flexible lcd module brands

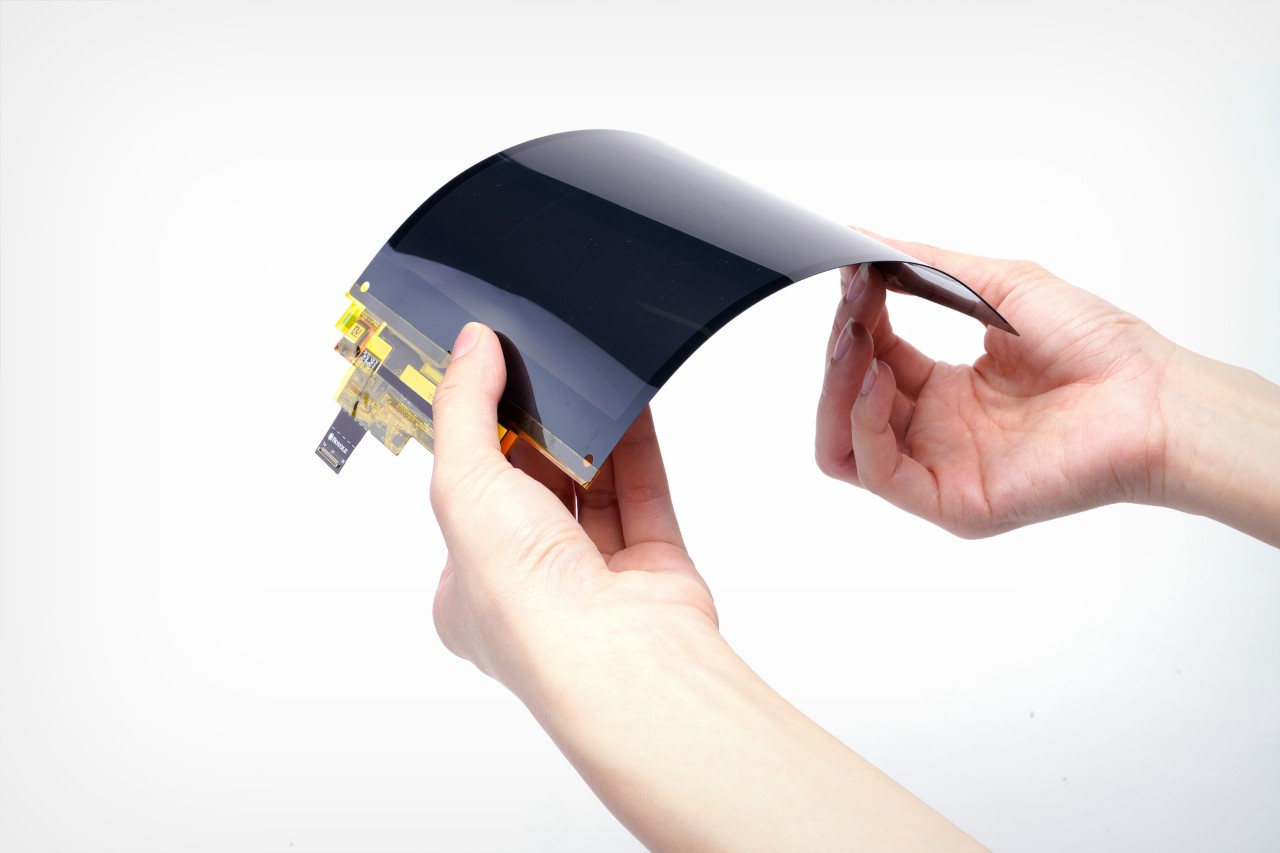

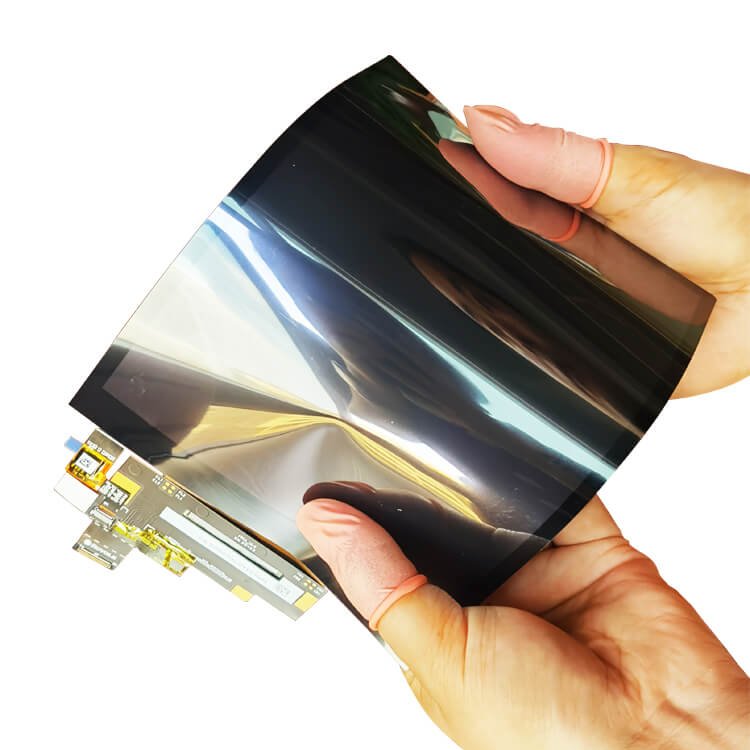

In July this year, FlexEnable announced partnership with Truly to bring OLCD (Organic Liquid Crystal Display) in volume production by 2018. In January, JDI (Japan Display) announced its plan for mass production of plastic Flex LCD in 2018. Flexible OLED has been in full production for some time and is playing a major role in the smartphone market gaining market share. Can LCD technology bring flexible LCD in volume production to open up new opportunities?

This licensing agreement aims to bring FlexEnable’s flexible OLCD technology into mass production on Truly’s lines within 2018. FlexEnable’s OLCD is based on flexible low temperature organic thin-film transistor (OTFT) backplane technology.

According to the company’s press release, it can be manufactured on existing TFT-LCD production lines using low cost plastic substrates such as TAC and PET. The company asserts that OLCD has better electrical performance than a-Si TFT, giving plastic LCDs the same display quality and reliability as glass-based LCDs. As it is using a plastic substrate, displays can be thinner, lighter, unbreakable (durable), shatterproof, and conformable enabling differentiated design. The FlexEnable process is compatible with existing flat panel lines. So most of the existing equipment can be reused, lowering the cost of getting into production. The use of low cost plastic substrate due to lower (less than 100º centigrade) processing temperature, contributes to lower costs and higher yield rates. Truly is the first display manufacturer to adopt OLCD and it will implement the process into its existing LCD production line in China.

According to the company‘s press release, by combining FlexEnable’s OTFT with Merck’s polymer wall LC technology, organic LCD can be curved around even more complex surface and shapes. These polymer walls can enhance cell gap control while providing excellent display performance. The organic LCD from FlexEnable can have a bend radius below 30mm.

The OLCD display can be used in applications such as smart homes, automotive, digital signage and others. The FlexEnable OLCD has been shown as a pillar display in a future concept car. The automotive display market is experiencing dynamic growth due to connected vehicle development, auto computerization and autonomous car implementation. Auto designers are hoping to move away from rigid rectangular shape displays to free form or conformable shapes with more differentiated designs.

The auto display market has stringent requirements, with a very long design cycle. The market is getting to be more competitive with a-Si LCD, LTPS LCD, OLED and now OLCD displays all now competing for market share. Companies such as LG Display are already targeting the auto market with flexible high performance OLEDs. At SID"s Display Week 2017, AUO showcased a 3.5” flexible TFT LCD using plastic substrate. To succeed in the auto market display, makers need to meet design differentiation, high quality (high resolutions, wide viewing angles, low reflection, accurate colors, high luminance, wide temperature range, high reliability) and lower costs.

AUO showcased 3.5" plastic flexible LCDs, using a Polyimide (PI) plastic substrate. It is a bendable, unbreakable, conformable display designed for the instrument cluster auto market. The company also showed an 8.9" free form LCD display for rearview mirrors and a 9" curved LCD for CIDs (center information display). LCD panels are adopting curved form factors to meet future auto display requirements.

JDI is planning to start mass production of this display in 2018. The company is targeting this technology not only for smartphones, but also for notebook PCs, automotive applications and other products. Flexible OLED is already gaining market share in the smartphone market, mostly in the high end. But supply is constrained and the cost is high. Higher production of plastic flexible LCDs with lower cost could provide new options to smart phone brands.

The biggest differentiator between LCD and OLED display is flexibility. The shift from glass-based to plastic displays enables thinner, lighter, and flexible form factors with more design differentiation options. Smartphone, automotive, wearable and many other applications are requiring display flexibility. Flexible OLED is already meeting those needs especially in the smartphone market. The upcoming iPhone 8 products are expected to include flexible OLED display models. In future, foldable smartphones are also expected.

In spite of great advantages, there are still many challenges for flexible OLED display, especially manufacturing difficulties. Up to now, Samsung is the only maker with successful high volume manufacturing capabilities. Even though many other suppliers are planning to come to market in the 2H of 2017 and 2018, it will take time and the process is challenging.

Up to now there has been no volume production of plastic LCDs. But these recent announcements from JDI, AUO, FlexEnable, Truly, and Merck will enable volume production. Flexible LCDs are still in the phase of bendable or confirmable (due to LCD ‘s inherent structure) phase rather than truly flexible/foldable as OLED.

In conclusion, flexible LCDs will be coming to the market at last, but only with higher volume production and lower cost can it open new opportunities. - Sweta Dash, President, Dash-Insights

OLED is an emerging display technology that enables beautiful and efficient displays and lighting panels. OLEDs are already being used in smartphones, laptops, wearables, tablets and TVs, and many of OLEDs are flexible ones.

A flexible OLED is based on a flexible substrate (usually polyimide). The first generation of OLEDs produced on these were not really flexible from the user perspective. The device maker bends the displays, or curves it - but the final user is not able to actually bend the device. These first-gen flexible OLEDs are adopted many premium smartphones, for example the Samsung edge-type Galaxy phones or Apple"s latest iPhones. A plastic-based OLED has several advantages especially in mobile devices - the displays are lighter, thinner and more durable compared to glass based displays.

Second generation flexible OLED displays can be bent by the user - these can be used for example to create foldable smartphones - the first range of which started shipping in 2019. Rollable OLEDs are also now entering the market for both TVs and smartphones.

If you are interested in buying a flexible OLED panel for your project or device, look no further. Our OLED Marketplace offers several flexible OLEDs, which can be ordered through us with ease.

During the summer it was my pleasure to work with two interns from local universities. As part of their instruction I asked each of them to pick a topic of their choice, and to generate a patent landscape report on the area. For each project the interns were asked to research the technical aspects of their topic, suggest a patent search strategy for identifying documents, reduce their collections to remove family duplicates, cleanup various data fields, categorize the collection into a variety of facets, conduct relevant analytics on the data, and finally generate both a written report and a PowerPoint presentation to summarize their results. I am excited to publish the first of these projects produced by Riley Collins who did his project on Flexible Electronic Displays. So without further ado here"s Riley"s project:

Unlike traditional flat panel displays OLEDs, one of the more popular types of flexible electronic displays are solid-state devices composed of thin films of organic molecules that create light with the application of electricity. OLEDs can provide brighter, crisper displays on electronic devices and use less power than conventional light-emitting diodes (LEDs) or liquid crystal displays (LCDs) used according to HowStuffWorks.com. Using glass substrates, flexible technology OLED‘s utilizes plastic substrates, which allow the display to bend and twist. Flexible OLED‘s only need one sheet of substrate while LCD‘s require two and a separate backlight. Because of this, OLED‘s are able to be paper thin and lightweight, a perfect candidate for mobile phones and wearable electronics. The challenge for manufacturers currently is allowing the device to be repeatedly deformed while keeping the internals intact. Currently, electronic flexible displays are being used to make curved phones and televisions. This is possible because while the display may be “flexible”, the internal components remain fixed. Figure 1 shows a diagram of the layers in different types of displays. Samsung refers to their flexible OLED display as FAMOLED.

Electronic paper displays are the oldest type of flexible display. They differ in that they reflect light and have a wider viewing angle. E-paper is used predominately in E-readers and signage because text can be read in direct sunlight without fading. Similar to flexible OLED and LCD, it also uses plastic substrates, allowing display to bend like paper. E-paper displays are not ideal for phones and tablets because they have a very low refresh rate, ghosting problems, and are yet to be mass-produced in color.

As flexible displays become cheaper to manufacture we will likely see new functions of this technology. While curved devices are the first to hit the market, recent patent filings by top display manufacturers suggest that foldable, bendable, and rollable devices are not that far away. Foldable displays will likely come first to accommodate the growing demand for larger displays and the need for portability. As the wearable device market grows, bendable displays could be used to wraparound an individual’s wrist. Finally, displays that can be rolled up may be used in televisions and eventually a tubular device with a retractable roll out display.

Some benefits of flexible displays are better durability, lighter weight, thinner dimensions, and unique software commands. The use of a plastic substrate and the ability to flex locally when dropped makes the device less likely to crack, saving the users the trouble of having their screen replaced or being forced to buy a new device. Flexible devices will also be lighter and thinner than their rigid counterparts because they use plastic instead of glass. The ability to deform the device may allow the user to access a set of commands in their devices user interface. For example, when the device is folded it will go into sleep mode.

Demand for flexible displays is on the verge of a sharp increase. According to a new IHS report, “Global Flexible Display Technology and Market Forecast” (Figure 2 above). It is estimated that the flexible display market will grow to $1.1 billion in 2015 and will continue to develop at rate of 226% to $42 billion by the end of 2020. Units sold are projected to rise from 3.2 million in 2013 to 792 million in 2020. This means that in 2020, flexible display market will have captured 13% of the total display market. Even though smartphones with flexible displays have not yet achieved their desired potential, it is probable that they will soon capture the market by storm.

The search was started by locating as many Cooperative Patent Classification (CPC) codes that referred to flexible displays.. A sample of highly relevant documents were used to cross-reference and make sure that no CPC codes were left out.. The codes used were are:

OLEDA family reduction was conducted, but all unique US application numbers were retained. Foreign inventions were reduced to one invention per extended family. This list of CPC codes produced 2156 documents. After manually sorting the files, 177 were on E-Paper, and 1218 were Flexible OLED/LCD technologies. Many of the relevant documents included the key words flex*, deform, roll*, curve, bend* or bent, fold*, and a flexible or plastic substrate.

The objective of preforming this research is to complete an analysis of the Flexible Display IP landscape and assess the position of leading display manufacturers. According to the total number of applications by publication year, the patent filings for flexible displays are increasing at an exponential rate. They increased from 48 publications in 2010 to 566 in 2014/2015. This represents more than a 100% increase on average each year. Even more impressive is that almost 60% of the filings between 2010 and 2015 have came in the past 18 months. An initial look at the top companies by publications shows Samsung with the most at 271, LG with 97, and SEL with 85. Trailing behind are Creator Technology, Nokia, Apple, and Blackberry. Samsung and LG are likely to have the most filings because they are the only companies on this list that manufacturers portable devices and displays. Flexible displays are a relatively new technological field and because of this, the majority of the publications have not gone on to grant yet. It remains to be seen how much legal coverage will be given to these companies. The requirements for protection may still be uncertain and this could lead to lawsuits down the road.

When looking at the patent filings by type, the display component, electronic device, and display panel publications all increased sharply after 2013. Display panel filings surpassed electronic device filings in 2014/2015. Samsung is the clear leader in flexible display panel with 95 publications in 2014/2015 alone. Comparatively, LG and SEL both produced slightly more than 30 in this same time. The story is very similar for the display components except instead of SEL, Nokia trails slightly behind LG. The device patents have increased considerably since 2013 with Samsung going from 11 to 49, LG from 5 to 32, and Apple from 4 to 19. Blackberry has also increased their device patents steadily. The findings suggest that devices are already being specially made utilizing this new display technology. Companies such as Apple and Nokia who have few patents on the flexible display are perhaps exploring future licensing deals if they plan on releasing a device that contains a flexible display.

Samsung, SEL, Creator Technology, and Philips have most of their filings on the display, while LG, Nokia, Apple, Blackberry, Pantech, and Motorola have more patents on a device that uses a flexible display. Some other display-oriented companies include Sony, Sharp, ITRI, Toshiba, Universal Display Corporation, Fujifilm, Kodak, AU Optronics, and Boe Technology. To emphasize how much of a force the top two companies in this landscape are, a chart is included of Samsung and LG combined vs. all other companies. In 2014/2015 the top two combined surpassed all remaining companies in number of publications with 276 vs. 248. This shows the push that the leading display manufacturers are making to protect their intellectual property before this technology is mass-produced.

Charts and graphs associated with these analysis as well as a few other views on the data can be found in a PowerPoint presentation summarizing this research. The presentation can be downloaded by clicking on the following link: Flexible Electonic Displays Patent Analysis.

In January 2013 at the Consumer Electronics Show (CES), Samsung showcased prototypes of their flexible YOUM brand displays. In October of 2013, they released their first product using a flexible display. It appears that Samsung abandoned the YOUM branding because the Galaxy Round now uses a Flexible Super AMOLED display (FAMOLED). The Korean company then released the Galaxy note edge in September 2013. The note edge utilizes the curve to display information on the side of the display. Samsung’s latest installment of a flexible display device was the Galaxy S6 Edge in March 2015. The S6 differentiates itself from the note edge because it has two curved edges. Samsung announced in August of 2015 that they will be investing $3 billion to expand their OLED plant in Vietnam.

LG showed one of its 6 inch flexible prototypes in June of 2013 at the Society for information Display (SID). They then announced the release of the G Flex, a curved phone, shortly after CES in January 2014. The new and improved G Flex 2 would be released a year later at CES. In a private showroom at CES 2015, LG unveiled a prototype phone with a dual edge display, similar to the Galaxy S6 edge, which was released a few months later. In June 2015, at SID, LG released an 18 inch rollable display prototype at SID. LG has plans to make a 60 inch version by 2017. In July 2015, LG announced that it was investing $905 million into a 6th generation flexible OLED production line in South Korea. The project is said to finish in 2017 and will allow LG to meet the increasing demand for flexible displays in phones and wearable devices.

Originally a spin off from Philips Electronics, Polymer Vision was acquired by Wilstron Corp in 2009. The original Polymer Vision patent portfolio is now owned by the Netherlands company Creator Technology. Polymer Vision was trying to release a product called the readius which is essentially an E-reader with a 5 inch roll out display. Creator Technology may become a force in the flexible display industry, especially in regards to roll out displays. http://www.engadget.com/2012/12/03/wistron-reportedly-closes-polymer-vision/

In August 2014, Au Optronics released a 5 inch flexible AMOLED panel at a trade show. They also released a similar prototype in August 2015 that can detect how the user bends it. http://www.androidauthority.com/galaxy-s6-and-zenfone-2-top-charging-test-636708/

Boe Technology has recently created a prototype 9.55 inch flexible display that can be rolled into a tube, they have also created a 55 inch UHD flexible AMOLED display, the largest of its kind. Boe Technology also has an ongoing partnership with Universal Display Corporation. http://company.boe.com/portal/en/chuangxinkeji/boechuangxin/wenzhangxiangqing/dynamic/pecbwd264.html

There are still challenges to overcome before truly flexible devices hit the market, as the machinery behind the display is not meant to be bent. While plastic has its advantages, it is not as good as glass when it comes to encapsulating the thin-film-transistor and other components from moisture, oxygen, and other unwanted particles. Phone technology need to become tough enough to handle the stress of daily flexing over an extended period of time. Another barrier of a flexible device is the battery. Batteries are typically rigid in nature and until these batteries can be manipulated to flex, the notion of a bendable phone is unlikely. Similar to the battery, the silicon circuit board and its components are also not malleable. Device manufacturers will have to find cost effective alternatives to these problems before these new gadgets hit the shelves.

Samsung and LG are likely to be the first manufacturers of the next generation of flexible display devices. They have both proven that they have the expertise to create flexible display devices, as evidenced by the S6 edge and G Flex2. Nokia, Apple, and Blackberry are likely the next manufacturers to produce a flexible device based on their elevated number of patents. However, they will likely have to license the display technology in order to incorporate their devices. There is currently a need for lighter and thinner devices that are extremely portable and durable, a flexible device that can change its form for convenience appears to be the solution. It is simply a matter of time before manufacturers cross these last barriers and release a new wave of flexible devices that will flood the market.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Flexible LED displays panels are made of premium PCB and rubber material. Extremely soft, suitable for creative installations in any size and shape. Features compact design, 5 mm thickness, and magnetic connections. Easily fixed anywhere, including shopping centers, hotels, stadiums, etc. Viewpointec is devoted to providing the best flexible LED screen solutions.

We are professionalflexible LED screen manufacturerswith over 25 years of experience. No design is too complex and no project is too large for us to implement. Our team will work closely in consultation with you and other relevant project consultants to deliver stunningflexible LED screen displays.

Further, Viewpointec flexible LED displays are produced from our very ownflexible video wall factory.This gives us full control over production and enables us to maintain high quality standards. We also have the capacity to produce flexible LED screens in bulk and in any size that your display may require.

A flexible LED screen is made up of LED pixels pitched on a pliable material like rubber or PCB. It is insulated using a flexible transparent material on both sides to protect the LED circuit from getting damaged. This structure makes flexible LED screens highly resilient. They can be contorted during installation and still deliver crisp images.

A flexible video wall consists of manyfoldable LED screensmounted together. It can take different shapes depending on how the individual screens are arranged. The flexible LED screen display panels are joined using magnets along their borderlines to create a seamless video wall display.

We offer flexible LED displays that are tailor-made to fit in your space and captivate audiences. Whether it’s a 3D gaming lounge or a conference, you can rely on our flexible LED screens to deliver high-resolution images at all times. They are available in different dimensions and pixel pitch options depending on your needs.

Viewpointec flex LED screen modules are made of durable lightweight rubber. They are easy to install and can be mounted as far as 15 meters from a remote power source to provide you with more installation options. Additionally, we can create customized flex tiles for you that are trimmed and tilted in special angles for even more adventurous displays.

A giant curved LED advertising screen is a great choice when you need to reach a wide audience from a focal point. We can help you achieve this by custom-making one to your preferred size and design. It would comprise several standard-sized flexible LED screens mounted together to form a seamless giant curved LED display.

Our giant curved LED advertising screens are lightweight and display dynamic images in true Viewpointec style. They can be mounted on their own or supported by a custom frame. Further, all the flexible screens that make up the giant curved advertising screen have internal thermal management. This makes the giant advertising screen more durable as the LEDs would not overheat even with long durations of use.

Our flexible LED screens thrive in indoor setups of different kinds. They display bright, high-contrast images with distinct clarity. Moreover, they are versatile enough and can be installed in hallways, meeting rooms,display windows, or even hanging from a ceiling. If you are looking to catch your customers’ attention, this would certainly be an effective solution for you.

Viewpointec supplies flexible LED displays in China and to clients across the world. Our indoor LED advertising displays are affordable and customizable to suit any premises. We also guarantee you impeccable service and timely delivery on all the projects that you entrust us with.

When it comes to boosting your business, one of the best tools to invest in is a flexible LED display. These LED displays are designed to feature LED pixels on a rubber or PCB material and are used to display eye-catching images.

You also have the option of investing in a flexible video wall that makes it easier to run ads and other materials. These LED displays come in handy when attracting new clients to your business and are designed to communicate what you offer. Investing in these displays proves to be beneficial in a variety of ways that you should take advantage of.

Flexible LED displays are designed in such a way that they offer the best images and videos. The quality featured on these displays allows you to let your creativity shine through. You get to easily work on designs that are aligned with your business and the products or services you offer.

Flexible LEDs panels come in handy when you are looking to attract new customers to your business. They offer you a great opportunity to showcase your products and services to let people know more about you. For this, the best way to capture the attention of the viewers is by crafting an irresistible offer.

As a business, finding cost-effective solutions is always number one on the list. This is where flexible displays come in. They are designed to be budget-friendly and great investments overall.

Flexible LED displays come with a straightforward implementation that does not require you to jump through the hoops. They are very easy to install which means that you can set them up yourself. They come mounted on a solid substrate that allows them to take up the desired space you are working with.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey