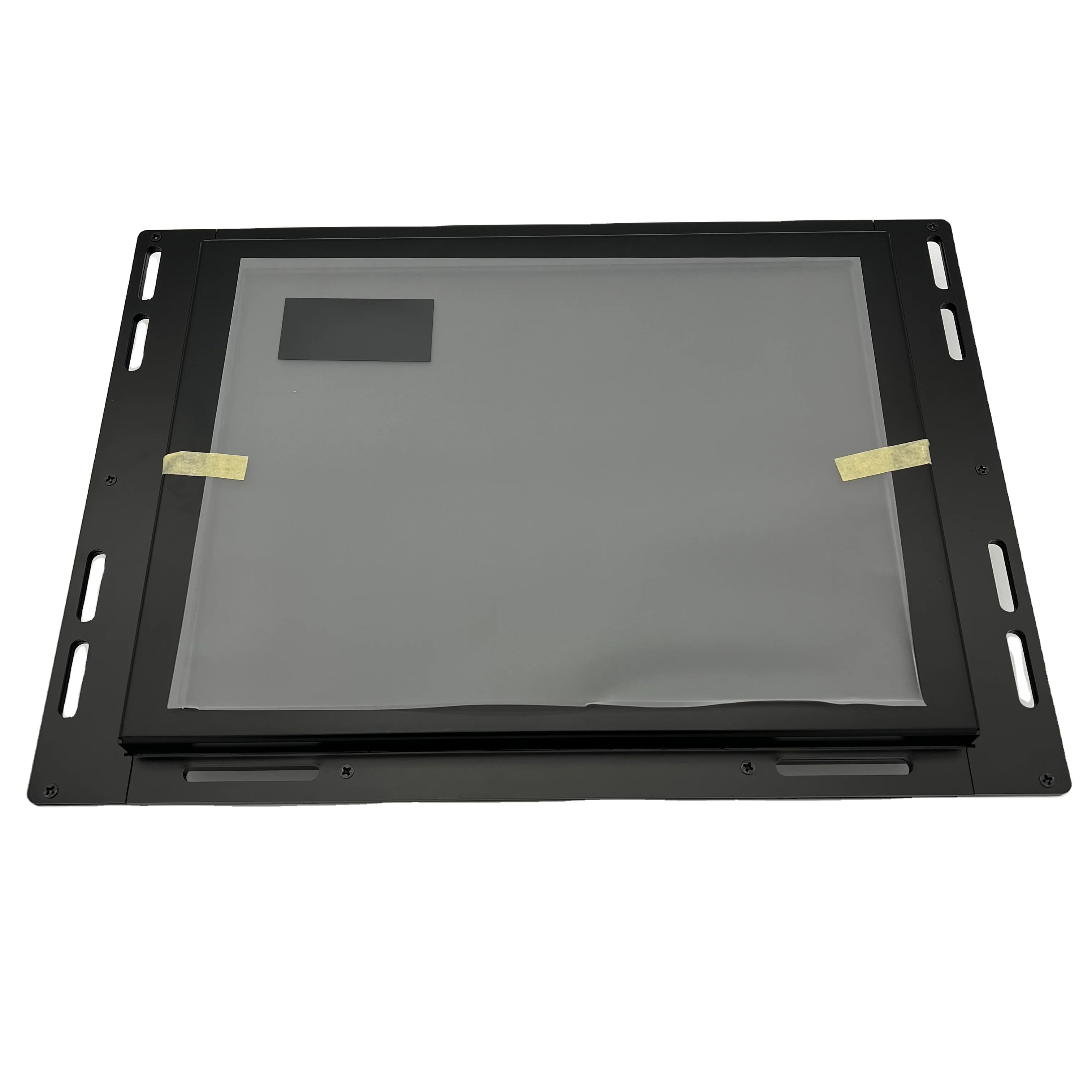

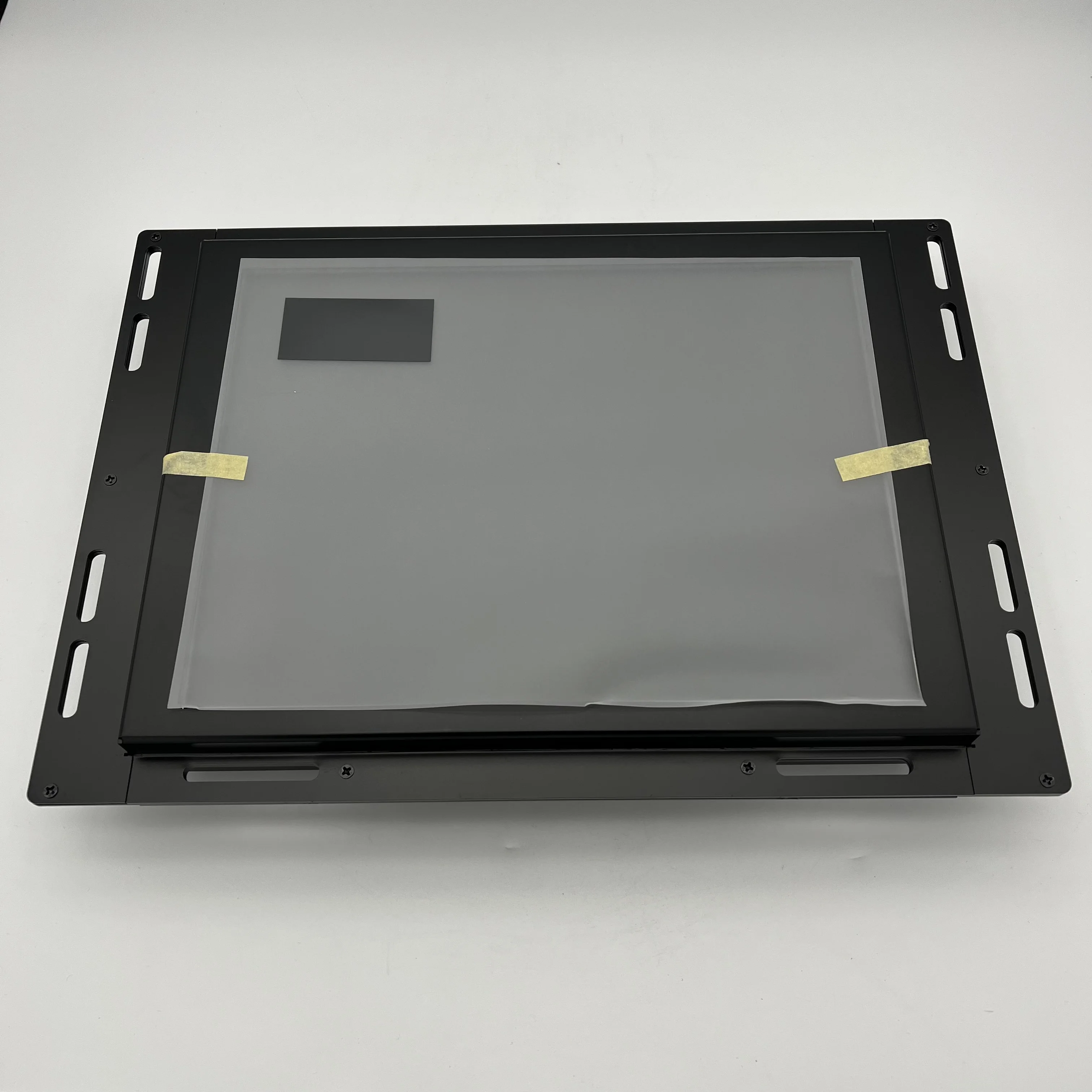

The CNC education simulator is designed specifically for educational purposes, ensuring affordable access to the latest FANUC 0i-MODEL F Plus CNC platform in a compact and portable package, easily integrated into any classroom. Add the screen display function software to take over partial control of the simulator on the PC, via the Ethernet connection.

The latest in the line up of educational CNC equipment is the EDU mill. Lightweight and portable, the rigid gantry style machine runs on 110VAC and is ideal for cutting wood, plastic and metals. The machine is equipped with the new FANUC 0i-F Plus Control and features a single tool spindle with automatic tool measurement.

Teach with a top of the line CNC Milling Machine utilizing FANUC 0i-MF hardware that is both affordable and portable and runs on only a standard single phase 110vAC outlet. Help your students gain exposure to milling practices including

Designed for classrooms and small machine shops that need a complete CNC solution in a limited space. Utilizing the FANUC 0i-TF control, the LTC-F30 is capable of 24/7 industrial production of small parts in a variety of materials ranging from plastics to soft metals

Doosan"s DEM series is a compact vertical machining center for 3-axis general machining with high rigidity structure. This model is designed with a 22” x 16” bed which is very suitable for basic cutting processing. The DEM 4000 is controlled by a Doosan FANUC 0i-F Plus control with 10.4” LCD. The operation panel enhances operating convenience by incorporating common-design buttons and layout, and features the Qwerty keyboard for fast and easy operation.

Incepted in the year 2021, “VR Technologies”is a distinguished wholesaler offering an enormous consignment of Lcd Display, Repairing Service, Membrane Keypad etc.

Established in the year 2016, we "Kusum Enterprises" are one of the leading Wholesale Trader & Exporter of Fanuc Encoders, Fanuc CNC Machine Spare Parts, CNC Machine Cables, IGBT Modules, CNC LCD Displays, Fanuc battery, PCB Board and many more. Our claim to success is hallmarked by the offered quality products that gained us huge recognizance. We are working towards development through a determined team of people to meet the most stringent requirements of customers.

MoniServ, Inc.(lcdparts.net/lcdpart.com), we carry thousands of replacement parts for all types of industrial LCD screens (LCD panels), such as the LCD screens for ATM, PLC, Kiosks, POS, CNC machinery, Medical, Gaming, Digital signage, Avionic and other industrial applications. Varieties of LED backlight upgrade kits are also available! With simple tools, you can repair these expensive display assemblies at the fraction of the cost

Alibaba.com offers 961 fanuc display products. About 58% % of these are plc, pac, & dedicated controllers, 13%% are other electrical equipment, and 4%% are cnc controller.

Alibaba.com offers 251 fanuc monitors products. About 46% % of these are plc, pac, & dedicated controllers, 11%% are lcd modules, and 11%% are lcd monitors.

Tri Star CNC Services LLC provides superior FANUC repair services to CNC machine customers. Our technical phone support lets us help you solve common problems your machine may experience. For deeper issues, we offer a parts exchange service that will allow your machine to keep running while we perform necessary repairs. Our FANUC service engineers provide support for a variety of machines and can send on-site technicians through our partnered companies.

Critical FANUC CNC component failure such as excessive current, faulty memory, blown fuses or signal mismatch throws an error and brings your CNC machinery to a grinding halt. Tri Star CNC Services provides comprehensive FANUC alarm code lists for:

If your CNC machine controls or sub-assemblies are malfunctioning, send them to our expert CNC machine repair technicians at Tri Star CNC Services, LLC. We have the experience and equipment to repair this exhaustive list of FANUC CNC modules and parts.

When we receive your malfunctioning machine controls we perform a detailed inspection to find the damaged parts which need repair or replacement. We work diligently to repair FANUC machine controls back to normal operation so they can be returned to you in a timely manner. We understand the criticality of quickly replacing machine controls, sub-assemblies, and power supplies for your CNC machines. Our qualified repair technicians can restore all of the CNC machine controls listed below:

Our Tri Star repair technicians will do a thorough inspection of your FANUC servo drive and determine whether or not they need to be repaired. If they do not need repairs, we will clean your machine and only charge you a small fee for the inspection and cleaning. When servo drives or motors are causing the problem, we will restore them to normal operation. Our technicians will even replace other components with higher failure rates to ensure your machine will work efficiently longer. Trust Tri Star to repair or restore any of the parts listed below:

When spindle motors decelerate, their spindle drive pushes electrical energy back into the line to continue power. When these parts malfunction it can result in an overcurrent alarm or abnormal operation of your CNC machine. Untrained staff attempting to repair FANUC modules can cause serious damage to your machine and render it nonoperational.

The skilled repair technicians at Tri Star have the expertise to inspect and diagnose the problems of your FANUC spindle drive or motor. Whether your machine parts just need a good cleaning or require repairs, our technicians will use great attention to detail to restore your spindle drive back to proper operation. Our repair technicians have the knowledge, experience, and equipment to repair all of the parts listed below:

It’s no problem when you trust in Tri Star CNC Services. With many years servicing FANUC robots and their critical components, we’ve had exposure to all sorts of FANUC alarm codes and what they mean for your CNC machinery.

We provide the best value on the market for all CNC/FANUC parts and repairs. Our prices are usually lower than other repair centers and we provide the best warranties for our serviced parts. We go further than any other company to deliver the best possible service, proactively replacing high failure rate components before they fail. Learn more about our pricing, lead times, and availability by browsing our parts pages.

When your CNC machine has a constant need for FANUC part replacements, Tri Star CNC can help keep your modules working longer. Our custom FANUC part engineers develop components with known high failure rates to quickly resolve issues and keep your machines running smoothly.

Our expert technicians install higher quality replacement components with longer mean times between failures compared to original FANUC components. We automatically replace high-failure components at no extra charge even if they aren"t the cause of the failure. If the smaller components of your CNC modules fail regularly, it may be more cost-effective to have our FANUC service engineers look for a better solution. Between engineering better-performing solutions at lower prices and proactively replacing high-failure components, we offer the best repair services for CNC machine FANUC parts.

Computer Numerical Control - refers to a computer controller that reads G-code instructions and drives a machine tool, which is typically used to selectively remove material in the fabrication of components. CNC repair is defined by Tri Star CNC Services, the premiere CNC service, CNC parts and FANUC parts distributor.

An indicator on a teach pendant or CRT display screen at which command entry or editing occurs. The indicator can be a highlighted field or an arrow (> or ^).

FANUC (Fuji Automatic Numerical Control) is a Japanese electromechanical robotics manufacturer that has partnered with GE to bring automated robotic technology to the US. Tri Star CNC Servicesis the premiere provider of GE FANUC repairs and GE FANUC parts.

A specified area of a record used for a particular category of data. 2. A group of related items that occupy the same space on a CRT/KB screen or teach pendant LCD screen. Field name is the name of the field; field items are the members of the group.

The serial bus that provides communications between blocks, controllers, and other devices in the system especially with respect to GE FANUC Genius I/O.

1. A category displayed on the teach pendant on a menu. 2. A set of adjacent digits, bits, or characters that is treated as a unit and conveys a single unit of information. 3. Any unique manufactured or purchased part or assembly: end product, assembly, subassembly, component, or raw material.

A digital display on the teach pendant that consists of two sheets of glass separated by a sealed-in, normally transparent, liquid crystal material. Abbreviated LCD.

1. A hand-held device used to instruct a robot, specifying the character and types of motions it is to undertake. Also known as teach box, teach gun. 2. A portable device, consisting of an LCD display and a keypad that serves as a user interface to the KAREL system and attaches to the operator box or operator panel via a cable. The teach pendant is used for robot operations such as jogging the robot, teaching and recording positions, and testing and debugging programs.

Alibaba.com offers 961 fanuc display products. About 58% % of these are plc, pac, & dedicated controllers, 13%% are other electrical equipment, and 4%% are cnc controller.

This hands on class will cover the various screens used in diagnosing problems on a CNC control. On the CNC side, we will be covering Position, Program and the Offset / Settings pages. A considerable amount of time will be spent on the System pages. This will include parameters, diagnostics, servo settings, configuration and others. On the PMC side we will be looking at the PMC maintenance pages including the status and force screens, I/O link configurations, timers, counters and PMC errors. We will also be going over the ladder logic screen navigation and settings pages. The configuration pages will include information on alarm messages, system display and troubleshooting.

Fanuc sold you a motion control device. It makes motors move. If they don’t do what they are supposed to, the Fanuc controls throws up an alarm. All of the other components on a machine are controlled by the machine tool builder. This builder will install alarms in the machine. Some of these can be confusing. This class shows you how to chase the alarms through the ladder logic to find the resolution. In the labs for this class, the students will initiate an alarm, locate the cause of the alarm and find the resolution.

In this lab the students will be introduced to multiple types of counters and timers that are used in the Fanuc ladder logic. You will learn the difference between variable and fixed function statements. Alarms will be induced into the machine that will make use of these functions. Students must use these settings to diagnose the resolution.

This training sessions is a follow up to the timers and counters lab. You will make use of the Move function statements in the Fanuc ladder logic. Learn how items, such as alarm messages, are moved around in the ladder. Once again, alarms will be introduced into the machine. Using what you learn in this class, solve the issue on the machine.Data Tables

The trace function is one of the most powerful diagnostic tools built into the Fanuc control. It’s grown up considerably since the first version came out. This can be used to capture intermittent problems on a machine. For example, the machine randomly goes into a feed hold condition. It only happens once or twice a day. Use the trace to find out why. Think of it as a strip recorder on steroids.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey