tft lcd editor factory

(Yicai Global) June 19 -- China National Building Material has built the country"s first production line capable of producing 8.5th-generation TFT-LCD glass substrates, making China one of few nations to master the technology.

TFT-LCD, or thin-film-transistor liquid-crystal displays, are classified by the size of their glass substrate. Sixth-generation displays are now widely considered out-dated while 8.5th-gen tech is the most advanced. The newer technologies use larger substrates, which are more efficient to make and can be used in larger screens.

The traditional mechanical instrument lacks the ability to satisfy the market with characters of favorable compatibility, easy upgrading, and fashion. Thus the design of a TFT-LCD (thin film transistor-liquid crystal display) based automobile instrument is carried out. With a 7-inch TFT-LCD and the 32-bit microcontroller MB91F599, the instrument could process various information generated by other electronic control units (ECUs) of a vehicle and display valuable driving parameters on the 7-inch TFT-LCD. The function of aided parking is also provided by the instrument. Basic principles to be obeyed in circuits designing under on-board environment are first pointed out. Then the paper analyzes the signals processed in the automobile

instrument and gives an introduction to the sampling circuits and interfaces related to these signals. Following this is the functional categorizing of the circuit modules, such as video buffer circuit, CAN bus interface circuit, and TFT-LCD drive circuit. Additionally, the external EEPROM stores information of the vehicle for history data query, and the external FLASH enables the display of high quality figures. On the whole, the accomplished automobile instrument meets the requirements of automobile instrument markets with its characters of low cost, favorable compatibility, friendly interfaces, and easy upgrading.

The digital instrument has functions of vehicle information displaying, chord alarming, rear video aided parking, LED indicating, step-motor based pointing, and data storage. The instrument adopts dedicated microcontroller MB91F599, a 7-inch LCD, and two step-motors to substitute for the traditional instrument. All the information generated by other ECUs can be acquired via not only the sample circuits but also the CAN bus.

The CAN bus interface and the 7-inch TFT-LCD make it more convenient to upgrade the instrument without changing the hardware. If the software needs to be upgraded, we need not bother to take the instrument down and program the MCU. Instead, we can upgrade the instrument via the vehicle’s CAN network without taking the instrument down, which makes the upgrading more convenient. Most of the information from other ECUs can be transmitted via the CAN bus; so, we do not have to change the hardware circuits if some of the ECUs’ signals are changed in different applications. Besides, since most of the driving parameters are displayed on the TFT-LCD, and the graphical user interface can be designed with great flexibility by programming, only the software needs to be revised to meet different requirements of what kind of driving parameters to display and so forth. These characters, together with the reserved interfaces, enhance the instrument’s compatibility in different applications.

On the one hand, there are some automobile instruments which adopt 8-bit MCUs or 16-bit MCUs which have limited peripherals, so it is difficult for them to meet some requirements such as rearview video and high real-time data processing performance. And many extra components are needed if the designer wants to accomplish some functions such as video input. On the other hand, there are some advanced automobile instruments which adopt high performance MCUs (such as i.MX 53, MPC5121e, and MPC5123) and run Linux on them. They even use larger TFT-LCDs (such as the 12.3-inch TFT-LCD with a resolution of 1280 × 480 pixels) to display driving parameters. These automobile instruments show higher performances than the instrument in this paper. However, they are more expensive than this automobile. This instrument is able to provide almost all the functions of the advanced automobile instrument with a lower cost.

The instrument receives signals from other ECUs via the sampling circuits or the CAN bus interface. It can also receive commands from the driver via the button interface. The signals are then processed by the MCU, after which the MCU may send the vehicle information to the LCD or light the LEDs and so forth, according to the results. Therefore, the automobile instrument can be viewed as a carrier of the information flow. And the design of the system can be viewed from two aspects: the hardware system and the information flow based on it.

Since the FLASH size of the microcontroller is only 1 MB which is limited for the storage of pictures displayed on the LCD, external FLASH is needed to store different kinds of meaningful pictures such as the background of the dial. Two S29GL256N chips with a memory capacity of 256 Mb are chosen for picture data storage for their high performance and low power consumption. The application circuits of the chips are provided in their datasheets, so it is unnecessary to go into the details of them here.

The 7-inch TFT-LCD has a resolution of pixels and supports the 24-bit for three RGB colors. The interface of the 60-pin TFT-LCD can be categorized into data interface, control interface, bias voltage interface, and gamma correction interface.

The data interface supports the parallel data transmitting of 18-bit (6 bits per channel) for three RGB colors. Thus, a range of colors can be generated. The control interface consists of a “horizontal synchronization” which indicates the start of every scan line, a “vertical synchronization” which indicates the start of a new field, and a “pixel clock.” This part is controlled by the graphics display controller which is integrated in the MB91F599. We just need to connect the pins of the LCD to those of the microcontroller correspondingly.

Bias voltages are used to drive the liquid crystal molecules in an alternating form. The compact LCD bias IC TPS65150 provides all bias voltages required by the 7-inch TFT-LCD. The detailed circuit is also provided in the datasheet of TPS65150.

The greatest effect of gamma on the representations of colors is a change in overall brightness. Almost every LCD monitor has an intensity to voltage response curve which is not a linear function. So if the LCD receives a message that a certain pixel should have certain intensity, it will actually display a pixel which has intensity not equal to the certain one. Then the brightness of the picture will be affected. Therefore, gamma correction is needed. Several approaches to gamma correction are discussed in [20–22]. For this specific 7-inch LCD, only the producer knows the relationship between the voltage sent to the LCD and the intensity it produces. The signal can be corrected according to the datasheet of the LCD before it gets to the monitor. According to the datasheet, ten gamma correction voltages are needed. These voltages can be got from a resistive subdivision circuit.

For this instrument, the LED indicators, the backlight, and the chord alarm need to be supplied with a voltage of +12 V; the CAN transceiver, the EEPROM, and the buttons need to be supplied with a voltage of +5 V; the video buffer circuit, the external FLASH, and the data interface of the LCD need to be supplied with a voltage of +3.3 V. Besides, the microcontroller needs to be supplied with voltages of +5 V and +3.3 V simultaneously. Figure 8 offers a detailed block diagram of the power supply for the automobile instrument.

The main task for the program is to calculate the driving parameters of the vehicle and display them on the TFT-LCD. The calculation is triggered by the input signals via the sampling circuits or the CAN bus. The main program flow chart of the system is shown in Figure 10.

The design scheme of a TFT-LCD based automobile instrument is carried out form aspects of both the hardware and the main program flow chart. The MB91F599 simplifies the peripheral circuits with its rich on-chip resources and shows high performance in real-time data processing. The automobile instrument is capable of displaying the velocity of the vehicle, the engine speed, the cooling water temperature, the oil pressure, the fuel volume, the air pressure, and other information on the TFT-LCD, which contributes a lot to driving safety and satisfies drivers’ aesthetics. Besides, the rearview video makes the parking and backing easier and safer for the driver. Moreover, the CAN bus interface and TFT-LCD make it easier for the upgrading of the instrument without changing the hardware, thus saving the cost.

Alibaba.com offers 27997 factory tft screen products. About 36% % of these are lcd modules, 1%% are digital signage and displays, and 1%% are led & lcd tvs.

A wide variety of factory tft screen options are available to you, You can also choose from original manufacturer, odm and agency factory tft screen,As well as from tft, ips, and standard.

(Yicai Global) June 19 -- China National Building Material has built the country"s first production line capable of producing 8.5th-generation TFT-LCD glass substrates, making China one of few nations to master the technology.

TFT-LCD, or thin-film-transistor liquid-crystal displays, are classified by the size of their glass substrate. Sixth-generation displays are now widely considered out-dated while 8.5th-gen tech is the most advanced. The newer technologies use larger substrates, which are more efficient to make and can be used in larger screens.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

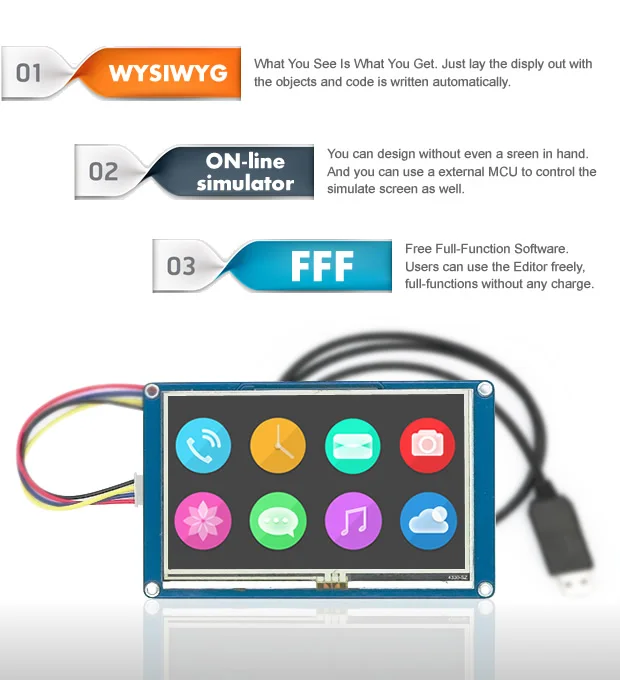

Pay once and never worry about it again. Once you buy Visual TFT you are entitled to a lifetime of free upgrades. Upgrading the software takes only a few minutes and a few clicks. We are constantly adding new features, and you can keep track of what is happening on the Software Roadmap page.

The Visual TFT currently supports 17 graphics controllers from leading manufacturers. You can be a part of the process by letting us know what graphics controllers you wish to see supported next, by using our helpdesk and submitting a ticket.

Visual TFT supports a total of 17 TFT controllers and many different display sizes, from 131x131 to 800x600 pixels. The most popular ones are the 320x240 TFT displays running on ILI9341controller. This display is found in many embedded devices worldwide. All MikroElektronika multimedia boards have this display integrated, so you’ll have all the hardware you need to get started. You can also order TFT displays separately from MikroElektronika’s online store.

Visual TFT also supports FTDI chip™ - the latest EVE GUI Platform and FT8x and FT81x families of graphics controllers. These powerful devices allow for sophisticated forms of human-machine interaction and more satisfying user experiences, including video playback. EVE integrates display, audio and touch onto a low cost, easy-to-use, single-chip solution. The EVE family has an object-based structure (where objects can be images, fonts, etc). This offers you an easy way to design more effective GUIs for TFTs, with all the display, audio and touch functionality included. Visual TFT is the first software in the world to provide full support for many of EVE’s powerful features like sound, transparency and anti-aliasing fonts. There are many new components available for GUI design, which are natively supported in the controller itself.

Visual TFT supports all our development and multimedia boards, so you will find all the hardware you could possibly need in one place. Each board has a hardware pattern, a configuration template with hardware connections for TFT and touch screen, and you can do all necessary settings with a single click.

Three major compiler groups are currently supported: mikroC, mikroBasic and mikroPascal for PIC, dsPIC, PIC32, AVR, ARM and FT90x. This means that no matter what compiler you will write your project in, source code generated by Visual TFT Tool will be integrated smoothly.

The Visual TFT Interface is really easy to use, and implements standard intuitive behavior, so you will feel like using any other vector graphic editors. But we have mixed functionalities from both worlds: world of design and world of programming. There are several palettes of most useful components that you can use in your application. Just drag a component onto a pixel grid display screen and it will be drawn instantly. Use Object Inspector to edit component properties and to assign desired events.

Do you need more space for your images and fonts? Do you want to create image slideshows, or to even play a video from MMC/SD Card? With new Resource file feature, Visual TFT software brings you all this and much more. If this option is selected, after code generation, Visual TFT will store all of your images and fonts in the resource file and will optimize them as much as possible for faster utilization. You just have to copy that file onto your MMC/SD card and you are ready to go.

The help file is the best place to start if you want to get to know the Visual TFT software. The easy-to-read format and detailed explanations of every functionality and feature will make you an expert in no time.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey